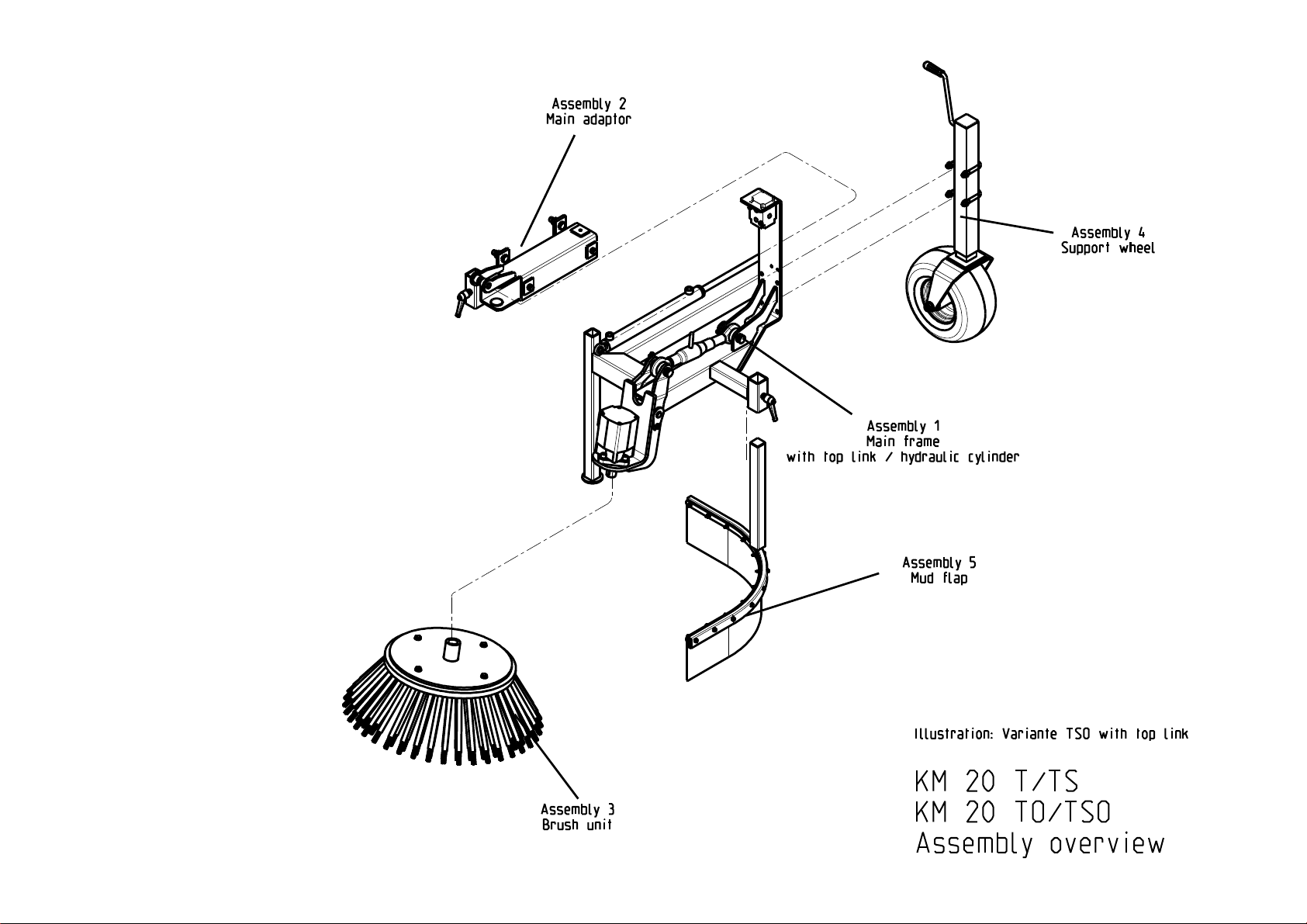

Michaelis Maschinenbau KM 20 T User manual

Edition 03/2016

Operating Instructions /

Spare Part List

Michaelis

Weed Control Maschine

KM 20 T/TS – TO/TSO

Fabr.-Nr.: ……….-……….

MICHAELIS

masc hinenbau

Huxfelder Straße 8 Telefon (0049) 4208 8294-0

D-28879 Grasberg Telefax (0049) 4208 506

www.michaelis-maschinenbau.de info@michaelis-maschinenbau.de

KM 20 T / TS

with hydraulic cylinder

KM 20 TO / TSO

with top link

- 2 -

MICHAELIS

masc hinenbau

1. Contents

1. Contents page 2

2. Technical data page 3

3. Operating Instructions page 4

4. General description page 5

4.1 Field of Application page 5

4.2 vehicle to be used page 5

4.3 Technical requirements page 5

5. Attachment page 6

6. Start up page 6

6.1 Typ KM 20 T/TS with hydraulic cylinder

the brush head tilt

page 6

6.2 Typ KM 20 TO/TSO with top link

the brush head tilt

page 7

7. Operation page 8

7.1 KM 20 T/TS –

Function mini control panel with hydraulic cylinder page 8

7.2 KM 20 TO/TSO –

Function mini control panel with top link page 8

8. Work deployment page 9

8.1 Tip to the period of implementation page 10

9. Brush types page 10

10. Brush change page 11

11.1 Brush change - Flat steel brush page 11

11.2 Brush change - Quick-change system page 12

11. Impact protection element page 13

12. Maintenance page 13

13. Support wheel page 13

14. Safety note page 14

Spare Part List KM 20 TO/TSO + T/TS

Electrical and hydraulic system with hydraulic cylinder

Electrical and hydraulic system with top link

in the appendix (Depending equipment)

Content errors reserved

- 3 -

MICHAELIS

masc hinenbau

2. Technical Data

Designation: Front device for weed removal and cleaning

__________________________________________________________________________

Typ KM 20 T / TO:

Front device for weed removal

With hydraulic sideshift

Weight KM 20 T/TO: 130 kg

Basic dimensions ca. (LxBxH): approx. 1,35 x 1,00 x 1,13 metres

Oil flow minimum: 25-30 l/min (Motor OMS 125) standard,

possibly amended by individual adaptation

to the carrier vehicle

Working pressure: 160 bar

Lateral adjustment of the brush: Hydraulic

Stroke of the side shift: 385 mm

Side reach from center: 1165 mm

Optionally with top link or cylinder

__________________________________________________________________________

Typ KM 20 TS / TSO:

Front device for weed removal

with hydraulic sideshift

Weight KM 20 TS/TSO 215 kg

Basic dimensions ca. (LxBxH): 1,70 x 1,07 x 1,15 m

Oil flow minimum: 35 l/min (Motor OMS 200) standard,

possibly amended by individual adaptation

to the carrier vehicle

Working pressure: 160 bar

Lateral adjustment of the brush: Hydraulic

Stroke of the side shift: 500 mm

Side reach from center: 1380 mm

Optionally with top link or cylinder

__________________________________________________________________________

Weed brush diameter Ø: standard flat steel brush KM20-5

On request twist knot brush with quick-change

system for individual removal twist knot KM20-8

According to directive: 2006/42/EG

Manufacturer: Michaelis Maschinenbau GmbH,

D-28879 Grasberg

- 4 -

MICHAELIS

masc hinenbau

3. Operating Instructions

We are pleased that you have decided to purchase this machine. It has been made

using state-of-the-art technology and quality workmanship. To ensure that the

machine has a long service life some basic duties are necessary.

Description of safety notes

Safety notes are marked by a pictogram or a

signal word. The signal word describes the

severity of the impending risk.

DANGER Imminent danger to life and health of persons

(severe or fatal injuries).

WARNUNG Possible danger to life and health of persons

(severe or fatal injuries).

CAUTION Possible dangerous situation (minor injuries

or material damage).

NOTE Tips for use and other particular useful

information.

IMPORTANT Obligation of a particular behavior or an action

for the safe handling of the machine.

REFERENCE

Gives a cross-reference to a particular

document or an action for the safe handling of

the machine.

- 5 -

MICHAELIS

masc hinenbau

4. General description

The KM 20 T / KM 20 TS is a front-mounted attachment with special weeds brushes for easy

and effective, eliminating mechanical fugues and moss paved surfaces, paths, places and

roadsides. Ideal for work in the edge region.

It is easily controlled from the driver's cab, optimal overview is given and can be adapted to

different vehicle widths.

Drive over existing on the tractor or other vehicle carrier oil circuit.

A simple and independent installation by hydraulically driven Brush-plate and side

adjustment by hydraulic cylinders.

Brush head tilt as standard mechanical.

Please read the instructions carefully to familiarize yourself with the operation and

maintenance of the appliance!

The following points should always be observed:

4.1 Field of application

The primary function of the machine is to remove weed of paved areas from ways and

roadsides. In addition it is suitable for general cleaning (e.g. kerbs), but it is not for interior

use or for terraces and narrow paths.

4.2 Vehicle to be used

Most suitable are carrier vehicles with an automatic hydrostatic system for infinitely

adjustable back and forth driving at variable speed. The vehicle must have an excavation

device or floating position.

4.3 Technical requirements:

- When a tractor municipal traktors triangle should be available tob e able to

accommodate devices triangles (To appoint frame size in advance)

or an additional mounting plate

- Oil flow minimum:

KM20T= 20l/min (OMS125) or KM20TS=35l/min (OMS200)

- Power supply 12 V

- With at least one double-acting hydraulic control circuit

REFERENCE

The specifications of the documentation have to

be attended concurrently.

IMPORTANT

The technical requirements for operation have

to be met.

- 6 -

MICHAELIS

masc hinenbau

5. Attachement

A professional attachment has to be carried out by qualified staff.

Pay attention to the attachment specifications of the carrier vehicle manufacturer and the

road traffic act concerning: track protruding parts / distance steering wheel center to front

edge of attachment.

When attaching the machine it has to be further taken into account that all adjustment

options can be used in every operation position (clearance).

The fulcrums have to be well greased and must move smoothly.

6. Start up

The Weed machine needed to operate a hydraulic control circuit.

The drive of the machine is achieved on the hydraulic system of the carrier vehicle.

The hydraulic hoses are connected with the terminals on the carrier vehicle.

The working pressure is 160 bar.

6.1 Typ KM 20 T / TS (with hydraulic cylinder the brush head tilt)

With the help of change-over valves of the main frame during the brushing operation can on

or off (-2S1) are driven and the "tendency of the brush head" (-2S2) be set.

To select serves a mini control panel see 7.1.

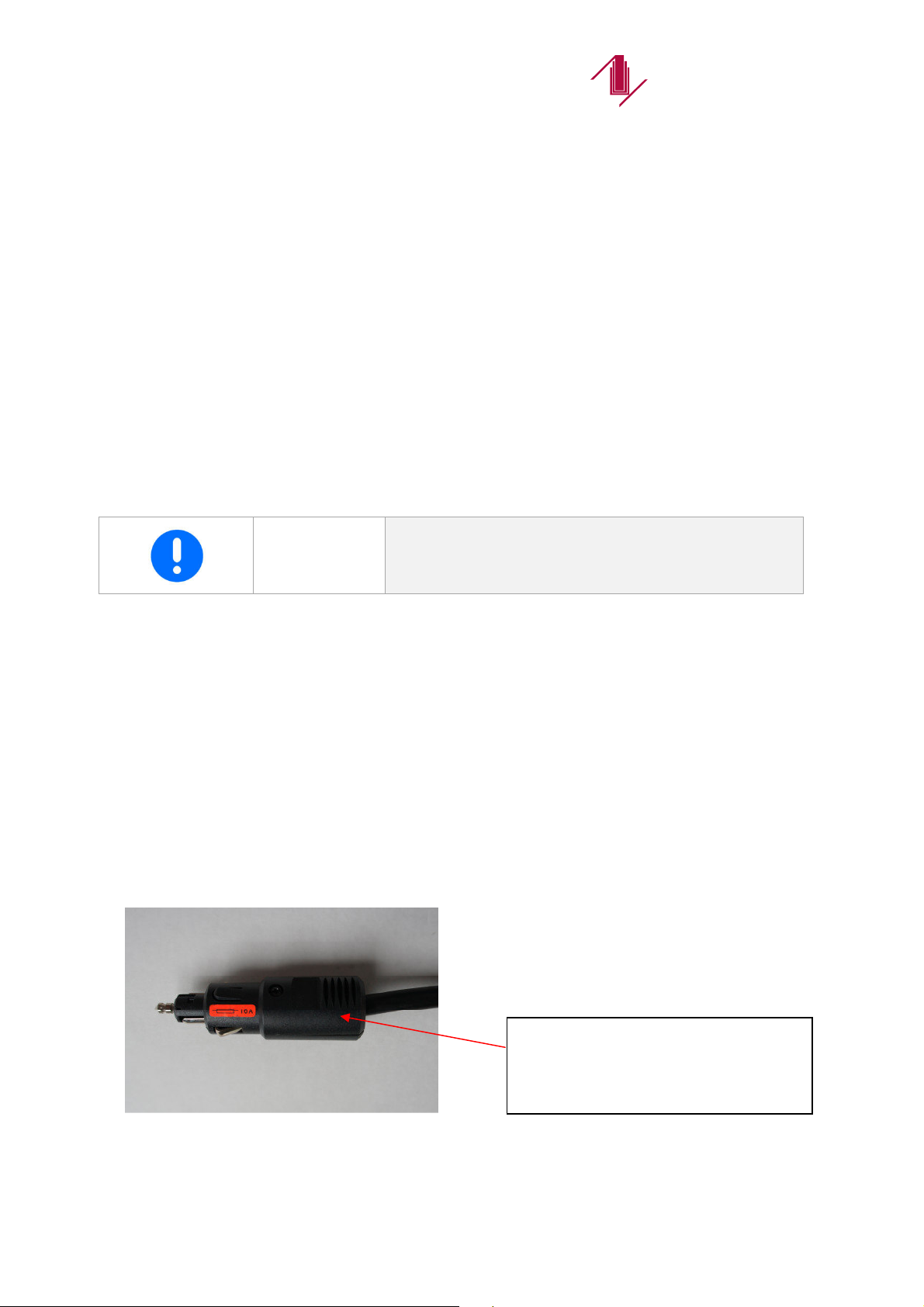

The control desk is equipped with 1 cable connection.

Plug –X01 is designated for the connection on the on-board power supply from carrier vehicle.

The telescoping of the main frame with brush and the tilting of the brush head is provided

by a hydraulic cylinders.

The oil flow is required at KM20T mind.: 25-30 l/min. (OMS-125)

KM20TS mind.: 35l/min. (OMS-200)

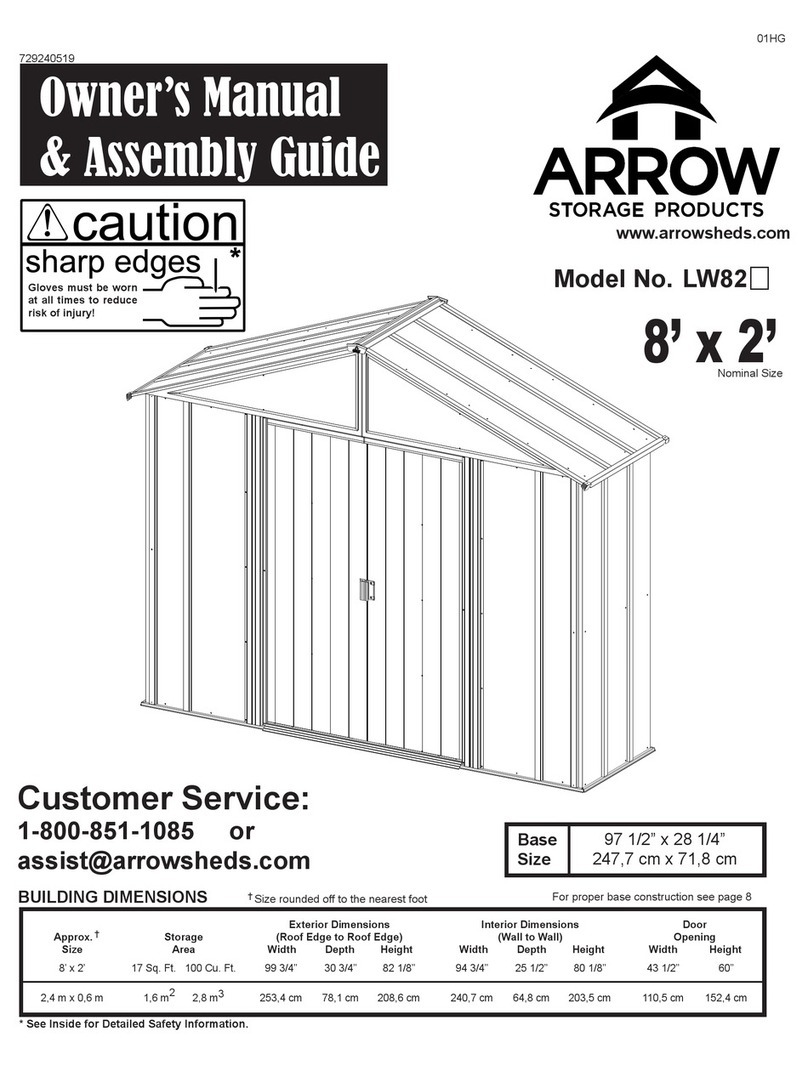

WICHTIG Tight fit of the connector and hydraulic hoses to

look out for

Plug – X01 Connection to the

on-board power

supply

Picture

1

- 7 -

MICHAELIS

masc hinenbau

6.2 Typ KM 20 TO / TSO (with top link the brush head tilt)

Using the integrated diverter valve can be either the brush driven or telescoped laterally.

To switch the functions "the brush operating" or "side adjustment" is a Mini control panel,

see Section 7.2

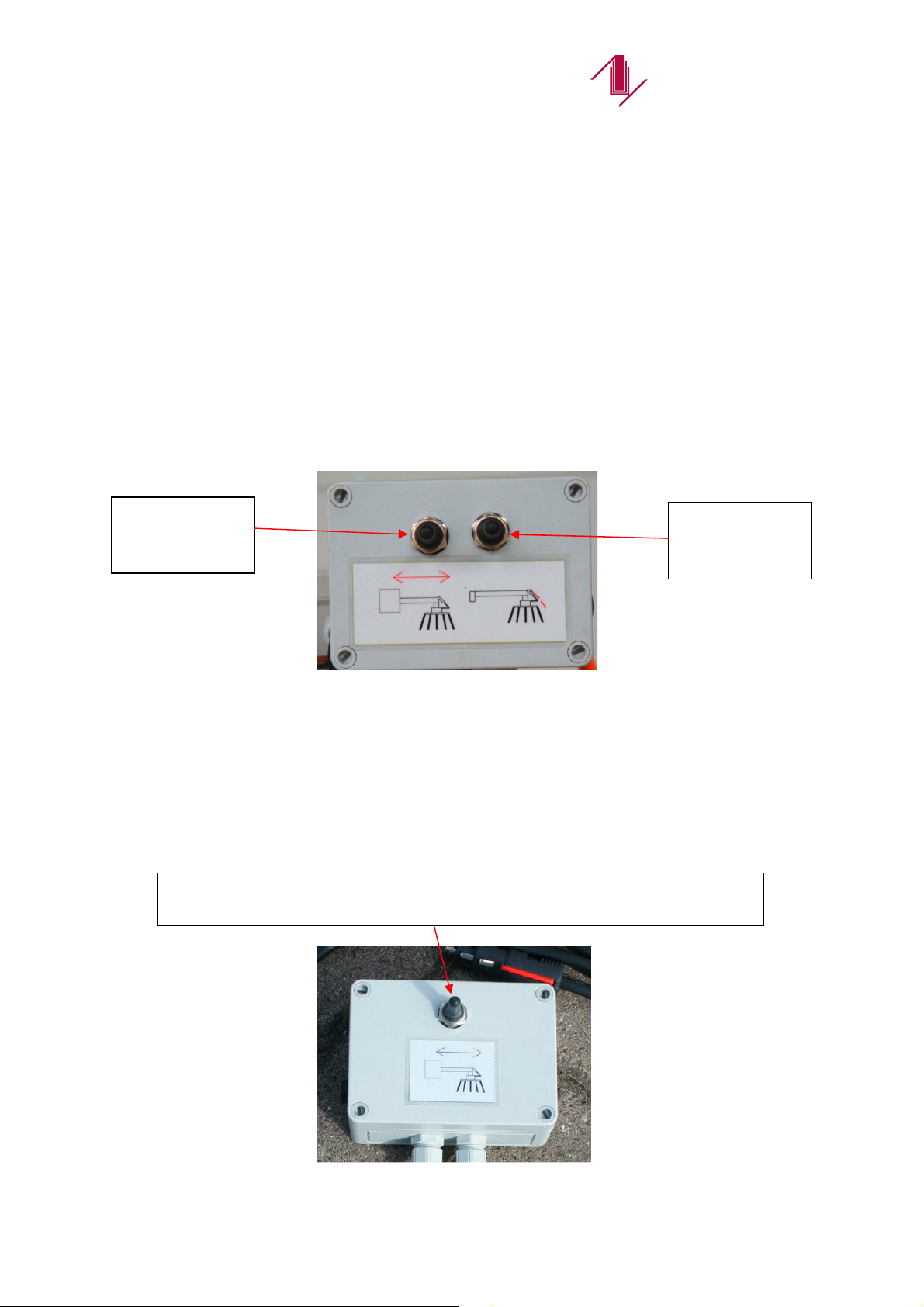

The control desk is equipped with 2 cable connection.

Plug –X01 is designated for the connection on the on-board power supply from carrier vehicle.

Plug –X02 is connected to the connection box to the equipment.

The telescoping of the main frame with the brush by means of hydraulic cylinders.

The oil flow is required at KM20TO mind.: 25-30 l/min. (OMS-125)

KM20TSO mind.: 35l/min. (OMS-200)

The brush head tilt is done by manual adjustment of the threaded top link

see page 9 - Picture 6

DANGER

Before starting work with the front-mounted

machine attention hast o be paid that no

persons are within the imminent work area.

IMPORTANT

The clearance of all moving parts hast o be

ensured

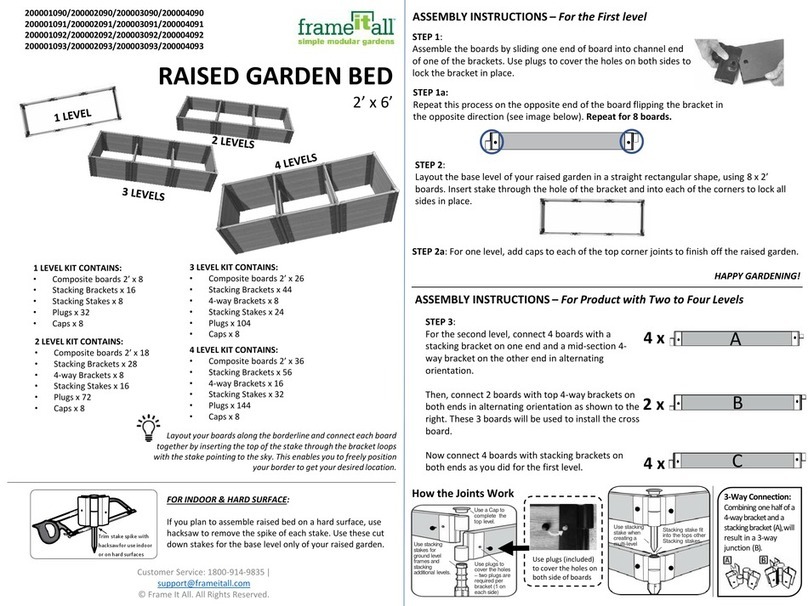

Connection box on the

unit for plug X02

Picture 2

Picture

3

Plug –X01 connection to 12V

power socket

- 8 -

MICHAELIS

masc hinenbau

7. Operation

During operation the machine has to be driven solely in floating position for better adaption to

ground unevenness and in order to avoid damage to the machine itself and to prevent high

brush wear. An additional contact pressure has to be absolutely avoided.

The depth wheel has to been adapted according to the brush position.

The adaption of the machine has to take place through the implement triangle or the three-

point hitch. The hydraulic hoses have to be firmly mounted. The clearance of all movable

parts has to be ensured.

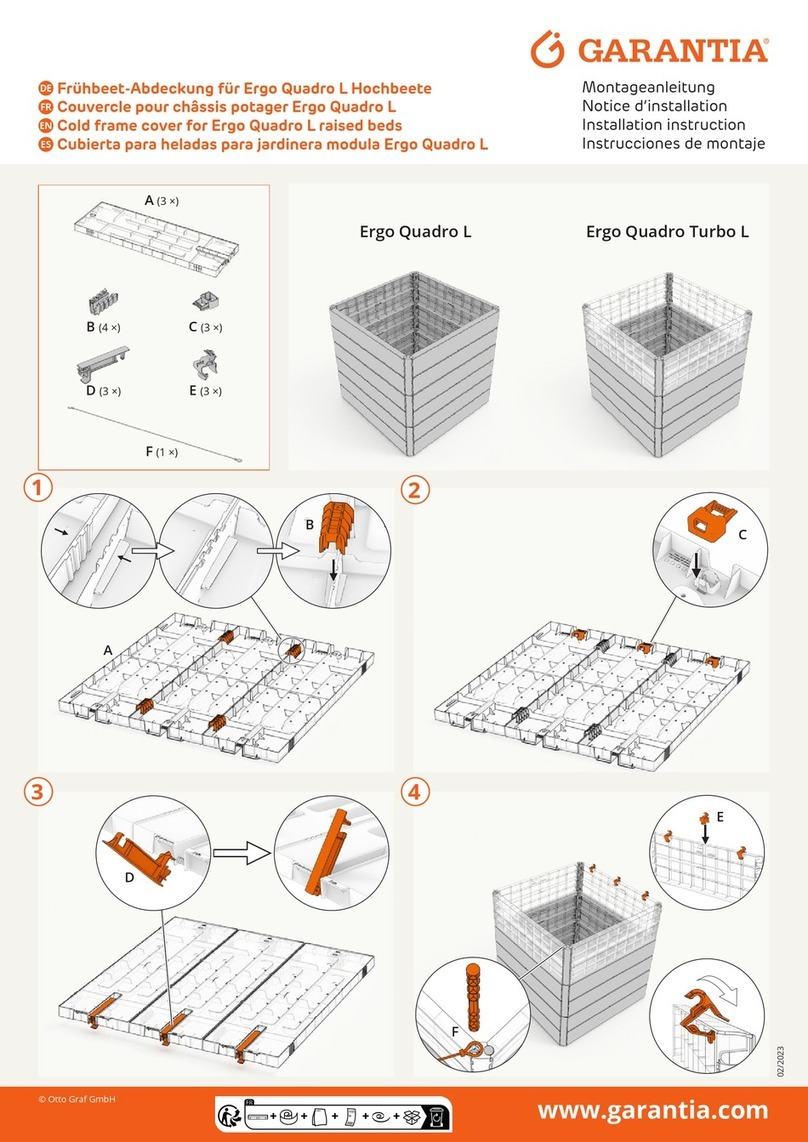

7.1 KM 20 T / TS - Function mini-control panel with hydraulic cylinder

The control desk has 2 functions. On the one hand the telescoping of the main frame

with brush (2S1, left-right) and the other hands tilting the brush head (2S2: up-down).

All functions are applicable during the brush is working.

7.2 KM 20 TO / TSO - Function mini-control panel with top link

With the control panel you have the option by tilting back of the toggle switch

the function of the brush to choose operating or side adjustment.

Both functions are activated with the control valve of the carrier vehicle.

.

-2S1:

telescoping

-2S2:

tilting the

Brush head

Picture 4

Mini control panel with hydraulic cylinder

toggle switch left setting: retract /

extend side adjustment

toggle switch setting right: Brush operation

Picture 5

Mini control panel with top link

- 9 -

MICHAELIS

masc hinenbau

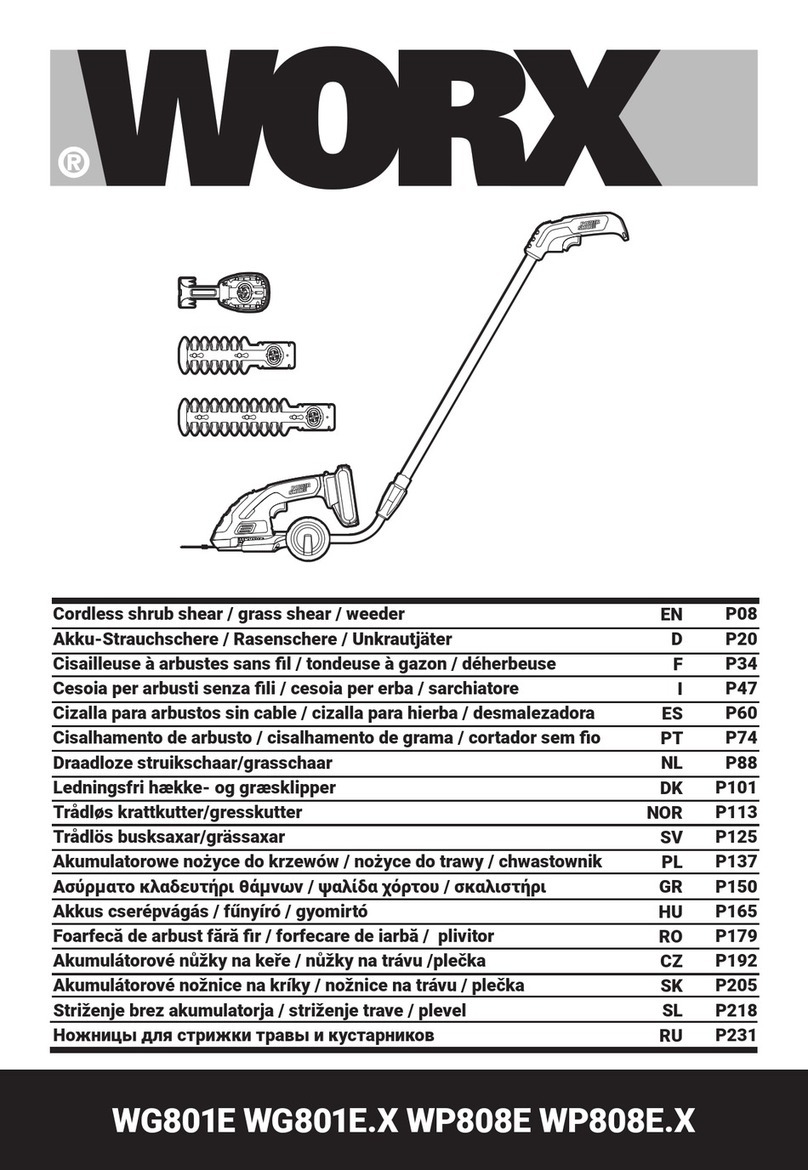

8. Work deployment

Depending on the intensity of dirt on the surface to be cleaned and its material the

performance and the necessary approach differ very much and it can only be learnt by

practice and experience.

To get an optimal cleaning result while treating slick or smoothed surfaces or for removing

heavy earth and snow the brush disc should be inclined accordingly.

For weed cleaning an inclined position has always to be selected.

This is the only way for intensive cleaning.

Setup: very steep - for cobblestone

Slightly flatter - rectangular or interlocking stone

Adjustment brush head tilt

mechanically

Picture 6

With top link

The tilt angle of the brush

is manually on preassembled

Top link set to.

Picture 7

with hydraulic cylinder

The tilt angle of the brush

is the hydraulic cylinder

set to.

Adjustment brush head tilt

hydraulic

- 10 -

MICHAELIS

masc hinenbau

8.1 Tip to the period of implementation

The mechanical weed removal should be executed primarily before a new growing season,

hence on frost-free grounds between October and March. Also wet ground conditions are

well suited for getting optimal work results. If using the machine in dry periods or on a

particular hot day the area should be watered.

9. Brush types

HINWEIS The manufacturer offers different types of

brushes.

The appliance is equipped with the universal flat steel brush KM20

NOTE Consider the weather conditions before starting

up see Section 8.1

Flat steel

brush KM 20

-

5:

For weed and moss

Especially intensive cleaning of joints

Only to be used on small tractors

SWS

-

Brush Quick

-

change system KM 20

-

8:

For surface cleaning with a high proportion of material

Not for cleaning joints

Picture

8

Pictu

re

9

- 11 -

MICHAELIS

masc hinenbau

10. Brush change

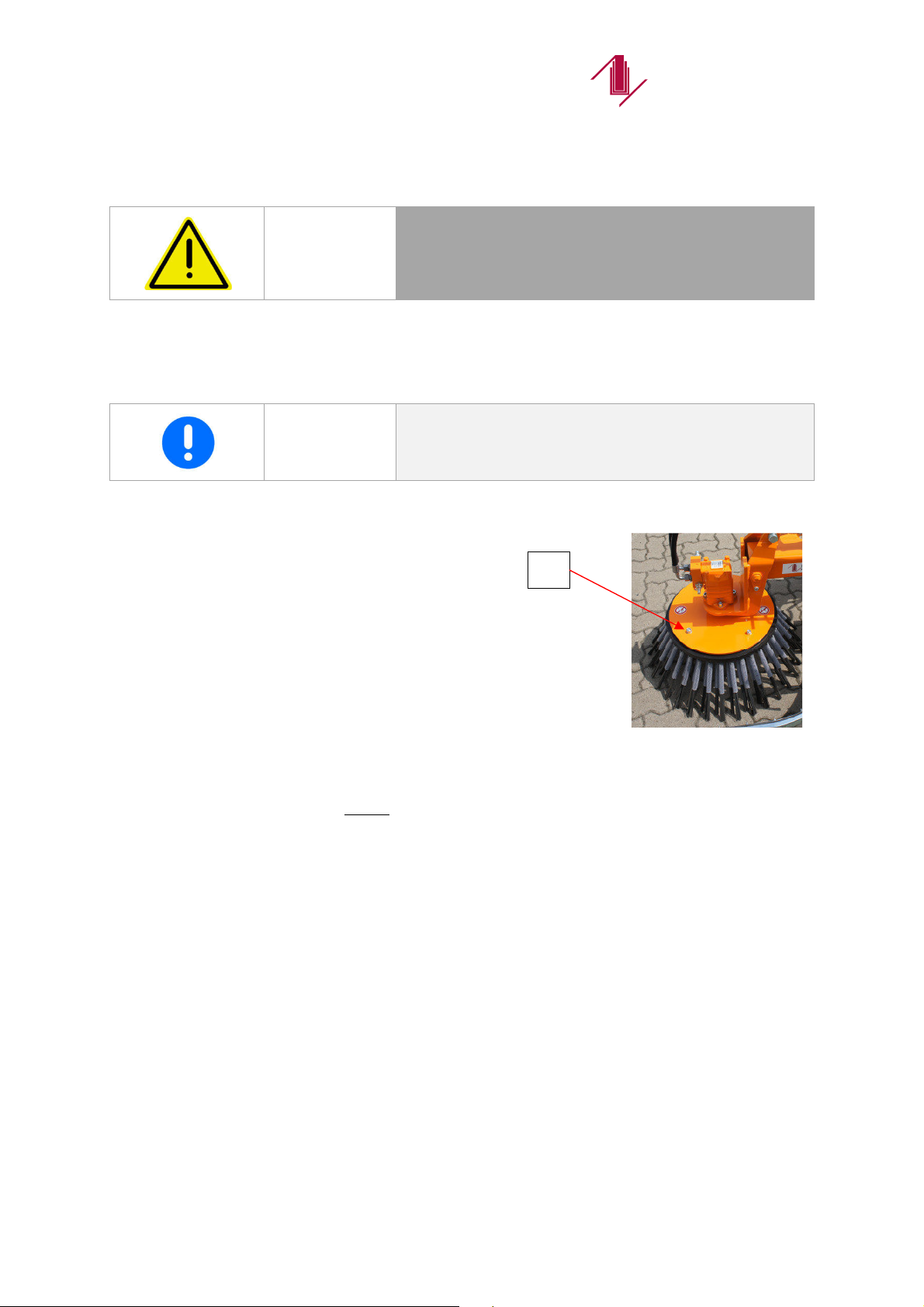

DANGER

Be sure to turn all aggregates before starting

work on the brush and solve power plug from

the unit.

After changing a brush for tight fit of the screws must be checked and these may need to be

tightened after one working hour.

IMPORTANT

Check all fittings and locks are secure.

10.1 brush change – Flat steel brush

The different brushes at the brush plate

Attached and can be solved simply by

the 4 screws and remove the brush insert

changing.

In the flat steel brush (KM20-5) are for fixing rubber bushings

mounted at the top.

These need to be cut from the inside along at 3-5 cm after a brush wear of about 5 cm to the

worn area with a knife (ideally utility knife), so that they retain their elasticity.

4x

Picture 10

- 12 -

MICHAELIS

masc hinenbau

10.2 Brush change

Quick-change system – KM20-8 (available on request)

With the enclosed wrench it is easy to replace the single tufts of the twist knot brush KM20-8.

Put the wrench with the open-end under the sprung hexagon bolt (1) and lever towards the

middle of the brush. Thereby you loosen the locking and remove the tuft. Put the

replacement tuft in the square opening all the way to the stop and let the bolt lock in the

provided hole (2) by releasing the wrench.

Check the correct seat and fixture of the tufts after the replacement.

IMPORTANT

Make no joints cleaning with the Quick-change

system

Flatsteel brush only to be used on small tractors

1

2

Picture 11

Picture

13

Picture

12

- 13 -

MICHAELIS

masc hinenbau

11. Impact protection element

It has a lot of adjustment options and has to be set according to the different demands.

Depending on application possible additional protective measures have to be taken:

Barrier posts with plastic covering

Should be secured by covering it with a protection tube.

Base course

Should possibly be protected by putting a steel or wooden plate in front of it.

Traffic island

Should be additionally secured by a transportable large cover where necessary.

12. Maintenance

KM20T/TS und KM20TO/TSO

The 2 grease nipples on the wheel all

10 operating hours Lubricate.

Check bolts for tightness.

13. Support wheel

On different carrier vehicles the depth wheel has to be used in floating position as well in

order to ensure an exact guidance of the broom.

WARNING

When working with no or not properly adjusted

impact protection damage to property or

personal injury can arise!

CAUTION Mind a safety distance.

grease nipples

Picture

14

- 14 -

MICHAELIS

masc hinenbau

14. Safety notes

Before using the machine for the first time the operator has to make himself intensive familiar

with the machine and has to read the operation manual carefully.

The respective guidelines of the responsible employers’ liability insurance association have

to be observed.

The respective specifications for installation of the carrier vehicles such as payloads, number

of revolutions and clearance have to be strictly observed.

Also the attachment guidelines of the road traffic act for lateral protrusion and distance

steering wheel centre to front edge of the attachment have be strictly observed.

The machine may only be use for its intended purpose on open spaces without obstacles for

cleaning work, not in enclosed rooms, on steps and terraces or for other purposes.

The machine may only used with all protective equipment, whose functions and intactness

has to be continuously ensured, properly putted up.

The areas to be cleaned have to be relieved of foreign objects such as stones, because

these can be ejected, before starting work.

The operator is liable to third parties. Other persons have to be send out of the working area.

IMPORTANT

Every user must have undergone a detailed

instruction about operating the machine.

Edition 03/2016

Spare Part List

Michaelis

Weed Control Maschine

KM 20 T/TS – TO/TSO

Fabr.-Nr.: ……….-……….

MICHAELIS

masc hinenbau

Huxfelder Straße 8 Telefon (0049) 4208 8294-0

D-28879 Grasberg Telefax (0049) 4208 506

www.michaelis-maschinenbau.de info@michaelis-maschinenbau.de

KM 20 T / TS

with hydraulic cylinder

KM 20 TO / TSO

with top link

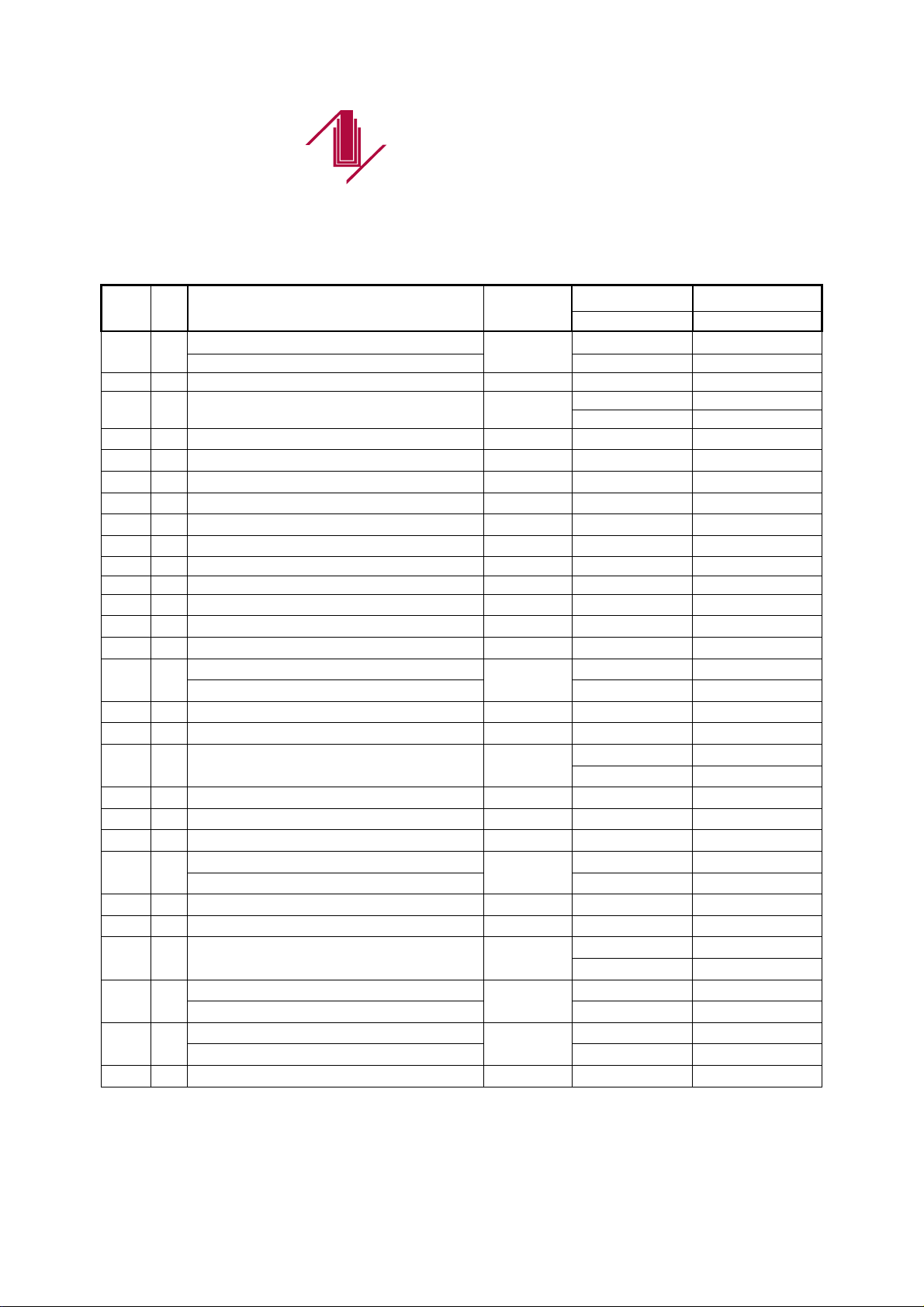

KM 20 T / TS

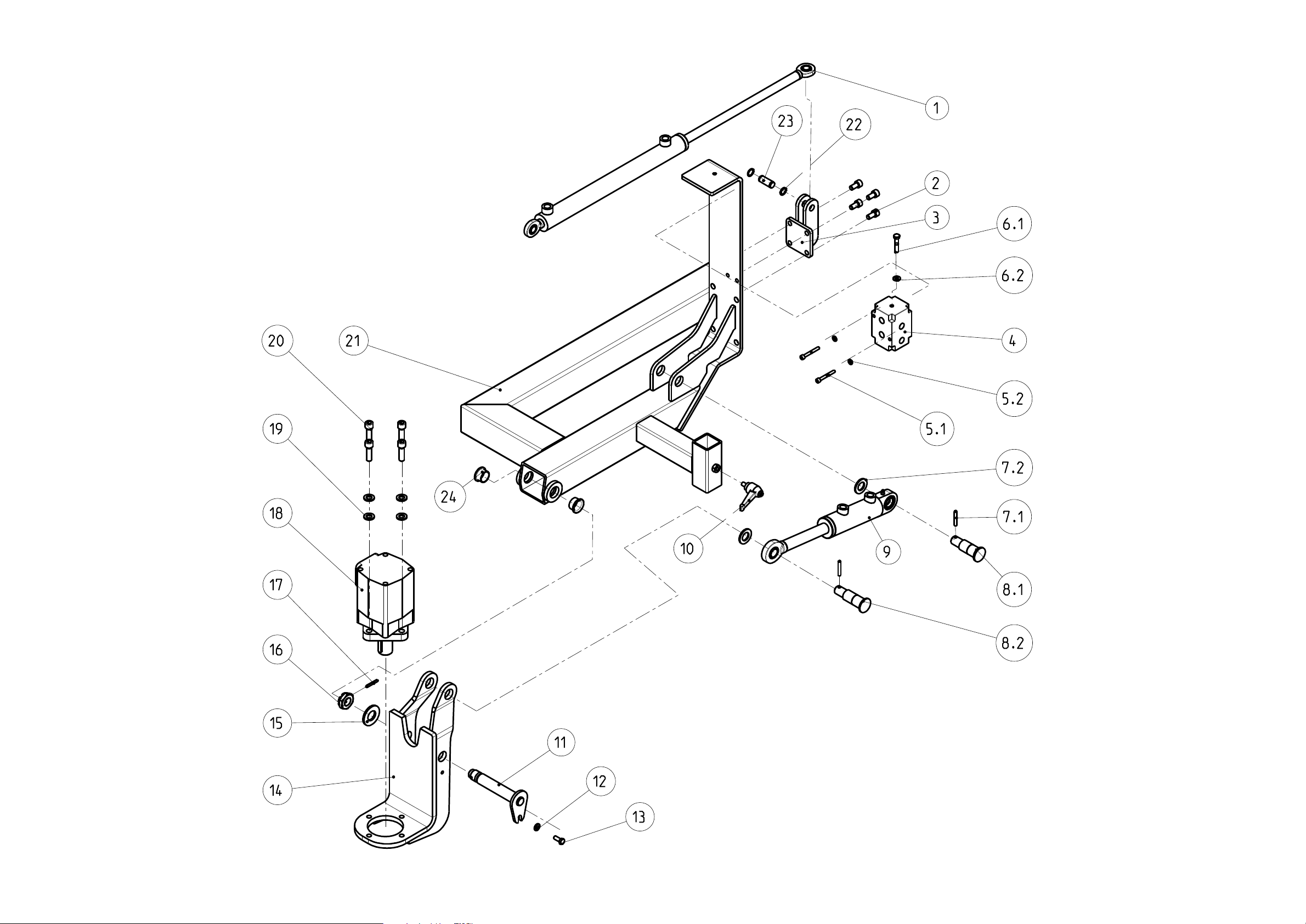

Assembly 1 Main frame with hydraulic cylinder

Pos.

St.

Description DIN

KM 20 T KM 20 TS

Order

-

Nr.

Order

-

Nr.

1 1 Extension cylinder 32x20x350 - SH-3220350 -

Extension cylinder 40x25x500 - SH-4025500

2 4 Socket head screw M10x20 DIN 912 S 006-067 S 006-067

3 1 Adaptor extension cylinder - 20T0500 -

- KM20TS_5_00

4 1 HPH Block 11106-MICH 010-00

11106-MICH 010-00 11106-MICH 010-00

5.1 2 Socket head screw M10x80 DIN 912 S 006-288 S 006-288

5.2 2 Schnorr Disc A10 DIN 6796 S 006-286 S 006-286

6.1 1 Hexagon bolt M8x140 DIN 931 00538140 00538140

6.2 1 Washer A8 DIN 125 S 006-106 S 006-106

7.1 2 Slotted straight pin 6x40 DIN 1481 S 006-456 S 006-456

7.2 2 Washer ø20 DIN 125 S 006-065 S 006-065

8.1 1 Step bolt short

KM20T_06_05_00 KM20T_06_05_00

8.2 1 Step bolt long

KM20T_06_03_00

KM20T_06_03_00

9 1 Hydraulic cylinder 35x25x50 STS4025500 STS4025500

10 1 Adjustable clamping lever - 40-5560 40-5560

11 1 Pin NL 120 ø25 - BOL_25123 -

Pin NL 143 ø25 -

BOLGEW_25143

12 1 Washer A8 DIN 125 S 006-106 S 006-106

13 1 Hexagon bolt M8x20 DIN 933 S 006-103 S 006-103

14 1 Motor bracket - 20T0301 -

- KM20TS_3_01

15 1 Washer A24 DIN 125 S 006-066 S 006-066

16 1 Castle nut M24 DIN 937 S 006-126 S 006-126

17 1 Slotted straight pin 5x36 DIN 1481 S 006-306 S 006-306

18 1 Hydraulicmotor

Sauer Danfoss OMS 125 *

- 151 F0 502 -

Hydraulicmotor

Sauer Danfoss OMS 200 *

- 151 F0 504

19 4 Schnorr Disc A12 DIN 6796 S 006-110 S 006-110

20 4 Socket head screw M12x35 DIN 912 S 006-053 S 006-053

21 1 Main frame - 20T0200 -

- KM20TS_2_01

22 2 Locking ring 15x1 DIN 471 A15 -

Locking ring 20x1 - S 006-845

23 1 Pin ø15x38 - 20T21100 -

Pin ø20x38 - 20T21101

24 2 Glycodur Collar bush 28x25x16,5 - 1170000 1170000

* please tell when ordering spare parts from the information

assisted by the motor nameplate

** Size possibly derogation

MICHAELIS

maschinenbau

Assembly 1

Main frame

with Hydraulic cylinder

KM 20 TO / TSO

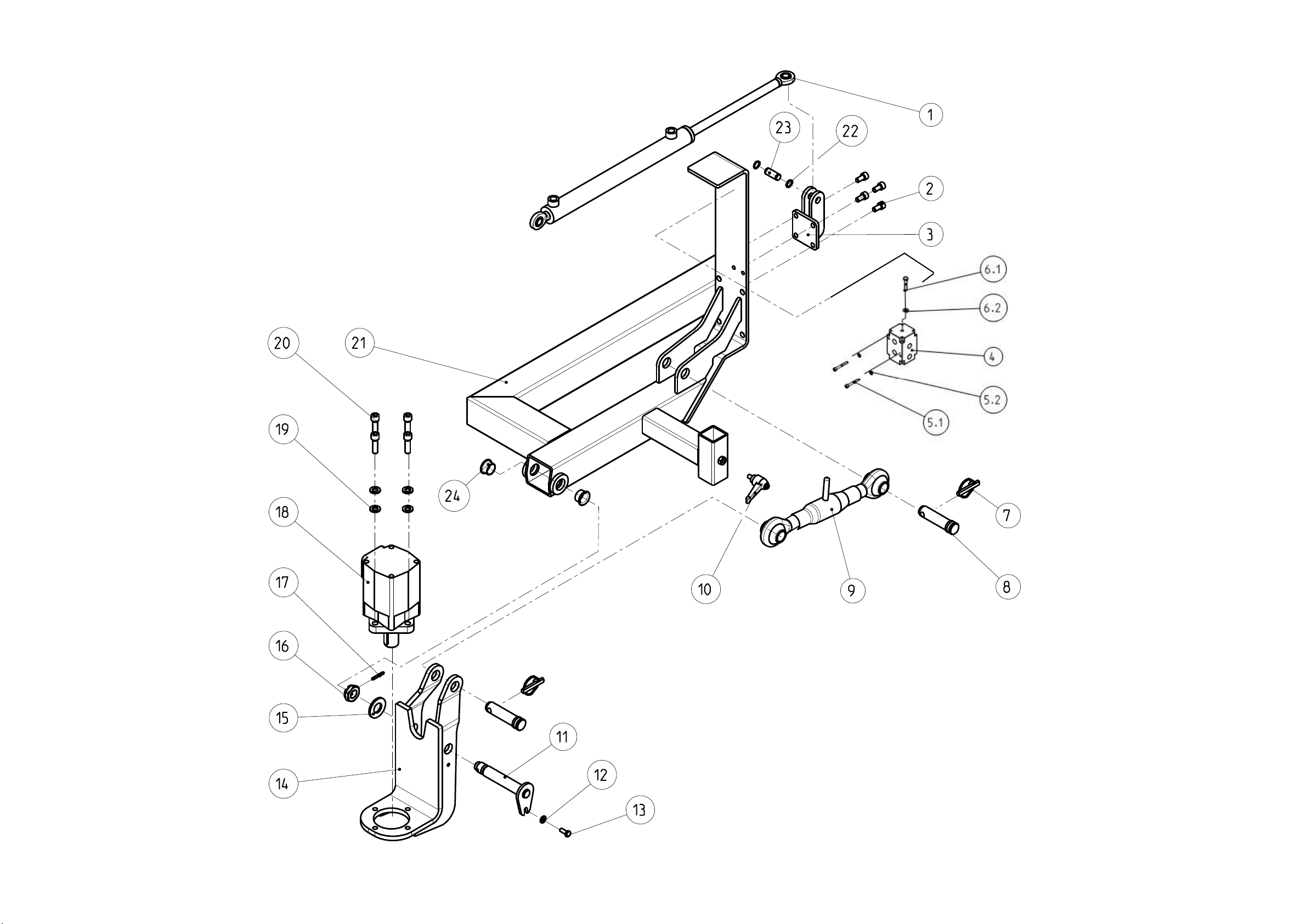

Assembly 1 Main frame with Top link

Pos.

St.

Description DIN

KM 20 TO

KM 20 TSO

Order

-

Nr.

Oder

-

Nr.

1 1 Extension cylinder 32x20x350 - SH-3220350 -

Extension cylinder 40x25x500 - SH-4025500

2 4 Socket head screw M10x20 DIN 912 S 006-067 S 006-067

3 1 Adaptor extension cylinder - 20T0500 -

- KM20TS_5_00

4 1 HPH Block 11106-MICH 011-00 -

11106-MICH 011-00 11106-MICH 011-00

5.1 2 Socket head screw M10x80 DIN 912 S 006-288 S 006-288

5.2 2 Schnorr Disc A10 DIN 6796

S 006-286 S 006-286

6.1 1 Hexagon bolt M8x140 DIN 931 00538140 00538140

6.2 1 Washer A8 DIN 125 S 006-106 S 006-106

7 2 Safety lynch pin 10,5 - 04729105 04729105

8 2 Top link pin cat.2 - OLEB2040 OLEB2040

9 1 Top link (manuell kippen) G-G01 G-G01

10 1 Adjustable clamping lever - 40-5560 40-5560

11 1 Pin NL 120 ø25 - BOL_25123 -

Pin NL 143 ø25 -

BOL

GEW

_25143

12 1 Washer A8 DIN 125 S 006-106 S 006-106

13 1 Hexagon bolt M8x20 DIN 933 S 006-103 S 006-103

14 1 Motor bracket - 20T0301 -

- KM20TS_3_01

15 1 Washer A24 DIN 125 S 006-066 S 006-066

16 1 Castle nut M24 DIN 937 S 006-126 S 006-126

17 1 Slotted straight pin 5x36 DIN 1481

S 006-306 S 006-306

18 1 Hydraulicmotor

Sauer Danfoss OMS 125 *

- 151 F0 502 -

Hydraulicmotor

Sauer Danfoss OMS 200 *

- 151 F0 504

19 4 Schnorr Disc A12 DIN 6796

S 006-110 S 006-110

20 4 Socket head screw M12x35 DIN 912 S 006-053 S 006-053

21 1 Main frame - 20T0200 -

- KM20TS_2_01

22 2 Locking ring 15x1 DIN 471 A15 -

Locking ring 20x1,2 - S 006-845

23 1 Pin ø15x38 - 20T21100 -

Pin ø20x38 - 20T21101

24 2 Glycodur Collar bush 28x25x16,5 - 1170000 1170000

* please tell when ordering spare parts from the information

assisted by the motor nameplate

** Size possibly derogation

MICHAELIS

maschinenbau

Assembly 1

Main frame

with Top link

This manual suits for next models

3

Table of contents

Other Michaelis Maschinenbau Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Husqvarna

Husqvarna 42" Collection System Operator and parts manual

AL-KO

AL-KO K-390 manual

Hanover

Hanover HANSQGB-1GRY Instructions for assembly

Gutta

Gutta BS Plus 160 Assembly instructions

Land Pride

Land Pride Food Plot Seeder FPS Specifications

Pontec

Pontec PondoSolar Air 150 Plus operating instructions