Micro Detectors CR0 Series User manual

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

1/16

!

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

2/16

!

!

SUMMARY

1.0!ABOUT)THIS)DOCUMENT)...............................................................................................................)3!

1.1!Function!of!this!manual!.....................................................................................................................!3!

1.1!Explanation!of!symbols!.....................................................................................................................!3!

2.0!SAFETY)AND)PROPER)USE)..............................................................................................................)3!

3.0!PRODUCT)DESCRIPTION).................................................................................................................)4!

3.1!Short!description!...............................................................................................................................!4!

3.2!Available!models!...............................................................................................................................!4!

3.3!Functions!description!........................................................................................................................!5!

3.3.1!Behavior!at!power-on!....................................................................................................................!5!

3.3.2!Teach!in!.........................................................................................................................................!6!

3.3.3!Beams!exclusion!menu!(blanking)!and!restore!factory!setting.!....................................................!7!

3.1!Electrical!drawing!..............................................................................................................................!8!

4.0!TECHNICAL)SPECIFICATIONS).........................................................................................................)10!

5.0!START-UP)INSTRUCTIONS).............................................................................................................)12!

5.1!Mechanical!mounting!of!CR!models!................................................................................................!12!

5.1!Electrical!installation!.......................................................................................................................!12!

5.2!Alignment!of!CR0!models!................................................................................................................!12!

5.5!Display!indications!and!diagnostics.!................................................................................................!13!

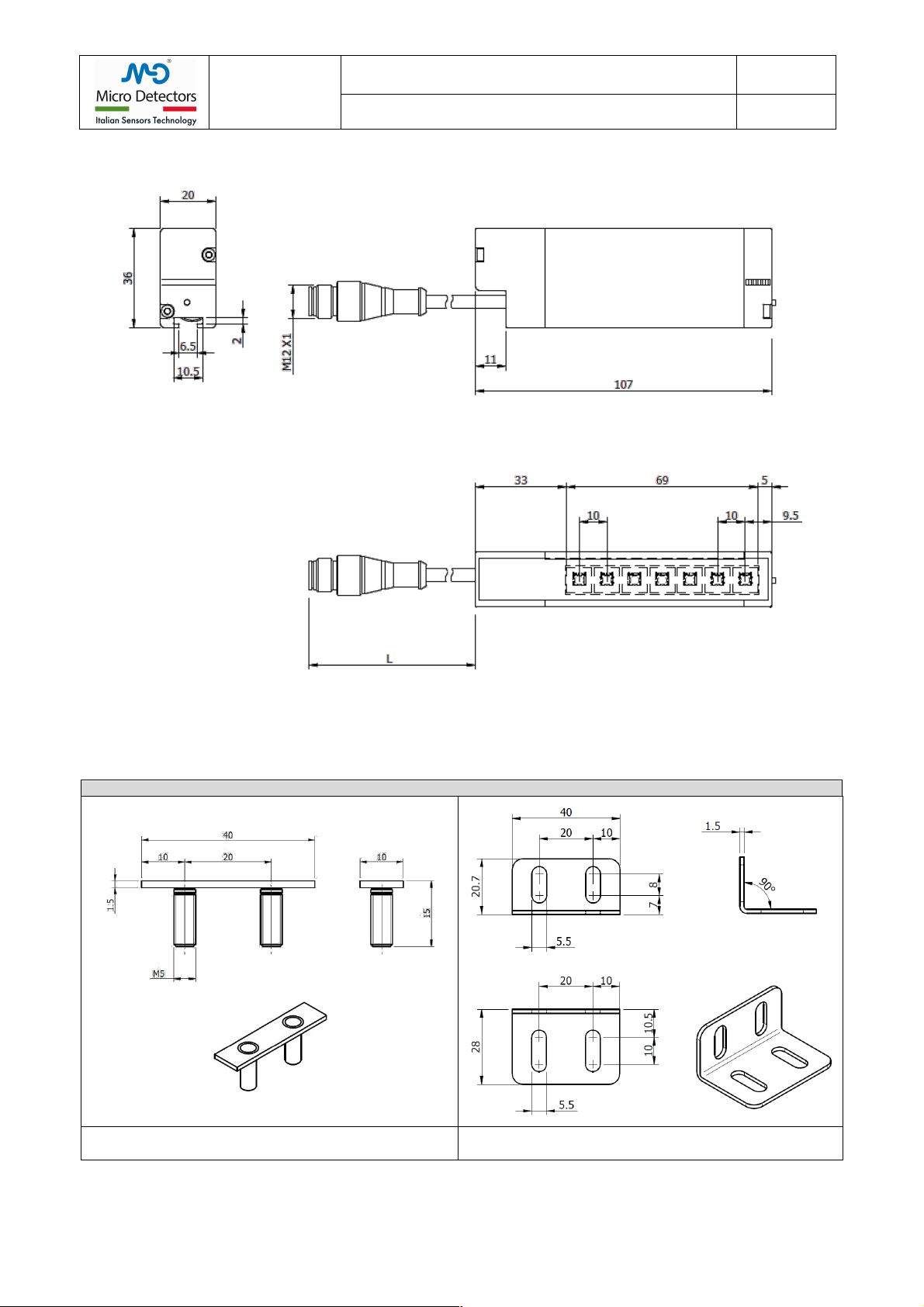

6.0!MECHANICAL)DIMENSIONS)OF)LIGHT)CURTAINS)AND)STANDARD)ACCESSORIES)..........................)14!

6.1!Mechanical!dimensions!!of!CR0*/10-010V!!reflex!curtains!.............................................................!14!

6.2!Standard!Mounting!accessories!......................................................................................................!14!

7.0!INSTALLATION).............................................................................................................................)15!

8.0!LIST)OF)AVAILABLE)ACCESSORIES).................................................................................................)15!

9.0!PACKAGE)CONTENT).....................................................................................................................)15!

10.0!CONTROL)OF)THE)INSTALLED)RETROREFLECTIVE)AREA)SENSOR)....................................................)16!

10.1!Purpose!of!controls.!........................................................................................................................!16!

10.2!Preliminary!controls!before!start-up!...............................................................................................!16!

10.3!Controls!device!efficiency!...............................................................................................................!16!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

3/16

!

!

1.0 ABOUT THIS DOCUMENT

Please read careful this document before installation, start-up, use and maintenance of CR0 light curtains. This manual contains detailed

instructions that must be carefully followed.

THIS MANUAL IS NOT IN THE ORIGINAL LANGUAGE

1.1 Function of this manual

This manual provides the user with the necessary instructions for safe and proper installation, electrical connection, start-up, use and

maintenance of CR0 retro-reflective area sensors.

1.1 Explanation of symbols

!

Warning

A warning sign indicates the presence of potential hazards.

It indicates procedures and behaviours which can be useful to prevent accidents.

Read and follow these instructions carefully.

!

Indication

It refers to indications that can help to achieve better performances.

!

Symbol

The symbol identifies optical devices that have the reflex function.

2.0 SAFETY AND PROPER USE

!

Warning

This it is NOT a protective device. Therefore, it should not be used to guarantee personnel safety.

!

Warning

CR0 works in DC and with a low voltage (the maximum value is 30VDC); the proper operation is guarantee only in

the range indicated in the technical data.

With voltages below 16VDC all outputs remain in the OFF state, with voltages in excess of 30VDC permanently, the

device may be damaged.

When the device is switched ON, outputs are inactive for a certain amount of time known as power on delay (see

the following documentation).

!

Warning

Some optics emit visible light that do not have dangerous levels; the device is classified RG0 (Exempt Group)

according to IEC 62471 standard: 2006-07.

!

!

Warning!

Please make sure that light curtains are used in proper environmental conditions.

Manual or automatic calibration must always be carried out aiming at the best possible alignment. More than one

calibration and alignment adjustment may be necessary to guarantee the best alignment.

Check any reflective surface next to the light beams which may influence them.

Check any transparent or similar panels which may change the beam angle of the area sensor.

Prevent the area sensor 's optical window from getting scratched or tarnished.

Do not expose the area sensor to strong natural or artificial light sources, including stroboscopic light.

Do not expose the area sensor directly to optical beams projected by other optical devices.

Ensure that the ambient temperature does not exceed the stated limits.

Keep in mind that smoke, vapour, liquids and powders may alter transparency of air or dirty the optical window.

Dispose of unusable or irreparable devices always in accordance with national regulations regarding waste disposal.

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

4/16

!

!

3.0 PRODUCT DESCRIPTION

3.1 Short description

CR0 light curtains are photoelectric devices built according to the IEC 60497-5-2 norms and they must not be considered as safety

devices. Therefore they must not be used to guarantee operators’ safety nor to protect users on dangerous machines. They must

rather be used to detect objects reducing or obscuring the intensity of light beams that returns from the reflector.

The housing is in aluminium painted in blue RAL5002, size 20x36mm, (20 mm refers to the front side). A groove on the back allows

connection with T-shaped components. The top side is in and the bottom side is in black PBT, the optical window is in PMMA.

Protection degree is IP67.

In all models of the series, CR0 have two LEDs indicators: Red and Green in combination, indicate the states of the sensor

(alignment, state optics and fault indication), they are arranged at the top of the curtain, the light is intense and diffused in all

directions, this ensures a great visibility in all conditions.

All models in the CR0 have an optic composed of a continuous array of 9x9mm lenses with a step of 10mm, CR0 have seven

lenses. The optical window has a height of 69mm; the total height of the curtain is 107mm.

Emitter and Receiver are alternate with the following sequence is: E1, R1, E2, R2, E3, R3, E4 with reference the cable side. This

allows to realize a continuous succession of six pairs of reflex elements; the emitted light is polarized and has a wave length of

617nm.

The working distance is 0.2...4.5m with reflector RL106Gand lower with smaller reflectors, the best detection capability is 6mm.

All models of CR0 series have a teach button (inductive teach could also be available) in the top of the curtain dedicated to the

activation of menu functions: two levels of Teach-in and Blanking.

The Teach_S(standard teach) select an excess gain equal to 2 times the threshold, the Teach_F (fine teach) select an excess gain

equal to 1.2 times the threshold; the latter should be used only if the system and the environment in which the product is used are

clean and with an high mechanical stability.

The sensor does not use automatic systems of signal tracking, but its repeatability is based on a sophisticated control of thermal drift.

The Blanking of the beams, allows gradually eliminate pairs of beams; the active couples (E+R) may range from a maximum of six to

a minimum of one.

This sensors has a standard output with M12 male flying connector (240 mm pigtail).

The CR0 models have four interface circuits which can be combined in different ways depending on the model and the number of

output cables:

a) Supply 15...30V

b) IO_Link output (C/Q), PNP/NPN/PUSH- PULL

c) Auxiliary output (Q): PNP/NPN/PUSH- PULL

d) Auxiliary input, output mode selection LIGHT/DARK (NC/NO) or more.

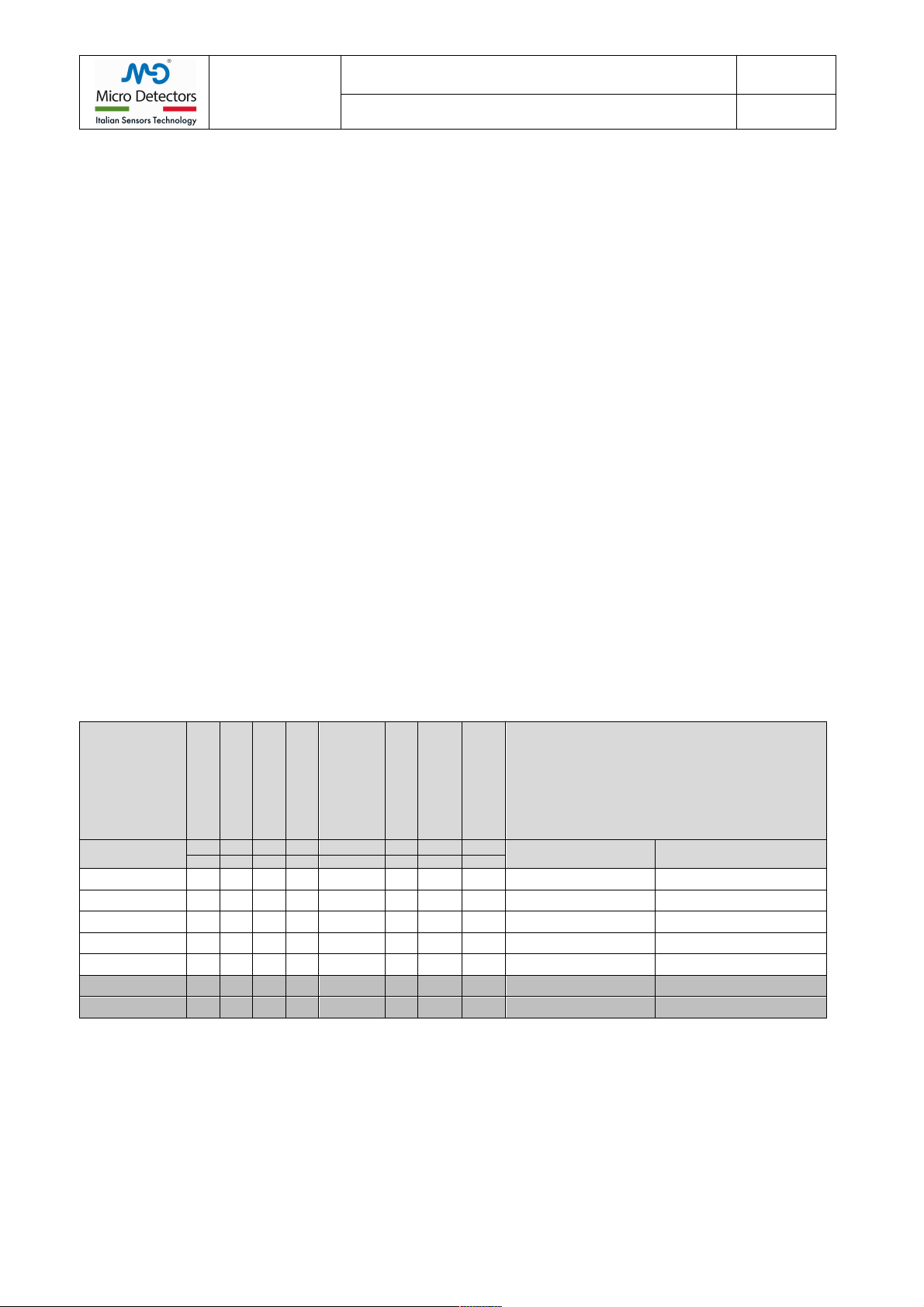

3.2 Available models

MODEL

OPTICAL PITCH

OPTICAL HEIGHT

BODY HEIGTH

OPTICS

SENSING

RANGE

RESPONSE

TIME

CONNECTOR

POLES

Interface

CODE ARTICLE

P

h

H

Sn

Tr

INPUTS

OUTPUTS

mm

mm

mm

N°

m

ms

No

CR0/0I-1V

10

69

109

7

0.2... 4.5

1.5

M12

4

None

b) IO_Link

CR0/0B-1V

10

69

109

7

0.2... 4.5

1.5

M12

5

d) NC/NO

b) PNP; c) NPN

CR0/0T-1V

10

69

109

7

0.2... 4.5

1.5

M12

4

d) NC/NO

b) Push-Pull

CR0/BP-1V

10

69

109

7

0.2... 4.5

1.5

M12

4

None

b) PNP-NO; c) PNP-NC

CR0/BN-1V

10

69

109

7

0.2... 4.5

1.5

M12

4

None

b) NPN-NO; c) NPN-NC

CR0/0P-1V

10

69

109

7

0.2... 4.5

1.5

M12

4

d) NC/NO

c) PNP

CR0/0N-1V

10

69

109

7

0.2... 4.5

1.5

M12

4

d) NC/NO

c) NPN

Tab.:1

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

5/16

!

!

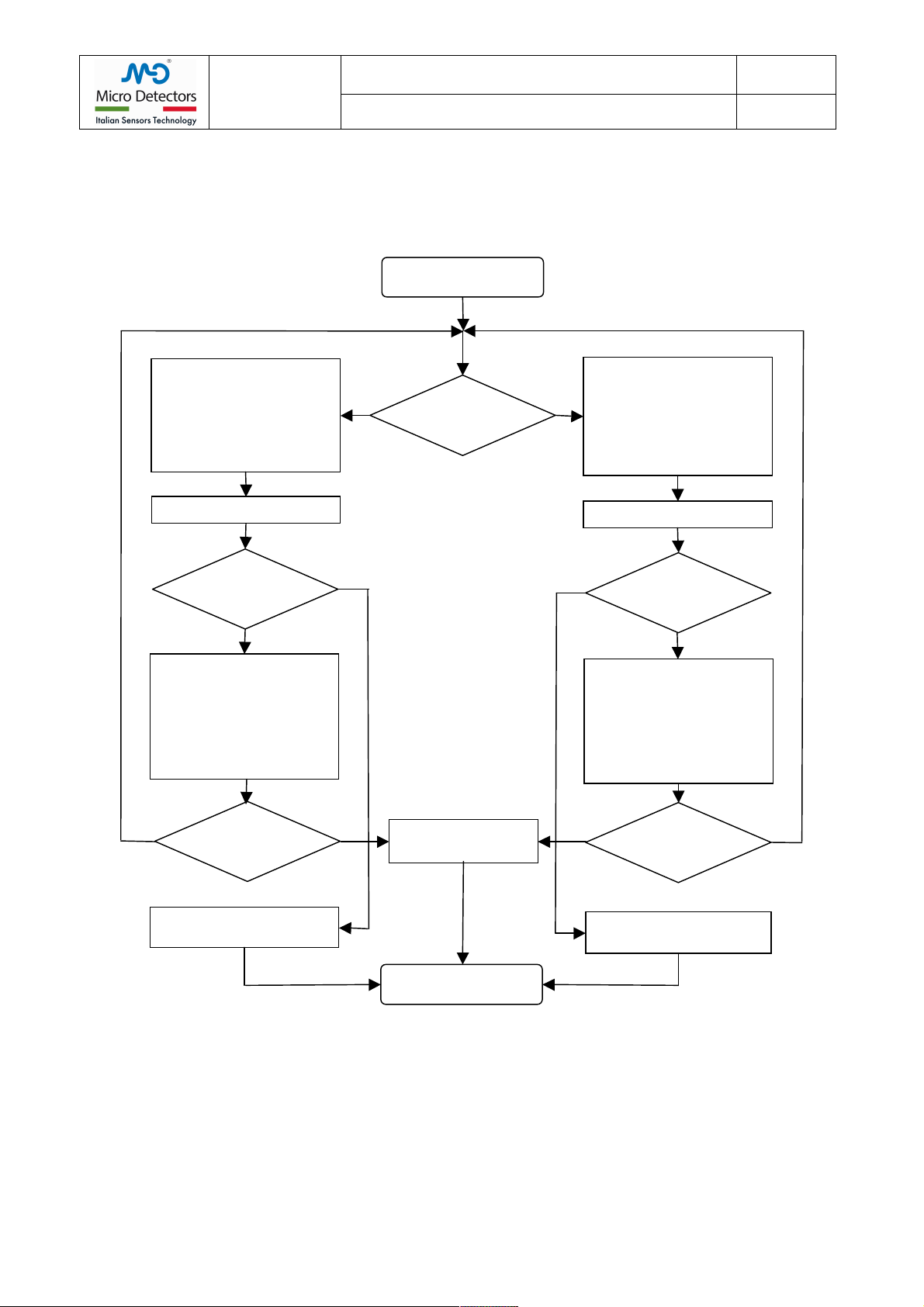

3.3 Functions description

3.3.1 Behavior at power-on

!

!

Power ON

All LEDs OFF!

Voltage <5V

5V<Votage <15V

!

Memory error

!

Green LED flashing

Red LED flashing

Flashing

!

See:

Restore factory setting

and

optic exclusion menu

Y

N

Y

Y

N

N

Normal operation

State

Green LED ON;

Red LED OFF.

Outputs state

as programmed.

Green LED ON; the Red LED

lights, with intensity inversely

proportional to the signal.

Outputs state as programmed.

Light

Dark

The Red LED lights;

Green LED flashing!

Non-recoverable

optical failure

Non-recoverable

optical failure

N

Y

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

6/16

!

!

3.3.2Teach in

!

!

Normal operation

Teach_in

Press the Teach button;

the Red LED lights;

the Green LED goes out;

Release the button

within 3s (before the Red

LED goes out and

the Green LED lights up).

The sensor starts a Teach_S

The alignment is right

G

F

Y

N

Press the Teach button;

The Red LED lights;

The Green LED goes out;

Release the button

3s elapsed (after the Red

LED turns OFF and

the Green LED lights up).

The Green LED flashes

proportional to the signal;

The Red LED flashes in

inverse proportion to the

alignment goodness.

Search for the best

alignment.

Fix the sensor

The sensor starts a Teach_F

The alignment is right

N

The Green LED flashes

proportional to the signal;

The Red LED flashes in

inverse proportion to the

alignment goodness.

Search for the best

alignment.

Fix the sensor

Y

Normal operation

Excess gain= 1.5

for current range

Excess gain= 1.2

for current range

Did you spend 2

minute?!

Did you spend 2

minute?

The previous set up is

taken!

Y

Y

N

N

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

7/16

!

!

3.3.3 Beams exclusion menu (blanking) and restore factory setting.

!

!

!

!

!

!

!

Power OFF

The Red LED lights;

Release Teach-in button.

The Red LED goes out.

Keep the Teach-in

button pressed

Power ON

Press the Teach button;

the Green LED lights;

Release the button

3s elapsed (after the Green

LED turns OFF and

the Red LED lights up).

Maximum ExG selected;

(Teach-in is recommended)

Beams exclusion menu:

All Red emitter (4) lights;

Emitters that contribute to a

single beam blink (E1, E4).

Emitters that contribute to a

couple of beams are steady.

Save

configuration ?

Y

N

N

Normal operation

Press the Teach button;

the Green LED lights;

Release the button

within 3s (before the Green

LED goes out and

the Red LED lights up).

A further beam has been

excluded

Is it the last beam?

Y

Restore factory

setting

With all optics

active

Normal operation

Press and leave the Teach-in button

pressed;

the Red LED lights up,

wait 3s for the

Green LED lights, Red LED goes out

wait 3s for the

Red LED lights, Green LED goes out

Release the Teach-in.

Red LED goes out

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

8/16

!

!

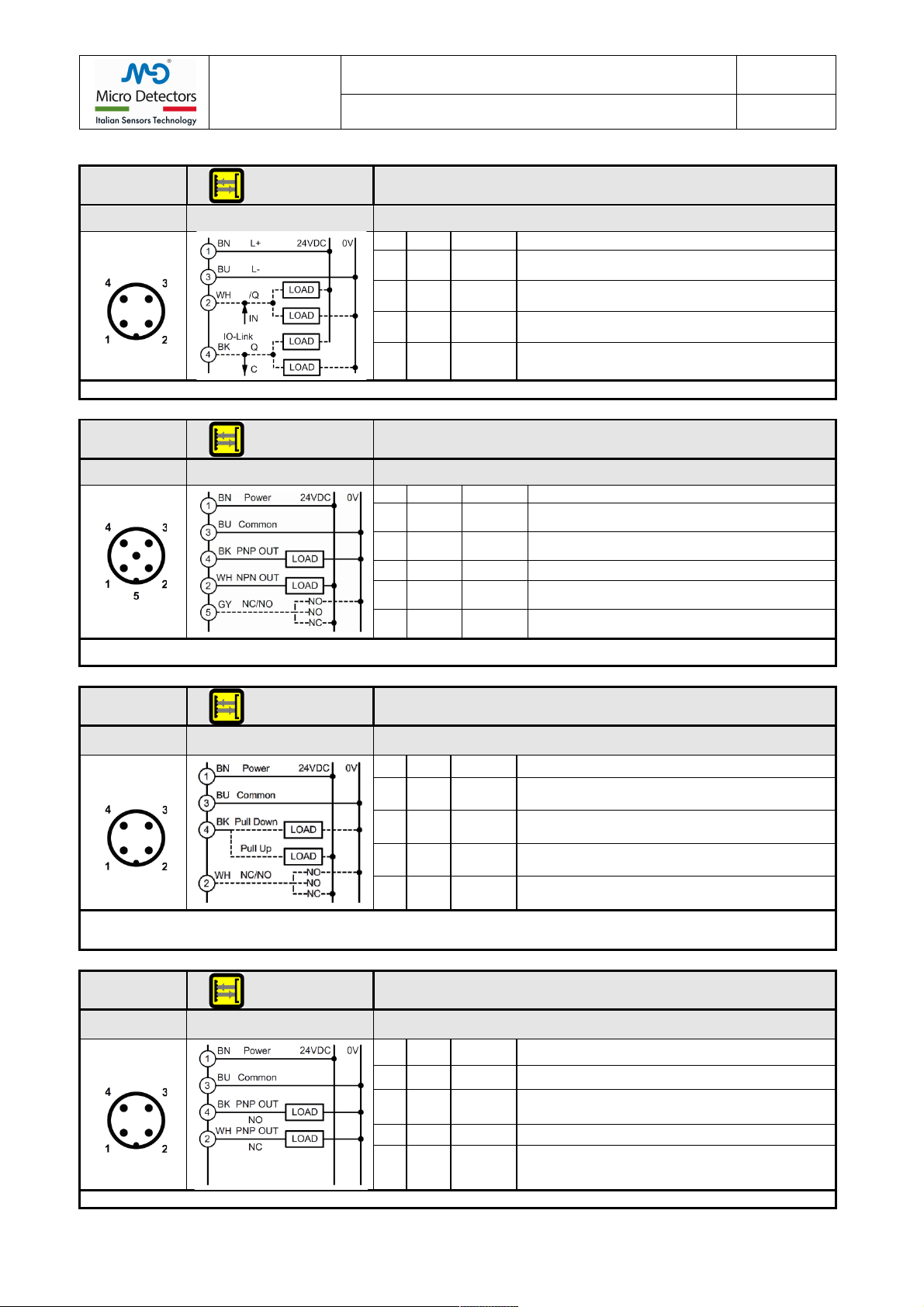

3.1 Electrical drawing

SERIE CR0

REFLEX

CURTAIN

CR0/0I MODEL

IO-Link interface

M12, 4 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

L+

Power supply input from 16 to 30V

2

WH

In/Q

Multifunction I / O

3

BU

L-

Supply voltage reference

4

BK

C/Q

IO-Link interface

NOTE:

Pin 2 is a multifuncion programmable I/O

Tab.:2

SERIE CR0

REFLEX

CURTAIN

CR0/0B MODEL

PNP and NPN outputs, NC/NO selectable

M12, 5 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

24VDC

Power supply input from 16 to 30V.

2

WH

NPN Out

Apply a load connected at the positive, maximum

current 100mA

3

BU

0V

Supply voltage reference

4

BK

PNP Out

Apply a load connected to the common, maximum

current 100mA.

5

GY or

YE/GR

NC/NO

Input for outputs logic selection.

NOTE:

The NC/NO input is read only when the sensor is switched ON. If it is left open or permanently wired to the common, it selects the output as

DARK ON. If it is connected to the positive, it selects the output as LIGHT ON. Enabling the button it is possible to execute the teach.

Tab.:3

SERIE CR0

REFLEX

CURTAIN

CR0/0T MODEL

Push Pull output, NC/NO selectable

M12, 4 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

24VDC

Power supply input from 16 to 30V.

2

WH

NC/NO

Input for outputs logic selection.

3

BU

0V

Supply voltage reference.

4

BK

Push Pull

Out

Apply a Pull up or a Pull down load

NOTE:

The NC/NO input is read only when the sensor is switched ON. If it is left open or permanently wired to the common the Push driver is Dark

switching and the Pull driver is Light switching. If it is connected to the positive the Push driver is Light switching and the Pull driver is Dark

switching.

Tab.:4

SERIE CR0

REFLEX

CURTAIN

CR0/BP MODEL

PNP outputs NO and NC

M12, 4 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

24VDC

Power supply input from 16 to 30V.

2

WH

PNP Out

NC

Apply a load connected to the common, maximum

current 100mA.

3

BU

0V

Supply voltage reference

4

BK

PNP Out

NO

Apply a load connected to the common, maximum

current 100mA.

NOTE:

Enabling the button it is possible to execute the teach.

Tab.:5

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

9/16

!

!

SERIE CR0

REFLEX

CURTAIN

CR0/BN MODEL

NPN outputs NO and NC

M12, 4 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

24VDC

Power supply input from 16 to 30V.

2

WH

NPN Out

NC

Apply a load connected to the positive, maximum

current 100mA.

3

BU

0V

Supply voltage reference

4

BK

NPN Out

NO

Apply a load connected to the positive, maximum

current 100mA.

NOTA:

Enabling the button it is possible to execute the teach.

Tab.:6

SERIE CR0

REFLEX

CURTAIN

CR0/0P MODEL

PNP output, NC/NO selectable

M12, 4 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

24VDC

Power supply input from 16 to 30V.

2

WH

NC/NO

Input for outputs logic selection.

3

BU

0V

Supply voltage reference.

4

BK

PNP Out

Apply a load connected to the common, maximum

current 100mA.

NOTE:

The NC/NO input is read only when the sensor is switched ON. If it is left open or permanently wired to the common, it selects the output as

DARK ON. If it is connected to the positive, it selects the output as LIGHT ON.

Tab.:7

SERIE CR0

REFLEX

CURTAIN

CR0/0N MODEL

NPN output, NC/NO selectable

M12, 4 poles

Male connector

Wiring

Connector

Pin

Color

Signal

Description

1

BN

24VDC

Power supply input from 16 to 30V.

2

WH

NC/NO

Input for outputs logic selection.

3

BU

0V

Supply voltage reference.

4

BK

NPN Out

Apply a load connected to the positive, maximum

current 100mA.

NOTE:

The NC/NO input is read only when the sensor is switched ON. If it is left open or permanently wired to the common, it selects the output as

DARK ON. If it is connected to the positive, it selects the output as LIGHT ON.

Tab.:8

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

10/16

!

4.0 TECHNICAL SPECIFICATIONS

OPTICAL BEHAVIOR

PARAMETERS

Min.

Nom.

Max.

NOTE

Standard detection range1

m

0

5.0

Depend on reflector type (see Tab.: 10)

Standard reflector range (excess gain≥1.5)1

m

0.20

5.0

Standard displacement between sensor and reflector (see Tab.: 10)

Reflector range with excess gain = 11

m

0.15

5.5

Min/Max displacement between sensor and reflector (see Tab.: 10)

Aperture angle

°

2.5

Detection capability

mm

6

Diameter of a testing rod normal to the area (see Tab.: 11)

Wavelength LEDs

nm

617

Red/Orange color, vertically polarized

Margin for a Teach_S

1.5

Ratio between taught Light level and Light threshold

Hysteresis for a Teach_S

%

15

Ratio between Light threshold level and Dark threshold

Margin for a Teach_F

1.2

Ratio between taught Light level and Light threshold

Hysteresis for Teach F

%

6

Ratio between Light threshold level and Dark threshold

Immunity for artificial light, direct

Klux

50

Incandescent lamp

Immunity for artificial light, direct

Klux

5

Fluorescent lamp

Tab.:9

NOTEs:

1)

It depends on the dimension and type of reflector, too close to the sensor the granularity of the reflector determine instability with

vibration. Fine granularity increase minimum, area and type determine maximum. The best active area of the reflector are 20x80mm.

The margin indicated refers to the factory setting; when the sensor is taught (G or F), it will have a specific margin, if available.

Tab.:10

RANGE WITH SPECIFIC REFLECTORS

Reflectors

ExG

1

ExG

≥1.5

ExG

1

Reflector

active

area

(mm)

Reflector

size

(mm)

RL106G

m

0.15

0.2...4.5

5.5

36 x 136

42 x 182

RL135

m

0.25

0.3...4

5

16 x 72

20 x 100

RL100DCR0

m

0.25

0.3...2.5

3

40 x 150

40 x 150

Tab.:11

DETECTION CAPABILITY

Range

(m)

Ø

Teach F

Teach G

Near

Far

Near

Far

0.5

mm

3

5

5

10

1

mm

2.5

4

5

14

1.5

mm

2.5

5

5

16

2

mm

2

6

5

18

2.5

mm

2

7

5

22

3

mm

2.5

10

5

30

4

mm

3

10

5

30

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

11/16

!

ELECTRICAL MECHANICAL BEHAVIOR

PARAMETERS

Min.

Nom.

Max.

NOTES

Power supply

Operatin voltage

V

16

24

30

From PELV power supply according to EN 60204-1 Chap.6.4

Ripple

V

1.2

Supply voltage must stay within the stated limits

No load supply current

mA

50

100

Maximum current with the minimum voltage range (constant power)

Digital Outputs

Output type (model 0I)

C/Q

IO-Link, COM3, 2ms cycle, 4 wires, pin 2 as output or input

Output type (model 0B)

1xPNP, 1xNPN

Completely protected, selectable NO or NC, 5 wires

Output type (model 0T)

1xPush-Pull

Completely protected, selectable NO o NC, 4 wires

Output type (model BP)

1xPNP NO; 1xPNP NC

Completely protected, 4 wires

Output type (model BN)

1xNPN NO, 1xNPN NC

Completely protected, 4 wires

Output type (model 0P)

1xPNP

Completely protected, selectable NO o NC, 4 wires

Output type (model 0N)

1xNPN

Completely protected, selectable NO o NC, 4 wires

Current

mA

100

Higher values are interpreted as overload or short circuit

Voltage drop @100mA

V

1.5

3

Reduction in output voltage compared to the supply voltage

Resistive load (at 24V)

Ω

280

Lower values are interpreted as short circuit

Leakage current, models0I, 0B, BP, BN

µA

100

Value at which the OFF state of the load must be guaranteed

Leakage current, models 0T, 0P, 0N

µA

10

Value at which the OFF state of the load must be guaranteed

Tolerated capacitive load

µF

0.7

Higher values can be interpreted as short circuit.

Switching time ON

µs

0.05

With load of 220/1000

Switching time OFF

µs

2

10

With load of 220/1000

Response times

Time delay before availability

ms

300

All outputs are in the OFF state during this time

Teach-in

s

1

Outputs response time

ms

1.2

All emission LEDs active (4 LEDs)

Switghing frequency

Hz

400

All emission LEDs active (4 LEDs)

Output response time (formula)

ms

((NLED*0.1)+0.2)*2

NLED: number of active LEDs (maximum 4, not in Blanking)

Input levels

Low level

V

0

0.8

Normally connected to common

Open level

V

1.3

1.9

2.35

Normally leaved open

High level

V

5.8

30

Normally connected to supply voltage

Integration time

ms

20

The input state must persist for at least this time

Input current for low level

µA

-250

520

Outgoing or incoming current

Input current for high level

mA

0.52

1.2

Incoming current

Teach-in time

Short push time

s

1

3

Long push time

s

8

Environmental parameters

Enclosure rating

IP67

Dust and water protection (immersion for 60 min. at a depth of 1m)

Working temperature

°C

-10

55

Without condensation

Storage temperature

°C

-25

70

To be respected also during transportation

Humidity

%

95%

Without condensation

Vibrations

Sec. IEC 60947-5-2

It complies with limits and conditions stated in the rule

Shock

Sec. IEC 60947-5-2

It complies with limits and conditions stated in the rule

Sensing range correction factors

Environmental factors

0.50 / 0.25

In presence of dust, fog, smoke (approximate values)

Connections

Cable sections

mm2

0.34

To be respected to guarantee the maximum indicated length

Total length of power cables

m

100

With cable of the indicated sections, standard models

Length of interconnect cables

m

20

Lenght of the connections: output, input, IO-Link

Size/Materials

Housing section

mm

20 (frontal) x 36

Painted aluminum, blue color RAL5002

Total height

mm

107

Fixing groove, for T shaped insert

mm

2/10/6.5

In the rear part of the sensor: depth/width/opening width

Width of the frontal window

mm

15mm

Active width: 9mm central, material: PMMA

Height of the frontal window

104mm

Active height: 69mm top

Number/Size of the lenses

7/ 9*9mm

Central part of the window, see Pict.: 1

Top closure

N°

1

Material: PC, transparent

Bottom closure

N°

1

Material: PBT + 30%GF, black colour

Closing screws

N°

2+2

M2, FE37 burnished

Connectors/Cables

Models 0I, 0T, BP, BN, 0P, 0N

1xM12, 4p, male

Pigtail length 240mm, PVC, Ø 4,7mm, 0,34mm2

Models 0B

1xM12, 5p, male

Pigtail length 240mm, PVC, Ø 4,7mm, 0,34mm2

Tab.:12

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

12/16

!

5.0 START-UP INSTRUCTIONS

5.1 Mechanical mounting of CR models

It is extremely important to fix the sensors and the reflectors to a rigid structure, not subject to deformation or to strong vibrations.

Choose the position of the sensor so as not to expose it to strong sources of natural or artificial light and to light interference with

other sensors in the visible emission.

Keep in mind that the devices are not suitable for outdoor installation, IP67 despite being declared, it is not guaranteed that the long

exposure to the weather does not cause water penetration and performance degradation.

Choose the most suitable reflector to the required detection capabilities and sensing range.

Mount the sensor with the optical axes as much as possible perpendicular to the reflector surface. The mutual distance depends on the

type of reflector and must be included in the field of specification. To secure the sensors to a support, use the corresponding inserts to

be applied in the rear groove and the brackets in the normal provisioning.

If the application is subject to vibrations, which anyway do not prevent the optical alignment, use damping supports.

Though used polarized light, the light beams can in part be deflected by reflective surfaces parallel and near to the beams, this can

lead to a missed detections of the interruption of direct path of the of the optical beam, or incorrect calibration values that may

generate unstable operation, so all reflective surfaces and reflective objects should maintain a minimum distance from the direct path

of the rays. This distance depend on the aperture angle of optics.

Keep in mind that even if a surface is black, if it is shiny, it can be highly reflective.

If you can’t eliminate or reduce the effect of a reflective surface, it is important that this effect remains stable or that

the system behaves in an acceptable and predictable manner.

Temporarily block the sensor and reflector so that they are aligned and parallel to each other.

5.2 Electrical installation

Use PELV power supplies, in compliance with Chap.6.4. of EN 60204-1.

If using a non-stabilized power supply, the transformer must have double insulation and adequate power, the secondary winding must

not exceed 18Vac. Use a bridge rectifier, a filtering capacitor with a minimum value of 1000F.

Connect the supply cables directly to the source and not downstream of other power or highly inductive devices.

Run the cables of the light curtains in dedicated raceways or where only signals run; do not use raceways already carrying power

cables.

Comply with the specification of the maximum length of the connection cables. Make sure that the part or parts of the metal structure

on which the sensors are installed are effectively connected to the same earth ground.

Before inserting the connector, check that the mains voltage and the supply voltage are within the required limits, apply the connector

and check again that the supply voltage has a correct nominal value and remains within the limits defined in all working conditions.

Check the limits in the two extreme conditions of minimum and maximum absorption of all devices connected to the same power

supply, especially if this is not a stabilized power supply.

!

Danger!

In order to carry out the following operations, a voltage supply to the sensor is needed. Before starting this phase,

make sure that the outputs’ switch cannot lead to any danger.

!

Make the minimum electrical connections for proper operation, connect the power cables, connected to the necessary

inputs devices; suitably connected the NC / NO input if it is available, this status is only acquired at power on.

5.3 Alignment of CR0 models

Applied the supply voltage, the Green LED must be switched on, if it is off or flashes the supply voltage is not sufficient.

Verify that the emission optics are active and therefore emit a red light, if necessary make a teach-in (even without visibility of the

reflector) with the purpose to activate the alignment function. If possible, observe the reflector from a point near the optical axis and

corrects the alignment so that the light stain completely illuminate the reflector, simultaneously or alternatively use the alignment

function of the Red and Green LED (reduce the red light to a minimum).

Fix the sensor and run now a Teach_F and check the status of the LEDs, if the Red LED is off and the Green on, the alignment was

acceptable and the Teach was successful. If both LEDs are still blinking it means that the alignment is incorrect, so try to get a better

alignment then run a second Teach S or F. After successfully aligned, permanently block the sensor and verify that the sensor detects

properly as expected. If possible, urging the structure, verify that the vibrations do not cause unstable operation.

If the LEDs show no recognizable behaviors check the error codes in Chapter 5.5

!

!

Indication

A correct optical alignment with a good signal margin prevents unstable functioning of the light curtains, reduces

optical interferences and reflection by shiny surfaces and guarantees better stability in general.

If the range is short, the graininess of the reflector can cause instability, check the behaviour of the system by shifting

the reflector, as an alternative use of reflective paper composed of micro prisms.

Please do not forget to reconnect all the cables and to control the correct functioning of the application.

!

!

!

!

!

!

!

!

!

!

!

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

13/16

!

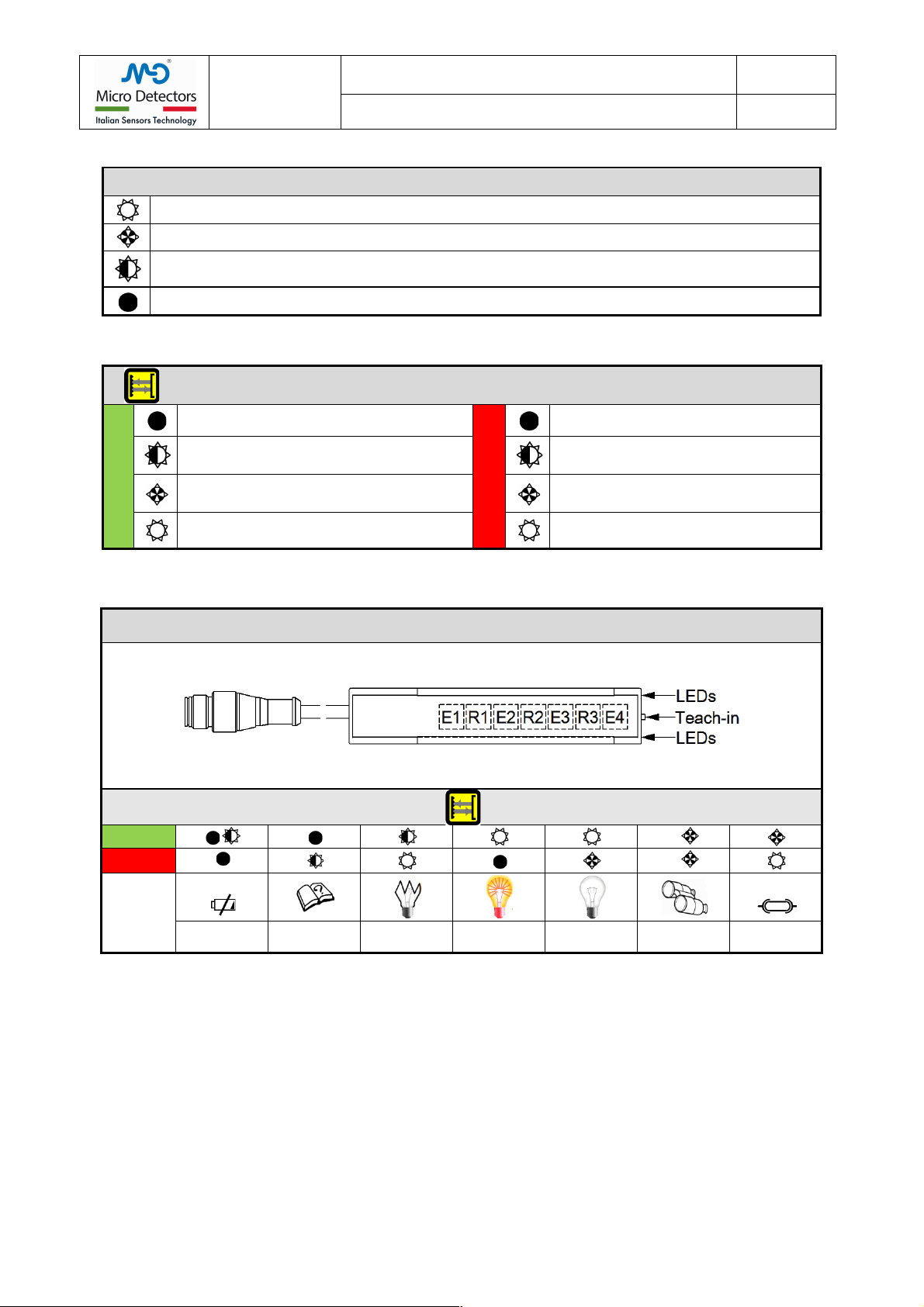

5.4 Display indications and diagnostics.

MEANINGS OF LEDs SIGNALLING MODES

!

Indication of full light and steady

!

Indication of low intensity or intermittently with fast periodic flashing

!

Indication of slow continuous flashing

!

Off

Tab.:13

LEDs INDICATIONS

GN

!

No power supply or below 5V.

Memory reading error.

RD

!

Light state.

No power supply.

!

Power supply below 16V.

Emission LEDs failed.

!

Memory reading error.

!

Alignment.

Outputs in short circuit

!

Alignment.

Some optics in Dark

!

Normal operation.

!

Many or all optics in the DARK

Fault or outputs in short circuit

Tab.:14

COMBINED INDICATIONS

GN

↑

RD

↓

STATUS

Power

Out

OFF or LOW

MEMORY

ERROR

FAULT

LIGHT

DARK

ALIGNEMENT

OVERLOAD

Tab.:15

!

!

!

!

!

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

14/16

!

6.0 MECHANICAL DIMENSIONS OF LIGHT CURTAINS AND STANDARD ACCESSORIES

6.1 Mechanical dimensions of CR0/**-1V reflex curtains

!

Pict.: 1

Pigtail cable length L= 240mm

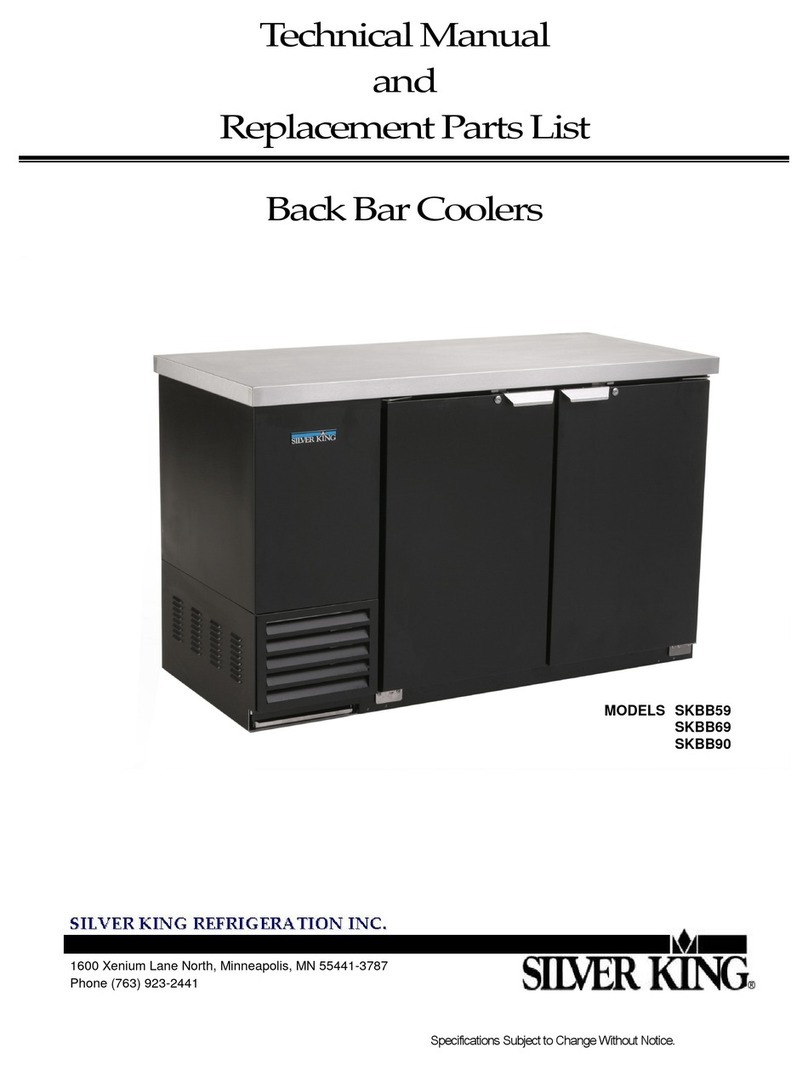

6.2 Standard Mounting accessories

One unit is supplied by type

Kit mounting accessories ST151

!

!

!

!

!

!

!

Pict.: 2

T-shaped insert, with two M5 nuts and two split washers.

Pict.: 3

L-shaped mounting bracket

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

15/16

!

7.0 INSTALLATION

Securing CR0 light curtains with accessories’ kit ST151

Place the T-shaped insert

Mount the L-shaped bracket on the

T-shaped insert

Secure light curtains to the wall

Pict.: 2

8.0 LIST OF AVAILABLE ACCESSORIES

M12 CONNECTORS, 4 POLES, WITH CABLE

CD12M/0B-020A1

M12 connector, straight, 4 poles, female, 2m PVC cable

CD12M/0B-050A1

M12 connector, straight, 4 poles, female, 5m PVC cable

CD12M/0B-100A1

M12 connector, straight, 4 poles, female, 10m PVC cable

M12 CONNECTORS, 4 POLES, WITH CABLE

CD12M/0B-050A5

M12 connector, straight, 4 poles, female, 5m PUR cable

CD12M/0B-100A5

M12 connector, straight, 4 poles, female, 10m PUR cable

M12 CONNECTORS, 5 POLES, WITH CABLE

CD12M/0H-050A5

M12 connector, straight, 5 poles, female, 5m PUR cable

CD12M/0H-100A5

M12 connector, straight, 5 poles, female, 10m PUR cable

STANDARD MOUNTING KIT FOR LIGHT CURTAINS

ST151

Kit with T-shaped insert with four M5 screws complete with nuts and washers and an L-shaped bracket

VIBRATION DAMPING SUPPORTS

ST 4V S

Kit of 4 vibration-damping supports

Tab.:16

9.0 PACKAGE CONTENT

Each package has the following content:

•A retroreflective area sensor.

•An accessories’ kits ST151 (T-shaped insert and L-shaped bracket)

•Reflector R106G

•Multilingual installation short manual.

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

CR0 SERIES

RETROREFLECTIVE AREA SENSOR

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ECR1780101

16/16

!

10.0 CONTROL OF THE INSTALLED RETROREFLECTIVE AREA SENSOR

10.1 Purpose of controls.

The controls described here below are meant to ensure the functional and reliable performances required.

10.2 Preliminary controls before start-up

All devices must be correctly installed and well secured.

The maximum response time must be adequate to the application. Make sure that the sensor’s response time is compatible with the

specific application, detecting objects of minimum and maximum size, in different positions and, if possible, with even faster movements

compared to what the application allows.

Make sure that no optically interfering devices are in the visual field of the sensor. Make sure that other devices do not undergo

interferences by the emitted light.

Make sure that sensors are not exposed to any substance which might dirty or damage the optics.

Make sure that technical documentation is available for operators in charge of maintenance.

10.3 Controls device efficiency

State and efficiency of the device can be checked using a test stick, which must be detected in a way that is repetitive in time.

Make sure that there are no damages nor dirt on optical windows’ surface. Scratches and tarnished surfaces can negatively affect the

light curtain’s resolution.

If necessary, clean the optical surface with a humid antistatic cloth. Do not use any alcohol, nor solvents, nor abrasive substances.

Other manuals for CR0 Series

1

This manual suits for next models

7

Table of contents

Other Micro Detectors Accessories manuals

Popular Accessories manuals by other brands

Silver King

Silver King SKBB69 Technical manual and replacement parts list

Battery Tender

Battery Tender 030-1030-PS instruction manual

Xtant

Xtant XSC manual

SNAIGE

SNAIGE CD290 Series instruction manual

Braeburn

Braeburn 7490 Installer's guide

Electro-Sensors

Electro-Sensors Electry-Sentry 1 Installation & operation manual