Micatrone MF-PFT User manual

MF-PFT

ver 3.x

Micaflex PFT ver 3.

Pressure- and Flow transmitter with

control output

[© AB Micatrone, mi-302gb_171025] Page 1 of 8

Installation- & Operation manual

[Doc.id: mi-302gb_171025]

NOTE !

Read through the entire manual before you begin

installation and programming.

APPLICATION

MF-PFT is a microprocessor controlled transmitter/

controller for measurement and control of differential

pressure or flow. With the four keys on the front panel

it is possible to access all functions, make settings

and scaling the output signal. The double row, 2x16

character, LCD with backlight displays functions and

values.

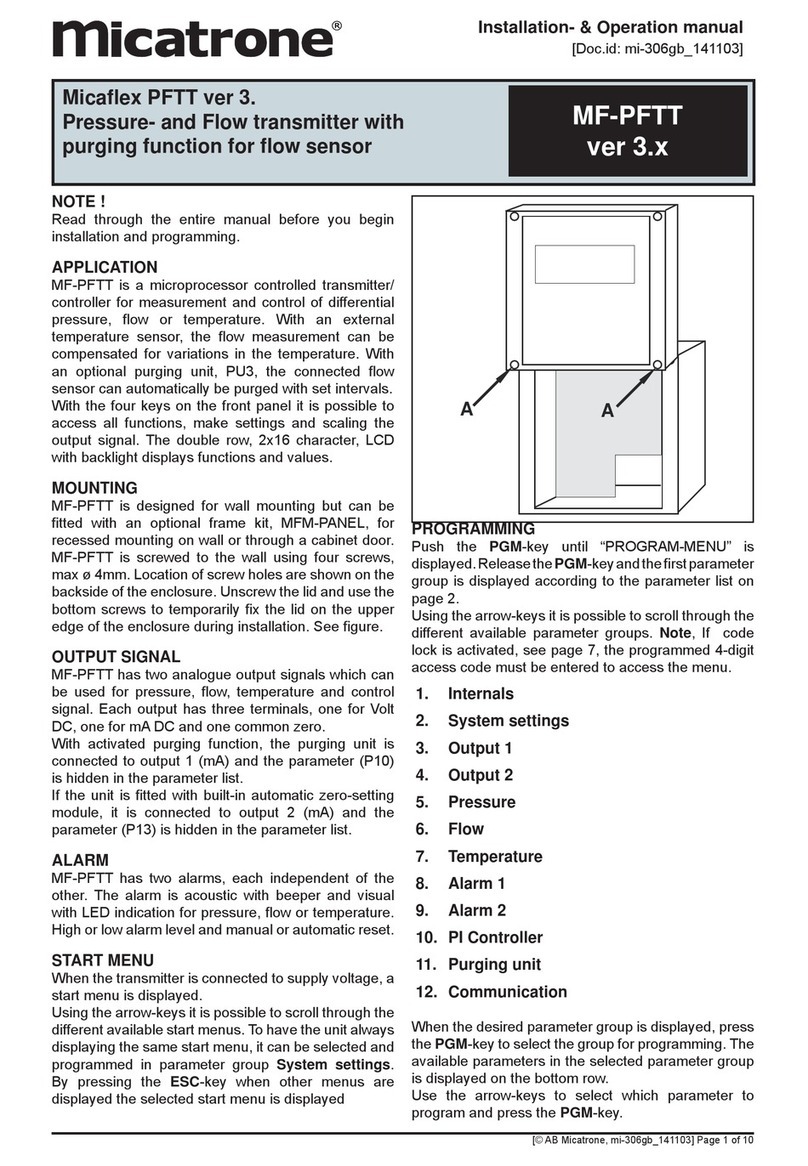

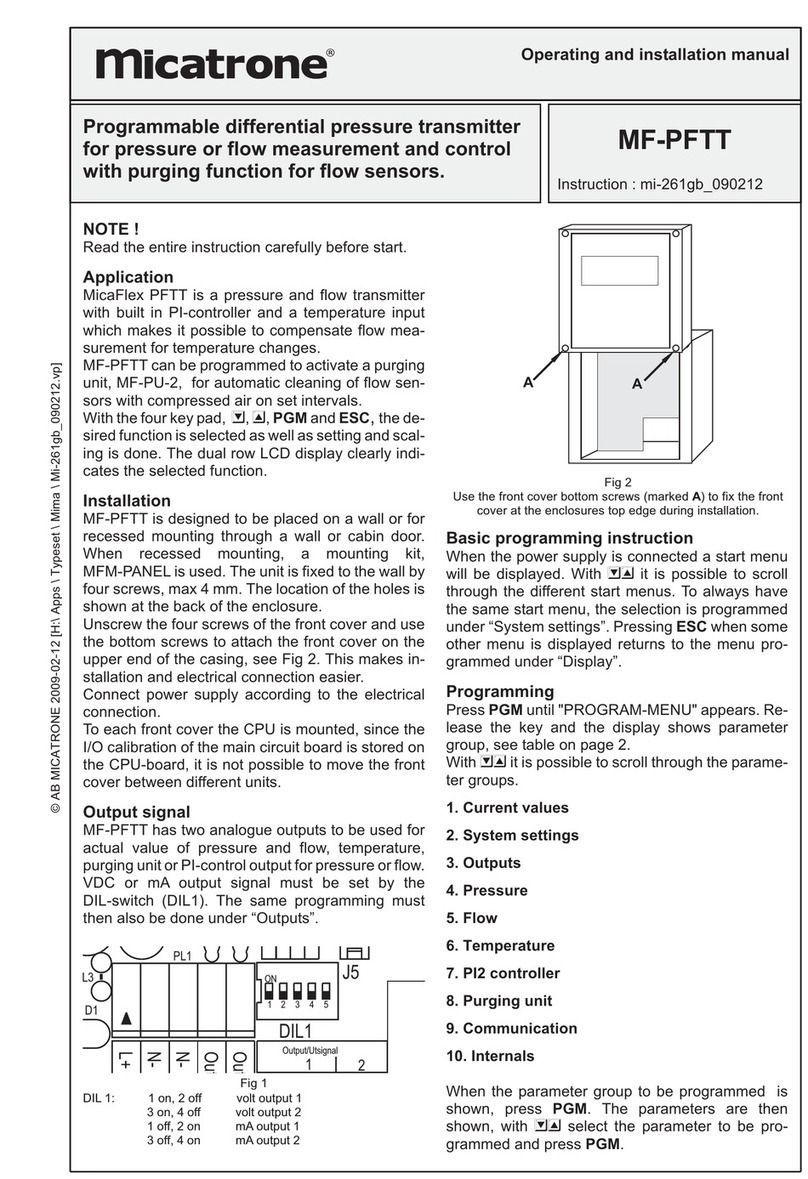

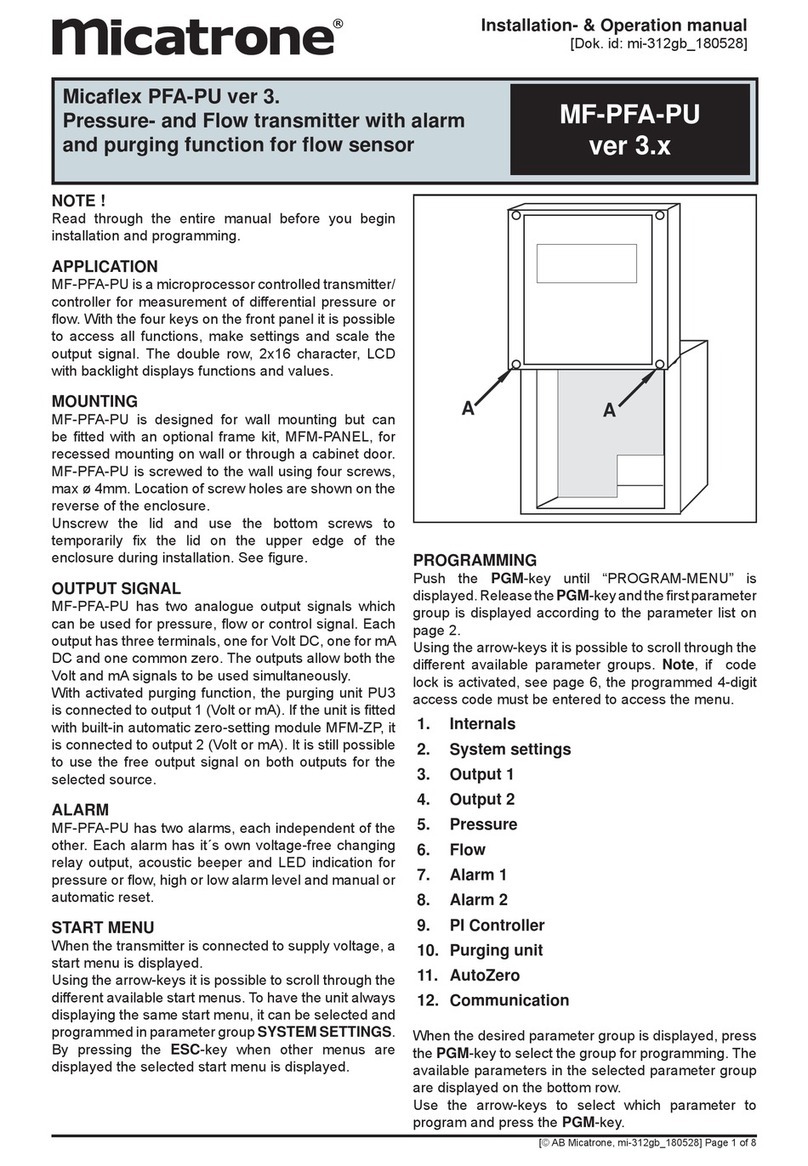

MOUNTING

MF-PFT is designed for wall mounting but can be

fitted with an optional frame kit, MFM-PANEL, for

recessed mounting on wall or through a cabinet door.

MF-PFT is screwed to the wall using four screws, max

ø 4mm. Location of screw holes are shown on the

backside of the enclosure.

Unscrew the lid and use the bottom screws to

temporarily fix the lid on the upper edge of the

enclosure during installation. See figure.

OUTPUT SIGNAL

MF-PFT has two analogue output signals which can be

used for pressure, flow or control signal. Each output

has three terminals, one for Volt DC, one for mA DC

and one common zero. The outputs allow both the Volt

and mA signals to be used simultaneously.

If the unit is fitted with built-in automatic zero-setting

module MFM-ZP, it is connected to output 2 (Volt or

mA). It is still possible to use the free output signal on

output 2 for the selected source.

ALARM

MF-PFT has two alarms, each independent of the

other. The alarm is acoustic with beeper and visual

with LED indication for pressure or flow, high or low

alarm level and manual or automatic reset.

START MENU

When the transmitter is connected to supply voltage, a

start menu is displayed.

Using the arrow-keys it is possible to scroll through the

different available start menus. To have the unit always

displaying the same start menu, it can be selected and

programmed in parameter group System settings.

By pressing the ESC-key when other menus are

displayed the selected start menu is displayed.

PROGRAMMING

Push the PGM-key until “PROGRAM-MENU” is

displayed. Release the PGM-key and the first parameter

group is displayed according to the parameter list on

page 2.

Using the arrow-keys it is possible to scroll through

the different available parameter groups. Note, If code

lock is activated, see page 6, the programmed 4-digit

access code must be entered to access the menu.

1. Internals

2. System settings

3. Output 1

4. Output 2

5. Pressure

6. Flow

7. Alarm 1

8. Alarm 2

9. PI Controller

10. AutoZero

11. Communication

When the desired parameter group is displayed, press

the PGM-key to select the group for programming. The

available parameters in the selected parameter group

is displayed on the bottom row.

Use the arrow-keys to select which parameter to

program and press the PGM-key.

AA

Page 2 of 8 [© AB Micatrone, mi-302gb_171025]

Nr Lead text Min Max Default

Internals

P00 SW: I/O

P01 SW: OPI

System settings

P03 Display dP

FLOW

dP+FLOW

SRC+CTRL

dP

P04 Damping [s] 0,0 9,9 1,0

P05 Access code 0000 9999 0000

P06 Number of OPI 1 3 1

Output 1

P08 Source dP

FLOW

CTRL

dP

P09 Signal V 0..10

2..10

0..10

P10 Signal mA 0..20

4..20

4..20

Output 2

P11 Source dP

FLOW

CTRL

CTRL

P12 Signal V 0..10

2..10

0..10

P13 Signal mA 0..20

4..20

4..20

Pressure

P15 MinCal [Pa]

P16 MaxCal [Pa]

P17 Unit dP Pa / mbar / iwc Pa

P18 Decimals 0 4 0

P19 Min range MinCal

P20 Max range MaxCal

P21 Min out MinRange MaxRange MinCal

P22 Max out MinRange MaxRange MaxCal

P23 Sign dP POS / NEG POS

Flow

P24 Unit flow l/s

m3/s

m3/h

m/s

cfm

l/s

P25 Decimals 0 4 0

P26 Max flow 0 32767 0

P27 Scale flw 0 32767 0

P28 Set flow 0 32767 0

Alarm 1

P33 Mode OFF

HIGH

LOW

OFF

P34 Source dP

FLOW

dP

P35 Limit MinRange MaxRange 0

P36 Delay [s] 0 3600 0

P37 Reset MANUAL

AUTO

AUTO

P38 Beeper OFF

ON

OFF

P39 Mute time [s] 0 3600 0

Alarm 2

P40 Mode OFF

HIGH

LOW

OFF

P41 Source dP

FLOW

dP

P42 Limit MinRange MaxRange 0

P43 Delay [s] 0 3600 0

Nr Lead text Min Max Default

P44 Reset MANUAL

AUTO

AUTO

P45 Beeper OFF

ON

OFF

P46 Mute time [s] 0 3600 0

PI Controller

P47 Mode OFF

ON

OFF

P48 Source dP

FLOW

dP

P49 Set point MinRange MaxRange 0

P58 NZ [%] 1 50 2

P59 P-band [%] 0 100 0

P60 I-time [s] 0 999 10

P61 BZ [%] 0 100 0

P62 I-time BZ [s] 0 999 0

P63 Output DIRECT

REVERSE

REVERSE

P64 Min output [%] 0 100 0

P65 Max output [%] 0 100 100

AutoZero

P81 Interval [h] 0,0 60,0 0,0

P85 Output Volt 2

mA 2

mA 2

Communication

P73 Address 1 247 21

P74 Baud OFF / 600 128000 38400

P75 Parity NONE

ODD

EVEN

NONE

P76 Protect NO

YES

NO

Programming of a numeric value

Each digit in a numeric value is programmed separately.

Press PGM to begin programming. The selected digit

is flashing. Press the up-arrow key for digits between 1

and 9. When passing digit “9”, negative digits between

-9 and 0 are shown if they are allowed in the parameter

value. Confirm each digit by pressing the PGM-key.

When all digits are programmed, press the PGM-key

to save the new value. The entire row is flashing to

confirm programming. To abort ongoing programming,

press the ESC-key and then begin a new programming

with the PGM-key.

Note! It is always possible to abort or cancel incorrect

programming using the ESC-key unless you have

pressed the PGM-key after programming the last digit.

Programming of alternative units or values

Press the arrow-keys to select the desired alternative

unit or value. Press the PGM-key to save the change.

The entire row is flashing to confirm programming.

Note! It is always possible to abort or cancel incorrect

programming using the ESC-key unless you have

pressed the PGM-key after selected unit/value.

End programming mode

Press the ESC-key to return to parameter group

selection display. Press the ESC-key a second time

to close the programming menu and return to the start

menu.

If no key has been pressed during 5 minutes, the

program menu is closed automatically.

PARAMETER LIST

[© AB Micatrone, mi-302gb_171025] Page 3 of 8

1. INTERNALS

Displays the program versions for the I/O-board

(motherboard) and Operator Interface (display).

No Lead text Min Max Default

P00 SW: I/O

P01 SW: OPI

2. SYSTEM SETTINGS

General settings in MF-PFT

No Lead text Min Max Default

P03 Display dP

FLOW

dP+FLOW

SRC+CTRL

dP

P04 Damping [s] 0,0 9,9 1,0

P05 Access code 0000 9999 0000

P06 Number of OPI 1 3 1

• P03 Display, select start menu to display. Select-

ing ‘SRC+CTRL’ show the selected source (SRC)

in the PI-controller + control output signal (CTRL).

• P04 Damping, programme, in seconds, the damp-

ing for the pressure output signal.

• P05 Access code, used for activating or deactivat-

ing the code lock, see page 6.

• P06 Number of OPI, number of operator interfaces

connected. See separate instruction.

3-4. OUTPUT 1 och OUTPUT 2

Settings for the two output signals

No Lead text Min Max Default

P08 Source dP

FLOW

CTRL

dP

P09 Signal V 0..10

2..10

0..10

P10 Signal mA 0..20

4..20

4..20

P11 Source dP

FLOW

CTRL

CTRL

P12 Signal V 0..10

2..10

0..10

P13 Signal mA 0..20

4..20

4..20

MF-PFT has 2 output signals which can be set to either

0..10 Volt, 2..10 Volt, 0..20 mA or 4..20 mA. Both Volt

and mA are simultaneously available for both outputs.

• P08/P11 Source, is used to select which measuring

value/signal (source) to direct as output signal. ‘dP’

is the pressure signal, ‘FLOW’ is the flow signal

and ‘CTRL’ is the control signal from the PI-control-

ler.

• P09/P12 Signal V is used to switch between 0..10

Volt and 2..10 Volt output signal.

• P10/P13 Signal mA is used to switch between

0..20 mA and 4..20 mA output signal.

If the unit is fitted with built-in automatic zero-setting

module MFM-ZP, it is connected to output 2 (Volt or

mA) and the parameter (P12 or P13) is hidden in the

parameter list. It is still possible to use the free output

signal on output 2 for the selected source.

5. PRESSURE

Settings for pressure measurement

No Lead text Min Max Default

P15 MinCal [Pa]

P16 MaxCal [Pa]

P17 Unit dP Pa / mbar / iwc Pa

P18 Decimals 0 4 0

P19 Min range MinCal

P20 Max range MaxCal

P21 Min out MinRange MaxRange MinCal

P22 Max out MinRange MaxRange MaxCal

P23 Sign dP POS / NEG POS

• P15/P16 MinCal[Pa] / MaxCal[Pa],

The MF-PFT is factory calibrated for a specific

range. The range is written on a label located on

the right side of the enclosure. The calibration is

always in Pascal (Pa). MinCal and MaxCal is the

calibrated pressure range in Pa. These values are

notes and not possible to change.

• P17 Unit dP, Select in which unit to display the

pressure. The alternatives are Pa, mbar or iwc

(inch water column).

• P18 Decimals, Number of decimals to show for the

pressure value. When using Pa as unit it is recom-

mended not to use decimals.

In case any set value is above 32767 regardless of

where the decimal point is placed the adjustment is

not carried out.

E.g. If Set Point = 5000 and one decimal is se-

lected, the adjustment will not work since the value

5000,0 is greater than the allowed max value of

3276,7. Of the same reason, 500,0 cannot be

adjusted to 500,00.

• P19/P20 Min range / Max range

When programming a new unit, min and max limits

in the new unit are displayed in parameter Min

range and Max range. These values are notes and

not possible to change.

• P21 Min out, Lower limit for scaling the output

signal is set in pressure units, e.g. 10 Pa will result

at 10 Pa pressure the min output signal of, 0/2 V

resp. 0/4 mA.

• P22 Max out, Higher limit for scaling the output

signal is set in pressure units, e.g. 90 Pa will result

at 90 Pa pressure the max output signal of 10 V

resp. 20 mA.

• P23 Sign dP, If the transmitter is without zero

crossing, the MF-PFT will indicate a negative pres-

sure similar to positive pressure (i.e. Without nega-

tive sign). When programming Sign dP = ‘NEG’

a negative sign (-) is shown in front of the current

value.

To change the range for the output signal, the Min out

and Max out are programmed. Programmed values

must be in the selected unit (Pa, mbar, iwc). When

scaling, be aware that the accuracy is always in

percent of the factory calibrated pressure range.

To measure and control the flow or velocity it is

necessary to connect the transmitter to flow sensors

with a known formula and k-factor.

Page 4 of 8 [© AB Micatrone, mi-302gb_171025]

6. FLOW

To measure and control the flow or velocity it is

necessary to connect the transmitter to flow sensors

with a known formula and k-factor.

Settings for flow measuring.

No Lead text Min Max Default

P24 Unit flow l/s

m3/s

m3/h

m/s

cfm

l/s

P25 Decimals 0 4 0

P26 Max flow 0 32767 0

P27 Scale flw 0 32767 0

P28 Set flow 0 32767 0

• P24 Unit flow, select a suitable unit for flow display,

l/s, m3/s, m3/h, m/s or cfm (cubic feet / minute).

• P25 Decimals, Number of decimals to show for the

flow value. In case any set value is above 32767

regardless of where the decimal point is placed the

adjustment is not carried out.

E.g. if Max Flow = 5000 and one decimal is se-

lected, the adjustment will not work since the value

5000,0 is greater than the allowed max value of

3276,7. Of the same reason, 500,0 cannot be

adjusted to 500,00.

• P26 Max flow, set the flow that correspond to the

pressure range on the MF-PFT.

• P27 Scale flw, set the flow for max output signal,

10 V resp. 20 mA.

• P28 Set flow, Programme this parameter if adjust-

ing the displayed flow is necessary. Programme

the current flow using a reference flow measure-

ment. Max flow is re-scaled to correspond with the

reference measurement. If the unit is connected to

a computer system or similar, the receiving system

should also be programmed if the Scale flw value

is higher than the new value of Max flow.

NOTE! Programming must be performed at the

same time as when the reference value is meas-

ured (The PGM-key is pressed for the last digit and

the value is stored).

The basic flow calculation used is made with √dP.

To have the display and the output corresponding

to the actual flow or velocity in the selected unit it is

necessary to make some calculations.

Different manu factors of flow measurement devices

have different calculation, but common for all is √dP.

Use the actual formula to calculate the max flow for the

factory calibrated measure range.

The calculated flow or velocity is then programmed

under Max flow in the selected unit. E.g. 5,0 m3/s. It

is possible to scale the flow range under Scale flw.

When scaling the flow, note that the accuracy depends

on the “Max flow” range. Scale flw must always

be set to the same or a lower value than Max flow.

E.g. 3,5 m3/s = 10 VDC.

The output signal is linear to the flow or velocity.

7-8. ALARM 1 and ALARM 2

Settings for two alarm limits.

No Lead text Min Max Default

P33 Mode OFF

HIGH

LOW

OFF

P34 Source dP

FLOW

dP

P35 Limit MinRange MaxRange 0

P36 Delay [s] 0 3600 0

P37 Reset MANUAL

AUTO

AUTO

P38 Beeper OFF

ON

OFF

P39 Mute time [s] 0 3600 0

P40 Mode OFF

HIGH

LOW

OFF

P41 Source dP

FLOW

dP

P42 Limit MinRange MaxRange 0

P43 Delay [s] 0 3600 0

P44 Reset MANUAL

AUTO

AUTO

P45 Beeper OFF

ON

OFF

P46 Mute time [s] 0 3600 0

MF-PFT has an alarm with two, each independent,

alarm limits. The alarm is acoustic with buzzer and

visual with LED (light emitting diode). Normal state

is indicated with green LED and alarm state with red

flashing LED on the lid. The acoustic alarm can be

disabled for each alarm limit. Red LED is activated

by the first alarm state that occur. At the alarm limit,

the red LED is lit and after set time delay it begin to

flash. The display show which of the alarm limits that

triggered the alarm.

• P33/P40 Mode, select if the alarm should be trig-

gered for high or low level. Programme as ‘OFF’ to

deactivate monitoring.

• P34/P41 Source, Choose which measuring value

to be monitored. ‘dP’ = pressure, ‘FLOW’ = flow.

• P35/P42 Limit, set at which level the alarm to be

triggered.

• P36/P43 Delay [s], set time delay before alarm

state occur.

• P37/P44 Reset, ‘MANUAL’ if the alarm should be

reset manually by pressing the ESC-key or ‘AUTO’

if the alarm state should return automatically to

normal state when the level is back to normal.

• P38/P45 Beeper, ‘OFF’ disable the acoustic alarm.

‘ON’ if alarm state should sound.

• P39/P46 Mute time, is used to silence (mute) the

alarm for a set time in seconds when the ESC-

key is pressed. If the time is set to ‘0’, the alarm is

mute until the alarm is reset and a new alarm state

occur.

[© AB Micatrone, mi-302gb_171025] Page 5 of 8

9. PI-CONTROLLER

Settings of PI-controller.

No Lead text Min Max Default

P47 Mode OFF

ON

OFF

P48 Source dP

FLOW

dP

P49 Set point MinRange MaxRange 0

P58 Nz [%] 1 50 2

P59 P-band [%] 0 100 0

P60 I-time [s] 0 999 10

P61 BZ [%] 0 100 0

P62 I-time BZ [s] 0 999 0

P63 Output DIRECT

REVERSE

REVERSE

P64 Min output [%] 0 100 0

P65 Max output [%] 0 100 100

MF-PFT has a PI-controller specially made for pressure

and flow control.

The controller could be programmed as a standard PI-

controller, but in most of the applications together with

pressure and flow control we recommend to program it

as an integral controller without P-band.

There are two programmable I-times. Outside a

desired limit on both sides of the set point it is possible

to have a shorter I-time and inside the limits a longer

I-time. The PI-control signal is directed to a desired

output in parameter group Output 1 or Output 2.

• P47 Mode, ‘ON’ activates Pi-controller, ‘OFF’ dis-

able the controller.

• P48 Source, select which measuring value to con-

trol. ‘dP’ = pressure, ‘FLOW’ = flow.

• P49 Set point, Set point value in the selected unit.

• P58 NZ [%], select desired neutral zone, normally

1..5%. Half zone above and half below set point

value. Set in percent of the measuring range.

• P59 P-band [%], normally not used for pressure or

flow control, default 0%. If P-band is programmed

to 0 % the P-function is disabled and the I-time is

calculated for a P-band of 100%.

• P60 I-time[s], set suitable I-time, normal 10s.

• P61 BZ [%], Break zone, used when you want to

reduce the control speed when surrounding the set

point.

• P62 I-time BZ, set I-time inside the break zone. En-

ter a longer I-time for a stable control when close

to the neutral zone.

• P63 Output, direction of the control output signal.

Normally ‘REVERSE’ (if the pressure or flow is

above set point, the output signal will decrease).

• P64 Min output, set a lower limit for the control

output signal in %.

• P65 Max output, set a higher limit for the control

output signal in %.

I-time

When programming as an I-controller there are two

possibilities.

• The same I-time over the full range. Normally used.

Program BZ = 000 and I-time BZ = 000. The I-time

should normally be longer than the time for the

damper motor etc. to go from min to max.

• Shifting between two I-times. The reason for work-

ing with two I-times is often that outside a set pres-

sure or flow limit you want to have a fast response

and inside a slow response (see figure below).

BZ: limit for switching I-time. BZ is in % of the scaled

pressure or flow range. The set break zone, BZ, is

counted from the neutral zone, NZ, higher and lower

limit. The set value is on each side of the neutral zone

and moves with any changes in the neutral zone. If

the control output is not entering a stable position,

increase the I-time, you could also try to increase the

neutral zone.

Manual operation

Return to the start menu and select the display

option where output signal for PI-controller together

with pressure or flow is indicated. Which one that is

displayed is determined by what the PI controller is

programmed for.

“Flow / dP”

“AUTO 50.00 %”

Press PGM, ‘AUTO’ changes to ‘HAND’ and the output

signal can be set in % using the arrow keys.

Return to position ‘AUTO’ by pressing the PGM-key.

To display the programmed start menu, press the

ESC-key.

The display showing the text “PI-” in front of ‘HAND’

or ‘AUTO’ is not possible to use for manual operation.

10. AUTOZERO

Automatic zero adjustment. This parameter group is

only visible when solenoid valve MFM-ZP is installed.

No Lead text Min Max Default

P81 Interval [h] 0,0 60,0 0,0

P85 Output Volt 2

mA 2

mA 2

Using the optional built-in solenoid valve, automatic

zero adjustment can be set. During this process, the

displayed values and the output signals are halted.

After the zero adjustment is done in approx. 15

seconds, the transmitter restore to normal operation.

Zero adjustment can also be carried out manually

according to instructions on page 7.

• P81 Interval[h], The time between adjustment can

be set between 0,1 and 60 hours.

• P85 Output, Select which output the solenoid valve

is connected to.

DP/Flow

BZ

BZ

Setpoint

NZ

NZ

12

I-time BZ

I-time I-time

sec.

Page 6 of 8 [© AB Micatrone, mi-302gb_171025]

11. COMMUNICATION MODBUS

Modbus RTU through RS-485 serial connection.

This parameter group is only visible when communi-

cation module is installed.

No Lead text Min Max Default

P73 Address 1 247 21

P74 Baud OFF / 600 128000 38400

P75 Parity NONE

ODD

EVEN

NONE

P76 Protect NO

YES

NO

MF-PFT can be fitted with a built-in expansion module

(Option) for network communication with a computer.

P73 Address, network address for MF-PFT, factory

default as 21.

P74 Baud, transfer rate, factory default 38400 baud.

P75 Parity, Parity bit in data transfer. Factory default

‘NONE’.

P76 Protect, Protection for parameter programming

through network communication. ‘YES’ = write

protection. This parameter can only be set to ‘NO’

using the MF-PFT keypad.

CODE LOCK PROTECTION

The code lock is used to protect against an authorized

programming. A four-digit code must be entered to

access the program menu and the functions menu. It

is still possible to read measuring values and operating

state without entering the access code.

At delivery, the code is set to ‘0000’, unless otherwise

agreed on. When the code is set to ‘0000’, the code

lock is inactivated and no protection against an

authorized programming is present.

Activation

To activate the code lock, a 4-digit code must be

programmed in parameter P05 Access code which is

found in parameter group System settings. The code

can not be ‘0000’, since this code is used to deactivate

the function. When a code has been programmed and

saved, the next time it will be necessary to enter the

code to access the program menu and the functions

menu.

Deactivating

The code lock can only by deactivated in the program

menu and therefore the access code must be available

to deactivate the code lock. Set the parameter P05

Access code to ‘0000’. The parameter is found in the

parameter group System settings.

Contact Micatrone if the code has been lost!

Entering the code

To access the program menu or functions menu it is

necessary to enter the access code.

Example:

1. Press the PGM-key to open the program menu.

Press the PGM-key until “PROGRAM- MENU” is

displayed.

2. Release the PGM-key. Following text is displayed

if key code is activated: “ENTER CODE:” and

“0***”.

3. The first digit of the access code can be entered

using the arrow keys. When ready press the PGM-

key to continue with the next digit. Repeat until all

digits are entered.

4. When the 4 digits are entered, press the PGM-key

a final time. The entered code is now compared

with the programmed code in parameter P05

Access code. If the codes match, the program

menu is displayed. The program menu is available

until it has been exited using the ESC-key.

5. If the entered access code is incorrect, the text

“INVALID CODE” is displayed during 2 seconds.

Restart from point 1.

6. By pressing the ESC-key, the entering code

operation is cancelled and the default start menu

is displayed.

FUNCTIONS MENU

Functions that are not used frequently on daily basis

are found in the functions menu. The functions menu

is accessed by pressing simultaneously the PGM

and ESC-key until the text “FUNCTIONS-MENU” is

displayed. If code lock is activated, see page , a valid

access code must be entered to access the menu.

Use the arrow keys to scroll through the different

functions, when displayed, select the desired function

by pressing the PGM-key. Exit the present menu by

pressing the ESC-key.

Functions

• Serial number Display the serial number xxxxx-xxx.

• Date of cal. Display the latest factory calibration

date.

• Reset Defaults Restore all data to the latest

factory calibration.

- List of params All values in the entire parameter

list are restored to default values at factory

delivery.

- Calibrations All calibrations are restored to

original values at factory delivery.

Note: field calibrations will be reset.

• Calibration

- Input, five-point calibration of the pressure

measurement

• Statistics Displays statistics for internal restarts.

- Power on, Number of normal power-on´s.

- Brown out, Number of restarts due to poor supply

voltage.

- Watchdog reset, Number of restarts due to runt-

ime error.

- SW error reset, Number of restarts due to soft-

ware error.

- Last reset cause, The cause for the latest restart.

- Operating time, Operating time since latest start.

Shown in days, hours and minutes (d:hh:mm).

[© AB Micatrone, mi-302gb_171025] Page 7 of 8

Zero setting of pressure transmitter

Disconnect the pressure connections or place the

block valve in position calibration.

Press repeatedly on the ESC-key until the start menu

is displayed.

Press simultaneously on both arrow keys, keep

pressed until the display show:

Release the keys when following is shown:

When the zero setting is done, the display show:

Followed with the start menu.

If the transmitter is equipped with built-in auto zero

module, manual zero setting is done using the arrow

keys without the need to detach any tubes or changing

position of a connected mono block valve.

Calibration of MF-PFT

MF-PFT can be re calibrated against a pressure

reference.

1. Keep PGM and ESC pressed until following text

is displayed: “FUNCTIONS-MENU”.

2. Scroll using the arrow keys until “Calibration” is

displayed.

3. Press PGM. ‘Input’ is shown.

4. Press PGM. ‘Cal dP’ is shown.

5. Press PGM. The first calibration point is shown.

Example:

MF-PFT (-50..50 Pa)

Pnt 1(5) = -50

6. Connect shown pressure. In this case, 50 Pa, to

the pressure connection marked negative [-].

7. Press the PGM-key and the MF-PFT will

start to measure the first calibration point (9

measurements).

8. Press the PGM-key to continue with the second

calibration point, ESC aborts the calibration.

9. Proceed with all five calibration points and

be careful to connect to the correct pressure

connection.

10.When all calibration points are done, following

text is shown:

“PGM=OK/ESC=ABORT”

11.The PGM-key will confirm the calibration and

store the new calibration values.

12.The ESC-key will abort and cancel the calibration.

Press repeatedly on the ESC-key to return to the

start menu again.

Note! The pressure reference should comply with the

demand of desired accuracy in the measurement.

ZERO OFFSET

ZERO OFFSET

ADJUSTING

ZERO OFFSET

DONE

AB Micatrone Telephone: +46-8-470 25 00

Aldermansvagen 3 Fax: +46-8-470 25 99

SE-171 48 SOLNA Internet: www.micatrone.se

Page 8 of 8 [© AB Micatrone, mi-302gb_171025]

TECHNICAL DATA:

Display: Alphanumeric LCD

2 row, 2x16 characters

with backlight

Power supply: 24 ± 15% VAC

20...32 VDC

Pwr consumption: 7 VA (24 VAC)

3,5 W (24 VDC)

Pressure range: see label on enclosure.

Flow range:

(max 4 decimals)

l/s 0...32767

m3/s 0...32767

m3/h 0...32767

m/s 0...32767

cfm 0...32767

Measurement error: < ± 0,5 % of the pressure

range ± 0,5 Pa

Temperature drift: < ± 0,5 % /10 °C

Damping: 0,0...9,9 sec.

Output signal: Two analogue outputs,

0/2...10 VDC, 0/4...20 mA

selectable and scalable.

Both mA and Volt output

can be used simultaneously

Ambient temp: 0...50°C

Alarm: Two separate alarms for

high & low level, alarm

indication with red LED and

buzzer (joint)

Degree of protection: IP 65, ABS plastic

El-connection: 1 x 2,5 mm2/ terminal

Cable entries: 4 pcs M16x1.5mm

(cable glands not included)

Dimensions: WxHxD = 122x120x90 mm

Weight: 0,81 kg

MAINTENANCE:

Check zero settings every 6:th. month.

ACCESSORIES:

• Mounting kit for recessed mounting,

MFM-PANEL

• External transformer 24, 115, 230 VAC

• MODBUS communication module

• Solenoid valve for automatic zero-adjustment.

EMC/LVD:

Applied EU directives:

- EMC SS-EN 61000-6-3:2007 + A1:2011

SS-EN 61000-6-2:2005 + C1:2005

- LVD SS-EN 61010-1:2010

G (+)

G0 (-)

Volt (+)

Volt (+)

Output 124 VAC/VDC Output 2

Main connection board

Ground (-)

Ground (-)

mA (+)

mA (+)

ELECTRICAL CONNECTION:

Table of contents

Other Micatrone Transmitter manuals

Popular Transmitter manuals by other brands

Lectronics

Lectronics DCHT instruction manual

Siemens

Siemens SITRANS LR560 operating instructions

Endress+Hauser

Endress+Hauser iTEMP TMT111 operating instructions

Key Digital

Key Digital KD-HDMIXCAT5 Specifications

ADEMCO

ADEMCO 5802WXT installation instructions

Signatrol

Signatrol SPYDAQ-1001-T quick start guide