Michel's Siderolling Tarp User manual

Siderolling Tarp

Systems Under 9’ 6” Wide

CRANK STYLE

INSTALLATION INSTRUCTIONS

MICHEL’S INDUSTRIES, LTD.

P.O. BOX 119

ST. GREGOR, SK. S0K 3X0

PH:306.366.2184 FX:306.366.2145

EM: sales@michels.ca WWW.michels.ca

Load Loc

Select

Maximizer

Grain Carts

Grain Bagger

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 1

This page intentionally left blank

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 2

PLEASE READ ENTIRE INSTRUCTIONS BEFORE BEGINNING

Note: THESE INSTRUCTIONS ARE FOR A STANDARD ROLLING TARP THAT LOCKS

CLOSED ON THE DRIVER'S SIDE.

IF ELECTRIC DRIVE, DO THE FOLLOWING FIRST AND THEN PROCEED TO THE ELECTRIC

INSTALLATION INTRUCTIONS

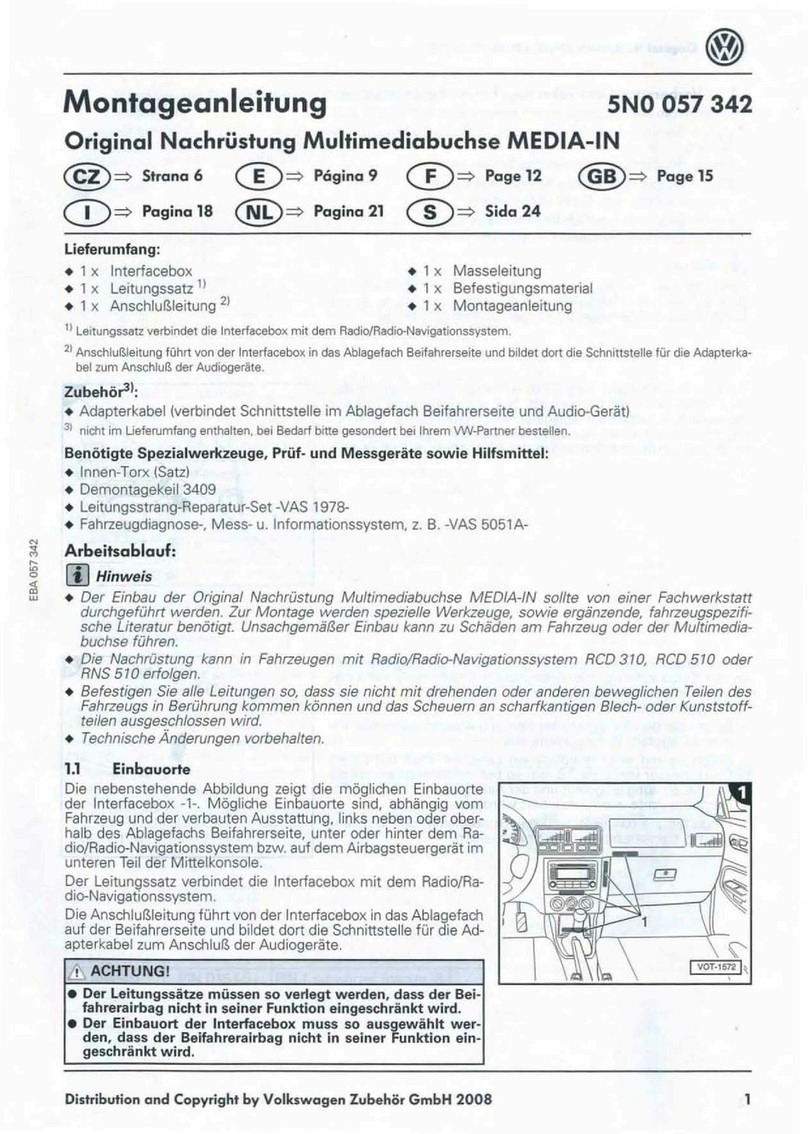

Step 1: Front Hood Installation

(See Figure 1)

Procedure: Center the front hood which has a wind deflector on the front wall of the trailer with the lower 1 inch flange

(A) positioned flush against the outside front edge of the trailer. If the hood is notched on the front corners then the hood

is to be positioned flush against the inside front edge of the trailer. Using a 3/16" drill bit, drill 14 holes through the 1inch

flange and into the box wall (B) placing 2 holes at approximately every 15 inches (see Figure 1). Secure the front hood to

the trailer using the 1/4"x1" lag screws (C) provided. Drill through the top portion on each side of the front hood and

secure using 1/4"x1" lag screws (C).

Step 2: Rear Hood Installation

Option 1 of 2: Semi Rear Hoods

(See Figure 1)

Procedure: Center the rear hood on the rear ledge of the trailer with the lower 1inch flange positioned flush against the

outside rear edge of the trailer. If the rear hood is notched on the corners then it is to be positioned against the inside rear

edge of the trailer.

Note: Continue from Step 1 to complete the rear hood installation.

Figure 1

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 3

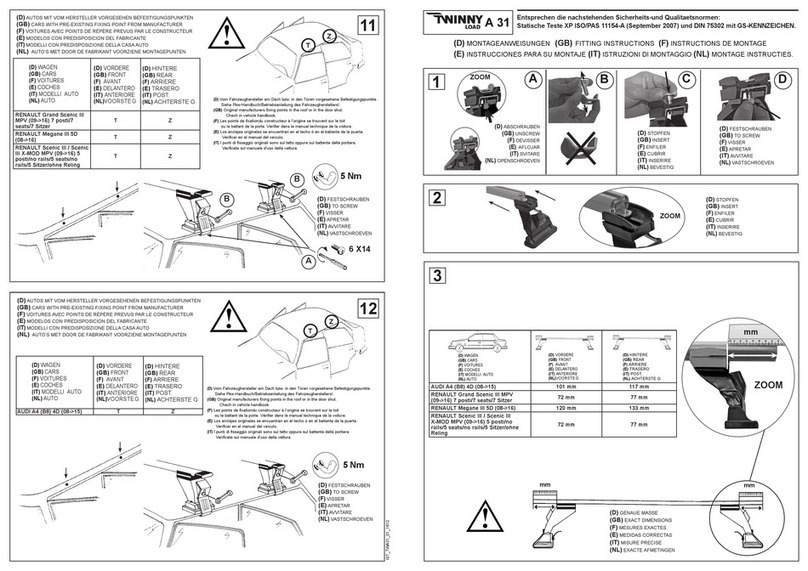

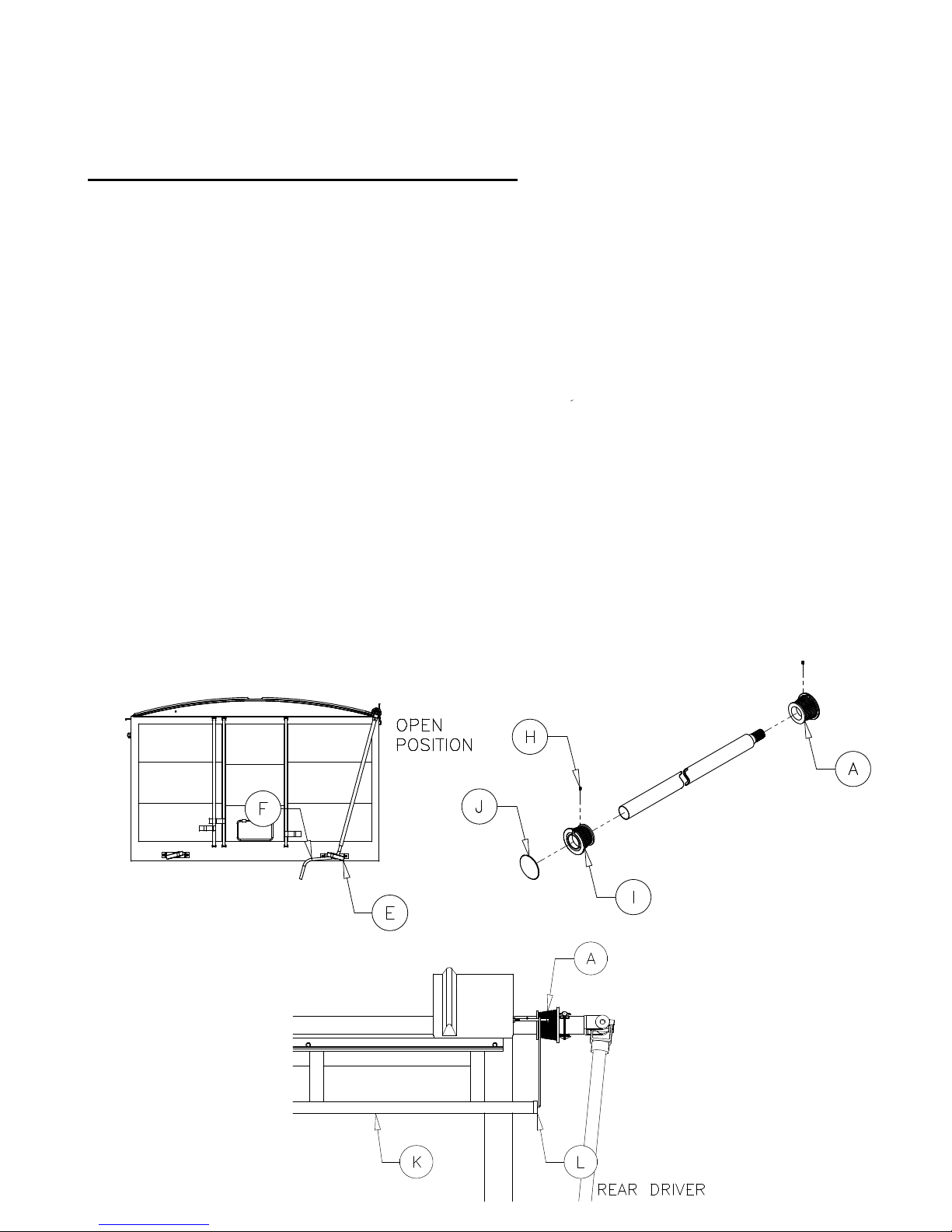

Option 2 of 2: Farm Rear Box Hoods

(See Figure

2)

Procedure: Temporarily place the rear hood on the rear ledge

of

the box with its flange (D) inside the box. Place two

bent

angles (E) into the tubular supports (F), which are welded to

the

underside of the rear hood. Slide the hoop

holder bracket (G)

v

e

r

ticall

y

until it is positioned just below the bend in the bent angle (E).

M

a

rk

hoop holder holes on

the inside box wall and secure the hoop

ho

lde

r

to the box wall using the 1/4"x1" lag screws provided. Apply

f

i

r

m

downward force on the ends of the rear hood and clamp the

hood

down on both sides. Drill a 1/4" hole through the

bo

tt

o

m

area of the bent angle (E). Be sure to drill the hole as close to

t

h

e

bottom of the hoop holder as possible to

prevent the rear hood

fro

m

moving. Insert the hitch pin (H). Weld the bent angle to the tube

(F)

on steel hoods

on

l

y.

For aluminum hoods d

rill a 1/4" hole through the tube

(F)

and the bent angle (E). Secure using the roll pin (I)

prov

ide

d.

Step 3: Optional Ratchet & Strap Installation

(See Figure 3)

Procedure: Insert the bar-hooks through the washer welded to the front (D) and rear (E) hoods. Slide the vinyl ratchet

covers onto the strap before hooking up the ratchet, the location of the ratchet (F) is not critical. Adjust the straps so they

are reasonably tight, once tight slide the ratchet covers over the ratchet assemblies. With ratchet brackets being optional,

they may have to be bolted in with 5/16 truss head bolts, to accommodate ratchet straps in standard hoods.

Note: Do not overtighten the straps or the front and rear hood will deform.

Figure 3

Figure 2

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 4

Step 4: Optional Hoop Installation

Please proceed to the Option which best suits your application. If order does not include hoops please proceed

to step 5.

Hoop Holder Spacer Installation

(See Figure 4)

Optional: Use the Hoop Holder Spacers if the top sill on the unit is less than 2 inches deep and does not have the adequate

room to mount the hoops properly, as described in the below steps. These are sent standard for grain carts, spreaders,

gravity wagons and grain baggers to be used on either hoops or tarp stops.

Procedure: Mount the hoop holder spacers (H) where the hoops are to be mounted, attach with two 1/4" x 1" self-

tapping lags. The remaining hoop holder spacers are to be centered according to the length of the unit, and the number of

hoops supplied.

Option 1 of 2: Steel Hoops (used on farm boxes and some semi-trailers)

(See Figure 5, 6)

Procedure: Hoops (J) are provided according to the length of the trailer. Equally space the hoop holders (G) along the

length of the trailer and locate the top edge of the hoop holder 1 inch down from the top edge of the inside trailer wall.

Once in place mark the position of the hoop holder and drill two 3/16" holes into the trailer wall. Secure the hoop holder

using the 1/4"x1" lag screws provided. Follow this procedure to the remaining hoop holders making sure that they are at

the same level, equally spaced, and directly across from each other. Insert bent angle (K) with one end fitted into the

hoop holder (G) and the other end in the hoop (J), then repeat for the opposite side of the trailer. Measure the vertical

distance from the inside of the trailer floor to the top center of the front or rear hood. Record the measured distance.

Center the hoop on the bent angles (K) and measure the vertical distance from the inside trailer floor to the top center of

the hoop. The measurement to the top of the hoop should be 3/4 inch greater than the distance from the trailer floor to

the top of either hood. If the distance is less than or greater than the required 3/4 inch, adjust the hoop and bent angles

accordingly. Weld the hoop to the bent angles making sure that the hoop is parallel with the bent angles (see Figure 5).

Figure 5

Figure 6

Figure 4

H

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 5

Option 2 of 2:Aluminum Hoops with Dimple (Typically used with fiberglass center rod in tarp)

(Figure 7, 8)

Procedure: Hoops (J) are provided according to the length of the trailer. Equally space the hoop holders (G) along the

length of the trailer and locate the top edge of the hoop holder 1inch down from the top edge of the inside trailer wall.

Once in place mark the position of the hoop holder and drill two 3/16" holes into the trailer wall. Secure the hoop holder

using the 1/4"x1" lag screws provided. Follow this procedure to the remaining hoop holders making sure that they are at

the same level, equally spaced, and directly across from each other. Insert bent angle (K) with one end fitted into the

hoop holder (G) and the other end in the hoop (J), then repeat for the opposite side of the trailer. Measure the vertical

distance from the inside of the trailer floor to the top center of the front or rear hood. Record the measured distance.

Center the hoop on the bent angles (K) and measure the vertical distance from the inside trailer floor to the top center of

the hoop. The measurement to the top of the hoop should be 3/4 inch greater than the distance from the trailer floor to

the top of either hood. If the distance is less than or greater than the required 3/4 inch, adjust the hoop and bent angles

accordingly. Drill and bolt the hoop to the bent angles using 1/4x1-3/4 inch bolts provided making sure that the hoop is

parallel with the bent angles (see Figure 8).

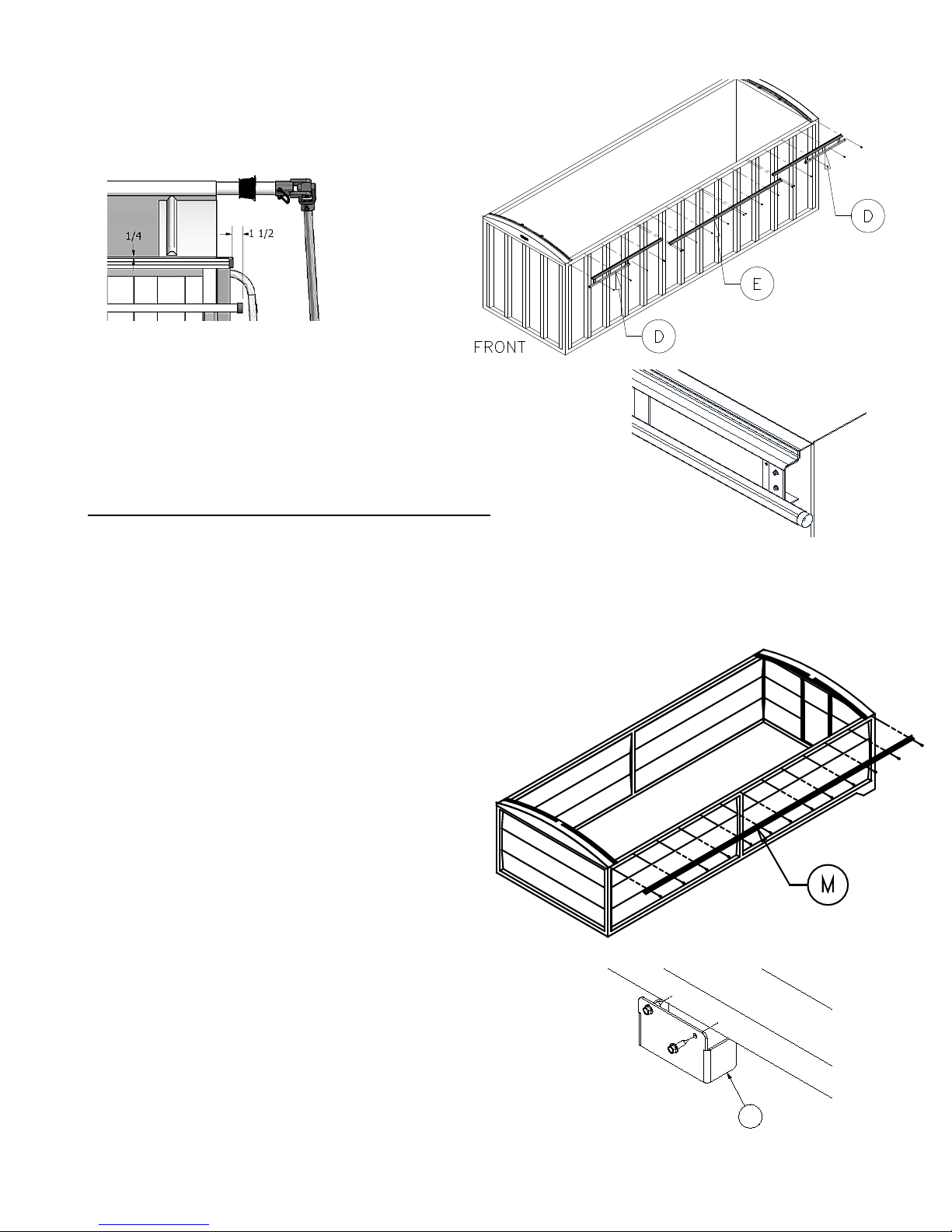

Step 5: Tension Control Unit & Filler Plate Installation

Please proceed to the Option which best suits your application.

Option 1 of 2: Select or Maximizer (Springs and Cables on front and back for tension)

(See Figure 9)

Note: Standard Rolling Tarps have the Holdback System mounted on the driver side. Reverse rolling tarps have the

Holdback System mounted on the passenger side.

Procedure: To mount the front and rear holdbacks (D), clamp the top flange 1/4 inch lower than the upper edge of the

trailer. Be sure that the 1-1/4 inch square tubing is facing down. Make sure that the PVC cable guide is approximately

1-1/2 inches ahead of the front/rear of the trailer. Predrill a 3/16" hole through the 1 inch flange and into the lip of the

trailer, 1/2” down from the top of the locking flange along the extruded line, spacing each hole at approximately every 15

inches. Secure the holdbacks to the box with the 1/4"x1" lag screws provided. After both holdbacks are secured mount the

filler plate (E).

DRILL & BOLT HERE

Figure 8

K

J

H

G

I

Figure 7

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 6

Note: In most cases the filler plate will have to be cut

shorter depending on the length of the trailer. Do not

leave a space between the holdbacks and the filler plate.

Note: When installing holdbacks on a unit with a side wall

as shown in Figure 9A mount a spacer behind the flat to prevent

the holdback from bending and deforming.

Option 2 of 2: Load-Loc (Rope on front for tension)

(See Figure 9B)

Note: Standard Rolling Tarps have the Latch Plate mounted on the driver side.

Reverse rolling tarps have the Latch Plate mounted on the passenger side.

Procedure: To mount the latch plate (M), clamp the top flange 1/4" lower than the upper edge of the box, making sure

that the latch plate is all the way to the front and parallel to the box lip. Predrill a 3/16" hole through the 1 inch flange and

into the lip of the box, spacing each hole at approximately

every 15 inches. Secure the latch plate to the box with the

1/4"x1" lag screws provided.

Note: In most cases the latch plate will have to be cut shorter

depending on the length of the box.

Step 6: Tarp Stop Spacer

Installation

(See Figure 10)

Optional: Use the Tarp Stop Spacers if the top sill on the unit is

less than 2 inches deep and does not have the adequate room to

mount the tarp stops properly, as described in the below steps. These are

sent standard for grain carts, spreaders, gravity wagons and grain baggers

to be used on either hoops or tarp stops.

Procedure: Mount the tarp stop spacers (H) where the tarp stops are

to be mounted, (See Step 7) attach with two 1/4" x 1" self-tapping lags.

The remaining tarp stop spacers are to be centered according to the

length of the unit, and the number of tarp stops supplied.

Figure 9

Figure 9B

Figure 10

H

Figure 9A

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 7

Step 7: Tarp Stop Installation

Please proceed to the Option which best suits your application.

Option 1 of 2: Round Tarp Stop

(See Figure 11)

Procedure: Raise the roll-tube and place it on the top passenger side of the bows and end caps making sure that the roll

tube spline is at the rear of the trailer. Reverse rolls would be placed on the driver side. Roll out the tarp to the driver side

(passenger side for reverse roll). Position the tarp so that the material sits 2 inches in from the face of the front end cap.

Smoothen the tarp out and apply as much tension to it as possible by pulling down on the loose end of the tarp. The

pocket holding the quick release pipe (H) should hang down the side of the trailer approximately 3-1/2 inches. The quick

release pipe (1-1/8” pipe in the tarps pocket) will be held against the side of the trailer by the round tarp stops (I) shown in

Figure 11. Make sure the tarp material is 2 inches in from the face of the front end cap. Mount the front round tarp stop 4

inches in from the front edge of the tarp material. Drill a 5/16" hole through the predrilled holes in the tarp stop and into

the trailer. Secure the stops using the 3/8"x1-1/4" self-threading bolts provided. Next mount the rear tarp stop 4 inches in

from the rear edge of the tarp material, ensure the tarp material is pulled tight from end to end. The remaining round tarp

stops are to be centered according to the length of the trailer. Make sure that the quick release pipe (H) is positioned

parallel with the trailer lip.

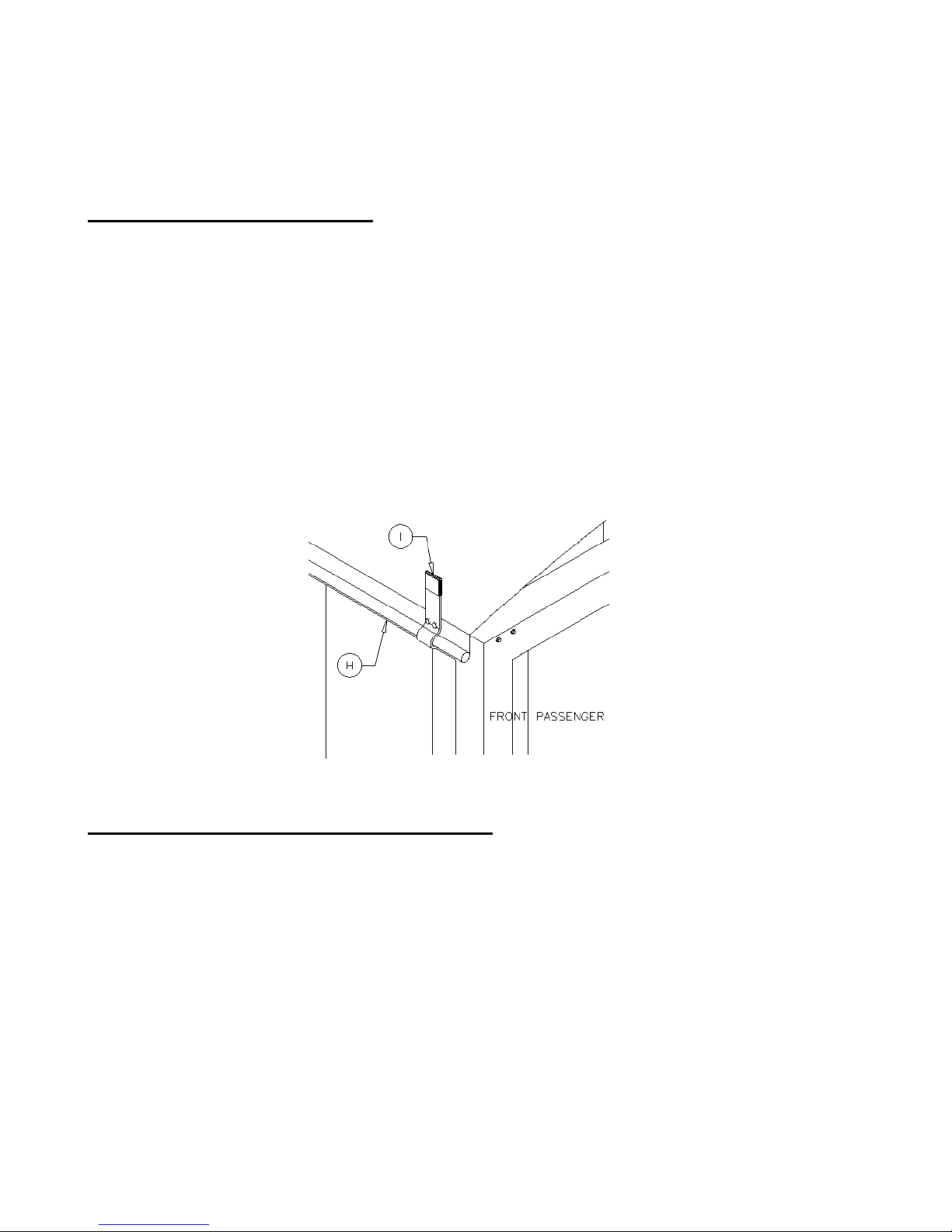

Option 2 of 2: Round Flip-Release Tarp Stop

(See Figure 12-14)

Procedure: Locate the front round bracket (J) 4 inches in from the face of the front end cap and 3/4" lower than the top

edge of the trailer. Using a 5/16" drill bit, drill two holes through the predrilled holes in the bracket and into the trailer.

Secure the bracket to the trailer using two 3/8"x1-1/4" self-threading bolts (K) provided. Remove the 1/4"x3" hex bolt (L)

from the flip-release tarp stop (M). Insert the bolt through the bracket (J) and through the tarp stop (M). Secure using the

1/4" lock nut. Torque the bolt appropriately so the flip-release tarp stop will remain in the unlocked position (see Figure

14). Remove the quick pin from the bottom hole of the flip-release tarp stop and adjust the tarp stop so it is in the

unlocked position (see Figure 14). Install the rear bracket 4 inches in from the face of the rear end cap and 3/4" lower than

the top edge of the trailer. Evenly space the remaining flip-release tarp stops along the same side of the trailer making

sure to mount the brackets 3/4" lower than the top edge of the trailer. Position the quick release pipe (N) in the round

brackets (J) (see Figure 12-13). Adjust the tarp so that it sits two inches in from wind deflector on the front end cap. Once

the tarp is in position engage the stops into the locked position (see Figure 14). Reinsert the quick pins through the

bottom holes in the round flip-release stops. (See next page for diagrams)

Figure 11

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 8

Step 8: Spring Lock Bracket Installation

(See Figure 15)

NOTE:If it’s a silage end gate the spring lock brackets get mounted on the

s

ide

of the box to allow the end gate to open

and

cl

os

e

.

If ordered as an electric without backup crank skip to step 10.

Drill a 5/16" hole through the predrilled holes in the spring lock bracket

a

nd

into the box. Secure the bracket with the

3/8"x1-1/4" self-threading

bo

lt

s

provided. Lock the tarp in the closed position, engaging the spring lock

(

E

).

Adjust the

angle of the spring lock so that the crank handles

s

eat

s

properly in the spring lock. Make sure that the spring lock

bracket does

no

t

interfere with the

taill

ig

h

ts.

Figure 12 Optional

Figure 13 Optional

Figure 14 Optional

Figure 15

OPTIONAL

SILAGE GATE INSTALLATION

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 9

Optional: Universal Crank Lock Bracket

Procedure: (See Figure 16-17)

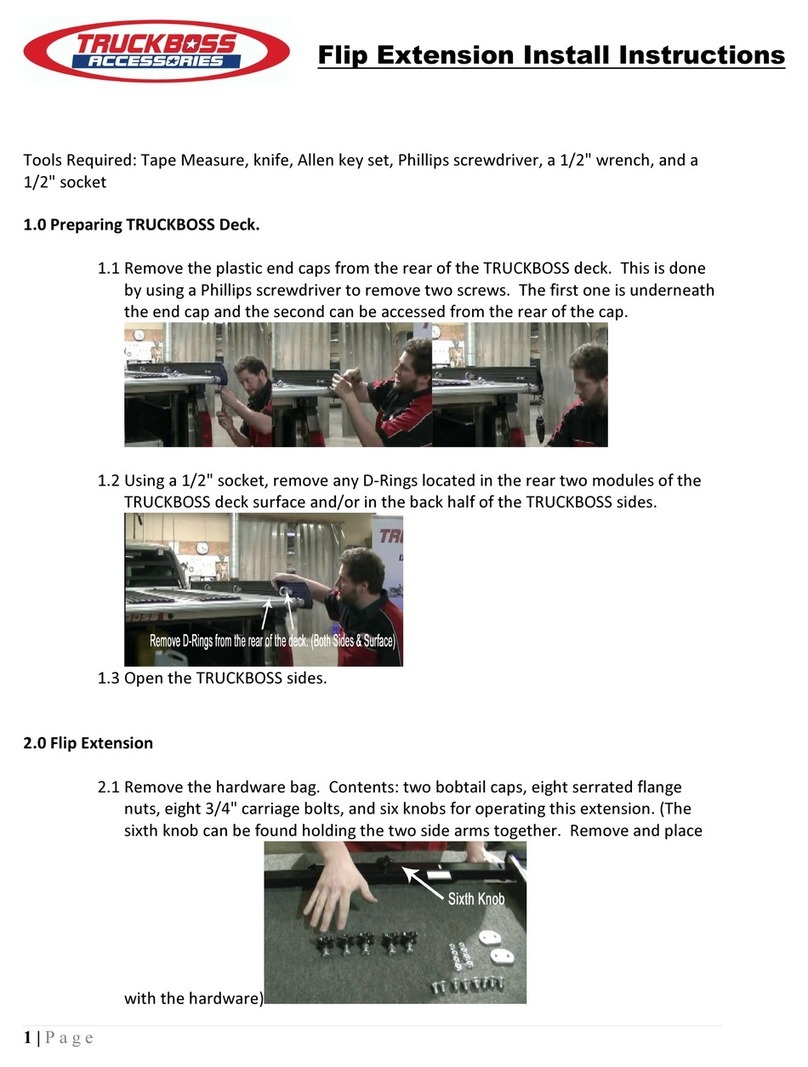

Assemble the spring lock bracket shown below. Bolt the vertical supports (A) to the middle supports (B), (If Crank Style)

Bolt steel retainers (C) and plastic spring retainers (D) with a 3/8"x1-1/2" hex bolts, flat washer and nylon nut. Bolt the

horizontal supports (E) to the mounting brackets (F) and the middle supports (B) with 3/8" bolts and nylon lock nuts. Do

not tighten bolts until it’s fully installed on the cart. Depending on your cart the mounting bracket will lag into the grain

tank wall or into support tubing’s. If it is mounting into support tubing’s determine the width and bolt together the middle

supports to achieve your desired width. If it is mounting into the wall then set it so it’s about 24" between the vertical

supports. Center the bracket on the back of the cart and mark your holes. Drill 5/16" holes at your marks and secure the

bracket to the cart with 3/8"x1-1/4" self-tapping bolts. With vertical supports secured rotate the horizontal supports up

and lag the mounting brackets to the cart with 3/8"x1-1/4" self-tapping bolts. You may need to shorten the horizontal

supports. Tighten all the bolts on the bracket with steel retainers on an angle shown here (If Crank Style).

On Electric Units the Pivot Arm will attach to this bracket as per instruction manual.

Step 9: Crank & Crank Lock

Installation

(See Figure

18)

Procedure: With the tarp roll hanging under the locking flange,

s

lide

the rear beveled pulley stamped FRONT REVERSE

(A) onto

the

roll-tube with the small flange sliding on first. Slide the

un

i

v

e

rs

al

joint (B) and shaft onto the spline (C) so

that the end of the

c

r

a

nk

is on the outside of the box by approximately 1ft (see Figure

15).

Insert quick pin (D) through

the universal joint. Pull the crank

t

ow

a

rds

the box where the spring lock bracket

(

E

)

is

m

oun

te

d.

Note: The crank handle

should have approximately 30 lbs. of

for

ce

applied to

it

.

If there is not enough force applied to the crank handle then

the

position of the universal joint must be altered.

Adjust the length of the crank handle

(F)

and drill a 1/4" hole through the crank shaft and handle.

F

a

s

te

n

the crank

handle to the shaft with the 1/4"x1-3/4" hex bolt and

1/

4"

nylon lock nut

prov

ide

d.

Figure 18

CLOSED

POSITION

A

F

D

C

EB

Figure 16

Figure 17

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 10

Step 10:

Tension

Control

Adjustment

Option 1 of 2: Beveled Cable Pulley Installation

(See Figures

19-21)

Note: When rolling the tarp to the open position, tension must

be

kept on the opposite end of the crank to keep the

tarp rolling

e

v

enl

y.

Procedure: Roll the tarp to the open position. Adjust the angle of the spring lock to properly seat

the

crank

handle

.

Installing cable onto rear beveled pulley:Slide the correct beveled pulley onto the roll tube if not done already from

crank installation, pull the cable from the

r

ea

r

holdback system (K) (see Figure 21) towards the rear beveled

pulle

y

stamped FRONT REVERSE on a standard roll locking closed on the driver’s side (A). Insert cable end into pulley slot

a

nd

rotate beveled pulley 1-3/4 turns for an 8-1/2ft box or 2-1/4 turns

for

an 8ft box. Rotate the pulley from the underside

of it on the large

diamete

r.

Properly position the beveled pulley on the roll-tube so that the

ny

l

on

cable guide (L) on the

holdback lines up with the small diameter

on

the

pulley (see Figure 21). Tighten the 1/4" set screws (H) to hold

the

pulley in

place

.

Installing cable onto front beveled pulley:Pull the cable from

t

h

e

front holdback system towards the front beveled

pulley

s

tampe

d

FRONT STANDARD (I). Repeat the rear beveled pulley

pro

ced

ur

e.

Roll the tarp open and closed several

times checking each time

t

o

make sure that the cable follows in the pulley grooves and the

ta

rp

rolls evenly. If the

cable does not follow in the grooves, move

t

h

e

beveled pulley in or out until the correct position is achieved.

If

the tarp

does not roll evenly, roll the tarp to the open position;

l

oos

e

n

the 1/4" set screws in the front and rear pulleys and

increase the

cable

wrap. This will increase the tension. Do not allow the pulley to

ha

v

e

less than one complete wrap of

cable when the tarp is in the

o

pe

n pos

iti

on.

When finished secure the front beveled pulley cap (J) to the open

e

nd

of

the front beveled pulley

(I). If you are installing an

electric system do not cut

the front of the roll tube, as it will be

needed to drive the tarp.

Note: The front beveled pulley (I) must never ride on the front hood (see Figure 20).

.

Figure 19

Figure 20

Figure 21

Michel’s Industries, Ltd. Generic Siderolling Instructions

Rev: Feb 22/17

Michel’s Industries, Ltd., PH: 306.366.2184 11

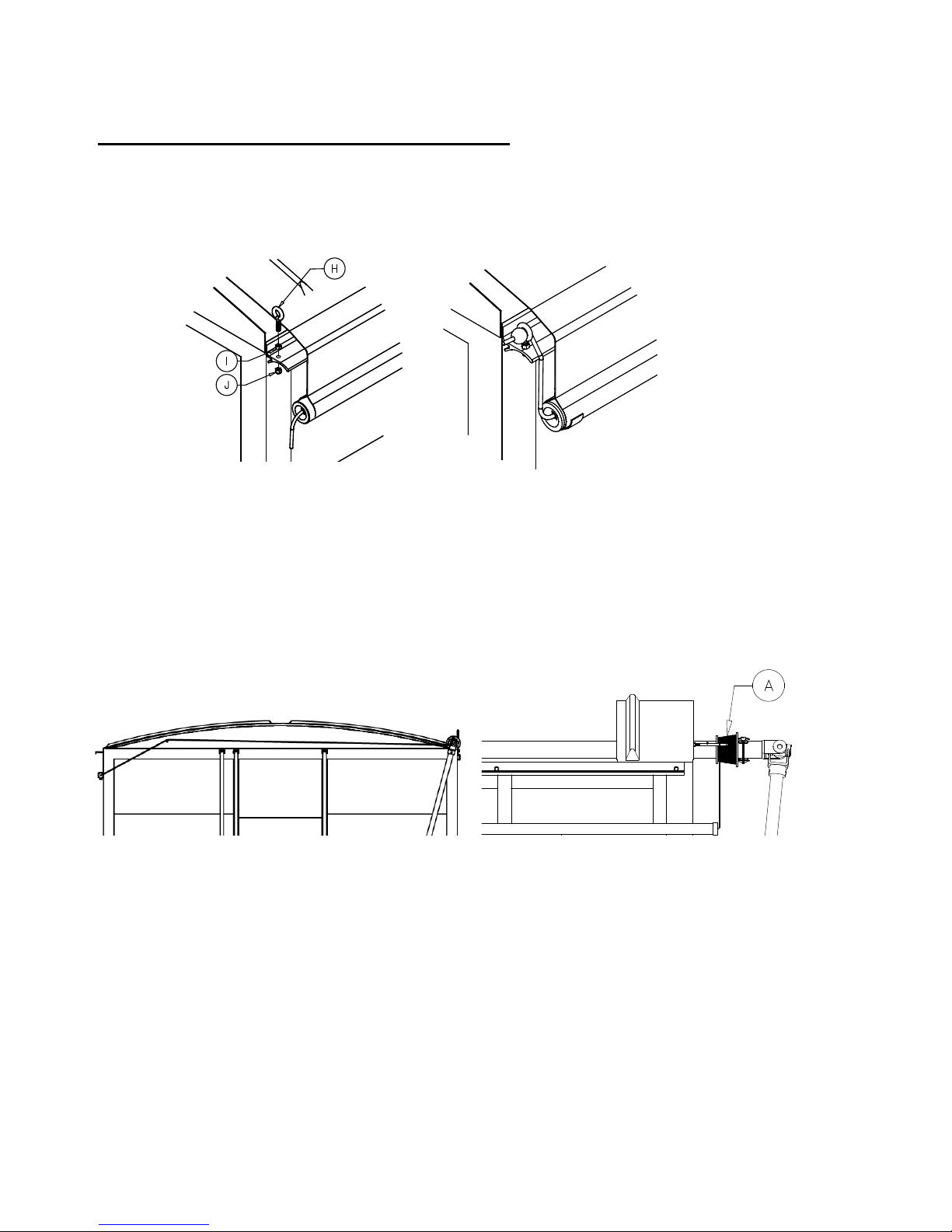

Option 2 of 2: Load-Loc Return Installation

(See Figure

22-23)

Procedure: First drill an 11/32" hole into the front of latch plate 1 1/2" from the edge of the tarp. Fasten the eyebolt (H) to

the latch plate with the 5/16" nut (I) and nylock nut (J). Thread the rope through the eyebolt shown in figure 23 and knot

the end of the rope to prevent it from going through the eyebolt. Cut any extra material off and melt the end to prevent it

from fraying.

Step 11: Rear Hood Bolt

Installation

(See Figure 24 & 25

)

Note: The rear hood bolt (G) prevents the cable from coming

int

o

contact with any obstructions when the tarp

is

o

pe

n.

Procedure: Drill a 1/4" hole through the rear hood at

a

ppro

ximatel

y

18" from the edge of the rear hood and

centered according to

the

height of the hood (see Figure 24). Fasten the 1/4"x4" hex bolt to

the

rear hood; making

sure that the bolt protrudes out far enough for

the

cable to rest on it properly when the tarp is in the open

pos

iti

on.

If Electric see additional instructions included in your kit.

WARNING:

Crank must be locked for transport in either the fully open or fully closed position. Traveling with the tarp in the open

position with the tarp sitting on the hoops will cause premature wear on the tarp material.

WARRANTY:

Michel's Industries warrants their products for a period of one year from date of purchase. Any parts returned to Michel's

Industries LTD. will be shipped prepaid and will be returned F.O.B. St. Gregor, Sk. Canada. We will not assume

responsibility

for shipping, labor or travel expenses. Please Note: We reserve the right to make improvements; therefore specifications

are subject to change without notice.

FOR

INSTALLATION ASSISTANCE

PLEASE CALL MICHEL’S INDUSTRIES, LTD. COLLECT AT (306) 366-2184

Figure 22

Figure 23

Figure 24

Figure 25

Table of contents

Other Michel's Automobile Accessories manuals