Micro Autonomations Fan Controller v3 User manual

Micro Autonomations LLC –Fan Controller v3

1

Document Rev 1.0

Fan Controller v3

Micro Autonomations LLC

www.ma-embedded.com

© 2014

Description

This controller was designed to control C-Class fans from Mercedes. It will work with any standalone

temperature sensor, or it may piggyback on any 5v EFI temperature sensor. Use, described in more

detail later, entails entering programming mode to set the turn on and 75% fan speed temperatures.

The controller will command the fan speed linearly between and above those two temperature set

points.

As a safety feature, if the controller does not detect a temperature sensor, it will turn the fan on; or, if

the active sensor wire gets grounded, it will turn the fan on.

Micro Autonomations LLC –Fan Controller v3

2

Document Rev 1.0

Contents

List of Figures ............................................................................................................................................ 2

Revision History ............................................................................................................................................ 2

Theory of Operation...................................................................................................................................... 3

Maximum Voltage Specifications.................................................................................................................. 4

Pin Diagram................................................................................................................................................... 4

Signal Descriptions........................................................................................................................................ 5

Onboard status LEDs..................................................................................................................................... 7

Wiring Diagrams –One Terminal Sensor ...................................................................................................... 8

Wiring Diagrams –Two Terminal Sensor.................................................................................................. 9

Wiring Diagrams –EFI Sensor ................................................................................................................. 10

Wiring the Fan.............................................................................................................................................11

Recommended sensors............................................................................................................................... 11

Compatibility...............................................................................................................................................12

Programming the controller ....................................................................................................................... 13

Error Modes ................................................................................................................................................16

Troubleshooting..........................................................................................................................................17

Mounting the controller ............................................................................................................................. 18

Warranty .....................................................................................................................................................19

List of Figures

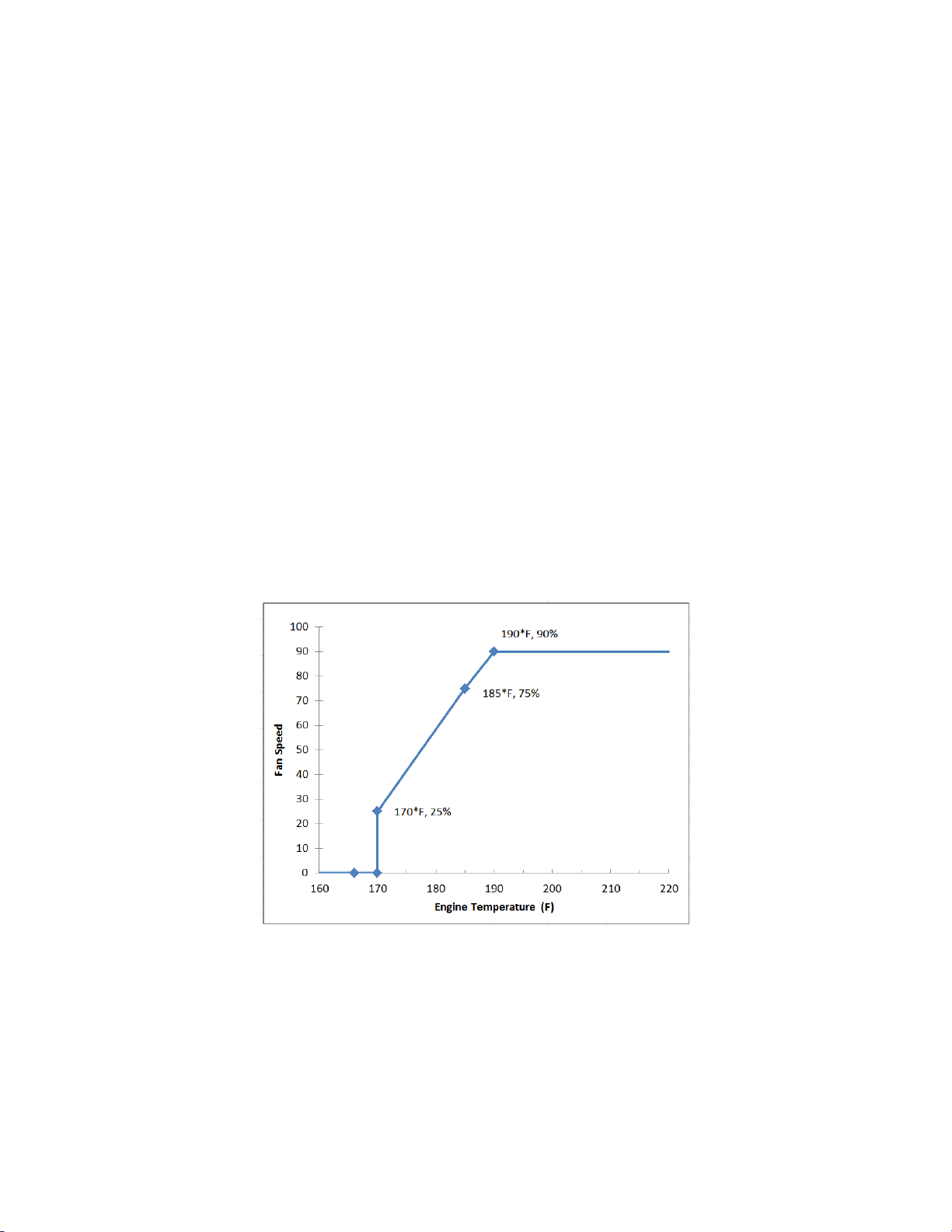

Figure 1 –Fan speed vs. Engine Temperature.............................................................................................. 3

Figure 2 - Pin Diagram................................................................................................................................... 4

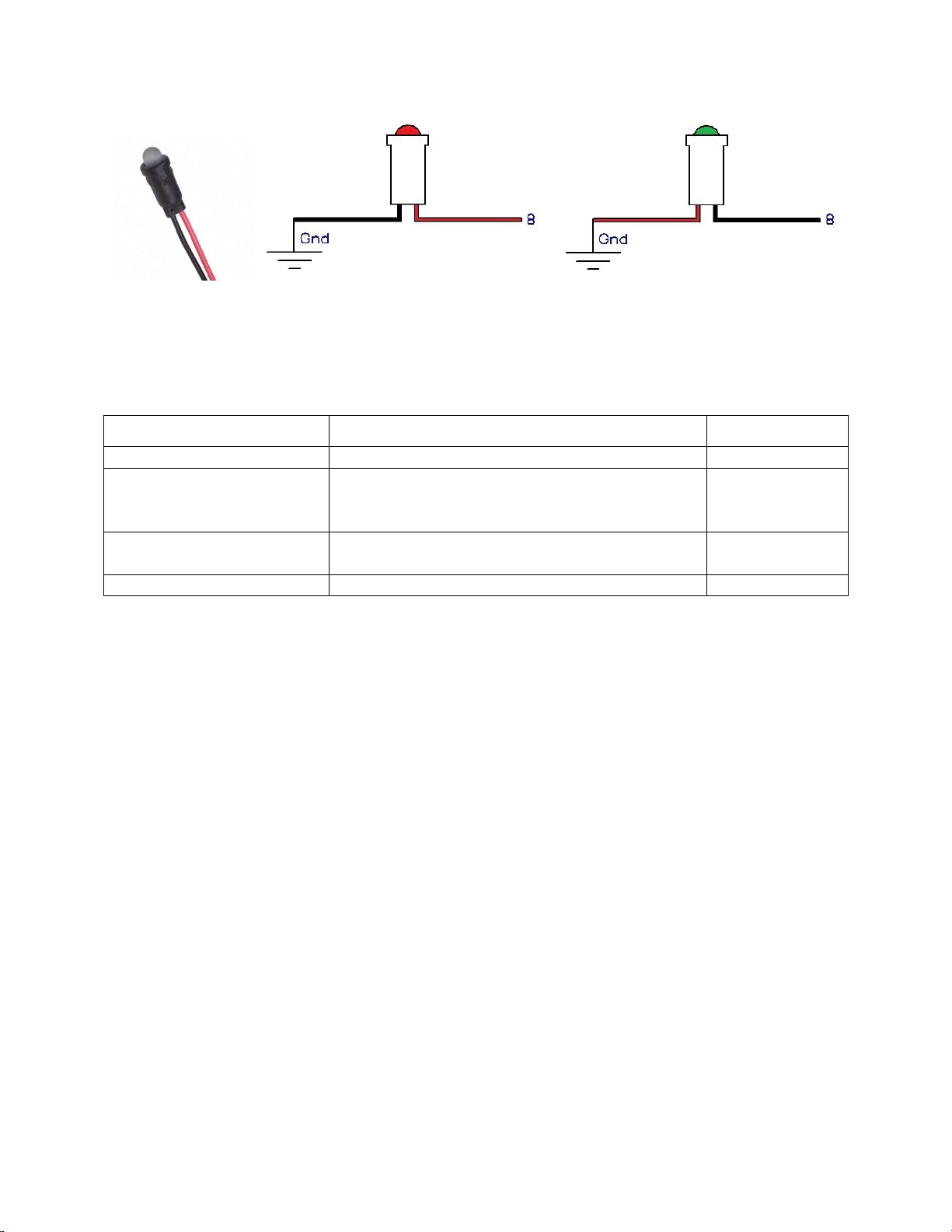

Figure 3 - Installing the Remote Status LED to operate either Red or Green............................................... 7

Figure 4 - Wiring with a one terminal temperature sensor installed ........................................................... 8

Figure 5 - Wiring with a two terminal temperature sensor installed ........................................................... 9

Figure 6 - Wiring using a 0-5v EFI temperature sensor............................................................................... 10

Figure 7 - Fan plug wiring............................................................................................................................ 11

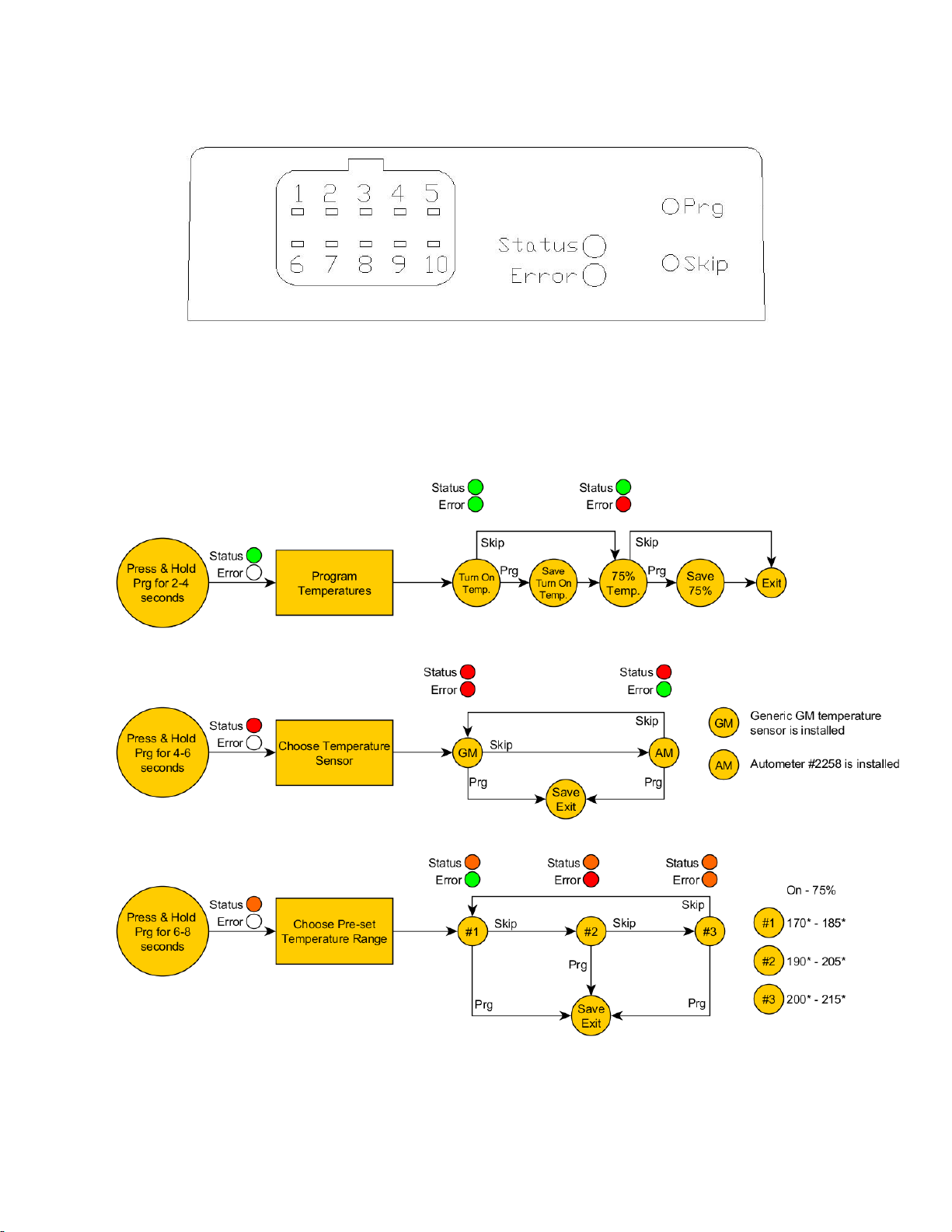

Figure 8 - Programming Flowchart ............................................................................................................. 13

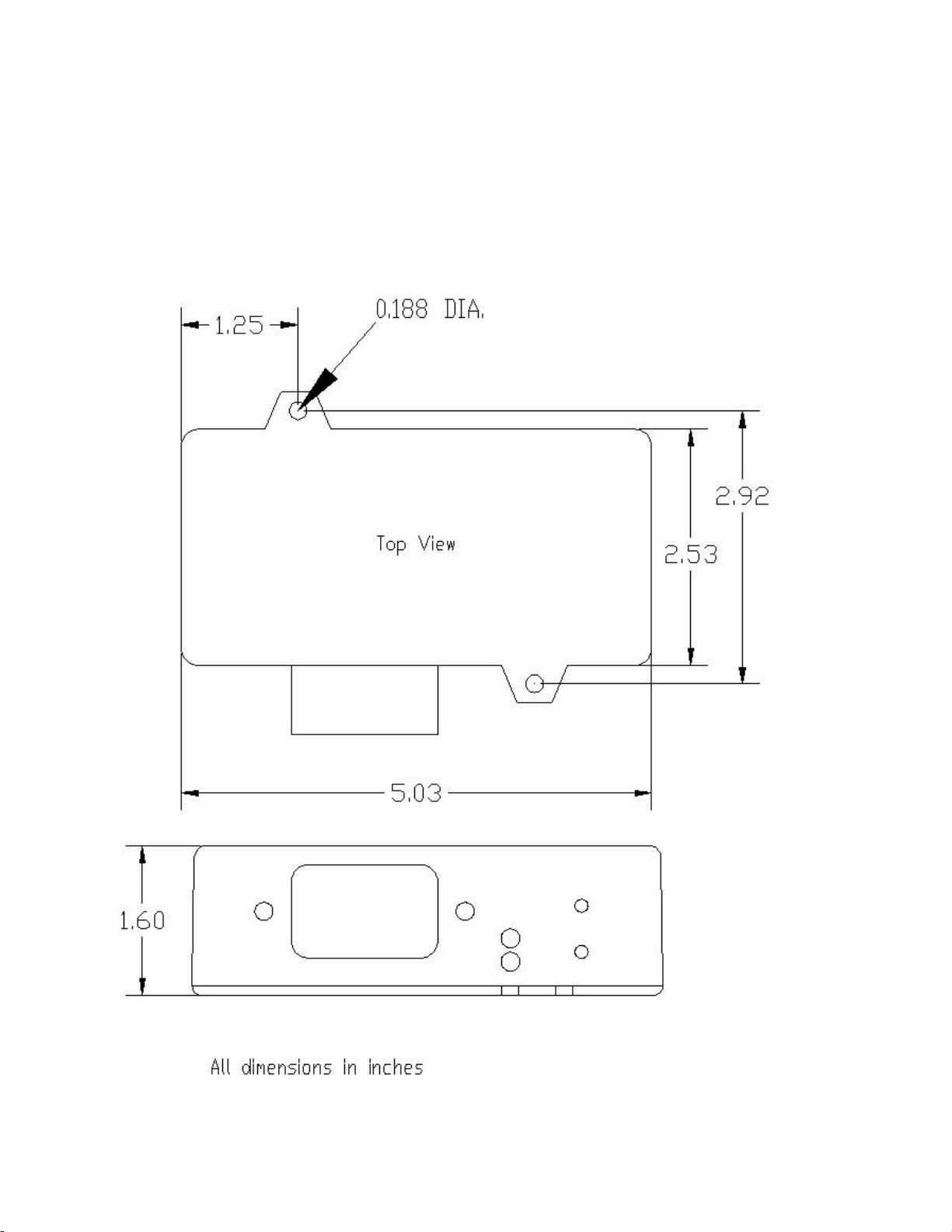

Figure 9 - Controller mounting dimensions ................................................................................................18

Revision History

Document version

Changes

Date

Rev 1.0

Initial Release

April 7, 2014

Micro Autonomations LLC –Fan Controller v3

3

Document Rev 1.0

Theory of Operation

The v3 controller has been designed to work in a variety of different systems. It can work with any

standalone temperature sensor, or it may piggyback off any 0-5v EFI temperature sensor. The controller

is able to detect and operate properly with both positive and negative going temperature sensors.

During programming, the controller detects whether the EFI or standalone temperature sensor input is

active. The controller is then able to use this information to aid in detecting various error modes.

During normal operation, the controller reads the current temperature at a rate of once a second. It

then checks several different factors in determining whether to turn the fan on or off, or what speed to

command the fan to operate at. The fan can operate at any speed between 25% and 90%.

After programming, the controller contains two temperature points: the turn on temperature, where

the fan will turn on to 25% speed, and the 75% temperature, where the fan will operate at 75% speed.

In the figure below, the controller has been programmed with pre-set temperature range #1, with a turn

on temperature of 170°F, and a 75% temperature of 185°F. As the engine temperature rises and

reaches the turn on point, the fan will turn on to 25%. As the engine temperature continues to rise, fan

speed will increase linearly until it reaches 75% speed at 185°. If the engine temperature still continues

to rise, fan speed will continue to increase until it reaches its full speed of 90% at 190°.

Figure 1 –Fan speed vs. Engine Temperature

As the engine temperature decreases, fan speed will also decrease, eventually reaching the 25% turn on

temperature. If the engine temperature continues to decrease below the turn on temperature, it will

maintain 25% fan speed until the engine temperature has dropped approximately 3-5°F below the turn

on temperature. Once the engine temperature is below this hysteresis point, the fan will turn off and

await the need to turn on again.

Micro Autonomations LLC –Fan Controller v3

4

Document Rev 1.0

Maximum Voltage Specifications

Maximum input voltage: 18v DC

Maximum voltage on AC input pin: 18v

Maximum voltage on pins 4 and 5: 5v

Do not apply external voltage to any pins other than 1, 3, 4, and 5.

We recommend using 18awg wire to install the controller. Nothing larger is necessary.

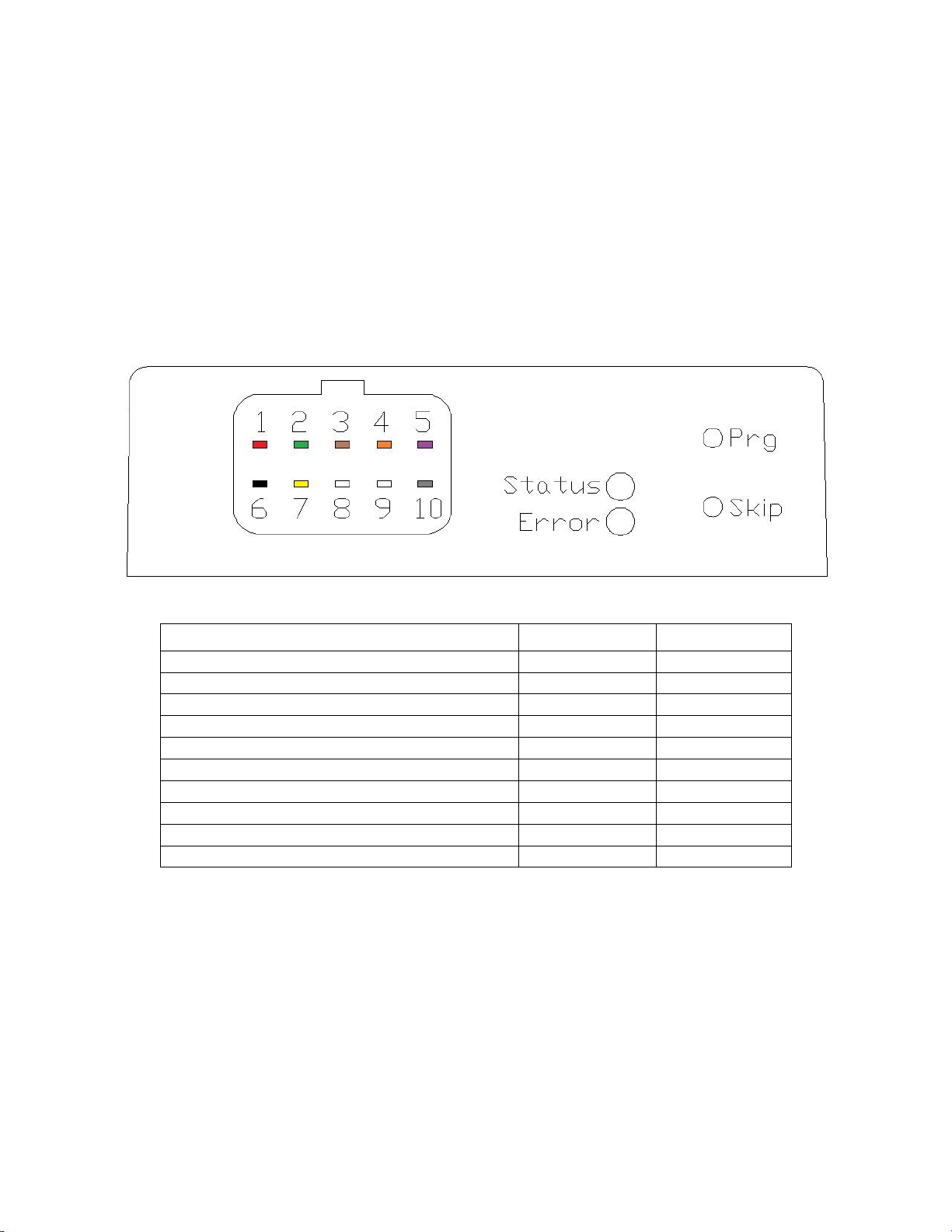

Pin Diagram

Figure 2 - Pin Diagram

Name

Color

Pin Number

Switched 12v Input

Red

1

Trigger Output

Green

2

Air Conditioning Input

Brown

3

Standalone Temperature Sensor (+)

Orange

4

EFI Temperature Sensor

Purple

5

Ground

Black

6

Speed Output

Yellow

7

Not Used

8

Standalone Temperature Sensor Return (GND)

White

9

Remote Status LED

Gray

10

Micro Autonomations LLC –Fan Controller v3

5

Document Rev 1.0

Signal Descriptions

Switched 12v –Red - 1

Main power input to the controller. This must be from a switched source so the controller is off when

the vehicle is off and during cranking. A 5 amp inline fuse is recommended.

Ground –Black - 6

Main ground for the controller. This must have a good connection to ground. This should be wired such

that it is near the main ground point near the battery. The engine ground strap, and the ground for the

fan, should also be located in the same spot.

Note:

Power and Ground to the fan are separate from the controller power and ground, and should include an

inline 50A fuse/breaker minimum

Trigger Output –Green - 2

This is the On/Off signal to the Mercedes Fan. Do not apply any external voltage or ground to this pin.

Do not reverse this wire with the Speed wire. This signal is required for the fan to operate.

Speed Output –Yellow - 7

This is the variable duty cycle speed signal to the Mercedes Fan. Do not apply any external voltage or

ground to this pin. Do not reverse this wire with the Trigger wire. This signal is required for the fan to

operate.

Air Conditioning Input –Brown - 3

This input indicates that the air conditioning (AC) system is operating, and that the fan should be turned

on. This pin may be either grounded, or tied to +12v by the air conditioning system, typically through

the trinary switch. This may also be controlled by a switch to manually turn the fan on. There is a 5

second delay after this signal is active before the fan turns on, and another 5 second delay before it is

turned off. When activated, the fan will operate at 50%. If the engine temperature requires it, fan

speed will automatically increase above 50%.

Note:

This input is optional, and may be left unused.

Standalone Temperature Sensor (+) –Orange - 4

Two Terminal Temperature Sensor –Either terminal may go on this pin. The other terminal

should go to Standalone Temperature Sensor Return (GND).

Single Terminal Temperature Sensor –The one terminal must go to this pin. The body of the

sensor must have a good connection to ground.

Micro Autonomations LLC –Fan Controller v3

6

Document Rev 1.0

Note:

Use this input only if there are no other EFI/gauge connections to the temperature sensor. Connecting

this input to an EFI/gauge signal could change the temperature reported to the EFI system, causing

significant issues.

Standalone Temperature Sensor Return (GND) –White - 9

This pin is internally connected to ground. When using a two terminal temperature sensor, connect one

terminal to this pin. Leave this pin unused when using a single terminal temperature sensor.

EFI Temperature Sensor –Purple - 5

This input may be connected to a temperature sensor connected to an EFI computer system. Its input

range is 0v-5v. Some aftermarket temperature gauges may use a 0-12v signal –verify this before

splicing this wire into the temperature sensor wire. Both positive or negative going sensors may be used

with the controller.

Note:

Use this input if you are piggybacking on the temperature sensor used by MegaSquirt, or any other EFI

system, even if it uses the standard GM sensor

Remote Status LED –Gray - 10

This output may drive the included LED which can be mounted remotely within view of the driver. The

LED is dual color, but only one color may be chosen during installation. Install the Red wire from the LED

to this pin for a Red color, and the other wire to ground. Or, reverse the colors for a Green status light.

The LED requires a ¼” hole to mount in, and has 6” long tinned wires.

The controller is designed to drive an LED with a forward voltage of 2v-2.2v, while supplying 12mA. Any

other suitable LED may be used if desired to match existing indicator lights on the dash. Contact me to

verify that your LED will work if you have any questions.

Mode

Action

Vehicle start

After doing a self-check, if no errors found, the Remote Status LED will be solid for 5 seconds

Fan turns On

When the fan turns on, the Remote Status LED will be solid for 5 seconds, then blink once

Fan turns Off

When the fan turns off, the Remote Status LED will be solid for 5 seconds, then blink twice

Air Cond. is

activated

When the fan is activated by the air conditioning signal, the Remote Status LED will be solid

for 5 seconds, then blink three times

Error

If there is an error, the Remote Status LED will blink in a pattern of 2, 3, or 4 blinks. See the

‘Error Mode’ section for explanation of each code.

Fan at full

speed

If the temperature requires the fan to operate at full speed, the Remote Status LED will turn

on steady until the fan speed drops below full speed

Micro Autonomations LLC –Fan Controller v3

7

Document Rev 1.0

Figure 3 - Installing the Remote Status LED to operate either Red or Green

Onboard status LEDs

There are two LEDs that show the current operating status of the controller.

Mode

Status LED

Error LED

Operating normally, fan off

Off

Green

Fan on

Green->Orange->Red gradient, depending on fan

speed

Green = 25%, Orange = 50%, Red = 90% (full speed)

Green

Error

Red

Blinking error

code

Programming

Various

Various

Micro Autonomations LLC –Fan Controller v3

8

Document Rev 1.0

Wiring Diagrams –One Terminal Sensor

Figure 4 - Wiring with a one terminal temperature sensor installed

Micro Autonomations LLC –Fan Controller v3

9

Document Rev 1.0

Wiring Diagrams –Two Terminal Sensor

Figure 5 - Wiring with a two terminal temperature sensor installed

Micro Autonomations LLC –Fan Controller v3

10

Document Rev 1.0

Wiring Diagrams –EFI Sensor

Figure 6 - Wiring using a 0-5v EFI temperature sensor

Micro Autonomations LLC –Fan Controller v3

11

Document Rev 1.0

Wiring the Fan

The picture below shows the wiring of the fan plug. Power to the fan should be supplied through a 50A

minimum fuse/breaker, connected directly to a main power distribution point.

Figure 7 - Fan plug wiring

Part numbers for the fan plug:

Description

Part Number

Quantity Required

Pin Housing/Bushing

220 545 03 29

1

Large Wire

000 540 36 05

2

Small Wire

000 540 38 05

2

Recommended sensors

Any generic GM type temperature sensor should work with the Controller. We have currently tested

with a TX3T two terminal temperature sensor. The associated pigtail for this sensor is Pico 5615PT. This

sensor has a 3/8” NPT thread.

Autometer #2258. This is a single terminal 1/8” NPT sensor. The sensor body must have a good

connection to ground. You may not be able to use sealant on the threads.

Micro Autonomations LLC –Fan Controller v3

12

Document Rev 1.0

Compatibility

Fan Controller v3 is known to work with the following fans/vehicles

Fan/Vehicle

Notes

2001 to 2007 C-Class Mercedes

600W, 800W

SLK32 AMG Fan

Speed wire to PWM terminal, Trigger to ‘15’.

100k pull-ups on old control lines to avoid CEL

Micro Autonomations LLC –Fan Controller v3

13

Document Rev 1.0

Programming the controller

During programming, the fan will turn off to allow the engine to warm up faster. Press and hold Prg

until the Status LED lights with the color of the sub-menu you wish to enter, then release Prg. Holding

Skip for 4 seconds will exit any programming menu and return the controller to normal operation.

Details about each programming sub-menu can be found on the next page. The Status and Error LEDs

will change colors to indicate the current location in the programming flowchart.

Figure 8 - Programming Flowchart

Micro Autonomations LLC –Fan Controller v3

14

Document Rev 1.0

Program Temperatures:

This mode allows the turn on temperature and 75% speed temperature points to be programmed.

Alternatively, the turn on or the 75% points may be programmed independently of each other, by

skipping one, and saving the other. The full speed temperature is then automatically calculated from

the turn on and 75% temperature points, whenever they are changed.

The controller will automatically detect whether the EFI or standalone temperature sensor is active.

When piggybacking on an EFI sensor, this is the only mode that should be used.

Note:

Choosing a sensor or selecting a pre-set range is disabled when the controller detects that the EFI input

is active

Use:

1. Press and hold Prg for 2 seconds until the Status LED turns green, then release Prg.The fan will

turn off to allow the engine warm up faster

2. When the engine reaches the desired turn on temperature, press Prg to save the new turn on

temperature

2a. Or, press Skip to keep the previously programmed turn on temperature, and continue to

change the 75% temperature

3. Continue idling the engine until it reaches the desired 75% temperature point, then press Prg

again to save the new 75% temperature

3a. Or, press Skip to keep the previously programmed 75% temperature point, and return to

normal operating mode

Programming will then finish, both the Status and Error LEDs will turn off for one second, then the

controller will return to normal operating mode.

Definitions:

Turn on temperature –This is the temperature where the fan will turn on to 25%. The fan will turn off

when the temperature has dropped approximately 3-5*F below the turn on temperature.

75% temperature point –This is the temperature where the fan will operate at 75% speed. When

manually choosing temperature points, after saving a new high point, the fan should immediately turn

on to 75%.

Example:

The engine is idled from cold and allowed to warm up. The turn on temperature is manually set at 180°,

and the 75% temperature is manually set once the engine reaches 200°. This will put the full speed

temperature at 206°, and the fan will turn off after the engine temperature drops below ~176°.

Micro Autonomations LLC –Fan Controller v3

15

Document Rev 1.0

Choose Temperature Sensor:

This option allows selection of the installed temperature sensor to enable the use of one of the pre-set

temperature ranges. If use of a pre-set temperature range is not desired, the controller may be

programmed by setting the turn on and 75% temperature points, and ignoring this option.

Use:

1. Press and hold Prg for 4 seconds, until the Status LED turns Red, then release Prg

2. Press Skip to switch between selecting the GM sensor, and the Autometer (AM) sensor

3. Press Prg to save the currently selected sensor

3a. Or, hold Skip for 4+ seconds to exit programming without changing the previously selected

sensor

By default, when a sensor is chosen, pre-set temperature range #1 will automatically be selected and

saved. The turn on and 75% temperature points may then be selected, or a different temperature range

may be selected.

Note:

Selecting a sensor that is not installed, then selecting a temperature range will result in unexpected fan

behavior

Choose Pre-set Temperature Range:

This mode allows selection of one of three pre-selected temperature ranges, assuming the installed

temperature sensor has already been selected.

The full speed temperature will be automatically calculated from the two temperature points.

Use:

1. Press and hold Prg for 6 seconds, until the Status LED turns Orange, then release Prg

2. Press Skip to switch between the three ranges

3. Press Prg to save the currently selected range

3a. Or, hold Skip for 4+ seconds to exit programming without changing the previously selected

range

Pre-set temperature ranges available for selection:

Range #

Turn On Temperature

75% Temperature

Full Speed Temperature

Error LED color

1

170°

185°

190°

Green

2

190°

205°

210°

Red

3

200°

215°

220°

Orange

Micro Autonomations LLC –Fan Controller v3

16

Document Rev 1.0

Reset all variables:

Press and hold both Prg and Skip together for 10 seconds, until both the Status and Error LEDs turn

Orange, and then release both of them. This will reset the saved temperature points, saved sensor, and

the saved temperature range.

Error Modes

When an error is detected, the Status LED on the controller, and the Remote Status LED (if installed), will

blink a repeating error code. This code consists of the following number of blinks in a row, followed by a

brief pause, then the code again. Only one code will be shown at a time. During each error mode, the

fan will be commanded to run at full speed.

Code

Problem

Solution

2

Current sensor does not match

the stored sensor

-The active temperature sensor (EFI or

standalone) is stored during programming. If

the detected sensor changes to the other

sensor, the fan will operate at full speed until

reprogrammed with the new sensor, or until

the previous sensor is hooked up again.

-The sensors are assumed to be missing if their

voltage is below 0.25v, or above 4.9v.

3

Neither sensor is installed, or

one/both are grounded

-If the active temperature sensor is shorted to

ground, or the wire breaks open, the fan will

operate at full speed.

-Verify that all temperature sensor wires are

connected with no shorts to ground.

-If piggybacking on an EFI sensor, verify that the

correct wire was tapped into. Often, one wire

will be ground, and the other will have the

variable voltage signal.

-For a single terminal sensor, verify a good

connection between the sensor body and

ground. Using tape or sealant on the threads

may prevent it from working properly.

4

Spread between turn on and

75% temperature points are too

close to each other

-The controller requires at least 0.1v between

the turn on and 75% temperature points. Try

re-programming with the turn on point lower,

and/or the 75% point higher.

Micro Autonomations LLC –Fan Controller v3

17

Document Rev 1.0

Troubleshooting

Problem

Solution

Fan does not turn on

-Verify that the fan has a constant 12v to it.

-Verify that the controller has power and that the LEDs are on.

-Verify the Speed and Trigger wiring between the fan and the

controller.

-Test the fan by disconnecting the controller, and jumping 12v to

the Trigger Output signal. After a moment the fan should turn on

and go to full speed.

Fan does not turn on with

air conditioning input

-Verify that the AC system is either grounding or providing 12v to

the air conditioning input.

-Wait 5 seconds for the fan to turn on.

After a short delay, the fan

turns on, and won’t turn off

-Check the Remote Status LED to see if it blinks 3 times after being

steady for 5 seconds. This indicates that the air conditioning

input is active.

-Disconnect the air conditioning input as a temporary test to verify

that the fan no longer turns on after a short delay.

-Verify that the air conditioning input is not being grounded or tied

to +12v, unless the system is commanding it.

Programmed values not

being saved

-Make sure you pressing the Prg button to save values, and not

the Skip button.

Micro Autonomations LLC –Fan Controller v3

18

Document Rev 1.0

Mounting the controller

We recommend using two #6 self-tapping screws to mount the controller, either in the engine bay, or

under the dash. Mark and predrill the holes, then mount the controller.

The controller is NOT sealed against water, so ensure that any locations will be free from water splashes.

Also, avoid any excessively hot areas under the hood.

Figure 9 - Controller mounting dimensions

Micro Autonomations LLC –Fan Controller v3

19

Document Rev 1.0

Warranty

Micro Autonomations LLC warrants this product to be free from defects in material and workmanship

for a period of twelve (12) months from the date of sale of the original purchaser. Micro Autonomations

LLC will repair this product free of charge if, in the judgment of Micro Autonomations LLC it has been

proven defective within the warranty period. The product should be returned, at the customer expense,

to the location of original purchase. This warranty does not cover any expenses incurred in the removal

and/or reinstallation of the product. Micro Autonomations LLC is limited in liability to the original sale

price of the product.

This warranty does not apply to any product damaged by improper installation, misuse, abuse, improper

line voltage, fire, flood, lightning, or other acts of God, or a product altered or repaired by anyone other

than Micro Autonomations LLC. This warranty is in lieu of other warranties, expressed or implied,

including any implied warranty of merchantability. No person is authorized to assume for Micro

Autonomations LLC any other liability concerning the sale of this product.

Table of contents

Popular Automobile Accessories manuals by other brands

DEFA

DEFA Solid 712800 installation manual

WilTec

WilTec XPOtool 63875 user manual

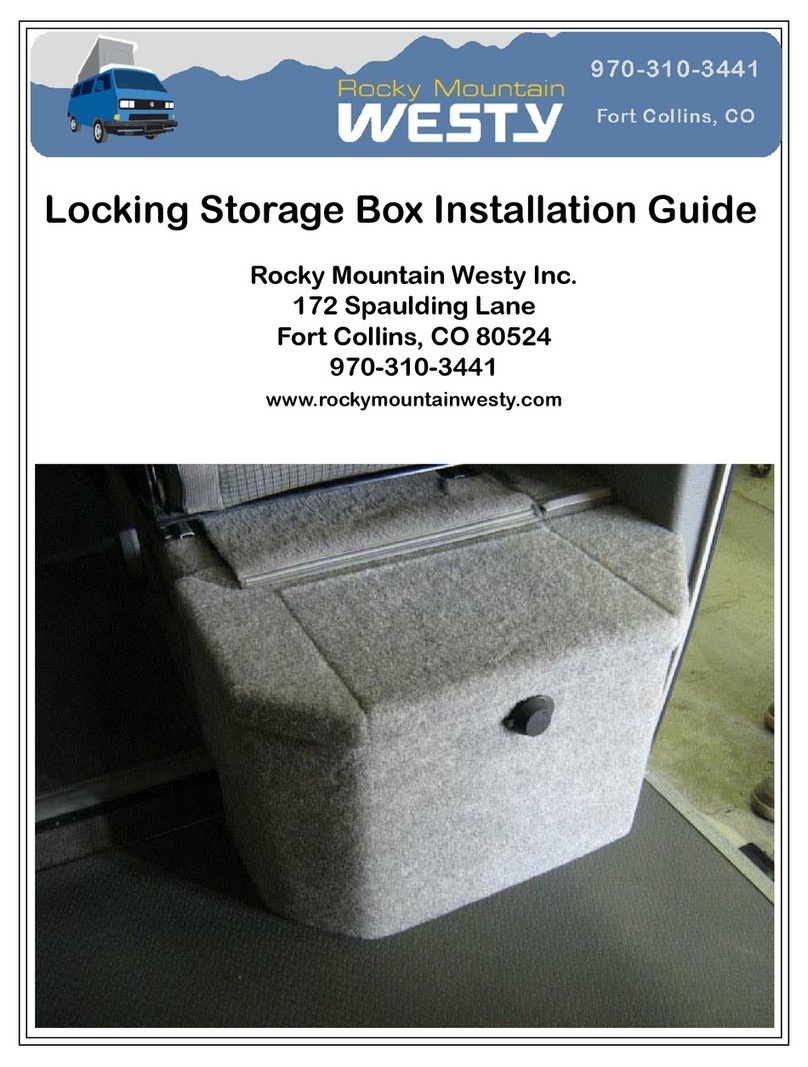

Rocky Mountain Westy

Rocky Mountain Westy Locking Storage Box installation guide

Saab

Saab 32 025 888 installation instructions

Fiamma

Fiamma 98655A910 Installation and usage instructions

Allen Sports

Allen Sports MT-1 instructions

Husky

Husky RAM 2500 Assembly, Installation, Operation and Maintenance Instructions

Axxess

Axxess AX-ALOC618 installation instructions

Whelen Engineering Company

Whelen Engineering Company G1MM90 installation guide

Conrad

Conrad 85 73 21 operating instructions

Pro-Lift

Pro-Lift Z-Creeper C-2040B Operating instructions & parts manual

Neidhart

Neidhart Performa Racing HMX 8 instruction manual