Micatrone MG-4000-R2 Specification sheet

MG-4000-R2

Mi-262gb / 2017-04-03

USE

MG-4000-R2 is designed to measure the O2-con-

tent in flue gases from oil burners, gas burners

and biomass-fired boilers. MG-4000-R2 can, to-

gether with a controller, optimize the air/fuel ratio.

The result is the highest possible firing efficiency

can be obtained and sustained over time indepen-

dent of changes in the fuel and combustion air.

The probe (MG-4000-R2/S) is installed in the flue

gas duct directly after the boiler. The tip of the pro-

be is easy to adjust so that it is positioned in the

centre of the flue gas zone. No special gas is re-

quired for calibration, this is done directly in the

surrounding air. Installation and use are as easy

as using a standard temperature sensor.

The O2-transmitter consists of two parts: the probe

and the central unit. The probe houses a sensor of

zirconium dioxide (ZrO2), heating element, signal

amplifier and generator for the ion pump. The cen-

tral unit houses the electronics for measuring the

sensor signal, analogue outputs, relay contacts for

the alarm outputs, control panel and the power

supply. All functions in the central unit are mana-

ged and monitored by a microprocessor.

Current measurement values, error indications

and set parameters are all presented on the inte-

grated display.

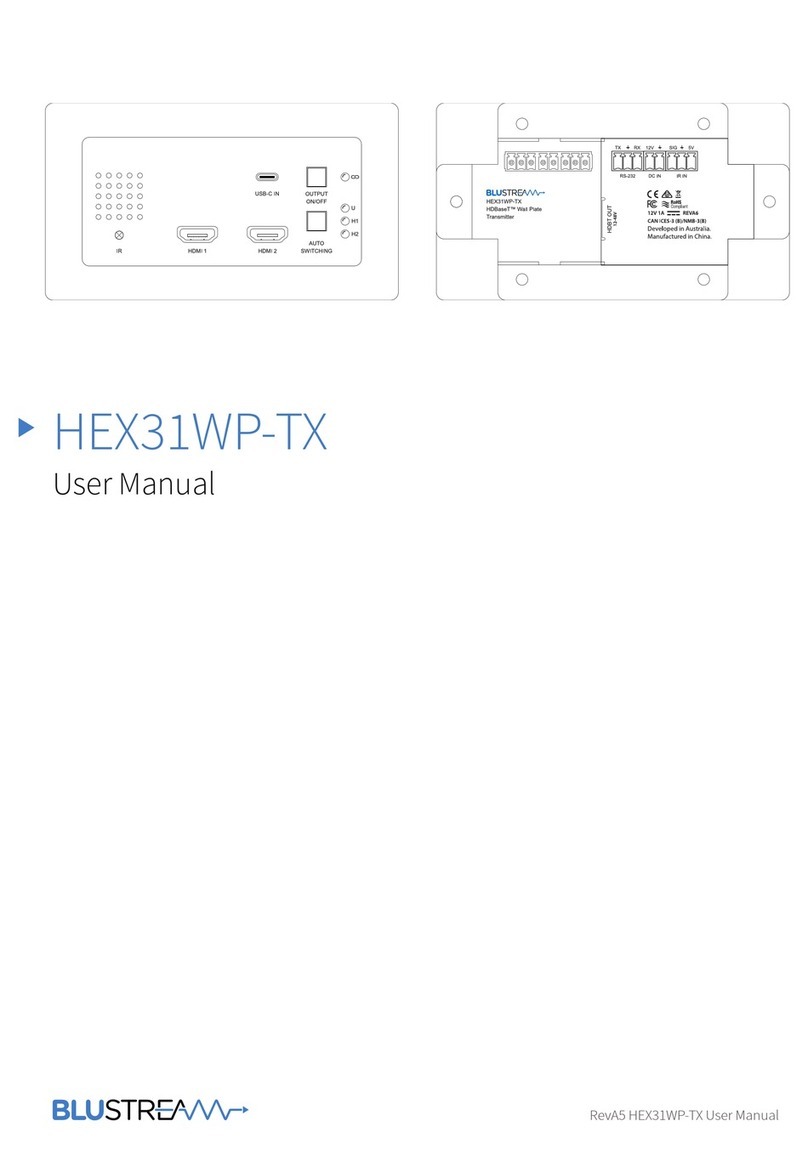

8 LEDs provide a quick indication of the operating

status.

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Oxygen (O2) transmitter with monitoring

catrone®

Operating and Installation manual

Version 1.3x

PGM ESC

O -transmitter

2MG-4000-R2

®

Measuring

Relay 1

Relay 2

High O -content

2

Low O -content

2

Out of range

Calibration

Error

AB MICATRONE

O2-cont 3.1 %

2

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

TABLE OF CONTENTS

USE........................1

MEASUREMENTPRINCIPLE..........3

Relationship between O2-content in dry and

wetfluegases ................4

Fuel-Oil...................4

Fuel-Biomass...............4

INSTALLATION..................4

Centralunit..................4

Probe.....................5

Galvanicisolation..............5

Wiring....................5

NOTE!....................5

OXYGENE SENSOR CROSS SENSITIVITY . . 6

CombustibleGases..............6

HeavyMetals.................6

Halogen and Sulphur Compounds ......6

Reducing Atmospheres ............6

Others.....................6

ELECTRICALCONNECTION..........7

Description ..................7

Signals to the probe .............7

Ground currents ................7

Connection diagram for Central unit and

Probe.....................8

Translation chart MG-4000 // MG-4000-R2. . 9

FUNCTIONS ..................10

Measurementvalues.............10

O2-content.................10

Nernst ...................10

Current&Voltage .............10

Temperature................10

Output signals ................10

Relays....................10

Communication ...............11

INITIALIZEOPERATION............11

PROGRAMMING................12

LCDdisplay.................12

Keypad....................12

Startmenu..................12

Theindicationofparameters ........12

Programmingaparameter..........12

Programmemenu.............12

Parameterselection............12

Programmingavalue ...........13

Cancelling programming mode ......13

Thefunctionmenu..............13

Defaultsettings ...............14

Communication...............14

Defaultsettings ...............14

Factory...................14

INDICATIONS..................15

Displays...................15

LEDs.....................15

Measuring.................15

Out of range ................15

Calibration.................15

Relay1...................15

Relay2...................15

High O2-content ..............15

Low O2-content...............15

Error....................15

Measurementvalues.............15

Status ....................15

PROBECALIBRATION.............16

Limitsforcalibration............17

MAINTENANCE.................17

Fuses.....................17

TROUBLESHOOTING.............18

Notextdisplayed..............18

The Out of range LED is lit.........18

TheHighO

2-contentLEDislit.......18

The Low O2-contentLEDislit.......18

MG-4000-R2 shows incorrect O2-content . 18

MG-4000-R2 cannot be calibrated.....18

Ground currents ..............18

Glitches...................18

Errorindications..............18

TECHNICAL DATA ...............19

Central unit MG-4000-R2 ..........19

Measuring probe MG-4000-R2/S ......19

LISTOFPARAMETERS ............20

This instruction applies for MG-4000-R2 software

version 1.2x

MEASUREMENT PRINCIPLE

At higher temperatures (>500 °C) stabilised zirco-

nium dioxide (ZrO2) is a solid electrolyte for oxy-

gen. This can be used in two ways:

1. To transport oxygen through a ZrO2-disc (ion

pump) according to Faraday’s first law.

2. To measure the ratio of partial pressure from

oxygen on each side of a ZrO2-disc according

to Nernst’s equation.

Most modern oxygen meters available on the mar-

ket use one of the aforementioned principles. To

avoid disadvantages such as relatively large pro-

bes, linearization of measurement signals, refe-

rence air, etc. both principles can be combined

into a dynamic oxygen sensor.

The sensor consists of two identical ZrO2-discs

with platinum electrodes and a platinum ring which

creates a small chamber between the discs. One

disc is used as a reversible ion pump according to

Faraday. The other disc generates a measurement

voltage proportional to the ratio of the oxygen par-

tial pressure in the chamber (P2) and surroundings

(P1)accordingtoNernst.

When measuring, the reversible ion pump will al-

ternately pressurise and evacuate the chamber.

Reversing takes place at two preset voltage levels

V1and V2on the Nernst voltage VN.

The time of a pump cycle (tp) becomes directly

proportional to the surrounding partial pressure

from the oxygen (P1). An increase in the surroun-

ding oxygen content increases the partial pressure

(P1) and tp increases. With a decreasing oxygen

content tp falls. At 0 % O2tp is approximately 0.5

seconds and in fresh air (20.7 % O2) tp is approxi-

mately 7 seconds.

The sensor is enclosed by a heating element to

maintain the temperature of the ZrO2-discs at 700

°C. This makes the sensor insensitive to changes

in the flue gas temperature and the flow rate.

qBased on this principle the sensor is very small

and with that the probe can be made small.

qNo reference air is required and the Nernst

voltage does not need to be linearized.

3

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

P1

P2

Figure 1

Principle construction for a dynamic O2-sensor.

Platinum-

electrodes

Platinum-

electrodes

Platinum-

ring

ZrO2-

disc

Ion pump

ZrO2-

disc

Voltage

VNacc. to

Nernst

Figure 2

Measuring signal from the O2-sensor.

Figure 3

Cross-section view of the sensor element.

Sensor of

ZrO2

Heating-

element

Relationship between O2-content in

dry and wet flue gases

MG-4000-R2, which has its probe mounted in the

flue gas duct, measure the O2-content in wet flue

gases. Portable O2-measurement instruments ex-

tract a gas sample from the duct and measure the

content in dry gases.

Fuel - Oil

Following approximate relation between wet and

dry flue gas is valid when excess air does not ex-

ceed 50%.

O2-content (wet gas) = 0.9 x O2-content (dry gas)

Fuel - Bio mass

See graph to the right

Note! If the measuring probe is exposed for redu-

ced atmospherers, e.g. high content of CO (car-

bon oxide), the life-span of the probe is reduced.

Therefore, it is of great importance the the O2-

control is operating properly.

INSTALLATION

Central unit

MG-4000-R2 should be located fully visible and

easily accessible. It is important to remember the

ambient temperature, max. 45 °C when positioning

the unit. The case is fitted with hinges on the

left-hand side of the cover for easy opening. Make

sure the cover can be opened fully.

Outside dimensions:

H x W x D = 360 x 300 x 140 mm.

Hole pattern for wall mounting:

When choosing the position for installation, re-

member the following:

1. The central unit must not be subjected to an

ambient temperature higher than 45 °C. Prefe-

rably the ambient temperature should be

below 30 °C.

2. The signal cable between the probe and the

central unit must be a shielded 10 conductor

cable e.g. FKAR-G 10 x 0.5 mm2. The area of

each conductor should be at least 0.5 mm2.

The correct cable, which is a prerequisite for

reliable operations, is enclosed. The cable shi-

eld must only be connected in the central unit.

3. The length of the signal cable between the

probe and the central unit should be as short

as is practically possible, maximum 10 m.

4. The signal cable between the probe and the

central unit must not be routed together with

cables used for low or high voltages.

The minimum permitted distance to low

andhighvoltagecablesis30cm. Cables

must cross at right angles.

5. Avoid placement where the central unit is sub-

jected to vibration.

6. The central unit should be positioned so that

the control panel is approximately at eye level.

4

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

1

2

3

4

5

6

7

8

O -content flue gases

2

10 20 30 40 50 60

% Excess air

Dry flue gas

Wet flue ga

s

Water content

in fuel (%)

40

45

50

55

60

Figure 4

Relationship between O2-content

in dry and wet flue gases.

250 mm

335 mm

Diameter 10 mm

Probe

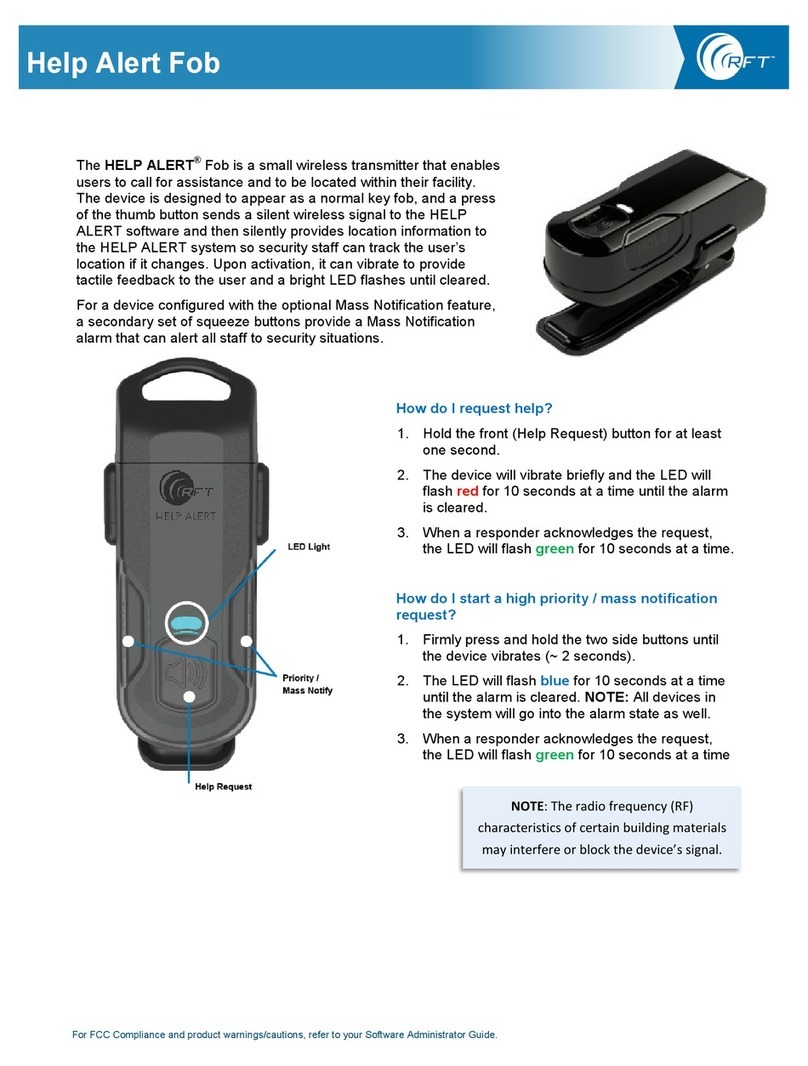

When installing the probe it is important to select cor-

rect placement. It should be easy to remove the pro-

be from the flue gas duct and easy to connect the

signal cable between the probe and the central unit.

1. Fit a 3/4" union on the flue duct after the boiler.

Make sure the union extends outside of the in-

sulation to facilitate installation of the probe. It

should be installed at a 15° angle to the hori-

zontal plane, so that the tip of the probe points

slightly downward (see figure 5), alt. top moun-

ted (see figure 6). This is to protect the probe

from condensation water.

2. Always install the supplied radiation protection

(see figure 7) on the probe’s insertion tube to

prevent the sensor’s electronics from overhea-

ting. Sole use of the radiation protection is not

recommended, the flue gas duct should also

be insulated.

3. The probe should be inserted so far that at le-

ast 10 cm of the tube hangs free inside the

duct. This is so the tip of the probe is not coo-

led via the union.

4. The supplied warning sign concerning precau-

tions that should be taken when the boiler is

swept must be set up where it is fully visible.

Galvanic isolation

The O2-probe should always be mounted using

the attached compression fitting which is fitted with

a isolation socket made of PTFE (TEFLON â)to

seperate the probe galvanically from protective

earth (ground) in the boiler/flue-gas duct which

could interfere with the measuring. Check that no

electrical connection is between the probe and

boiler/duct by measuring the resistance between

them both.

Wiring

The cable between the probe and the central unit

must NOT be extended. Leave an "eye" on the

cable by the probe so that the probe can be easily

removed from the flue gas duct for calibration and

duct sweeping.

The cable between the probe and the central unit

and cables to analogue output signals and data

communications must be shielded for the best me-

asurement result. The shield must only be connec-

ted to the ground rail in the central unit.

NOTE!

The probe must be operational (voltage fed) and

always maintain the operating temperature if it is

installed in the flue gas duct, irrespective of whet-

her the boiler is operational or not. When the pro-

be is not in use it should be kept in the surroun-

ding air. Wipe the probe dry if it is moist before in-

sertion.

5

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

NOTE! The measuring probe connection box should not be exposed to tempertures above 60 °C and must therefore be protec-

ted against the radiation heat caused by the flue gas duct or the boiler. Good insulation of the flue gas duct and enough space

between the insulation and the probes connection box is important. Always use the attached radiation protection shield.

max 20 m/s

max 400°C

~ 15°

min10cm

max 60°C

Union 3/4" inner thread

Max 260°C

Radiation shield

Probe pipe

INSULATION

Figur 5

Side mounting of the probe

Warning against dry-firing!

When "dry-firing" a biomass-fired boiler, the probe must not

be placed in the flue gas duct.

~ 15°

max 20 m/s

max 400°C

min10cm

Figure 6

Top mounting of the probe

Figure 7

Radiation shield for connection box

OXYGENE SENSOR CROSS SENSITIVITY

Cross sensitivity with other gases:

The oxygen sensor measures partial oxygen pressure. Gases or chemicals that will have an influence on

the life of the sensor or on the measuring results are:

Combustible Gases

Small amounts of combustible gases will be bur-

ned at the hot Pt-electrode surfaces or Al2O3filters

of the sensor.

In general combustion will be stoichiometric as

long as enough oxygen is available, the sensor will

measure the residual oxygen pressure. Investiga-

ted were:

qH2(Hydrogen) up to 2%; stoichiometric

combustion

qCO (Carbon Monoxide) up to 2%; stoichio-

metric combustion

qCH4(Methane) up to 2.5%; stoichiometric

combustion

qNH3(Ammonia) up to 1500 ppm; stoichio-

metric combustion

Heavy Metals

Vapours of metals like Zn (Zinc), Cd (Cadmium),

Pb (Lead), Bi (Bismuth) will have an effect on the

catalytic properties of the Pt– electrodes. Exposu-

res to these metal vapours has to be avoided.

Halogen and Sulphur Compounds

Small amounts (< 100ppm) of Halogens and/or

Sulphur compounds have no effect on the perfor-

mance of the oxygen sensor. Higher amounts of

these gases will in time cause readout problems

or, especially in condensing environments, corro-

sion of sensor parts. Investigated gases are:

qHalogens, F2(Flourine), Cl2(Chlorine)

qHCL (Hydrogen Chloride), HF (Hydrogen

Fluoride)

qSO2(Sulphur Dioxide)

qH2S (Hydrogen Sulphide)

qFreons

qCS2(Carbon Disulfide)

Reducing Atmospheres

Long time exposure to reducing atmospheres may

in time impair the catalytic effect of the Pt-electro-

des and has to be avoided.

Others

qVapours (organic silicone compounds) of

RTV (Room Temperature Vulcanised) rub-

bers are well known pollutants of zirconia

based oxygen sensors. The organic part of

the compound will be burned at hot sensor

parts, leaving behind a very fine divided

SiO2(Silicone Dioxide/Silica). This SiO2

completely blocks the pores and active

parts of the electrodes. If RTV rubbers are

used we advise to use high quality, well

cured.

qDust. Fine dust (Carbon parts/soot) might

cause clogging of the porous stainless ste-

el filter and might have an effect on the re-

sponse speed of the sensor.

qHeavy Shocks or Vibrations might alter

sensor properties.

qWater vapour. Condensing water vapour

might cause clogging of filters or internal

corrosion of sensor parts. We advise to

keep the sensor at operating temperature

or standby temperature when exposed to

exhaust gases. Direct exposure to water

droplets has to be avoided.

6

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

ELECTRICAL CONNECTION

Description

Voltage supply

MG-4000-R2 is fed with 230 VAC, 50 Hz on termi-

nals 1 (neutral) and 3 (phase). The supply should

incorporate a circuit-breaker to facilitate servicing.

Alarm function

On terminals 5-7 and 8-10, are two potential free

switching relay contacts. The relay contact func-

tion can be programmed on MG-4000-R2, e.g.

alarm with low O2-content and probe error. The re-

lay contacts are low voltage, 230 VAC.

Probe

Terminals 11-19 are connected to the probe’s ter-

minals 1-9.

Output signals

MG-4000-R2 has two analogue output signals for

the current O2-content, a mA-signal (0/4..20 mA)

on terminals 21 (+) and 22 (-) and a Volt-signal

(0/2...10 V) on terminals 23 (+) and 24 (-).

NOTE! Common neutral (-). The output signals

are not galvanically isolated from each other.

Communication

MG-4000-R2 has 2 interfaces, RS-232 and

RS-485. Only one interface at a time can be used.

RS-232 is connected to a modular jack (RJ45) and

is designed for Micatrone’s Programming adapter,

part no. 60-0972-2.

RS-485 is connected to terminals 25 (A) and 26

(B) and requires MG-4000-R2 to be equipped with

Micatrone’s Communication module, part no.

60-0973.

If both RS-232 and RS-485 are connected simulta-

neously RS-232 is given priority for communica-

tions. Also see the operating description for com-

munications on page 11.

Signals to the probe

Term Description Signal

11 Positive supply to the

probe’s electronics.

+7 Volt DC, 2.5 mA.

12 Feedback signal from

heating element in

probe.

± 50 mVolt, square

wave 1 kHz at 700 °C.

13 Control signal to the ion

pump for evacuation.

+6 / -4 Volt, square

wave 1 kHz.

14 Supply to the heating

element.

1.7 A, approx. 4.2 Volt

DC on probe.

15 Measurement zero from the electronics.

16 Neutral wire to the heating element.

17 Control signal to the ion

pump for pressurising.

+6 / -4 Volt, square

wave 1 kHz.

18 Measurement signal

from the zirconium

dioxide sensor.

Periodic signal

0...4 Volt DC.

19 Negative supply to the

probe’s electronic.

-5 Volt DC, 2.5 mA.

Ground currents

The probe has low voltage signals, 50 mV. Any

ground currents may influence the measurement

and it's important that the probe is galvanically iso-

lated from ground. This can easy be checked by

measuring the resistance between terminal 15 and

the ground rail in the central unit.

The result of the measuring should be a resistance

over 1 MW(Megaohm), break is prefered.

If the resistance is under 1 MW, the installation of

the probe need to be checked. Also check that the

output signal don't shorting between terminal 15

and ground. You might need a transmitter with gal-

vanic separation to the output signal.

7

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

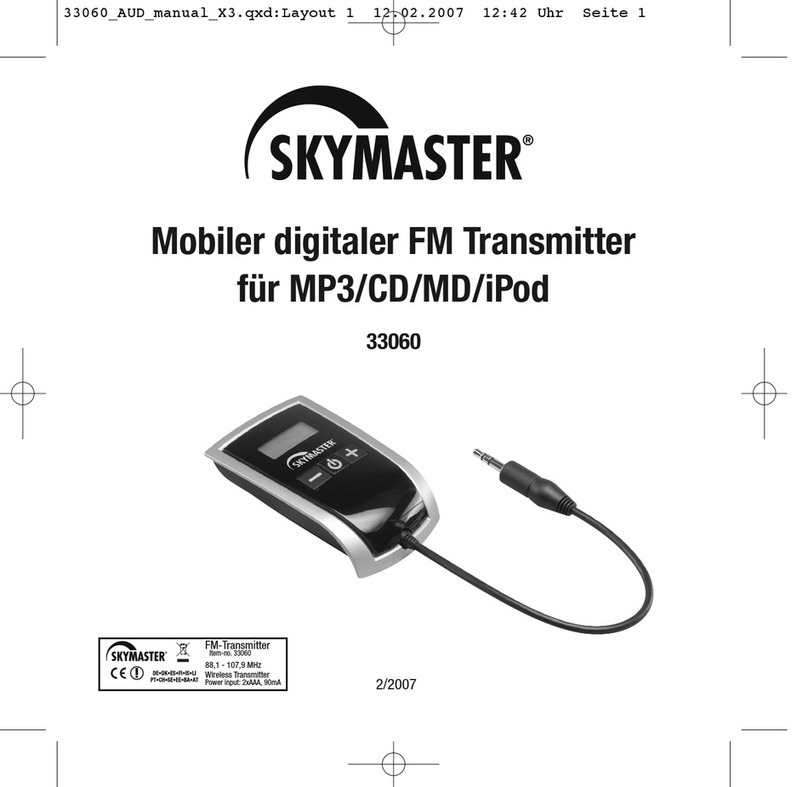

Connection diagram for Central unit and Probe

8

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

AB MICATRONE

Ritad

Det. nr Antal Benämning Material Anmärkning

Mod. nr Ämne

Dimension

Datum Sökväg

Filnamn

Ritningsnummer

LJ 2012-04-02

O:\Produkter\MG-4000-R2\CDR\

MG-4000-R2 Inkoppling.cdr

S-3767

Connection diagram for

MG-4000-R2 Ver 1.10

Page 1 (2)

PAD 1

SNAP1 SNAP2

SNAP5 SNAP6 SNAP7 SNAP8

SNAP4

SNAP3

J7

1

K3

E17

AC6

J2

R55

C41

R26

AC24

R77

C43

K1

IC1

LED1

C6

C12

R2

C27

C10

C16

C15

C17

C20

C28

D10

C63

R16

R67

D11

E18

E11

E3 E4

E15 E16

E10 E6

C13

C4

C5

IC3

IC8

IC24

IC25

KD1

C11

P2

C9

R76

R78

C53 D12

R70

T1

C26

TR1

TR2

FH3

FH2

FH1

R1

C1

C3

C2

1

PL1

400 mAT

5x20 mm

(3x)

D3

D2

D1

C8

C7

IC2

IC4

KD2 K2

E5

R4

TD2 TD1 IC9

P1

R5

C29

IC11

C30

IC12

FH4

2AT

5x20 mm

C18

D4 C19

C23 D5

R3

FM1

FM2 FM3

TD3

1

PL2

1

PL3

E12 E13

E14

L1

IC17

J1

R75

C54

R51

R42

C55

R46

R44

E2

E1

IC6

IC7

AC7

J8

R6

R7

R8 R9 R10 R11 R12

IC13

R61

AC21

AC22

R30

R31

C56

C59

C44

C52

R54

C35

D13

R20

C64

C65

R73

R28

D14

E8

C48

R27

R50

AC17

R45

R69

R74

R17

R29

AC25

C50 R57

R52

R43

D9

R71

R68

AC8

C51

R49

R48

R47

C60

C61

AC20

R62

R63

R64

IC20

R60

R66

C62

R65

C31

C57

AC27

R40

R72

C34

R32

C47

C49

C58

P3 P4

IC21

IC22

AC29 AC28

R58

R56

AC26

R25

R59

R53

IC27

IC29

IC28

IC26

IC15

IC16

C42

AC15

AC16

IC10

R23

R21

C36

C37

R18

D7 D8

R38

R41

R39

R37

AC19

IC19

C32

R15

C33

R13

D6

R33

AC14

IC14

C38

R24

C39

C40

R19

E9

E7

C22

C46

R36

IC18

AC18

RL1 RL2

AC23

R35

C45

R34

IC5

C25

R14

C14

AC13

R22

1

J3

1

J4

1

J6

C24

C21

IC23

P-3728 V2.00

2007-02

Top Silk

17

12

9

15

11

8

714 21

18

22 24 25 26

13

10 16

A

BRS-485

Current loop

Output signal 1

Output signal 2

19 20 23

NO

C

NC Relay 2, 230 VAC

Signal voltage

1

Fuse FH4 for heating

element in sensor 2 AT

5x20 mm

Fuses for the electronics

3 pcs. 400 mAT 5x20 mm

Location for RS-485

Communication.

plug-in module

10 11 26

+

Ri

0/4...20 mA RL max 500 ohm

-

-5 Volt

Low voltage

230 VAC

56

Ri

+

+7 Volt

132 4

N

N

L

L

Neutral

Line

230 VAC

MG-4000-R2

NO

C

NC Relay 1, 230 VAC

0/2...10 Volt Ri min 50 kohm

RL

+++

Ri

9

8

7

56

132 4

Probe

MG-4000-R2/S

NOTE!!! The shield of the signal

cable may NOT be connected to

the O -probe. The shield must

only be connected to the ground

rail in the central unit.

2

Translation chart MG-4000 // MG-4000-R2

9

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

AB MICATRONE

Ritad

Det. nr Antal Benämning Material Anmärkning

Mod. nr Ämne

Dimension

Datum Sökväg

Filnamn

Ritningsnummer

LJ 2007-12-21

I:\MG-4000-R2\CDR\

MG-4000-R2 Inkoppling.cdr

S-3767

Inkoppling av MG-4000-R2

Ver 1.00

Sidan 2 (2)

17

12

9

15

11

8

714 21

18

22 24 25 26

13

10 16 19 20 23

56

132 4

17

12

9

15

11

8

714

18

13

10 16 19 20

56

132 4

MG-4000-R2

MG-4000

FUNCTIONS

Measurement values

O2-content

MG-4000-R2 measures the O2-content in flue gas

using a zirconium dioxide sensor. The measure-

ment range of the output signal can be selected

between 0...5%, 0...10%, 0...20% or 0...100% O2.

If the measured O2-content is outside of the selec-

ted measurement range an orange LED is lit on

the control panel.

MG-4000-R2 has visual alarms (red LEDs on the

control panel) for specific high and low O2-content.

The limits are stated in % O2-content.

Theprobemustfirstbecalibratedtoprovideaccu-

rate measurements. Calibration is performed in

fresh air, see page 16. The current barometric

pressure can be programmed during calibration on

MG-4000-R2 to give the best possible accuracy.

The value is stated in mBar.

Nernst

Indicates the measurement signal from the probe.

Nernst will vary between 0 and 4 Volts during nor-

mal measurements.

Current & Voltage

Indicates the present current and voltage to the

probe’s heating element.

Temperature

Indicates the present temperature of the probe’s

zirconium dioxide sensor.

Output signals

MG-4000-R2 produces two output signals (one for mA

and one for Volt). The output signals state the current

O2-content for the selected measurement range.

Output signal 1 can be selected between 0...20

mA or 4...20 mA and output signal 2 can be selec-

ted between 0...10 Volt or 2...10 Volt.

Relays

MG-4000-R2 has two potential free switching con-

tactsthatcanbeusedtomonitortheO

2-content or

the function of the probe.

The function is activated in parameter 14/21 by se-

lecting whether the high or low signal is to be mo-

nitored. Select a source (input signal) in parameter

15/22. If error indication is chosen the function

(parameter 14/21) needs to be programmed to

HIGH.

When monitoring the O2-content a level is pro-

grammed (parameter 16/23) and a hysteresis (pa-

rameter 17/24). The level and the hysteresis are

stated in % O2-content. These two parameters are

not used when monitoring error indication.

Switching on and off can be delayed by the cho-

sen number of seconds in parameters 18/25 and

19/26. In parameter 20/27 the position of the swit-

ching contact is selected when the monitoring sta-

te is in normal mode. A yellow LED on the control

panel comes on when the relay contact is active.

10

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Par.no: Description Range Value

O2-measurement

1Range 0..5%

0..10%

0..20%

0..100%

2High O2 0,0...99,9

3Low O2 0,0...99,9

4Barometer 800...1200

Par.no: Description Range Value

Outputs

28 Source 1 O2-cont

29 Signal 1 0..20mA

4..20mA

30 Source 2 O2-cont

31 Signal 2 0..10V

2..10V

Par.no: Description Range Value

Relay 1

14 Function OFF

HIGH

LOW

15 Source O2-cont

ERROR

16 Level 0,0...99,9

17 Hysteresis 0,1...99,9

18 Delay on [s] 0...999

19 Dly fall [s] 0...999

20 Norm.pos. FALLEN

ACTIVE

Relay 2

21 Funktion OFF

HIGH

LOW

22 Source O2-cont

ERROR

23 Level 0,0...99,9

24 Hysteresis 0,1...99,9

25 Delay on [s] 0...999

26 Dly fall [s] 0...999

27 Norm.pos. FALLEN

ACTIVE

Communication

A communications module (accessory) can be fit-

ted in MG-4000-R2 to provide data communica-

tions using RS-485 (2-wire current loop) as the

interface.

There is also an adapter for RS-232 (serial port)

available as an accessory. The adapter is intended

for temporary use, for example, during installation

and trimming and does NOT require a communi-

cations module to be installed. Only one interface

(RS-485 or RS-232) can be used at any time.

The protocol used is Comli. Parameters and mea-

surement values are read with message type 2

and new values for parameters are transferred

with message type 0. The Comli number is the

same as the parameter number. Data communica-

tions can be limited so that only reading is

possible. (parameter 36).

INITIALIZE OPERATION

NOTE! The probe must be operational (voltage

fed) and always maintain operating temperature if

fitted in the flue gas duct, irrespective of whether

the boiler is operational or shutdown. If the probe

is not operational it should be stored in the sur-

rounding air.

NOTE! If the probe is subjected to reducing at-

mospheres, e.g. high content of CO (carbon mo-

noxide), this will reduce the service life of the pro-

be. It is important that the O2-control works cor-

rectly.

Check that all connections between the probe and

the central unit are correct before MG-4000-R2 is

connected to the mains supply, 230 VAC.

When the power is switched on MG-4000-R2 will

start to heat the probe. This takes 180 seconds

and during this period, the display shows "Start

up", the O2 content shows 0.0% and the outputs

are 0/4 mA respectively 0/2 Volt.

Should an error be discovered, e.g. a faulty con-

nection on the signal cable between the probe and

the central unit, the "Error" LED lights and the fault

is presented in plain text on the display. For a

description of how to rectify the error, refer to page

18.

If it is the first time that MG-4000-R2 has been

started the settings for the selected measurement

range and output signals should be checked.

MG-4000-R2 also needs to be calibrated in fresh

air to match the central unit with the probe, see

page 16.

11

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Par.no: Description Range Value

Communication

32 Address 1...247 21

33 Location 0...32767 0

34 Protocol COMLI COMLI

35 Baud 600 b

1200 b

2400 b

4800 b

9600 b

4800 b

36 Protect NO

YES

NO

Par.no: Description Range Value

O2-measurement

1Range 0..5%

0..10%

0..20%

0..100%

2High O2 0,0...99,9

3Low O2 0,0...99,9

4Barometer 800...1200

Par.no: Description Range Value

Outputs

28 Source 1 O2-cont

29 Signal 1 0..20mA

4..20mA

30 Source 2 O2-cont

31 Signal 2 0..10V

2..10V

PROGRAMMING

LCD display

MG-4000-R2 has a two-row alphanumeric LCD

display with back light and can show 16 characters

on each row. Normally the display indicates pre-

sent operating values but it is also used to indicate

measurement values and programmed parameter

values.

Keypad

MG-4000-R2 has a keypad with four keys, mar-

ked, 65, PGM and ESC.

qThe arrow keys, 65, are used to scroll

between different parameter groups, para-

meters and functions and increase or de-

crease the value of programmed parame-

ters.

qThe PGM key is used for programming and

indicating of set parameters.

qBy pressing the ESC key ongoing program-

ming can be aborted. The ESC key is also

used when returning to the start menu.

Start menu

The start menu is the entry point for indication and

programming of parameters along with special

functions such as default programming and calib-

ration.

If the start menu is not showed on the display,

press repeatedly on the ESC button. The start

menu is by default replaced to indicate operating

values. One press of the ESC button shows the

start menu for a short while and returns automati-

cally to indicate operating values. Use the arrow

keys, 6 5, to scroll between different display alter-

natives as follows.

Top row Bottom row

AB MICATRONE O2-content

Voltage Current

Status Relay 1, Function Status Relay 2, Function

Error message

Run time

Serial number

The indication of parameters

One press of the PGM key when default start

menu is showing will activate an automatic scroll

and list all parameters for about two seconds. The

top row indicating the parameter group and bottom

row the parameter and its value. The listing will

end when all parameters has been showed, or if

the ESC key is pressed.

Programming a parameter

Programme menu

The program menu includes all parameters and

measuring values that are accessible. All parame-

ters are divided into different parameter groups

where each function has its own group.

To activate the program menu, continuously press

the PGM key until following display is shown. Re-

lease the key.

The second parameter group is shown on the top

row.

Parameter selection

By using the arrow keys, 65, different groups of

parameters can be selected. If the last group is

shown and the arrow key, 6, is pressed, the first

menu is shown and vice versa.

Parameter groups

1Internals 5Outputs

2O2-measuring 6Communication

3Relay 1 7Current values

4Relay 2 8Status

When the desired group is shown, it can be selec-

ted by pressing the PGM key once. The first para-

meter inside the selected group is shown on the

bottom row of the display.

12

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

AB MICATRONE

O2-cont 3.1 %

MG-4000-R2

START-MENU

Internals

Prog.ver. 1.30

MG-4000-R2

PROGRAM-MENU

O2-measuring

O2-measuring

Range 0..10%

With the arrow keys, 65, all parameters inside

the group can be selected. If the last parameter in

the selected group is shown and the arrow key,6,

is pressed, the first parameter is shown and vice

versa.

To select another group of parameters when a pa-

rameters is shown on the bottom row, press the

ESC key. The programming mode is cancelled

when the ESC key is pressed repeatedly until the

default start menu is shown.

Programming a value

Parameters with a numeric value (integers and de-

cimal values):

When the selected parameter is sh

own in the display it can be selected for program-

ming by pressing the PGM key once. The first digit

will flash to indicate that it can be changed using

the arrow keys, 65.

If the digit flashing is “9” and the arrow key, 5,is

pressed, the counter will start from “0” and count

forwards (-9 for parameters that accept negative

values) without changing any other of the digits in

the value. The counter will continue in the opposite

way if the digit is flashing “0” and the arrow key,

6, is pressed. Continue to the next digit by pres-

sing the PGM key again.

When the last digit is set and the PGM key is pres-

sed the actual change of the parameter value is af-

fected. The entire bottom row in the display will

flash to confirm that the programming was suc-

cessful.

Parameters with preset alternatives

When the selected parameter is shown in the dis-

play it can be selected for programming by pres-

sing the PGM key once. The entire text will flash to

indicate that it can be changed to the preset alter-

natives using the arrow keys, 65.

The same procedure as with digits will occur if an

arrow key, 65, is pressed when the last, re-

spectively the first, parameter alternative is shown.

By pressing the PGM key, when the desired para-

meter alternative is shown, will execute the pro-

gramming and change the parameter. The entire

bottom row in the display will flash to confirm that

the programming was successful.

Cancelling programming mode

Ongoing programming can be cancelled by pres-

sing the ESC key. The parameter value will stop

flashing and the original value remains the same.

The function menu

To activate the function menu, press both PGM

and ESC key simontaneously and keep the keys

pressed until the following display is shown. Rele-

ase the buttons.

The first function is shown in the display.

Selecting a function:

With the arrow keys, 65, different functions can

be selected, for instance, default programming

and calibration. If the last function is shown and

the arrow key, 6, is pressed, the first function will

shown again and vice versa.

Functions

1Calibration of probe

2Default settings, Communication

3Default settings, Factory

4Calibration analogue inputs *)

5Calibration analogue outputs *)

When the desired function is displayed it can be

selected by pressing the PGM key.

The functions menu can be aborted by pressing

the ESC key.

*) Calibration of analogue inputs and outputs

require use of special equipment. All ana-

logue signals are factory calibrated and

should not during normal circumstances

have to be calibrated again.

13

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

O2-measuring

Low O2 00.5

Relay 1

Function HIGH

MG-4000-R2

FUNCTIONS-MENU

Calibration of

probe

Default settings

Communication

Default settings

Factory

14

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Par.no: Description Range Value

Communication

32 Address 1...247 21

33 Location 0...32767 0

34 Protocol COMLI COMLI

35 Baud 600 b

1200 b

2400 b

4800 b

9600 b

4800 b

36 Protect NO

YES

NO

Par.no: Description Range Value

Internals

0Prog.ver. 0,00...9,99 1,00

O2-measuring

1Range 0..5%

0..10%

0..20%

0..100%

0..10%

2High O2 0,0...99,9 10,0

3Low O2 0,0...99,9 0,5

4Barometer 800...1200 1013

Relay 1

14 Function OFF

HIGH

LOW

LOW

15 Source O2-cont

ERROR

O2-cont

16 Level 0,0...99,9 0,5

17 Hysteresis 0,1...99,9 0,1

18 Delay on [s] 0...999 10

19 Dly fall [s] 0...999 2

20 Norm.pos. FALLEN

ACTIVE

ACTIVE

Relay 2

21 Function OFF

HIGH

LOW

HIGH

22 Source O2-cont

ERROR

ERROR

23 Level 0,0...99,9 0,0

24 Hysteresis 0,1...99,9 0,1

25 Delay on [s] 0...999 0

26 Dly fall [s] 0...999 0

27 Norm.pos. FALLEN

ACTIVE

ACTIVE

Outputs

28 Source 1 O2-cont O2-cont

29 Signal 1 0..20mA

4..20mA

4..20mA

30 Source 2 O2-cont O2-cont

31 Signal 2 0..10V

2..10V

0..10V

Communication

32 Address 1...247 21

33 Location 0...32767 0

34 Protocol COMLI COMLI

35 Baud 600 b

1200 b

2400 b

4800 b

9600 b

4800 b

36 Protect NO

YES

NO

INDICATIONS

Displays

Different operating values are shown on displays

in the start menu, see page 12. Use the arrow-

keys, 6or 5, to scroll through the different dis-

plays with operating values.

Top row Bottom row

AB MICATRONE O2-content

Voltage Current

Status Relay 1, Function Status Relay 2, Function

Error message

Run time

Serial number

LEDs

The LEDs on the control panel indicate the follo-

wing:

Measuring

Flashes green for each new measurement pe-

riod/pump cycle (tp) from the probe, see page 3.

Outofrange

Lit orange when the measured O2-content is outsi-

de of the measurement range selected in parame-

ter 1.

Calibration

Lit orange while calibration of the probe is in pro-

gress.

Relay 1

Lit yellow when the relay contact for terminals 5-7

is active.

Relay 2

Lit yellow when the relay contact for terminals 8-10

is active.

High O2-content

Lit red when the measured O2-content exceeds

the value set in parameter 2.

Low O2-content

Lit red when the measured O2-content is below the

value set in parameter 3.

Error

Lit red in the event of a probe error. The error is

shown in plain text on the display, see page 18.

Measurement values

The following measurement values can be read on

the display from the program menu, see page 12.

Status

The following status values can be read on the

display from the program menu, see page 12.

Key to status texts

R1 Func. and R2 Func.

OFF The relay function is shutoff = not used.

WON Waiting for operation = the measurement value

has passed the limit, but the time for operation

has not elapsed.

ON The measurement value has passed the limit, but

the time for operation has elapsed.

W FALL Waiting for release = the measurement value is

on the normal side of the limit + connection diffe-

rence, but the time for release has not elapsed.

FALL The measurement value is on the normal side of

the limit + connection difference, but the time for

release has elapsed.

15

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Par.no: Description Range Value

Measuring values

100 O2-cont. 0,0...99,9

101 Nernst -0,50...4,50

102 Current 0,00...3,00

103 Voltage 0,00...9,99

104 Temp. 550...850

105 Reg. active NO

YES

106 Reg. out 0,00...100,00

107 CSP 0...999

108 Counter 0...65535

109 Counter OF -99...99

90 Cal. Temp. 550...850

91 Cal. Level 1520...6840

Par.no: Description Range Value

Status

110 R1 Func. OFF

WON

ON

W FALL

FALL

112 R2 Func. OFF

WON

ON

W FALL

FALL

114 Counting... STOP

UP

DOWN

115 Ionpump... STOP

PRESS

EVACU

PROBE CALIBRATION

Introduction

The central unit and probe must be calibrated to-

gether for MG-4000-R2 to measure the correct

O2-content. If any of the units are replaced a new

calibration must be made. Calibration takes about

10 minutes to complete.

Step 1

Make sure MG-4000-R2 is connected to the mains

supply and the probe. Start calibration at the earli-

est 10 minutes after MG-4000-R2 has been star-

ted, i.e. that both the mains supply and probe have

been connected. If no error is indicated it is assu-

med that the probe has reached its working tem-

perature, approx 700 °C.

Calibration is performed from the function menu,

see page 16. When the following is displayed:

press PGM to start calibration.

The following text is now shown:

You can cancel calibration at any time by pressing

ESC.

The function menu is displayed again. No calibra-

tion has been performed and the previous calibra-

tion value still applies.

Press PGM to continue the calibration. The pro-

grammed barometric pressure in mBar is now dis-

played.

Press PGM if the value is OK, otherwise you must

cancel (press ESC) and program the barometric

pressure in question via the program menu, see

page 12.

Step 2

The following text is now shown:

Theprobeiscalibratedinfreshair.Removethe

probe from the flue gas duct and place/hang the

probe so that at least 10 cm of the tip of the pro-

be is hanging freely in the air.

Remember that the tip is extremely hot. Ariskof

burns exists! Press PGM to continue.

If calibration is started less than 10 minutes after

the mains supply has been connected to

MG-4000-R2 the unit will wait until the time remai-

ning has elapsed before continuing with the

calibration.

When the counter reaches zero calibration conti-

nues with the next step.

Step 3

The Calibration LED now comes on and the cen-

tral unit makes 9 readings from the probe.

The measurement value and temperature from the

probe are shown for each reading.

Five dashes are shown if the measurement value

is not approved. If more than 2 measurements fail

the probe cannot be calibrated.

Cancel calibration and check the probe, see page 18.

16

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Calibration of

probe

[PGM] Continue

[ESC] Abort

Aborting...

Place probe in

air [PGM/ESC]

0of9

Barometer 1013

OK? [PGM/ESC]

1 of 9 3468

689

Calibration ERR

[ESC]

Waiting... 123

Step 4

The Calibration LED goes out when calibration is

complete and the following text is displayed.

The 2 numbers are values from the most recent

calibration and do not need to be the values

shown in the example above. Calibration is

approved!

Press PGM to continue. You will now be asked

whether the new calibration should be saved and

used from now on.

Press PGM to save or ESC to cancel.

Press ESC to close the function menu.

Step 5

Double check the calibration, i.e. measure the

O2-content with the probe in the flue gas duct and

read the measurement value on the central unit.

Estimate whether the measurement value is rea-

sonable or make a reference measurement using

another O2-transmitter. Change the air or fuel sup-

ply and check that the O2-content changes.

Limits for calibration

Barometer Low limit High limit

800 1520 4560

900 1710 5130

1000 1900 5700

1013 1925 5774

1100 2090 6270

1200 2280 6840

MAINTENANCE

NOTE! The probe must be operational (voltage

fed) and always maintain operating temperature if

fitted in the flue gas duct, irrespective of whether

the boiler is operational or shutdown. If the probe

is not operational it should be stored in the

surrounding air.

NOTE! If the probe is subjected to reducing at-

mospheres, e.g. high content of CO (carbon mo-

noxide), this will reduce the service life of the pro-

be. It is important that the O2-control works

correctly.

A design without moving parts means the probe is

fairly insensitive to external influences; resulting in

a long service life.

However, you should remove the probe from the

flue gas duct maybe once after each firing season

to check that the tip of the probe is not clogged by

soot or deposits. These deposits can affect the

probe’s time constant, i.e. the reaction time will in-

crease with the increase in deposits.

If the tip of the probe is dirty it can be carefully cle-

aned using a cloth dampened with, e.g. methyla-

ted spirit or petroleum spirits. Make sure that the

tip has had time to cool to room temperature.

MG-4000-R2 should be recalibrated for the first

time after about 2 months, then roughly once per

firing season.

Fuses

MG-4000-R2 contains 4 fine-wire fuses. These are

positioned to the right of the transformer and are

numbered FH3, FH2, FH1 and FH4 from the top.

Also see the figure on the terminal diagram.

FH3, 400 mA slow-burn.

Fuse for the control panel and processor card.

FH2, 400 mA slow-burn.

Fuse for the galvanically isolated supply for data

communications.

FH1, 400 mA slow-burn.

Fuse for the relay coils and supply to the probe’s

electronics.

FH4, 2 A slow-burn.

Fuse for the probe’s heating element.

17

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

Calibrering OK

3432 688 [PGM]

Cnt: 3432 T:688

Save? [PGM/ESC]

Cnt: 3432 T:688

Saving...

Completes...

TROUBLE SHOOTING

No text displayed

Check that MG-4000-R2 is voltage fed, 230 VAC

on terminals 1 and 3.

Check the 3 fuses to the right of the uppermost

transformer on the left-hand side of the PCB. They

should be 400 mAT, 5x20 mm glass-tube fuses.

The Out of range LED is lit

MG-4000-R2 is measuring O2-content that is outsi-

de of the selected measurement range. This is

normal when the boiler has stopped and the flue

gas duct contains fresh air. If this occurs when the

boiler is operational a larger measurement range

should be selected in parameter 1.

The High O2-content LED is lit

MG-4000-R2 is measuring O2-content in excess of

the value in parameter 2.

The Low O2-content LED is lit

MG-4000-R2 is measuring O2-content below the

value in parameter 3.

MG-4000-R2 shows incorrect O2-content

Calibrate, see page 16.

MG-4000-R2 cannot be calibrated

Check the connections between the central unit

and the probe.

Read the Counter measurement value via the pro-

gram menu. The value should be between 1925

and 5774 when the probe is warm and is in fresh

air at normal barometric pressure 1013 mBar.

Ground currents

The probe has low voltage signals, 50 mV. Any

ground currents may influence the measurement

and it's important that the probe is galvanically

isolated from ground. This can easy be checked

by measuring the resistance between terminal 15

and the ground rail in the central unit.

The result of the measuring should be a resistance

over 1 MW(Megaohm), break is prefered.

If the resistance is under 1 MW, the installation of

the probe need to be checked. Also check that the

output signal don't shorting between terminal 15

and ground. You might need a transmitter with gal-

vanic separation to the output signal.

Glitches

If MG-4000-R2 gets disrupted or receives transi-

ents, so that O2-measurement fails, the software

will reboot. The reboot takes 3 minutes and during

this period the outputs are 0/4 mA respectively 0/2

Volt.

Error indications

Should MG-4000-R2 discover an internal fault, for

example on the probe, this is indicated by a red

LED on the control panel and text on the display.

In the event of an error the O2-content will indicate

0.0 % O2and the output signals will drop to a mini-

mum. This is to guarantee an excess of air for

combustion.

Relay 1 and Relay 2 can be programmed to send

out a signal when an error occurs, see page 10.

The error texts that can appear on the display are

presented below.

Nernst, Signal too high/low

The measurement signal from the probe has been

outside of its working range 0...4 Volt for some

time. Restart MG-4000-R2 to try to reset the error.

Check the connections between the central unit

and the probe. Try another probe.

Current, Signal too high.

Too high current, > 1.9 A, is fed from the central

unit to the heating element in the probe. Try anot-

her probe.

Current, Signal too low.

Too low current, < 1.65 A, is fed from the central

unit to the heating element in the probe. Check

fuse FH4 in the central unit. Check the connec-

tions between the central unit and the probe. Try

another probe.

Voltage, Signal too high.

Too high voltage, > 8.0 Volt, is fed from the central

unit to the heating element in the probe. Check the

connections between the central unit and the pro-

be. Try another probe.

Voltage, Signal too low.

Too low voltage, < 4.0 Volt, is being fed from the

central unit to the heating element in the probe.

Check fuse FH in the central unit. Check the con-

nections between the central unit and the probe.

Try another probe.

Temperature, Signal too high/low

The probe does not maintain the right working

temperature. Restart MG-4000-R2 to try to reset

the error. Check the connections between the cen-

tral unit and the probe. Try another probe.

No measurement period, Defective probe

Restart MG-4000-R2 to try to reset the error.

Check the connections between the central unit

and the probe. Try another probe.

18

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

TECHNICAL DATA

Central unit MG-4000-R2

General

Supply voltage: 230 VAC, 50/60 Hz

Power consumption: 35 VA

Ambient temperature: 0...45 °C,

recommended < 30 °C

El. connections: Max. 2 pcs. 1,5

mm2/term.

Cable entries: 12 holes ø 20 mm

Degree of protection: IP 65

Dimensions: h x w x d 360 x 300 x 140 mm

Weight: 6,5 kg

O2-measuring

Range: 0...5 % O2

0...10 % O2

0...20 % O2

0...100 % O2

Resolution: 0,1 % O2

Accuracy: max 5 % of range

max 0,2 %-units of the

O2-content

Time constant: < 10 seconds

Heating time: < 200 seconds

Relay outputs

Max. load: 230 VAC, 2A

Outputs

mA

Signal range: 0/4...20 mA

Max. load: 500 W

Volt

Signal range: 0/2...10 Volt DC

Min. load: 50 kW

Data communication (optional)

Interface: RS-485 or. RS-232

Protocol: Comli

Measuring probe MG-4000-R2/S

General

Temperature range for

flue gases: 0...400 °C

Flue gas velocity: max 20 m/s

Ambient temperature for

connection box: 0...60 °C

Max. temperature at the

compression fitting: 260 °C

El. connections: 1.5 mm2/term.

Cable entries: 1 hole ø 20 mm

Cable to central unit: FKAR-G 10x0,5 mm2

Cable length: max 10 m

Degree of protection: IP 65

Material insertion tube: Stainless steel

Material connections

box: Aluminium

Duct fitting: G 3/4"

Weight: 1,5 kg

19

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

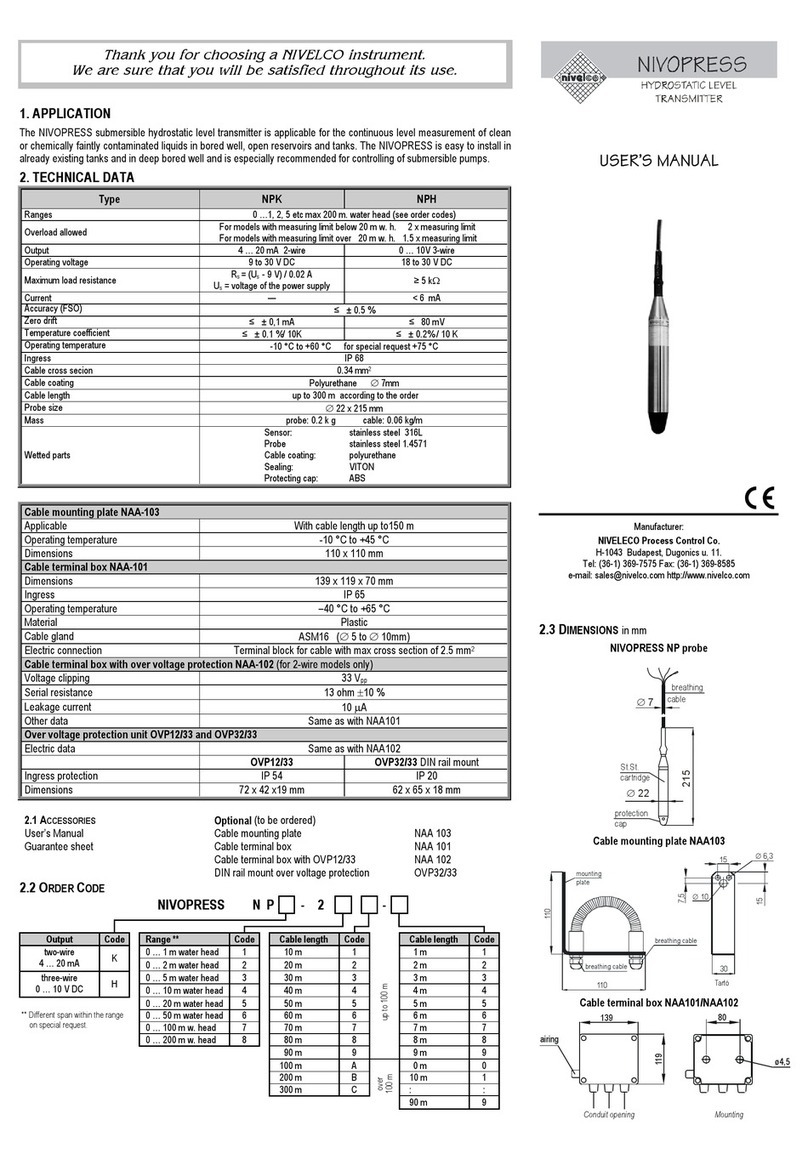

80

125

58

38

390

Figur 8

Dimensions measuring probe MG-4000-R2/S

20

© AB MICATRONE 2017-04-03 [O:\ Apps \ Typeset \ Mima \ mi-262gb_170403.vp]

AB MICATRONE Telephone: +46 8-470 25 00

Åldermansvägen 3 Fax: +46 8-470 25 99

SE-171 48 SOLNA Internet: www.micatrone.se

LIST OF PARAMETERS

Par.no: Description Range Value

Internals

0Prog.ver. 0,00...9,99

O2-measuring

1Range 0..5%

0..10%

0..20%

0..100%

2High O2 0,0...99,9

3Low O2 0,0...99,9

4Barometer 800...1200

Relay 1

14 Function OFF

HIGH

LOW

15 Source O2-cont

ERROR

16 Level 0,0...99,9

17 Hysteresis 0,1...99,9

18 Delay on [s] 0...999

19 Dly fall [s] 0...999

20 Norm.pos. FALLEN

ACTIVE

Relay 2

21 Function OFF

HIGH

LOW

22 Source O2-cont

ERROR

23 Level 0,0...99,9

24 Hysteresis 0,1...99,9

25 Delay on [s] 0...999

26 Dly fall [s] 0...999

27 Norm.pos. FALLEN

ACTIVE

Outputs

28 Source 1 O2-cont

29 Signal 1 0..20mA

4..20mA

30 Source 2 O2-cont

31 Signal 2 0..10V

2..10V

Communication

32 Address 1...247

33 Location 0...32767

34 Protocol COMLI

35 Baud 600 b

1200 b

2400 b

4800 b

9600 b

36 Protect NO

YES

Par.no: Description Range Value

Current values

100 O2-cont 0,0...99,9

101 Nernst -0,50...4,50

102 Current 0,00...3,00

103 Voltage 0,00...9,99

104 Temp. 550...850

105 Reg. active NO

YES

106 Reg. out 0,00...100,00

107 CSP 0...999

108 Counter 0...65535

109 Counter OF -99...99

90 Cal. Temp. 550...850

91 Cal. Level 1520...6840

Status

110 R1 Func. OFF

WON

ON

W FALL

FALL

112 R2 Func. OFF

WON

ON

W FALL

FALL

114 Counting... STOP

UP

DOWN

115 Ionpump... STOP

PRESS

EVACU

Table of contents

Other Micatrone Transmitter manuals