Industrial Performance Unit

Contents

1. Safety ........................................................................................................................................ 5

1.1 Symbols Used ................................................................................................................................................. 5

1.2 Warnings.......................................................................................................................................................... 5

1.3 Notes on CE Marking ...................................................................................................................................... 6

1.4 Notes on FCC Marking .................................................................................................................................... 6

1.5 Intended Use ................................................................................................................................................... 6

1.6 Proper Environment......................................................................................................................................... 6

2. Functional Principle, Technical Data ....................................................................................... 7

2.1 Short Description............................................................................................................................................. 7

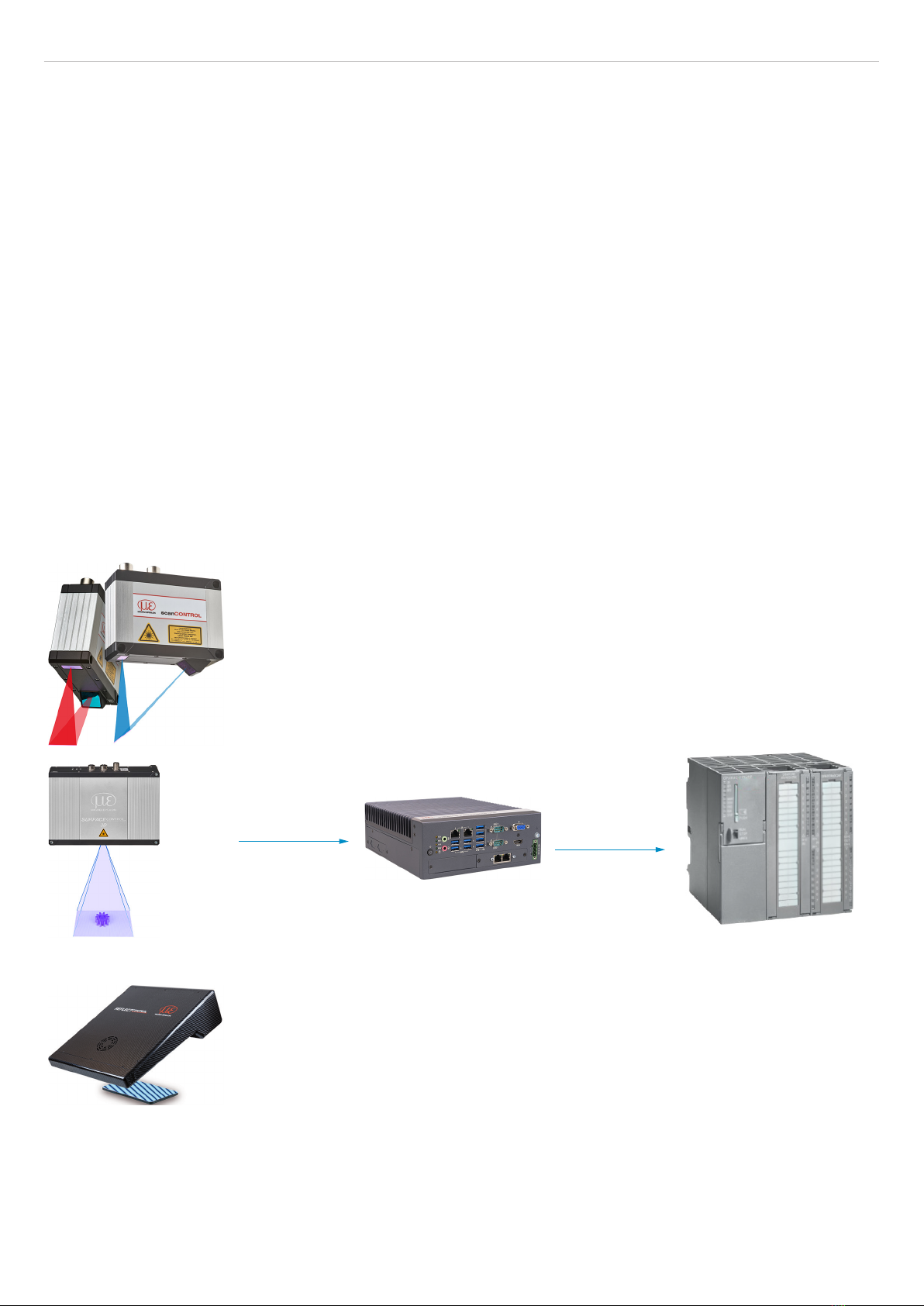

2.2 System Design................................................................................................................................................. 7

2.3 Special Performance Features ........................................................................................................................ 8

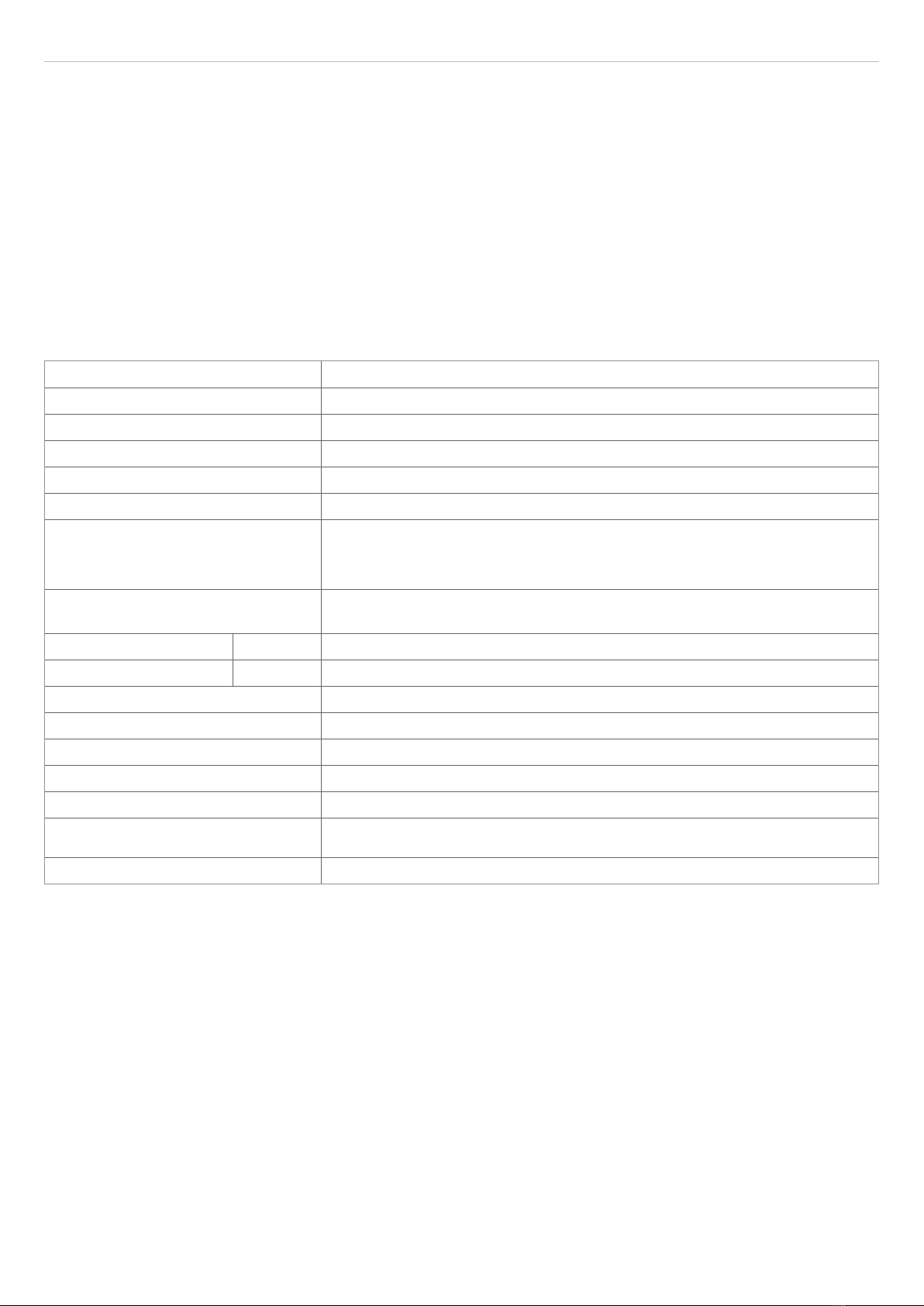

2.4 Technical Data ................................................................................................................................................. 8

2.5 Control and Indicator Elements....................................................................................................................... 9

3. Delivery ................................................................................................................................... 10

3.1 Unpacking/Included in Delivery .................................................................................................................... 10

3.2 Storage .......................................................................................................................................................... 10

4. Installation and Assembly...................................................................................................... 11

4.1 Controller ....................................................................................................................................................... 11

4.2 Electrical Connections................................................................................................................................... 12

4.2.1 Connection Diagram .................................................................................................................... 12

4.2.2 Interfaces ...................................................................................................................................... 13

4.2.3 Supply Voltage (Power)................................................................................................................ 13

4.3 Installation instructions .................................................................................................................................. 14

4.4 Initial Operation.............................................................................................................................................. 14

5. Operating System................................................................................................................... 15

6. Operation ................................................................................................................................ 16

6.1 Turning On ..................................................................................................................................................... 16

6.2 System Start-Up............................................................................................................................................. 16

6.3 Users and Passwords.................................................................................................................................... 16

6.4 Setting Up for Initial Use................................................................................................................................ 17

7. Setting Up Fieldbus Operation .............................................................................................. 18

7.1 General .......................................................................................................................................................... 18

7.2 Running Firmware on the Fieldbus Card ...................................................................................................... 18

7.3 Operating Program........................................................................................................................................ 19

8. Limitation of Liability ............................................................................................................. 20

9. Service, Repair ...................................................................................................................... 20

10. Decommissioning, Disposal .................................................................................................. 21

Appendix................................................................................................................................. 22

A 1 Further Literature ................................................................................................................... 22

A 2 Accessories ............................................................................................................................ 22