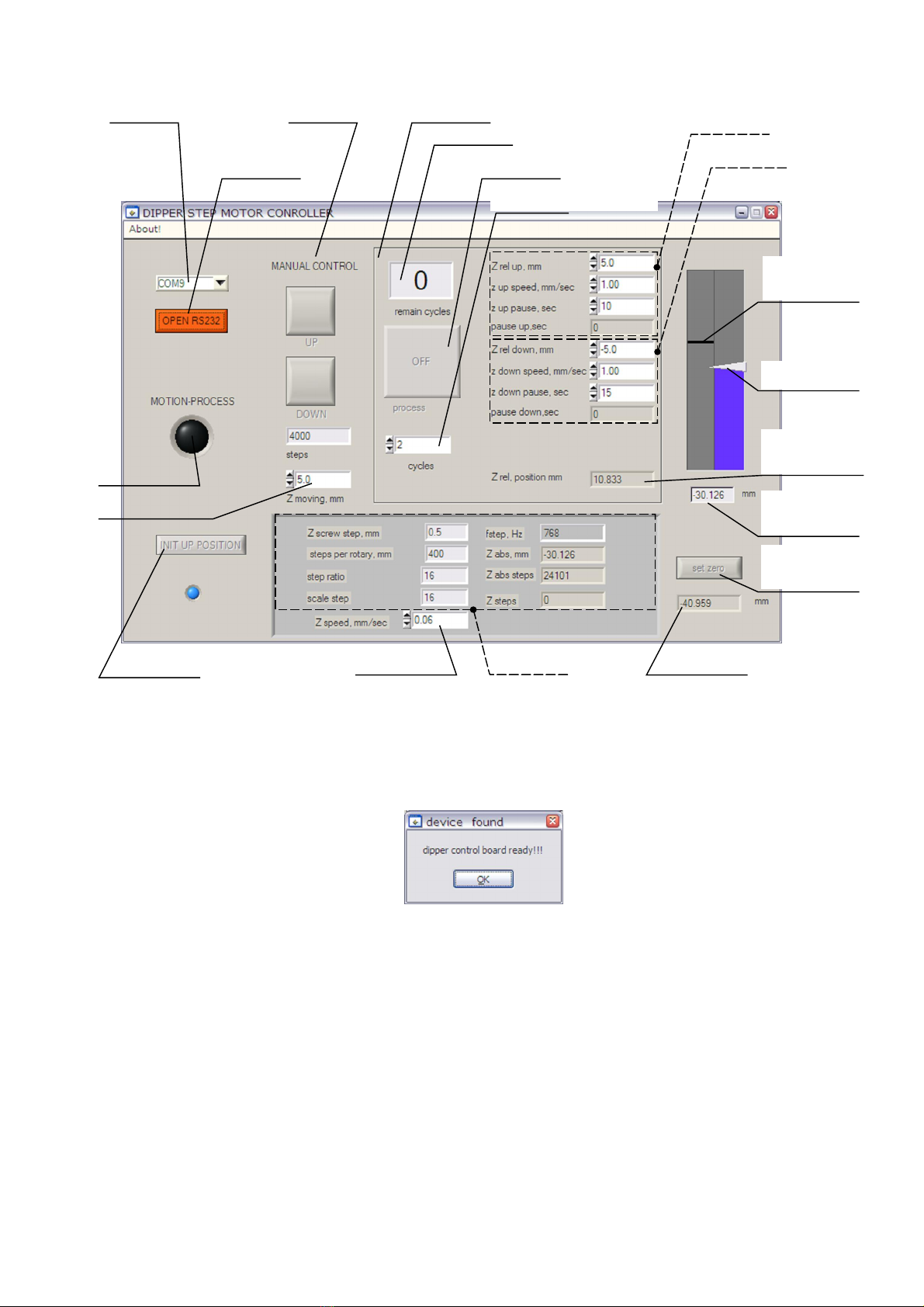

Using buttons of manual control you may, for example, position the arm with attached object at necessary height (e.g.

liquid in a vessel) and then set this position as soft 0 by pressing button ‘set zero’. That will simplify assignment of coordinates

for the object dipping and lifting under programmable operation mode.

[Programmable operation mode]

Automated dipper VT-04 provides possibility for multicycle operation with preset parameters separately for upward and

downward movement of the arm (carriage). All necessary parameters should be set in Programmable motion area of the control

program panel (see example below).

Enter in pane ‘cycles’ number of dipping/lifting cycles planned to perform. Other parameters are as follows:

Z rel up, mm – coordinates of upper point (relatively cutrrent soft zero) of the carriage cycle motion.

z up speed, mm/sec – speed at which the arm (carriage) will travel upward to the position set by ‘Z rel up, mm’.

z up pause, sec – pause in movement that will be performed by the mechanism in upper point of the cycle (set by

‘Z rel up, mm’).

pause up, sec – counter for pause performed in upper point of the cycle; the counter starts when the pause begins.

Z rel down, mm – coordinates of lower point (relatively current soft zero) of the carriage cycle motion.

z down speed, mm/sec – speed at which the arm (carriage) will travel downward to the position set by ‘Z rel down, mm’.

z down pause, sec – pause in movement that will be performed by the mechanism in lower point of the cycle (set by

‘Z rel down, mm’).

pause down, sec – counter for pause performed in lower point of the cycle; the counter starts when the pause begins.

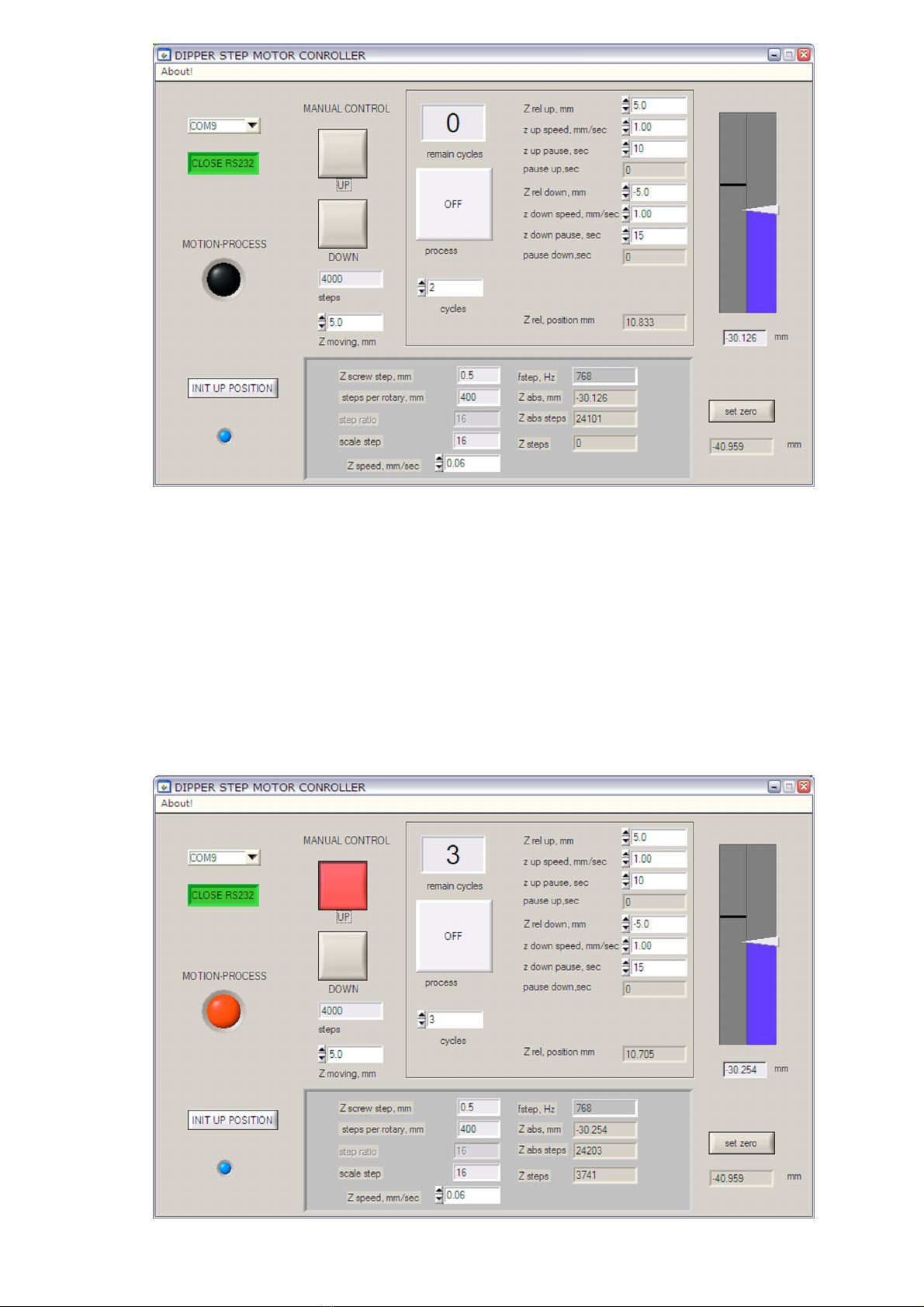

To start the programmable motion with the preset parameters, press ‘process’ button (with inscription ‘OFF’ in its middle

showing its current state). The cycle process will start and the button change color to green (inscription in the button middle will

change to ‘ON’). Note that buttons in manual control area will change their state correspondingly to currently performed motion,

i.e. when carriage goes down button ‘DOWN’ comes to activated state (red color). If carriage goes up, button ‘UP’ comes to

activated state (red color). You may stop the process fulfillment by pressing the activated buttons or spacebar on the host PC

keyboard.

[Exiting program]

Before exiting the control program it is recommended to disconnect from the device by pressing button ‘CLOSE RS232’.

It is recommended to disconnect from the device before switching the control electronic unit off as well.