Translation of the original instructions

1 About this document

This document describes the use of the above-mentioned product. For detailed

specifications on the product, a complete description, the software for the device

(IODD) and the declaration of conformity èwww.festo.com.

1.1 Further applicable documents

All available documents for the product èwww.festo.com/pk.

2 Safety

2.1 Intended use

The position transmitter SDAS-MHS is intended for monitoring the piston stroke.

Only use the position transmitter for suitable drives from Festo

èwww.festo.com/catalogue. Avoid positioning magnetic objects in close prox-

imity to the position transmitter.

2.2 General safety instructions

– Only use the product in original status without unauthorised modifications.

– Only use the product if it is in perfect technical condition.

– Take into consideration the ambient conditions at the location of use.

– Observe limit values .

Return to Festo

– Consult your regional Festo contact.

2.3 Area of application and approval

NOTICE!

CE declaration of conformity èwww.festo.com/sp.

2.4 Training of skilled personnel

Installation, commissioning, maintenance and disassembly should only be con-

ducted by qualified personnel.

3 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

4 Product overview

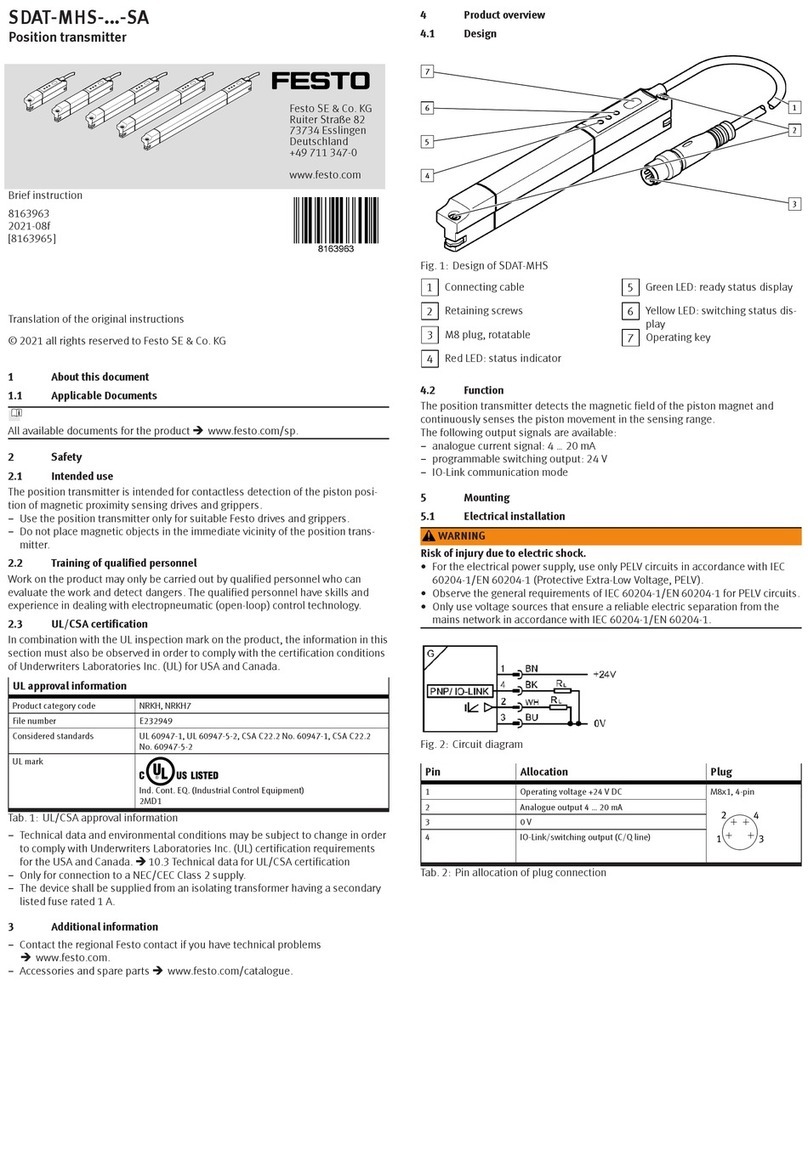

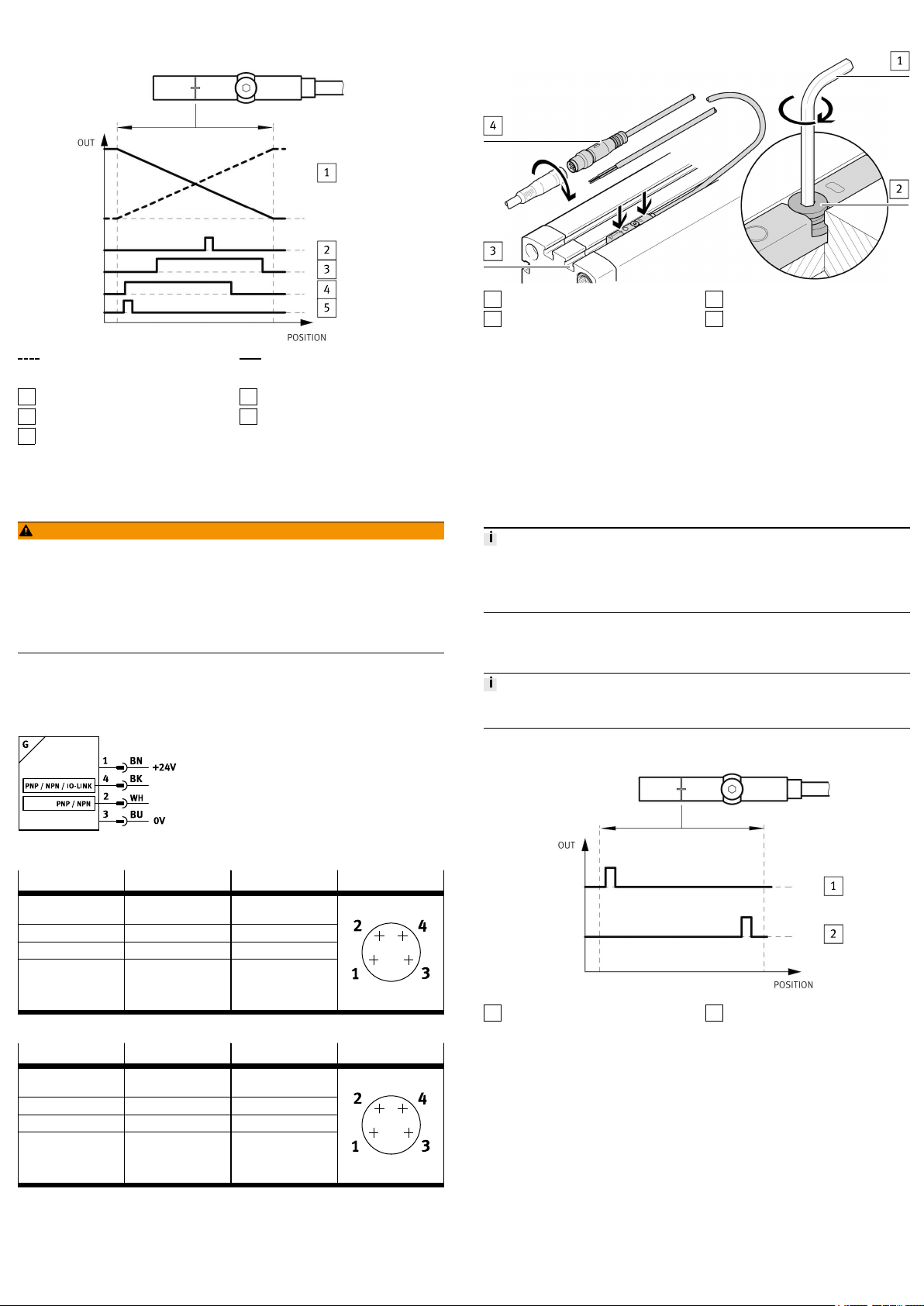

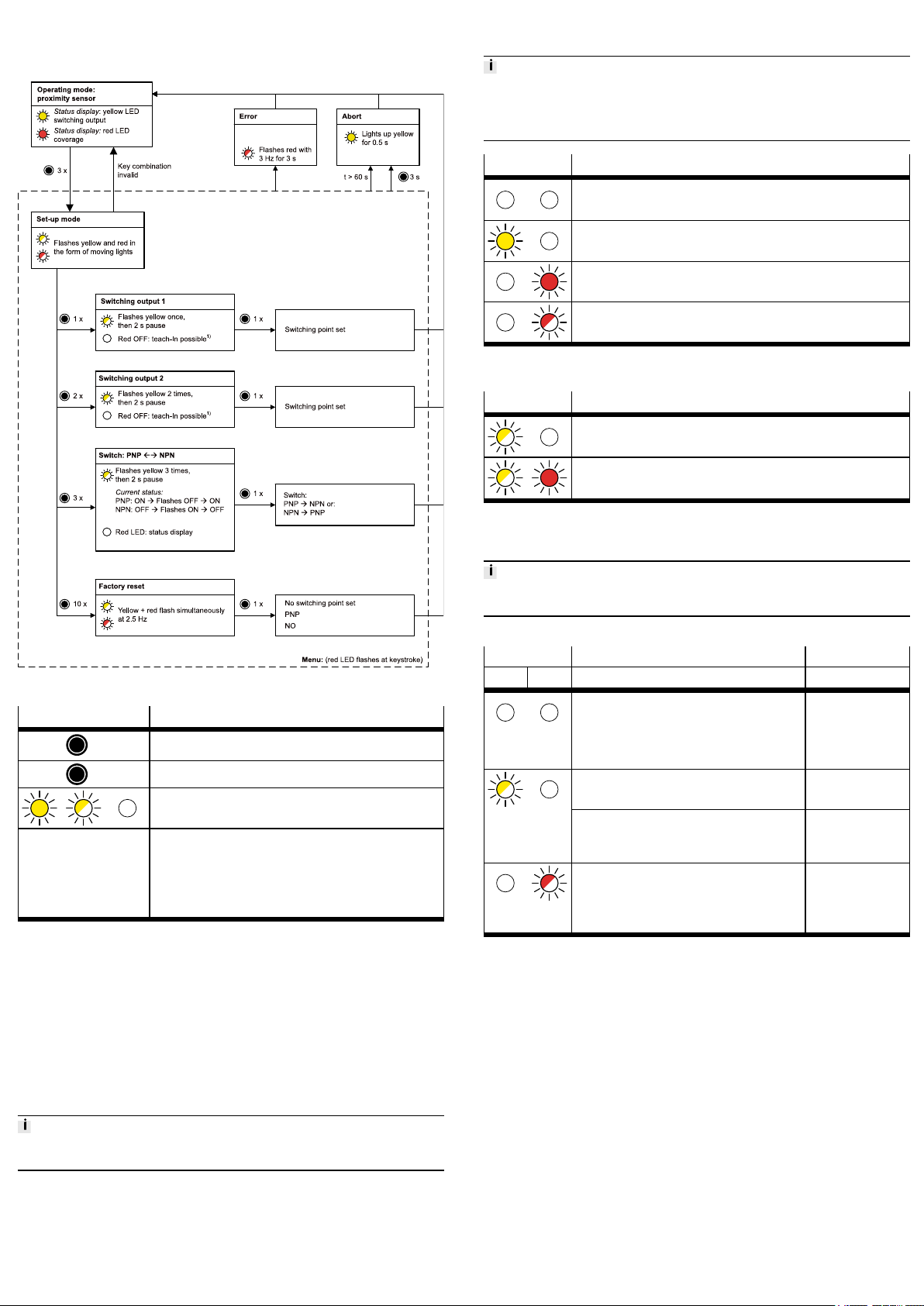

4.1 Design

1Connecting cable

2M8 plug, rotatable

3Red LED: status display

4Yellow LED: switching status dis-

play

5Marking: centre of the sensing

range

6Capacitive operating key

7Retaining screw

Fig. 1 Design of SDAS-MHS

5 Function

The position transmitter detects the magnetic field of the piston magnet and con-

tinuously senses the piston movement in the sensing range. The position trans-

mitter can be operated in one of the following operating modes:

– Cylinder switch with 2 programmable switching points (standard operation) .

– Position transmitter with IO-Link communication .

In the case of active IO-Link communication (IO-Link master required), the SDAS-

MHS switches automatically into the position transmitter operating mode.

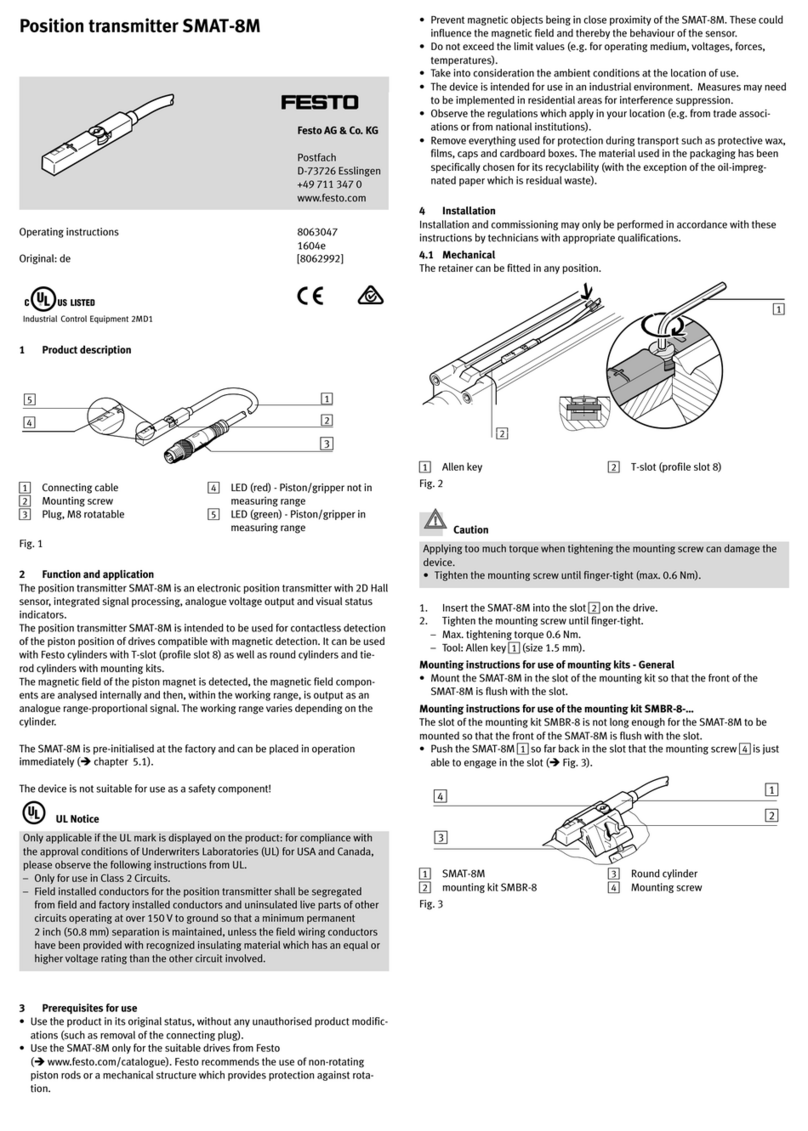

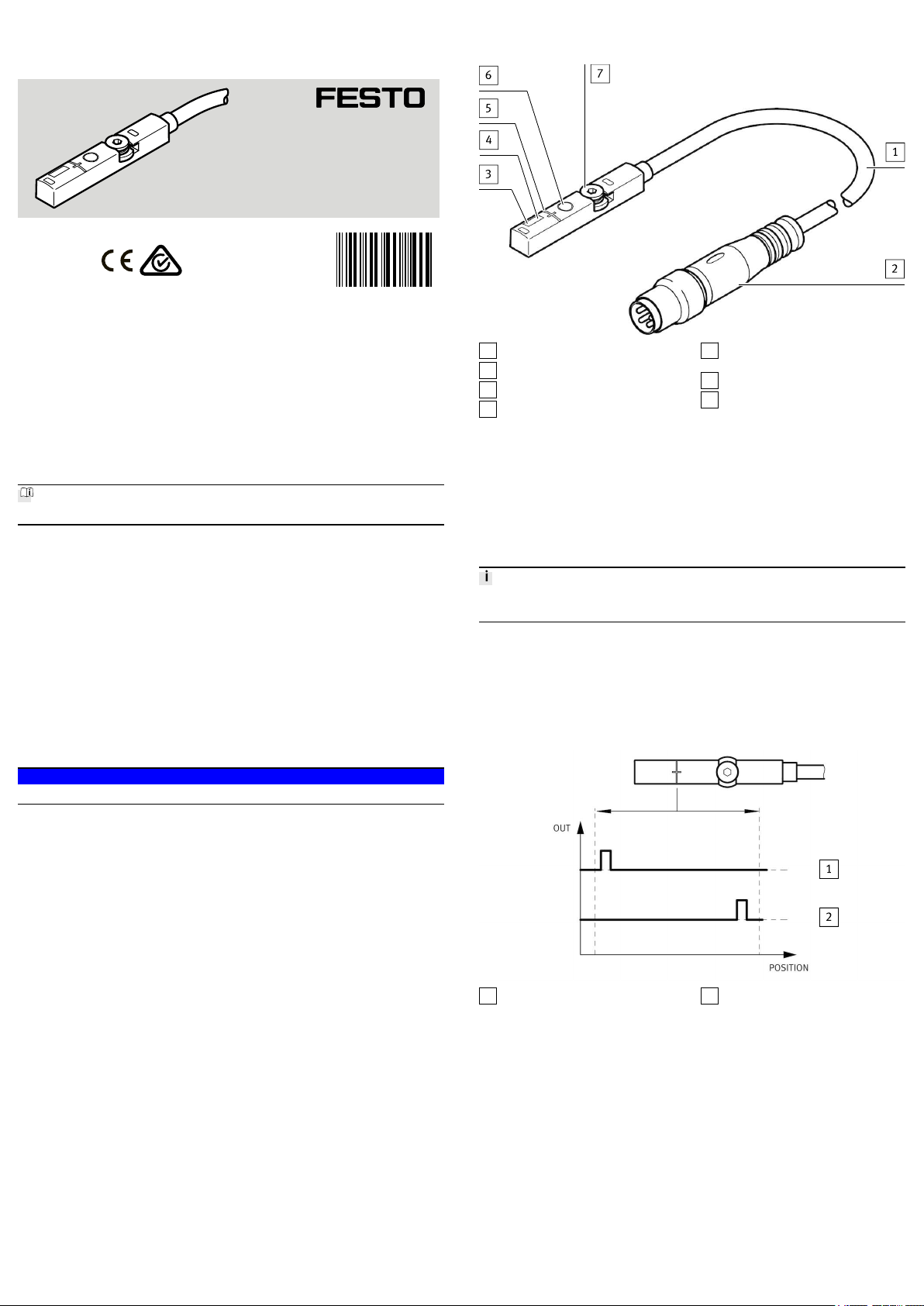

5.1 Cylinder switch operating mode

In the cylinder switch operating mode, 2 switching points can be programmed

within the sensing range.

– Operation using capacitive operating key

– Switching logic: normally open (NO)

– Output signal 24VDC (PNP or NPN)

– Marking on the housing indicates the centre of the sensing range.

1Electrical output 1 2Electrical output 2

Fig. 2 Application example: Cylinder switch operating mode

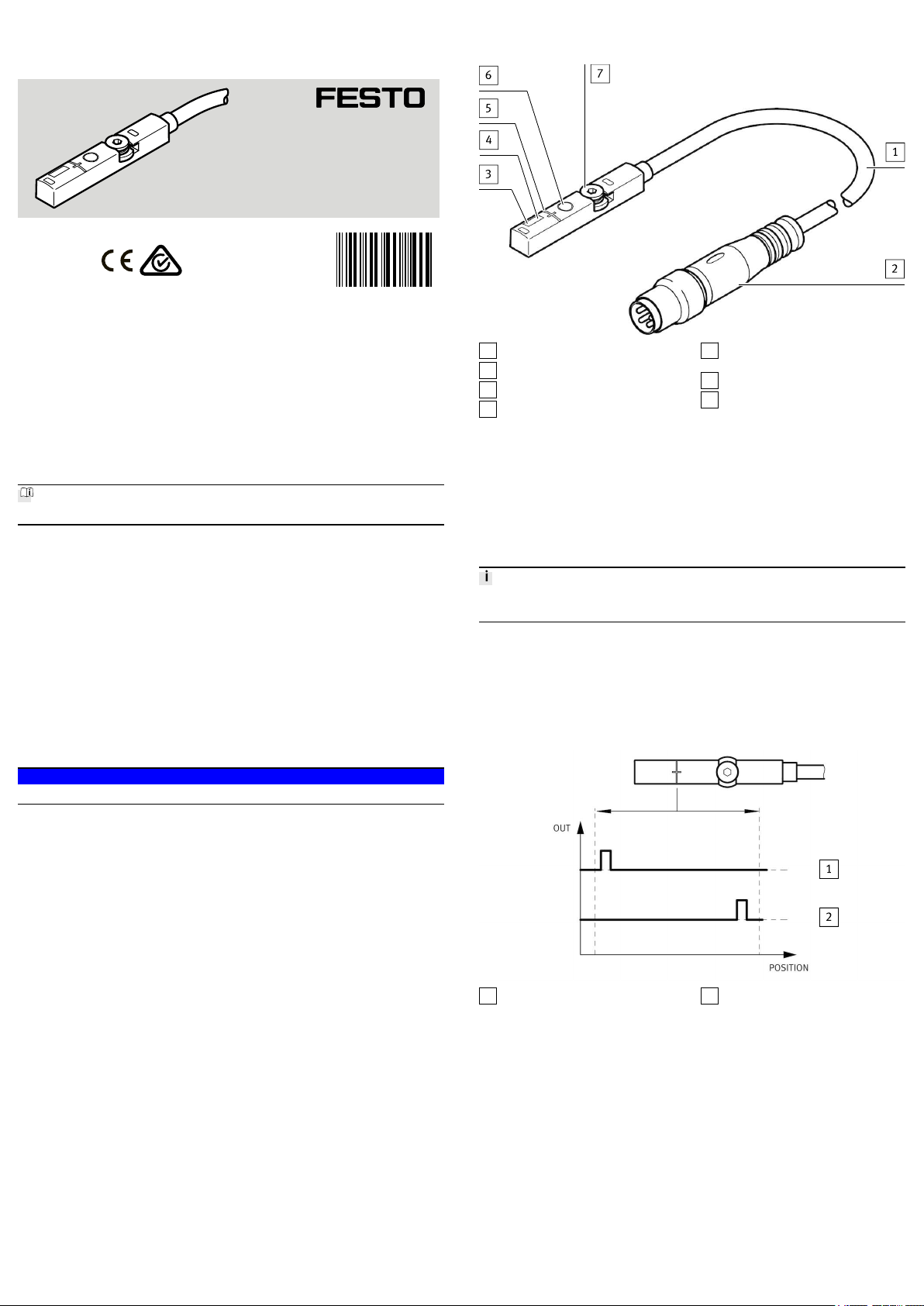

5.2 Position transmitter operating mode (IO-Link)

In the position transmitter operating mode, programmed switching signals and

the continuous position values (digitally coded analogue values) are transferred.

– Programming via IO-Link

– Device description file IODD èwww.festo.com/sp.

– Capacitive operating key is deactivated.

– Cylinder switches or window comparators or hysteresis comparators can be

programmed individually on 4 switching channels.

– The continuous position values are always transferred in parallel with and

independently of the position value output of the switching channels.

– Each channel can be set to be normally closed (NC) or normally open (NO).

– Data transmission is serially and digitally coded in the IO-Link protocol.

– Process data: 12 bit for position data and 4 bit for switching channels

– Unshielded standard cables of up to 20m in length can be used.

– Parameters and functions in accordance with Smart Sensor profile

– Support for the optional functions “Block parameterisation” and “Data

storage”

8096677

SDAS-MHS

Position transmitter

8096677

2018-07a

[8096679]

Instructions| Operating

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com