MICRO-AIR OM600 User manual

This manual contains specific cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all of the hazards of dust control equipment. It is important that use of the equipment be

discussed with a Micro-Air Representative. Persons involved with the equipment or systems should be instructed how to

operate in a safe manner.

OM600

Installation and Operation Manual

MICRO AIR

www.microaironline.com

2

OM600 MICRO AIR

WARNINGS:

CAUTION: Installation can cause exposure to live components. Disconnect electrical power

before proceeding with installation. Proper Lock Out / Tag Out procedures should be used.

All electrical work must be done by a qualified electrician according to local, state and

national codes.

Improper installation or operation of this equipment can cause damage to equipment and / or

injury to personnel. The installation / operation manual must be read and followed in its

entirety.

OM600 SPECIFICATIONS:

Motor: 3/4 HP, 3450 RPM, 1 Phase, TEFC

3/4 HP, 3450 RPM, 3 Phase, TEFC

Input Voltage: 1 Phase - 115/208-230V, 60 Hz

3 Phase - 208-230/460V, 60 Hz

Max Current: 1 Phase - 10.0/5.2-5.0 Amps

3 Phase - 2.5-2.4/1.2 Amps

Blower: Direct Drive

Air Flow: 600 CFM

Dimensions: 40” H x 24” W x 18” D w/ standard legs & standard exhaust

58” H x 24” W x 18” D w/ long legs & HEPA exhaust

Noise Level: 72 dB at 5’ away from unit

Shipping Weight: 180 lbs.

Actual Weight: 120 lbs.

PRE-OPERATING INSTRUCTIONS:

1. Inspect the unit for any visible damage that may have occurred during shipment. Report any

damage to the delivery carrier.

2. Remove the shipping crate, shipping straps and plastic wrap from unit.

3. Remove the unit from the shipping skid and set on a level surface. Note that the legs are not

installed from the factory.

4. Determine the location where the unit is to be installed. Be sure to allow sufficient access to the

unit for servicing and maintenance on all sides.

NOTE: The following instructions will vary depending on options ordered.

EQUIPMENT / TOOLS REQUIRED:

Forklift or Hoist

Lifting straps or chains

Socket wrenches

Wire nuts

Pipe wrench

3

OM600 MICRO AIR

INSTALLATION INSTRUCTIONS:

MACHINE MOUNT / FLOOR MOUNT:

1. Locate an installation site that will provide the following:

a. A solid structure capable of supporting the weight of the unit.

b. 3 ft of unobstructed exhaust space from the outlet of the unit.

c. Easy access to service panels and unit inlet.

d. A close location to the source of the oil mist unit to be captured.

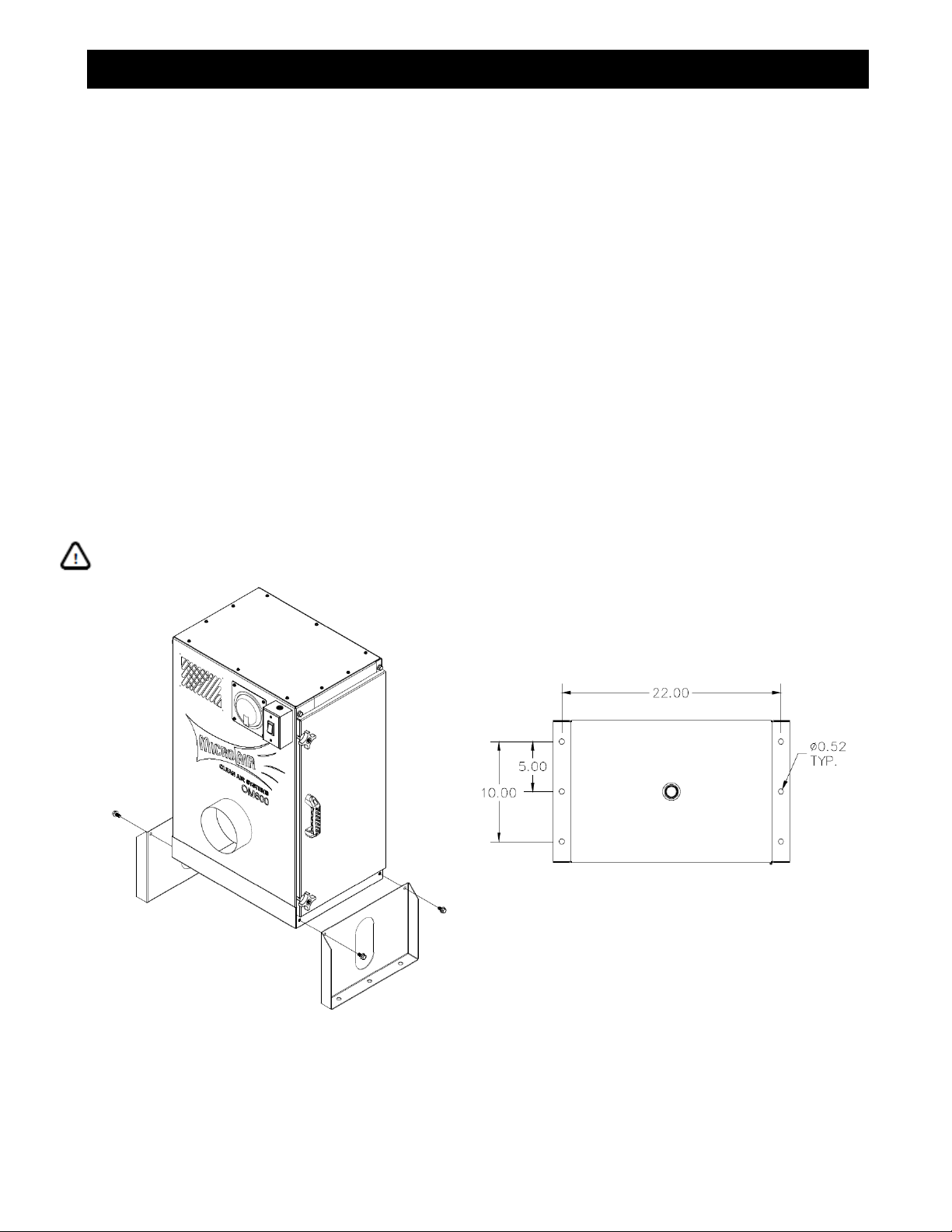

2. Remove the two 5/16-18 bolts from each side of the cabinet on the bottom side of the unit to

secure legs in place. Mount legs to cabinet using removed bolts (FIG. 1).

3. Mark location of the mounting holes on the surface where the OM600 is to be mounted. Note

hole pattern on bottom of cabinet (FIG. 2). Drill holes for a minimum of 3/8” mounting hardware.

4. Secure cabinet to machine using bolts, nuts and lock washers. If machine is mounted on the

floor, use concrete anchors. NOTE: Mounting hardware is not supplied by Micro Air.

5. Connect unit to oil mist source using 6” diameter duct. The duct may be flexible hose or formed

sheet metal. Maximum flow will be achieved with minimum bends in ductwork. The duct must be

sealed to contain oil that will get captured inside it. Use hose clamps or sheet metal screws to

attach duct to unit.

NOTE: There are 2 different set of legs, standard height, 10” tall, or long leg, 16” tall.

CAUTION: The size and weight of the OM600 unit requires two people or mechanical means

to lift and hold in place during mounting.

FIG. 1 FIG. 2

4

OM600 MICRO AIR

CEILING MOUNT:

1. Locate an installation site that will provide the following:

a. A solid structure capable of supporting the weight of the unit.

b. 3 ft of unobstructed exhaust space from the outlet of the unit.

c. Easy access to service panels and unit inlet.

d. A close location to the source of the oil mist unit to be captured.

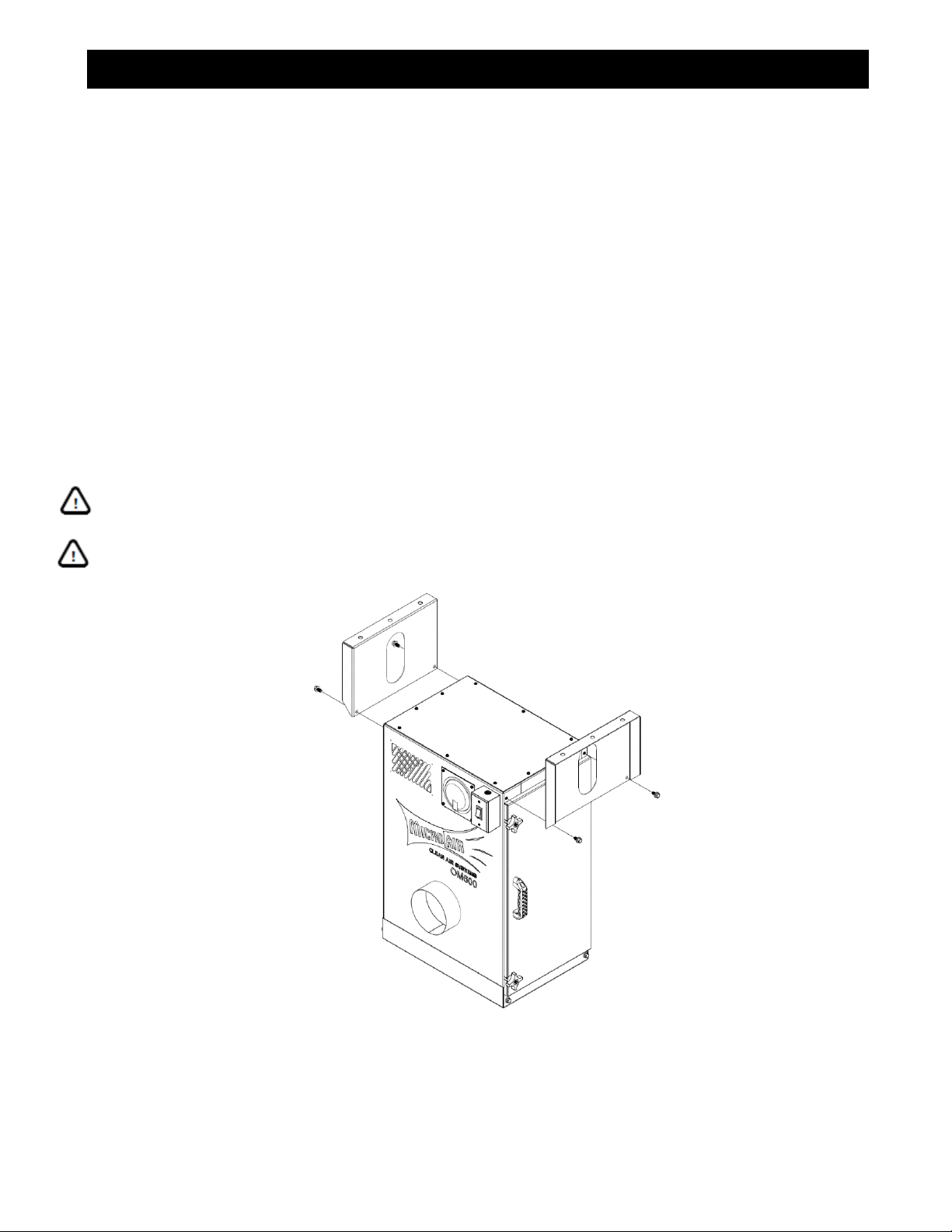

2. Remove the two 5/16-18 bolts from each side of the cabinet on the top side of the unit to secure

legs in place. Mount legs to cabinet using removed bolts (FIG. 3).

3. Firmly secure unit to 4 piece. Note hole pattern on bottom of legs (FIG. 2). Make sure unit is level

NOTE: Mounting hardware is not supplied by Micro Air.

4. Connect unit to oil mist source using 6” diameter duct. The duct may be flexible hose or formed

sheet metal. Maximum flow will be achieved with minimum bends in ductwork. The duct must be

sealed to contain oil that will get captured inside it. Use hose clamps or sheet metal screws to

attach duct to unit.

NOTE: There are 2 different set of legs, standard height, 10” tall, or long leg, 16” tall. Use

extended legs with HEPA after-filter when mounting from ceiling.

CAUTION: The size and weight of the OM600 unit requires two people or mechanical means

to lift and hold in place during mounting.

CAUTION: Use strong braided wire, threaded rod, or chain to support the cabinet. Hang from

ceiling / roof structural supports.

FIG. 3

5

OM600 MICRO AIR

OIL DRAINAGE:

If captured oil is to be discarded, make sure to follow local, state and national codes.

CAUTION: Always make sure that the unit is turned off before installing drain trap or

servicing the unit.

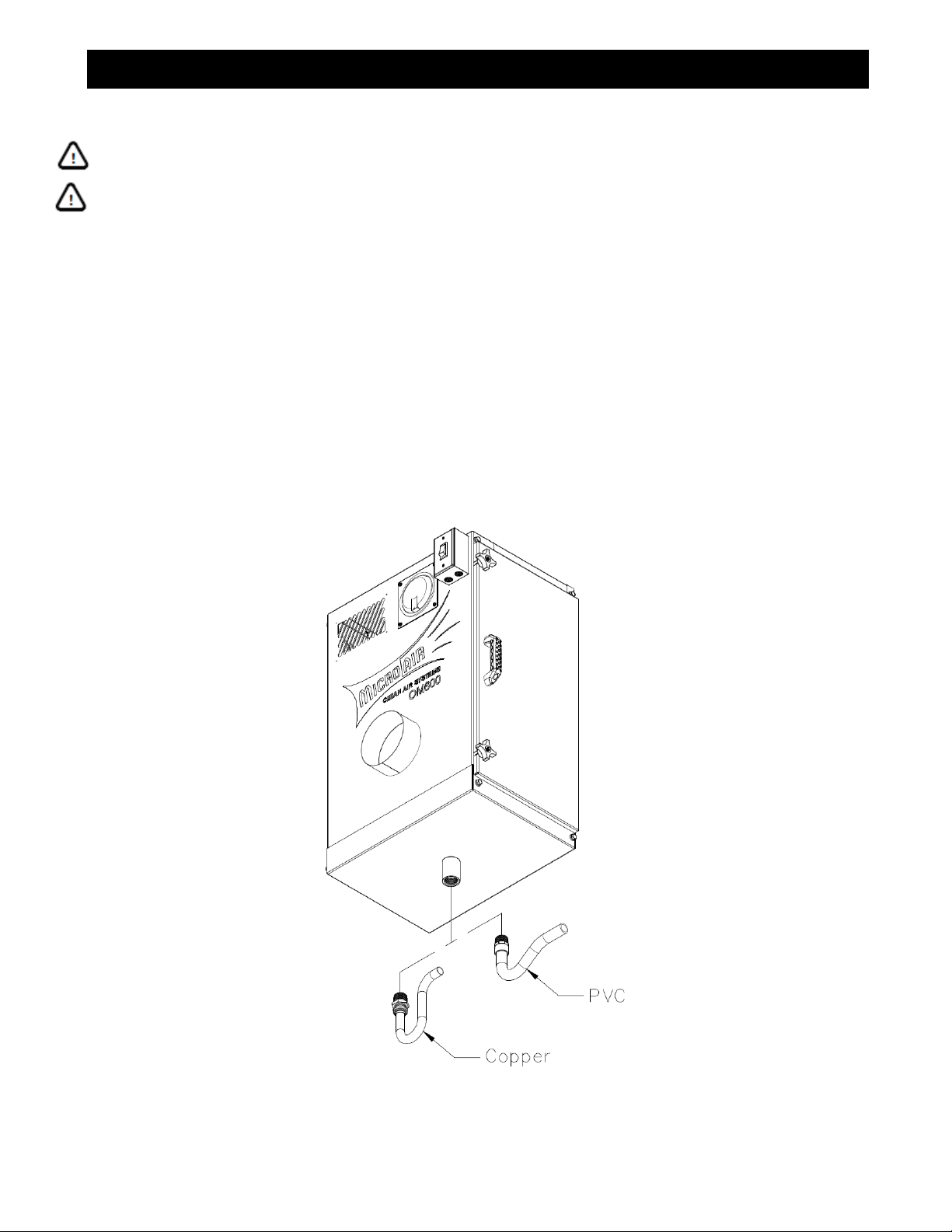

Provision for draining oil from unit is provided by a 1” NPT pipe coupling on the bottom of the unit.

Drainage should be piped to a central collection system. A shut-off valve or drain trap is required to

prevent air bypass through the drain opening. The cabinet may be equipped with either a copper

drain trap or a PVC drain trap (FIG. 4). The drain trap can also be retrofitted.

NOTE: If a shut-off valve is installed in the drain system, the unit must be emptied regularly to

prevent oil from overflowing into the intake duct.

1. For a Copper Trap:

a. The trap must be inserted into the adapter to a depth of 1-1/8”.

b. Use Teflon tape on adapter before installing on cabinet.

2. For a PVC Trap:

a. Use PVC primer and cement to install trap into adapter

b. Use Teflon tape on adapter before installing on cabinet.

FIG. 4

Table of contents