MiCo BioMed Veri-Q PREP M16 G2-16TU User manual

Veri-Q PREP M16

G2-16TU

User Manual

Apr. 2020

Cat No. 9S101

User Instructions

Common name : Nucleic Acid Extraction Device

Brand name : Veri-Q PREP M16

Model name : G2-16TU

For safe use, please use the device after reading the manual thoroughly.

Please furnish this document at a designated location so it can be used at all times.

MiCo BioMed Co., Ltd.

3rd and 4th Floor , 54 Changeop-ro, Sujeong-gu,

Seongnam-si, Gyeonggi-do, Korea, 13449

TEL: +82-70-5227-6000 FAX: +82-70-5227-6001~2

4 5

Veri-Q PREP M16 G2-16TU User Manual

5. Recommendations 29

6. Trouble Shooting 30

6.1 Error Messages 30

6.2 Additional Error Situation and Required Action 31

7. Warranty Policy 32

8. Return and Refund Policy 32

9. Disposal of Electrical & Electronic Equipment 32

10. EMC & Safety Test Results 33

11. Purchase of Reagents and Consumables 33

11.1 Consumables 33

11.2 Reagent 33

12. Cleaning 34

12.1 Cleaning of Air Rubber 34

12.2 Cleaning of Tray 34

12.3 Cleaning of Pre-run Cartridge 34

12.4 Cleaning of Solution Bottle34 34

13. Maintenance Checklist 36

Table of Contents

1. Before You Begin 4

1.1 About the manual 6

1.2 General Requirements for Installation 6

1.3 How to Obtain More Information 6

1.4 About Customer Support 6

1.5 Precautions on distribution or duplication of the manual 6

1.6 Laboratory Biosafety 6

2. Safety Guideline 7

2.1 Precautions when using the device 7

2.2 Working Environment and Installation Method 8

2.3 Operation and Maintenance 10

2.4 Transport and Storage 12

2.5 Limitation 12

2.6 Symbols of G2-16TU 12

2.7 Additional Symbols of this Manual 13

3. Product Components and Specications 14

3.1 Product Components 14

3.2 Product Performance 14

3.3 Purpose of Use 15

3.4 Detailed Information on Accessories 15

3.5 Consumable Components 15

3.6 Equipment Part Names and Functions 17

4. Product Features and Explanation 19

4.1 Product Features and Principle 19

4.2 Unpacking the G2-16TU 19

4.3 Transporting the G2-16TU 20

4.4 How to Use 20

4.5 G2-16TU Nucleic Acid Extraction Procedure 21

6 7

Veri-Q PREP M16 G2-16TU User Manual

2. Safety Guideline

This manual contains information and warnings the user must follow for the safe use of Veri-Q

PREP M16-G2-16TU. Hazards that could harm the user or damage theequipment are clearly stated

in this manual. If the product is used in a manner notdesignated by the manufacturer, the product

may become damaged.

Safety regulations are used like the following.

Warning

Warning is used to inform the user or other users that a situation like injury can

occur. Details about these situations are included in a box like this.

Caution

Caution is used to inform the situation that can cause damage to the product or

other equipment. Details about these situations are included in a box like this.

Before using the equipment, please read this manual carefully. And pay attention to the advice on

all hazards that may arise during operation. The caution clearly stated in this manual is intended to

supplement, not replace, safety requirements applied to the user’s country.

2.1 Precautions when using the device

2.1.1 Veri-Q PREP M16–G2-16TU must be only used by skilled personnel who have received

training on the relevant area.

2.1.2 Please thoroughly familiarize yourself with the manual before using the product We

recommend the user to read the warnings represented by symbols.

Warning

Risk of Injury and Damage to Materials

Improper use of G2-16TU may cause injury to the user or damage the product. G2-

16TU must only be used by users qualified after completing a training course.

Servicing on G2-16TU is performed by MiCo BioMed.

2.1.3 The user must use only components of MiCo BioMed in order to receive guarantee of the

product. Please perform regular maintenance according to the user manual. MiCo BioMed charges

the repair cost regarding problems arising due to incorrect maintenance.

2.1.4 In case of an emergency or malfunction, turn off the power switch on the back of G2-16TU,

and unplug the power cord from the power outlet. Afterwards, contact the contact address

specified on the user manual.

1. Before You Begin

1.1 About the manual

This manual is prepared for researchers or related staff for using and conducting research using

Veri-Q PREP M16-G2-16TU and for related staff who installs and maintains the product. This

product is a medical device.

1.2 General Requirements for Installation

If you wish to use this manual, the following is required.

-You must have basic knowledge in handling DNA and RNA samples for PCR.

1.3 How to Obtain More Information

To obtain detailed information on Veri-Q PREP M16-G2-16TU, please visit the following website

1.4 About Customer Support

For prompt response to customers, please contact us at +82-70-5227-6000.

Technical support is also available at our website at http://micobiomed.com.

1.5 Precautions on distribution or duplication of the manual

The content of this document cannot be sent or duplicated without the permission of the

copyright holder : MiCo BioMed Co., Ltd.

1.6 Laboratory Biosafety

Non-propagative diagnostic laboratory work (e.g. sequencing, NAAT) should be conducted at

facilities and procedures equivalent to BSL-2.

8 9

Veri-Q PREP M16 G2-16TU User Manual

2.2.5 Do not use a loose power cable or connector. If a power cable is overheated, it may be

damaged and can cause fire or electric shock.

2.2.6 Do not damage or alter the power plug. It may cause electric shock or fire.

2.2.7 When using a power extension cable, do not operate multiple devices at the same time. It

may cause an overload and cause a fire.

2.2.8 When handling a power cord, please handle it with hands that are completely dry.

Warning

Risk of Electric Shock

Do not touch G2-16TU with wet hands.

2.2.9 Do not place any objects in front of the door of the product which can interfere with the

door. It may lead to the malfunction of the door.

2.2.10 Have at least 30 cm of space between the product and the wall for proper ventilation. If

not, the product may be damaged.

Warning

Risk of Overheating

Maintain a space of a minimum of 30 cm for proper ventilation.

2.2.11 Do not install the product in a dusty environment since it may damage the product.

2.2.12 Make sure the product does not come in contact with heat sources.

2.2.13 Keep the product away from humid environment since it can cause electric shock, fire or

damage to the system.

2.2.14 Keep the product away from combustible and flammable vapor. If gas leaks, open the

windows and ventilate.

Do not operate electric switch during a gas leak because it may cause an explosionor fire. The

device must be installed on a clean and level place. A place with corrosive gas or high density

magnetic properties can damage the device.

2.2.15 Do not dismantle or repair the product. It may cause a fire and electric shock, and warranty

will not apply. Only a designated engineer can provide repair and services.

2.2.16 When the product is not used for a prolonged period of time, turn off the switch and

unplug the power plug. If not, the product may overheat and cause a fire.

2.2.17 Wipe off the dust from the power plug and do not use a loose power cord. If not, it may

cause a fire.

2.2.18 The optimum operating temperature of the product is 15℃~ 40℃. If the temperature is

higher or lower than this, it may damage the device or generate inappropriate data values.

2.1.5 If the device does not meet the performance conditions, make an inquiry to the

manufacturer.

2.1.6 This device is an electronic and mechanical device. Since there is a risk of electric shock or

physical injury, you must operate the device according to the user manual.

2.1.7 Follow the safety precautions attached to the device.

2.1.8 Do not touch the switch or power with wet hands.

2.1.9 When cleaning the device, turn off the power and unplug the power cord.

2.1.10 Only a designated engineer can provide repair and services.

2.1.11 Please install the device on a clean and level surface. Corrosive gas or high density

magnetic location can damage the device.

2.1.12 Avoid direct sunlight and strong light.

2.1.13 You must wear safety gear when handling toxic substances and substances which cause

infection.

2.1.14 Please close the door when operating the device. When you take out the door during

operation, physical shock may be applied to the device and cause malfunction of the operating

part, and you may also receive physical injury.

2.2 Working Environment and Installation Method

2.2.1 Please check the rated voltage of the power before operating the product. Veri-Q PREP M16

– G2-16TU uses 220V. For the safe use of the product, we do not recommend the use of Automatic

Voltage Regulator (AVR) or uninterruptible power supply (UPS) . This device is an electronic and

mechanical device. Since there is a risk of electric shock or physical injury, you must operate the

device according to the user manual.

2.2.2 This product must be grounded to protect it from electric shock. If not, it may cause a

serious injury or damage to the device.

2.2.3 Electromagnetic environment must be evaluated before operating the product.

2.2.4 Do not use this device near a powerful electromagnetic radiation source.

For example, unshielded intentional RF source may intefere with normal operation.

Warning

Electrical Hazard

Any interruption of the internal protective conductor (ground/grounded lead) and

disconnection of the protective conductor or external terminal may cause risk to

the product. Intentional interruption is prohibited.

Voltage inside the device

When the product is connected to line power, terminal may be active. If the cover

is opened or parts are removed, it is highly likely that active parts can be exposed.

10 11

Veri-Q PREP M16 G2-16TU User Manual

placed on the right position, malfunction may occur. (Both switches must be located on the left.)

2.3.6 Do not open the tray door for safe operation. Be sure to close the door when the device is

operating. When you take out the door during operation, physical shock may be applied to the

device and cause malfunction of the operating part, and you may also receive physical injury.

Warning

Moving parts

Never open the G2-16TU tray door during operation.

2.3.7 When cleaning the product, be sure to unplug the power cable from the power outlet.

2.3.8 Biological safety - Samples containing materials originated from humans should be treated

as follows. Use safe laboratory procedures as explained in the following publication. Biosafety in

Microbiological and Biomedical Laboratories, HHS (www.cdc.gov/od/ohs/biosfty/biosfty.htm).

2.3.9 Samples - Samples may contain infectious substances.

You should be aware of the health hazard presented by agents, and should use, store, and dispose

of such samples according to the stipulated safety regulations.

2.3.10 Chemical substances: You must wear safety gear when handling toxic substances and

substances which cause infection.

Warning

Harmful chemicals

Some chemical substances used with this product may be dangerous or may

become dangerous after the completion of the protocol execution. Always wear

goggles, gloves, and lab coat. A responsible person(e.g. Laboratory manager)

must take the necessary precautions to ensure that the workplace is safe and

that the equipment operators are not exposed to hazardous levels of toxic

substances(chemical or biological) defined in the applicable Material Safety Data

Sheets(MSDSs) or OSHA, ACGIH or COOSHH documents.

Ventilation for fumes and disposal of wastes must follow all national, and local

health and safety regulations and laws.

Please wash your hands after handling the reagents.

2.2.19 Operate the product in an environment with humidity of 20~80%. If not, the device may

malfunction or be damaged.

2.2.20 Prep reagent, sample type, and pre-treatment method may affect performance.

Operating Environment

A. Operating temperature: 15℃~ 40℃

B. Operating humidity: 20 ~ 80%

C. Max. 80% at 40℃, no condensation

D. Min. 20% at 15℃~ 40℃

Caution

Damage to the device [C1]

Make sure water or chemical substances are not spilt on the G2-16TU.

Product damage caused by water or chemical substance leakage will void the

warranty.

2.2.21 Do not place any objects in front of or behind the product. It may block the vent and

damage the product.

2.2.22 Do not drop or apply strong force to the product since it can damage the product.

2.2.23 Install Veri-Q PREP M16 (G2-16TU) away from direct sunlight and strong light.

2.2.24 Do not place paper or synthetic resin underneath the product. It may cause fire. Do not

cover the product with paper or plastic while operating the product. It may cause fire.

Warning

Explosive atmosphere

The G2-16TU is not designed for use in an explosive environment

2.3 Operation and Maintenance

2.3.1 Do not use the product for purposes other than extracting nucleic acid. It may damage the

product.

2.3.2 Please check if there is any foreign substance on the LabChip. It may cause damage and

malfunction of the product, and generate inaccurate test results.

2.3.3 Maintenance must be performed using the maintenance chart of Veri-Q PREP M16–G2-

16TU.

(Attachment) Last page of the user manual

2.3.4 In case of product malfunction, error message must be displayed on the LCD. If error

message is indicated, do not operate the product by force and make an inquiry to MiCo BioMed

A/S team.

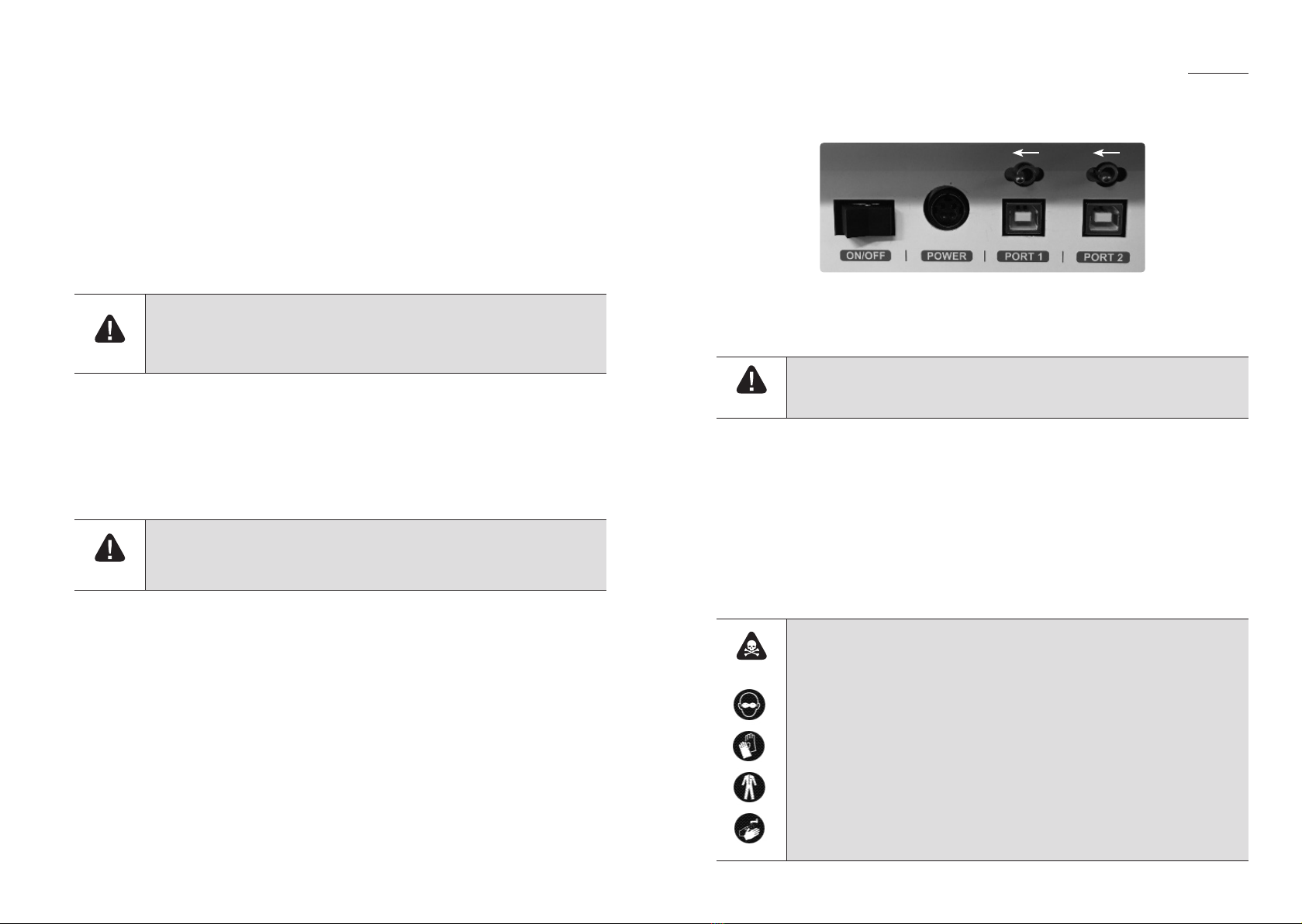

2.3.5 The setup port on the back side of the product is only for engineers. If the switch is not

12 13

Veri-Q PREP M16 G2-16TU User Manual

2.3.11 Waste disposal - Used lab ware such as sample tubes and filter-tips may contain harmful

chemical substances or infectious substances occurring from the extraction process. Such wastes

must be appropriately collected and disposed of according to local safety regulations.

2.3.12 If you need calibration, please make an inquiry to the manufacturer or dealer. And If there

is a change in the performance characteristics of QD-P100 device, please make an inquiry to the

manufacturer or dealer.

2.4 Transport and Storage

Operating Storage Transport

Ambient Temperature (℃)15 ~ 40 RT RT

Relative humidity (%) 20 ~ 80 10 ~ 90 20 ~ 90

Air Pressure (kPa) 70 ~ 100 70 ~ 100 70 ~ 100

2.5 Limitation

The G2-16TU is optimized to use with Veri-Q PREP M16 reagent kit made by MicoBioMed and it

couldn’t guaranteed performance excepting the system.

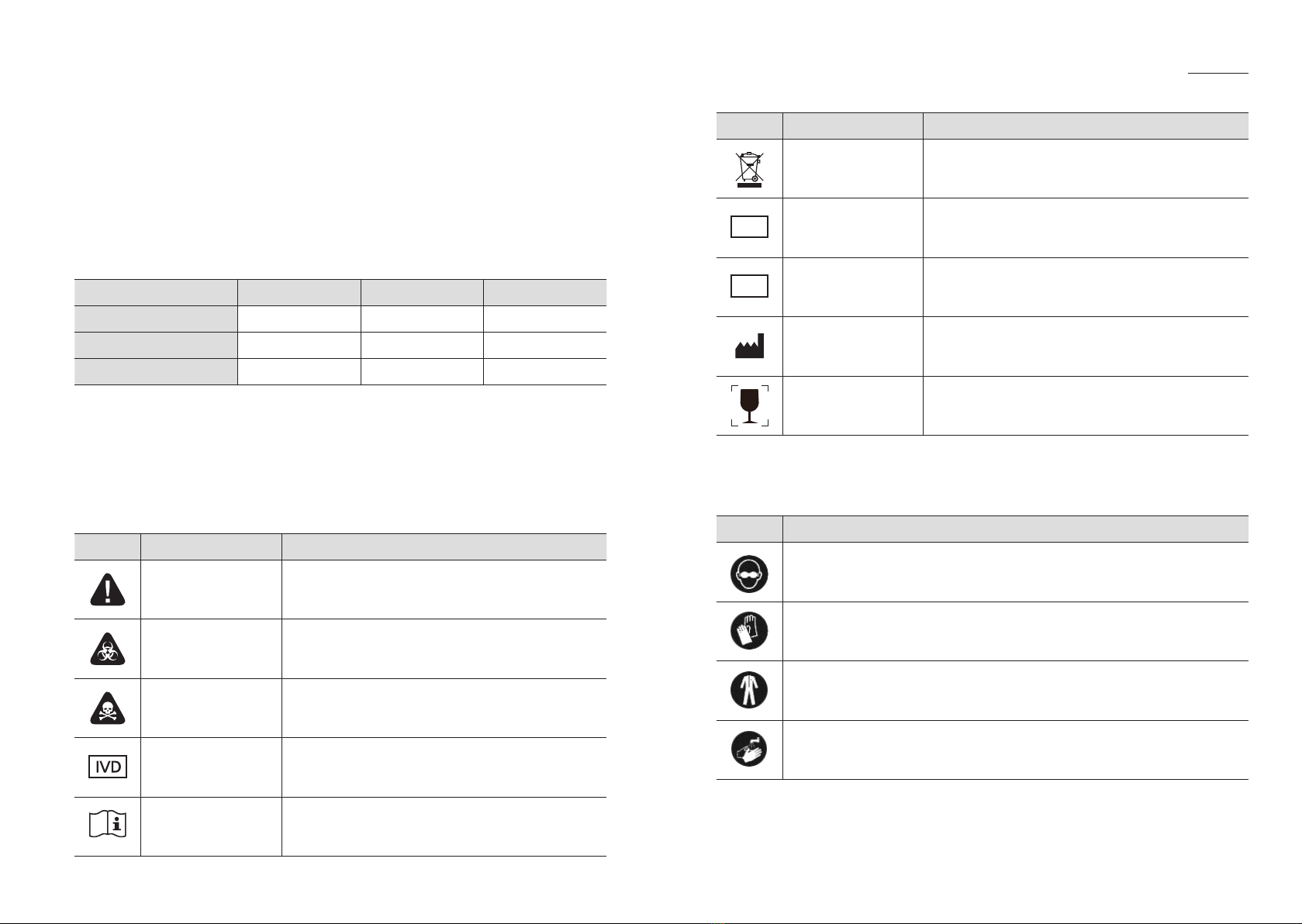

2.6 Symbols of G2-16TU

Symbol Location Explanation

Tray door Warning or Caution for each parts

Near sample tubes

Biological hazard - Since the tubes or waste cartridges

become contaminated with biohazardous materials, they

must be handled while wearing gloves.

Near buffer bottles and

sample tubes

Toxic material. Since the tubes or waste cartridges

become contaminated with toxic materials, they must be

handled while wearing gloves.

Label on the back side Used in in vitro diagnosis

Label on the back side Refer to the user manual

Symbol Location Explanation

Label on the back side Disposal of Electrical & Electronic Equipment

REP Label on the back side Indicates the manufacturer’s catalog number

so that the medical device can be identified

SN Label on the back side Indicates the manufacturer’s serial number so that a

specific medical device can be identified.

Label on the back side Indicates the medical device manufacturer as defined in

EU Directives 90/385/EEC, 93/42/EEC and 98/79/EC

Label on the back side Fragile, handle with care

2.7 Additional Symbols of this Manual

Symbol Explanation

Please wear protective goggles.

Please wear protective gloves.

Please wear lab coat.

Please wash your hands after using the product.

14 15

Veri-Q PREP M16 G2-16TU User Manual

3. Product Components and Specications

The warranty period of Veri-Q PREP M16–G2-16TU is 1 year from the date of purchase. This warranty

does not apply to damage from transport or handling, misuse of the device, or normal wear condition.

All repair work performed after thewarranty period will be charged. Before installing the product,

check if the following product components are included in the package.

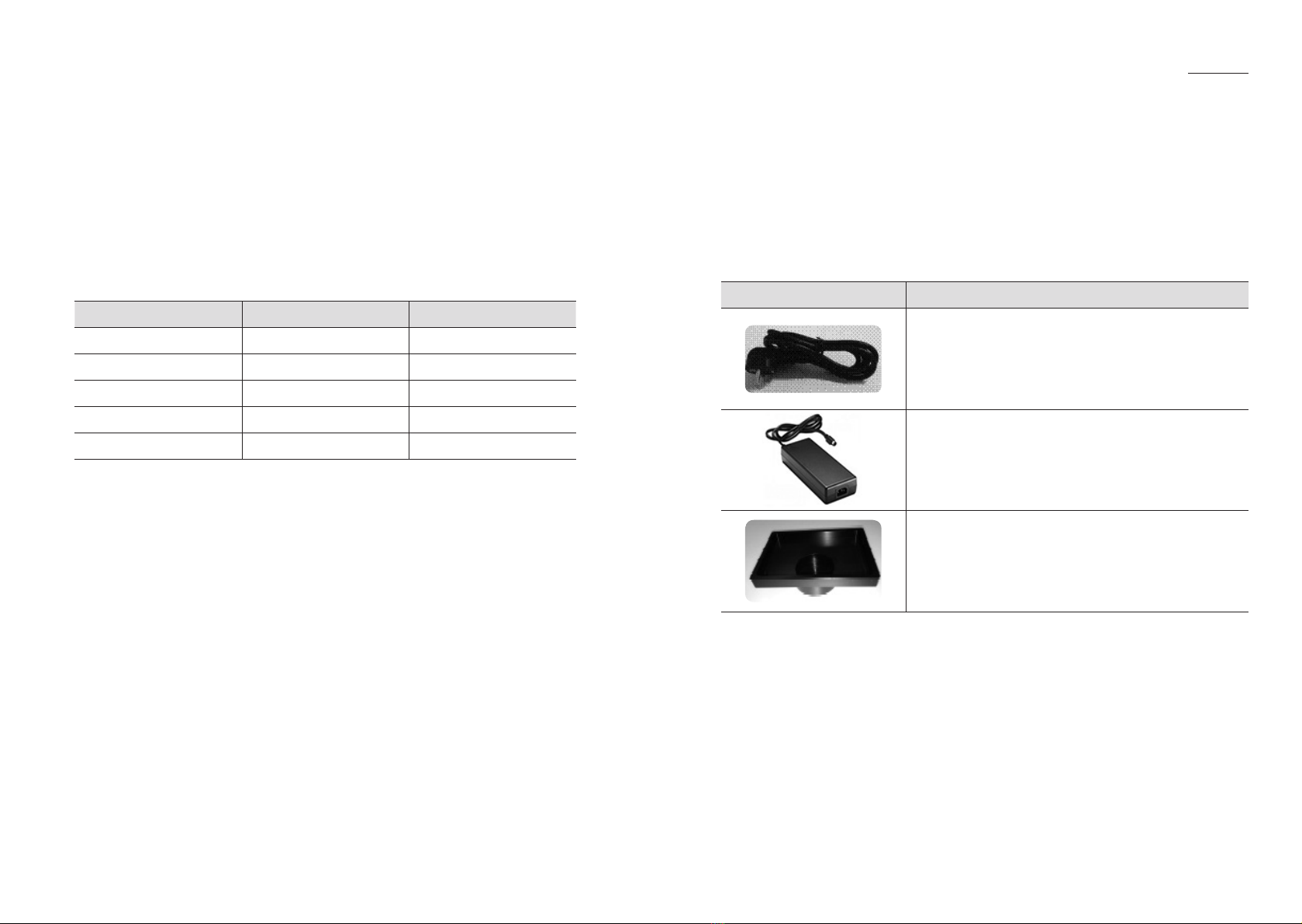

3.1 Product Components

Components Quantity Check(O/X)

Product 1 EA

Power cable 1 EA

Adapter 1 EA

Pre-run Cartridge 1 EA

User manual 1 EA

3.1.1 Product name

•Common name : Nucleic Acid Extraction Device

•Brand name : Veri-Q PREP M16

•Model name : G2-16TU

3.2 Product Performance

3.2.1 Specifications

•Equipment Input Voltage : 12V

•Frequency : 50~60Hz

•Adapter Output : 12V 16A

•Weight : 13.3Kg

•Dimensions : 260x335x355mm(DOOR OPEN: 260x620x355mm)

3.2.2 Product Specification

•Product input voltage: 12V

•SMPS requirement: 12V 16A

•Average electric consumption: 30W

•Instantaneous maximum power consumption: 110W

•Safety device: We made sure the electric shock inside the board does notaffect the element

by using Varistor on operating parts such as valve, pump, fan, etc. We made sure the electric shock

inside the board does not affect the element by using diode in the motor operating part.

3.3 Purpose of Use

As a device which separates nucleic acid from various samples such as blood, serum, sputum,

tissue, etc. for gene amplification test, this product is for In VitroDiagnostic device.

3.4 Detailed Information on Accessories

Components Explanation

Power cable

100~240V. Min. 10A

Operable with any cable approved by the European

Certification Authority

Adapter-

Output: 12V 16A

It must be used identically with the certified genuine

product.

Pre-run Cartridge

Product provided by MiCoBioMed must be used.

3.5 Consumable Components

Consumable components are needed to operate the product. Sample Prep kits for G2-16TU are

produced by MiCoBioMed. For sample treatment and preparation process, refer to the ‘guideline

for use’ of prep reagent for each sample (ex. Blood, sputum, serum, etc.)

16 17

Veri-Q PREP M16 G2-16TU User Manual

Contents Explanation

NST (Sample Tube)

Plastic tube with nucleic acid binding membrane.

Nucleic acid will be separated with this tube.

* Disposable, re-use prohibited.

NET (Elution Tube)

Extracted nucleic acid is collected with Elution Tube.

* Disposable, re-use prohibited.

Buers

Lysis solution, cleaning solution 1, 2, Elution solution, etc.

(Contents vary depending on the type of kit.)

NETR(Elution cartridge)

Elution tubes will be placed in the Elution cartridge.

NWTR(Waste Cartridge)

All wastes will be filled in this waste cartridge.

Lid

This lid will cover the Elution Cartridge.

3.6 Equipment Part Names and Functions

1

2

3

4

5

6

7

No. Name Explanation

1LCD Operates and sets equipment with touch LCD, and displays User

interface

2LED Indicates the equipment status with LED Power, Error, Run

3Button Operates and sets equipment

4Upper tray Upper tray can be manually inserted and taken out by pulling to

install and replace sample tubes.

5Lower tray Lower tray can be manually inserted and taken out by pulling to

install and replace Elution cartridge, and clean the lower tray

6Air vent hole Hole for discharging air inside the body(heat)

7Buer door The door can be manually opened and closed to fill up the buffer

18 19

Veri-Q PREP M16 G2-16TU User Manual

3 4

2

1

No. Name Explanation

1Fan Built-in fan for cooling heat inside the device

2Power switch Turns on and turns off equipment

3Power connector Connects to adapter and turns on equipment power

4Service port

Port for downloading the equipment operating program or

upgrading the operating program, port to be used by only

engineers

4. Product Features and Explanation

4.1 Product Features and Principle

4.1.1 Product Features

Main body Fluid control part for washing, air pumping, and extraction

Moving part to perform pre-treatment per channel

4.1.2 Operation Principle

This device has the function to rapidly extract nucleic acid from the samples that have gone

through the pre-treatment process.

Moving Part This part rotates the upper tray containing NST and lower tray containing NET

to filter waste and extract nucleic acid from a sample.

Fluid Control

Part

This part pours buffer and pumps air into NST to filter waste and extract

nucleic acid from a sample.

4.2 Unpacking the G2-16TU

Unlock the Case Open the Case Take out the

Equipment

Connect Power

cable and AC

adapter

Connect Power

cable to the

Equipment

20 21

Veri-Q PREP M16 G2-16TU User Manual

4.3 Transporting the G2-16TU

When moving the device, please protect the device by using the silver case. When packing the

equipment,

•Remove all liquid in a bottle

•Perform Pre-run 3 times to remove liquid in the equipment

•Place the power cable and AC adapter at the bottom of the case

•Put the equipment in the silver case

•Put the pre-run cartridge in the empty space on the side of the case.

4.4 How to Use

Check the G2-16TU device with the required parts according to installation protocol. You must

start the operation in a normal operating condition.

4.1.1 Power Supply and Self-Test Method

1) Connect instrument power cable on the power connect at the rear side of the G2-16TU, and

then, turn on the power.

2) When power is supplied to the device, POWER LED should light up. Please refer to the

following photo. The green light coming on means the device is working properly.

3) When the power is turned on, self-test and initialization is automatically performed. If a

problem occurs during a self-test, the equipment does not work properly, and a message,

“Motor Initialize (RUN-INIT)” appears on the bottom of the LCD. In this case, do not operate

the equipment by force. And please make an inquiry to the AS team of Mico Biomed Co., Ltd.

regarding such malfunction.

4.5 G2-16TU Nucleic Acid Extraction Procedure

For sample preparation, see the instructions for use of Veri-Q PREP M16 reagent kit made by

MicoBioMed

4.5.1 Filling buffer solution

1) Carefully fill up each bottle with the solution. Afterwards, place the bottle in a suitable location.

2) Open the lid after suitably placing the bottle.

22 23

Veri-Q PREP M16 G2-16TU User Manual

4.5.3 Placing Elution Tube and Cartridge

1) Open the lower tray and place a Waste cartridge.

2) Insert the Elution Cartridge: Place the Elution Cartridge so it fits in the location for insertion.

3) Insert Elution tube: Insert the Elution tubes into the Elution Cartridge.

Make sure the lid of each tubes faces outward.

4.5.2 Pre-running

1) Please check “PreRUN Required” message from the configuration screen.

2) Pull out the upper tray and place a “Pre-run Cartridge” in an appropriate position of “Sample

Rotor.”

** Do not place the Pre-run cartridge upside down. The buffer solution can flow into the

equipment. Please refer to the photo below.

XO

Correct Incorrect

A. Press “Prerun” button on the LCD screen.

B. If “YES” button is pressed, “Prerun” begins (It will take about ~80 seconds.)

C. If you hear a beep sound, the equipment automatically finishes “Prerun.”

D. Press “YES” button and then, remove “Pre-run Cartridge.”

E. Remove buffer solution from the waste liquid container.

F. Refill the bottle with solution

**Please fill the bottle with solution after Pre-run is finished.

**Please perform pre-run right before starting sample extraction.

24 25

Veri-Q PREP M16 G2-16TU User Manual

4.5.6 Load eluted sample

1) Carefully place the samples into the Sample tubes and close the upper tray.

(Never perform “Initializing step”after loading the samples.)

4.5.7 Select protocol

1) Press ‘ ’ button on the left side of the Configuration menu.

2) Select appropriate protocol from the menu, and then press “Next ” or “START” button to

return to the Configuration menu.

** You can change menu page by pressing ‘ ’ , ’ ’ image or pressing ‘ ’ , ’ ’ button.

** You can check the firmware version on the left corner. The latest version is v2.00.

4.5.8 Select extraction volume

1) Press “E-Volume” image or ‘ ’ button. You can select one of 3 extraction volumes.

4) Place the lid on the Elution Cartridge. This lid is for preventing the Elution tube from being

contaminated. Afterwards, close by pushing the lower tray again.

4.5.4 Placing the sample tubes

1) Press “Init” image or ‘SET’ button to initialize the position.

4.5.5 Placing the sample tubes

1) Insert sample tube

Open the upper tray and place the Sample tubes into the Sample rotor.

26 27

Veri-Q PREP M16 G2-16TU User Manual

B. Washing

During the washing process, the equipment will inject washing solutions into the

sample tubes. And current washing status will be shown in the LCD channel. During the

washing process, the following error message may appear.

Or

This error message occurs when there is almost no buffer in the bottle during injection. If

the user filled the bottle completely before operation, there is no need to fill up the bottle

with solution or halt operation. If the buffer is not filled completely, it may cause incomplete

operation.

4.5.9 Start operation

1) Press “START” button or “▶Start” image. The equipment automatically operates. Please refer

to the following for operating procedures.

A. Checking & Binding

When the user operates the equipment, the operation screen of the equipment

changes or is displayed.

In this procedure, the equipment rotates the sample rotor and checks the insertion of sample

tubes. If there is a sample tube, the image changes to inform the user. In addition, if there are

tubes in all channels, the image will change as shown below.

**

If the indicated image does not match the inserted sample tube position, stop the

operation.

After checking, the equipment starts the binding process. During the binding process, the

binded sample tube is highlighted with blue as shown below.

28 29

Veri-Q PREP M16 G2-16TU User Manual

D. Close the lid of the bottle containing solution.

E. Turn off the G2-16TU..

3) If you want to operate equipment again, follow below procedures.

A. Press 'SET' button or touch "Init" image.

B. Check the error message "Motor Initialize (Run INIT)" disappear.

C. Refill the all buffer bottles.

D. Go to section 4.5.3

4) Unless if you not, follow below procedures.

A. Close the lid of the bottle containing solution.

B. Turn off the G2-16TU.

5. Recommendations

We recommend that you use only MiCo BioMed reagents optimized for the equipment. For more

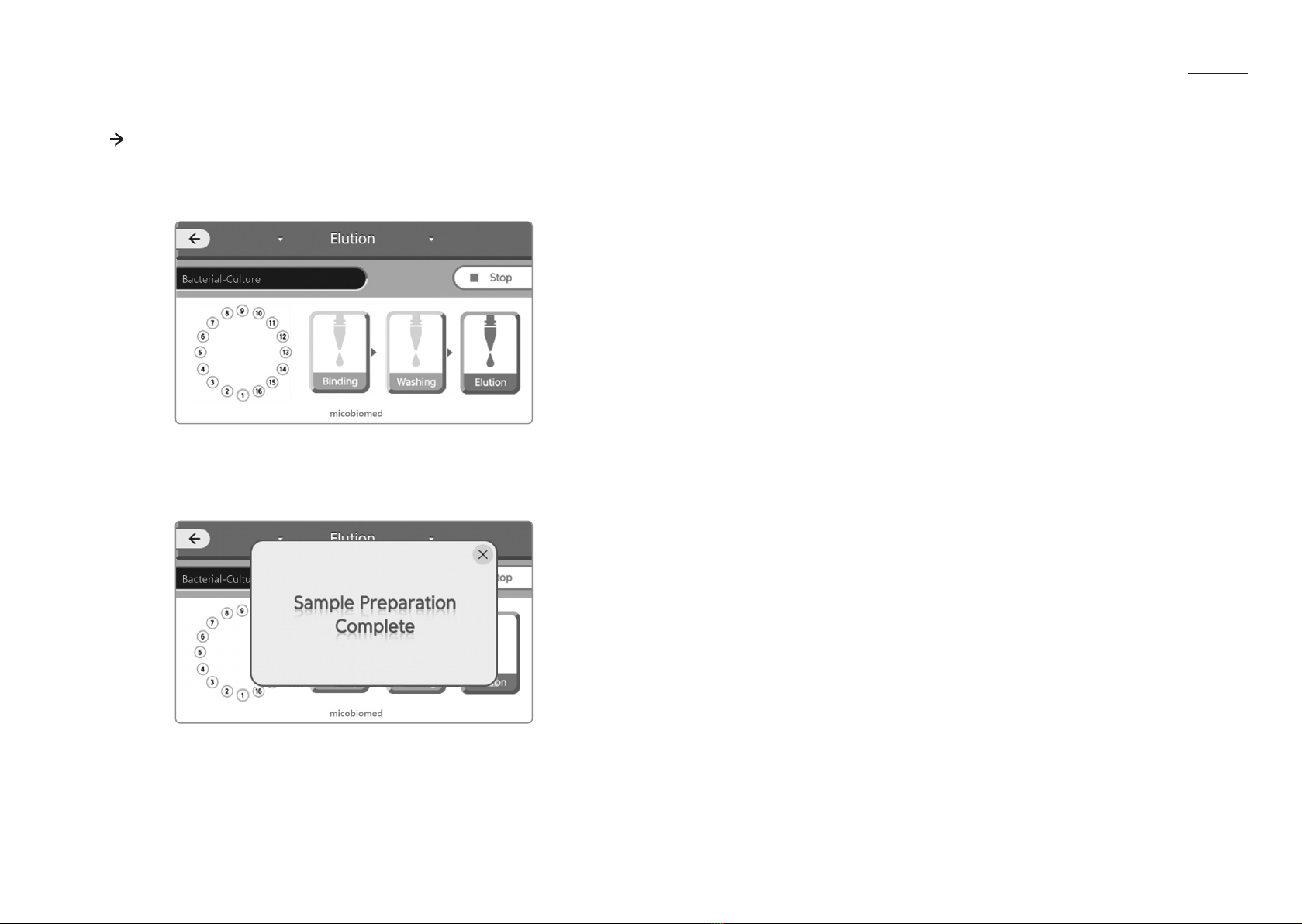

C. Elution

In this step, the eluate will be gathered in the micro tube which is inserted into the

elution cartridge. Because G2-16TU does not check the insertion of elution tube, if the user

does not insert the elution tube or insert the tube without matching the position of the

sample tube, the eluate may be poured out on the equipment.

4.5.10 Finish

1) If the device operation is finished, you will hear a‘beep’sound. And the following image will

appear.

2) Next, follow the following procedure.

A. Open the upper tray and remove the sample tubes.

B. Open the lower tray, take out the elution tubes containing DNA or RNA sample and store

them appropriately.

C. Please empty the waste solution from the waste cartridge.

30 31

Veri-Q PREP M16 G2-16TU User Manual

Elution Door Open

This error message occurs in the following situation.

a. When lower tray door is opened

b. In this case, close the lower tray.

Tube Empty

(Running

Interrupted)

This error message occurs in the following situation.

a. When there is no sample tube in the upper tray during the checking

step

In this case, insert the sample tube into the upper tray.

6.2 Additional Error Situation and Required Action

Error Situation Action

Equipment is turned

on but nothing is

displayed on the LCD

This error occurs in the following situation.

a. When USB port switch location is wrong

In this case, relocate switch position as described in 2.3. (5).

Equipment is turned

on but buzzer alarm

is constantly set o

This error occurs in the following situation.

a. When USB port switch location is wrong

In this case, relocate switch position as described in 2.3. (5).

Lower tray does not

open after inserting

sample tube

This error occurs in the following situation.

a. When Elution cartridge and lid are inserted into the lower tray

In this case, remove sample tube from the upper tray.

** If a problem cannot be solved, please make an inquiry for services through the manufacturer or

distributor.

6. Trouble Shooting

6.1 Error Messages

Message Explanation

Motor Initialize

(Run INIT)

This error message occurs in the following situation.

a. When motor initialization fails upon turning on the equipment

b. When sample extraction is complete

In this case, take the following measures.

a. Remove all sample tubes from the upper tray

b. Press “INIT” image or “SET” button.

Washing1 Buer

Empty

This error message occurs in the following situation.

a. When there is not enough Washing solution 1

b. When there is no bottle containing Washing solution 1

In this case, take the following measures.

a. Fill the bottle with sufficient amount of the solution

b. Properly insert the bottle in the rack

Washing2 Buer

Empty

This error message occurs in the following situation.

a. When there is not enough Washing solution 2

b. When there is no bottle containing Washing solution 2

In this case, take the following measures.

a. Fill the bottle with sufficient amount of the solution

b. Properly insert the bottle in the rack

Elution Buer Empty

This error message occurs in the following situation.

a. When there is not enough Elution solution

b. When there is no bottle containing Elution solution 1

In this case, take the following measures.

a. Fill the bottle with sufficient amount of the solution

b. Properly insert the bottle in the rack

PreRUN required

This error message occurs in the following situation.

a. When the equipment is turned on but pre-run is not carried out yet

In this case, follow 4.5. (2).

Buer Waste Empty

This error message occurs in the following situation.

a. When there is no waste cartridge in the lower tray

In this case, properly put the waste cartridge in the lower tray.

Sample Door Open

This error message occurs in the following situation.

a. When upper tray door is opened

In this case, close the upper tray.

32 33

Veri-Q PREP M16 G2-16TU User Manual

Recycling of device materials will be helpful in protecting the environment. Therefore, do not dispose

existing electrical and electronic wastes with household wastes. For details on recycling this product,

please make an inquiry to the city hall of the applicable area, household waste processing service or

the shop where the product was purchased.

10. EMC & Safety Test Results

The system fulfills the EU safety test & EMC test requirements (IEC 61010-1:2010, IEC 61326-1:2012).

This equipment complies with IEC 61326-1:2012, IEC 61326-2-6:2012 Class A requirements and

the emissions of the energy used are low and not likely to cause interference in nearby electronic

equipment.

The equipment is tested for immunity to electrostatic discharge at test level 2kV, 4kV, 8kV of air

discharge.

The equipment is tested for immunity to radio frequency interference at the frequency 80 MHz to 1.0

GHz and test levels 3V/m.

The equipment is tested for immunity to radio frequency interference at the frequency 1.0 GHz to 2.0

GHz and test levels 3V/m.

The equipment is tested for immunity to radio frequency interference at the frequency 2.0 GHz to 2.7

GHz and test levels 1V/m.

This instrument complies with IEC 61010-1("Safety requirements for electrical equipment for

measurement, control and laboratory use; General requirement")and was in perfect safety conditions

when it left the factory. Installation, use and maintenance of the G2-16TU is the full responsibility of

the user.

11. Purchase of Reagents and Consumables

11.1 Consumables

You must use the Pre-run Cartridge which is a G2-16TU product manufactured by MiCo BioMed.

For detailed purchase information, please check the homepage. (http://micobiomed.com/)

11.2 Reagent

You have to use only reagents optimized for GT-16TU. For detailed purchase information, please

check the homepage. (http://micobiomed.com/)

7. Warranty Policy

MiCoBioMed shall be excluded from warranty obligations when a person other than the dedicated

engineer performs repairs or modifications, except in cases where the company has given its written

consent to perform repair or modifications.

According to this warranty, all replaced materials are guaranteed only for the original warranty period,

and shall not exceed the original expiration date unless there is written consent from MiCo BioMed.

The device, interface device, and related software is guaranteed only during the period originally

provided by the manufacturer.

If any damage is found at device during shipment or before using, please contact the manufacturer or

dealer.

Representations and warranties made by any person including the representative of MiCo BioMed

which are inconsistent with or in conflict with the conditions of this warranty cannot be binding

unless there is written consent. This warranty is added to the legal or other rights of the purchaser.

8. Return and Refund Policy

Our goal is to provide our customer with the device of the highest quality at the lowest possible cost.

Due to this, we can only accept returns on devices wrongly delivered by mistake. Before returning the

product, you must process the procedures on the return beforehand. Please process the equipment

to be returned within 7 days. Refund can be made only when the device is shipped.

9. Disposal of Electrical & Electronic Equipment

The meaning of the symbol on the product, its accessory or packaging indicates that this product

must not be treated as a household waste. Dispose this equipment at the collection point for recycling

of electrical and electronic equipment waste. The European Union and other European countries have

a separate collection system for used electrical and electronic products. By guaranteeing the proper

disposal of this product, potentially harmful environment and damage to health can be prevented.

34 35

Veri-Q PREP M16 G2-16TU User Manual

12. Cleaning

12.1 Cleaning of Air Rubber

12.1.1 Open the upper tray.

12.1.2 Prepare a clean cotton or cloth wetted with 70% ethanol.

12.1.3 Scrub the air rubber, especially the bottom side, with cotton or cloth wetted with 70%

ethanol.

12.2 Cleaning of Tray

12.2.1 Open the upper tray.

12.2.2 Prepare a clean cotton or cloth wetted with 70% ethanol.

12.2.3 Wipe the top and bottom side of the upper tray. And if necessary, wipe the hole of the

upper tray with a cotton swab.

12.2.4 Open even the lower tray and wipe it in the same manner.

12.3 Cleaning of Pre-run Cartridge

12.3.1 Dispose the waste liquid from the‘pre-run cartridge.’

12.3.2 Wipe it clean with cotton or cloth wetted with 70% ethanol.

12.3.3 Dry the cartridge at room temperature.

12.4 Cleaning of Solution Bottle

12.4.1 Check solution bottle on whether there is particle or dust inside.

12.4.2 If there is, dispose the solution and clean the bottle with distilled water.

12.4.3 Dry the bottle under the clean bench.

Date of preparation : Apr. 2020

36 37

Veri-Q PREP M16 G2-16TU User Manual

13. Maintenance Checklist

4. Semiannual Checklist (through MiCo BioMed sta)

Checklist Pass Fail

The air pump pressure has been checked and calibrated if necessary.

The discharge amount of the buffer has been checked and calibrated if necessary.

The equipment has been checked for any contamination and cleansed if necessary.

※If the equipment cannot be calibrated on the basis of the inspection, the equipment is to be

recovered from the client and inspected by the manufacturer.

Equipment Checklist

1. Daily Checklist

Checklist Pass Fail

The equipment is in the designated location.

There are no foreign objects or leaks around the equipment.

The device is not exposed to direct sunlight.

There are no installations that can cause dust, heat, and fluid inflow into the equipment.

The port switch direction on the rear of the equipment is correct.

The solution bottle contains no foreign substances.

There are no objects on the equipment that can cause LCD damage.

The washing condition of the pre-run cartridge has been checked.

The cap of the solution storage bottle of the equipment is closed after operation.

※For any failed items, contact the equipment manager.

2. Monthly Checklist

Checklist Pass Fail

The equipment is free of contamination.

The solution storage bottle is clean.

※For any failed items, contact the equipment manager.

3. Quarterly Checklist

Checklist Pass Fail

The collet (rubber cover for pressurizing the sample tube) has been replaced.

※Contact the manufacturer for more collets.

38

Warranty

Manufacturer’s Warranty :

Mico BioMed co., Ltd. Warrants to the original purchaser that this device will be free from

detects for 1 year from the date of original purchase.

Limitation of Warranty :

This warranty is subject to the following exceptions and limitations :

1. Mico BioMed co., Ltd. Shall not be required to replace any unit which is damaged or malfunctions

due to abuse, accidents, alteration, neglect, misuse, maintenance by someone other than Mico

BioMed co., Ltd. or failure to operate in accordance with the instructions.

2. Mico BioMed co., Ltd. reserves the right to make changes in design without obligation to

incorporate such changed in to previously manufactured devices.

3. Mico BioMed co., Ltd. has no knowledge of the performance of the device when reagents is altered

or modified in any way.

This manual suits for next models

1

Table of contents

Other MiCo BioMed Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

SYSMEX

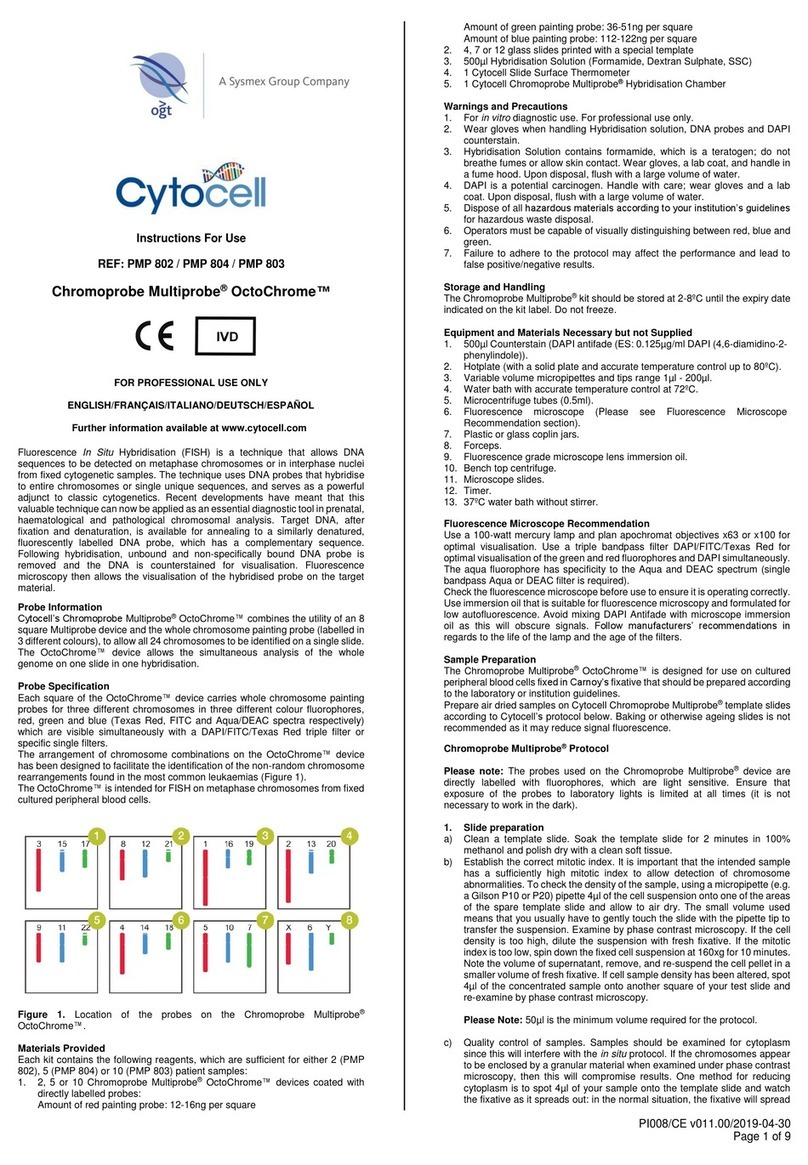

SYSMEX ogt Cytocell Multiprobe OctoChrome Instructions for use

Idexx

Idexx Quanti-Tray Sealer PLUS user manual

STERILUX

STERILUX SterOx System V Series Instructions for use

Spicer Consulting

Spicer Consulting SC28 user manual

Leica

Leica RM2235 user manual

Bullard

Bullard Edge Thermal Imager user manual