Deitz Pharmafill NB1 User manual

Model NB1 Neck Bander

Operation Manual

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page I

CONTENTS

1. ILLUSTRATIONS ........................................................................................ pgs III thru V

2. SAFETY REMINDER..................................................................................................... 1

3. INTRODUCTION.......................................................................................................... 2

4. SPECIFICATIONS ......................................................................................................... 4

General

Inputs

Dimension

5. GENERAL INFORMATION ........................................................................................... 5

What It Does

Features and Capabilities

Optional Features

6. INSTALLATION AND COMMISSIONING ...................................................................... 7

Unpacking

Set Up the Lift Stand

Install NB1 Bander onto Lift Stand

Apply Electric and Air Service

Integrate with Conveyor

Basic Operational Test

7. CONTROLS.................................................................................................................. 14

Control Panel (HMI, E-Stop, Spacer Wheel Speed Setting)

Using the HMI

Apply Bands Mode (Automatic, Manual)

Adjust Settings Mode

Manual Control Mode

Jog Mode

Technician Only Mode

8. SET UP ........................................................................................................................ 24

Set Up Check List

Select Change Parts

Adjust Machine Height

Adjust Start Sensor Height

Adjust Conveyor Rails and Spacing Wheel

Load Material

Adjust Spreader Support Roller Spacing

Adjust Spreader Guide Wheels

Install Spreader Assembly

Make Bands

Adjust Band Holder

Adjust Suction Cup Angle

Adjust Plunger Assembly Angle

Adjust Plunger Assembly Horizontal Position

Adjust Plunger Assembly Height

Start Production and Fine Tune

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page II

9. MAINTENANCE........................................................................................................... 39

Cleaning Recommendations

Washdown

Cleaning Solutions

Stainless Steel

Anodized Aluminum

Clear Plastic

Other Plastic (Not Clear)

Electricals/Electronics

Preventative Maintenance

10. TECHNICAL INFORMATION ........................................................................................

Principal of Operation

Cycle of Operation

Troubleshooting

Index of Technical Notes and Drawings

(Technical Notes/Drawings Begin After Last Page)

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page III

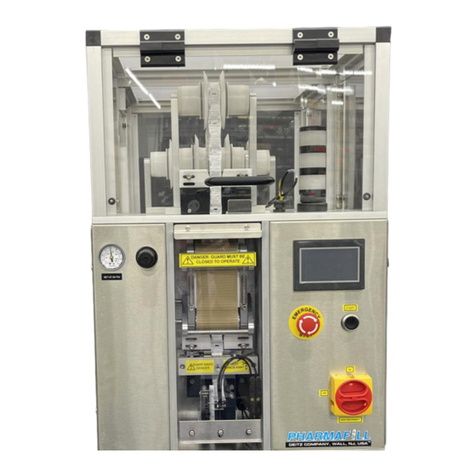

Section 1 - GENERAL ILLUSTRATIONS

NB1 Neck Bander –Front View

1. HMI (Human Machine Interface) –Touch Screen Operator Control/Display panel

2. E-stop (Emergency Stop Button) –Main power on/off. Push to stop, twist CW to release

3. Speed Setting Knob for Spacing Wheel

4. Spacing Wheel

5. Adjustment handle –Start Sensor assembly

6. Start Sensor –Optical retro-reflective

7. Adjustment Handle –Band Holder assembly

8. Spreader Guide Wheels (2)

9. Hub Support Rollers (2)

10. Feed Rollers (2)

11. Plunger assembly

12. Knife assembly

13. Band Holder assembly

1

2

3

4

11

12

13

5

8

6

7

9

9

10

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page IV

Section 1 - GENERAL ILLUSTRATIONS (cont’d)

NB1 Neck Bander –Rear View –Lift Stand with vertical Unwind Assembly and Spacing Wheel

NOTE: On machines made prior to March 2013, the Unwind Assembly is a different design (horizontal).

1. Air Pressure Regulator/Filter

2. Air supply tube to machine

3. Dancer Tension Roller

4. Spacing Wheel

5. Power cord for Spacing Wheel

6. Main power cord to machine

7. Spool for Band Material Roll

8. Dancer Brake Roller

1

8

3

2

4

7

5

6

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page V

Section 1 - GENERAL ILLUSTRATIONS (cont’d)

NB1 Neck Bander –Spreader Assembly (typical, 69mm shown)

1. Upper Blade

2. Hub (Large Hub shown)

3. Spreader Hub Rollers

4. Lower Blade

5. Hub Support Rollers (2) (part of machine)

6. Spreader Guide Wheels (2) (part of machine)

NOTE THE ORIENTATION OF THE BAND MATERIAL.

The seam of the band material should travel at the center of the Hub Rollers.

1

2

4

3

SPREADER ASSEMBLY

SPREADER ASSEMBLY WITH MATERIAL

5

6

HUB SUPPORT ROLLER

SPREADER HUB ROLLER

MBLY

HUB SUPPORT ROLLER

SPREADER HUB ROLLER

MBLY

MATERIAL SEAM

MATERIAL SEAM

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 1

Section 2 - SAFETY REMINDER

Warning

This machine contains moving parts and operates

automatically. This may present a hazard to personnel.

Never operate this machine with any covers or guards removed or any guard switches or safety

devices removed or bypassed.

Only people who have been correctly trained should operate or clean this machine.

Only people who are correctly qualified and trained should carry out maintenance, installation or

any other service work.

Never clean or service the machine without isolating the

electrical supply and isolating the air supply.

Always test for the presence of voltage before touching or working on electrical components.

Note that there might be other requirements that could apply.

Refer to the manuals supplied by the component manufacturers for further safety instructions.

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 2

Section 3 - INTRODUCTION

Thank you for purchasing a Pharmafill Model NB1 Neck Bander. We at Deitz Company hope you will find that the

Model NB1 meets or exceeds your expectations and requirements for an affordable, reliable and innovative

addition to your packaging operation.

Pharmafill products are designed and manufactured by Deitz Company Inc., in Wall, NJ, USA. We have

manufactured machinery for the bottle filling industry since 1966 and started our Pharmafill line in 1993. We are

a small (but growing) family-owned business that emphasizes quality, innovation and superior customer service.

If you have any questions or comments, please contact us by phone or visit our website. Chances are someone

whose last name is Deitz will handle your inquiry personally.

Deitz Company Inc.

PO Box 1108

1750 Route 34

Wall, NJ, USA 07719

Tel 732-681-0200

Fax 732-681-8468

E-mail

Web site deitzco.com or

pharmafill.com

The operation manual is designed to make it easier for you to know the machine and to make use of its intended

range of operation. It contains important instructions on how to operate the machine safely, adequately and

economically. Observing these instructions helps to avoid risks, to reduce cost for repair work and machine

downtime, and enhances the machine’s operational reliability and lifetime.

The operation instructions are to be supplemented by further instructions due to existing national regulations

on accident prevention and environmental protection.

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 3

Section 3 –INTRODUCTION (cont’d)

If used in compliance with the instructions contained in this manual and provided that safety devices are

regularly maintained and properly working, this machine is not dangerous to the operator.

This manual is to be kept accessible to all operators using this machine and it is assumed that, before use, the

operator will read fully and understand this manual and will follow instructions stated within.

As this machine may be used in the packaging of hazardous substances the operator should be aware of the

precautions required for these substances.

In addition to the operating instructions and the binding regulations on accident prevention valid in the country

where the machine is being used and at its operational site, the recognized technical rules on safe and proper

working must be observed as well.

These operating instructions and the information contained therein have been compiled with due care and

attention. However, DEITZ COMPANY does not take any responsibility for misprints, translation errors or other

errors and any damages resulting there from.

DEITZ COMPANY retains the right to make changes in the described products to improve functionality, reliability

and other design considerations. The measurements or data shown on schematics, sketches and photos are not

binding. They are for description purposes.

The information and drawings found in the operation manual are the intellectual property of DEITZ COMPANY

and may not be copied or given to third parties.

LEGAL NOTICE: DEITZ COMPANYTM, PHARMAFILLTM and any graphic representations of the same are

legal trademarks of Deitz Company Inc. and may not be used by others without specific written

permission from Deitz Company.

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 4

Section 4 - SPECIFICATIONS (Also see technical information at end of manual)

GENERAL

Model NB1 Neck Bander

Type AD1178 REV A

Product Capability All heat-shrinkable materials intended for tamper evident neck banding

Minimum lay flat width (LFW): 25 mm (.98 in.)

Maximum lay flat width (LFW): 123 mm (4.84 in.)

Minimum length of band after cutting: .70 in (18 mm)

Maximum length of band after cutting: 9.99 inch (253 mm)

Roll Specifications Core Diameter 5” (12.7cm) Maximum O.D. 17” (43.2 cm)

Maximum Rate up to 100 applications/minute

INPUTS

Voltage 110 VAC1(Optional 220VAC)

Cycles 50/60 HZ

Phase 1

Amperage 2.0A

Compressed Air20.5 CFM at 80 psi (14 LPM at 550 kPa)

Room Humidity 85% RH non-condensing

DIMENSIONS

Floor Footprint 28” wide x 29” deep (71cm X 74cm)

Height3Standard Variable 56”to 68” (142cm to 173cm)

Tall Variable 64” to 76” (162cm to 193cm)

Container Height Standard from 1” to 10” (2.5cm to 25cm) 3

Tall from 9” to 18” (23cm to 46cm)

Weight Fully assembled: 90 lbs (42 Kg)

Bander Unit alone: 45 lbs (21 Kg)

Lift Stand with Spacing Wheel: 45 lbs (21 Kg)

OTHER

Ideal Conveyor Height 36” +/- 1” (92cm +/- 2.5cm)

Construction Materials Stainless Steel (303, 304), Anodized Aluminum, Acetal, Polycarbonate

Notes:

1. Other input voltages are available as factory options if specified at the time of order

2. Compressed air must be clean and dry, free of impurities, moisture (water) and oil.

3. May be adjusted further by adjusting or modifying leveling feet.

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 5

Section 5 –GENERAL INFORMATION –Getting to know the machine

1. WHAT IT DOES

The Model NB1 Neck Bander is designed to convert rolls of heat-shrinkable flat tubing into individual

round cut bands and apply those bands onto containers as they pass through the machine via conveyor.

The containers then pass through a heat tunnel, where the bands will shrink around the containers. The

bands can be tamper-evident neck bands or partial- or full-body labels.

The raw material is flat tubing (typically PVC or PET) of various widths, supplied in roll form with a round

core (typically 5” diameter). The roll is installed vertically (upright) on a supporting wheel (unwind

spool). The loose end of the roll is threaded under a tension release bar and then over the machine. An

unfolding assembly (the spreader), which is matched to the size (width) of the tubing, is installed inside

the end of the tubing. The tubing will pass over the spreader and into the feed rollers. The feed rollers

deliver an exact length of material to the knife. The knife cuts the material, producing a band, and a

suction cup holds that cut band, waiting for a container. As a container passes under the machine, it is

detected by a photoelectric sensor. A pneumatic arm then pushes the cut band onto the container.

Finally, the machine produces another band and awaits the next container.

The Model NB1 applies bands “on the fly”; it does not stop or slow down the bottle. In order to work

properly, the incoming bottles must be separated by a few inches, proportional to the conveyor speed

(faster speed requires longer spacing). Every Model NB1 comes with a built-in bottle spacing wheel with

speed control to create space when there is none.

2. FEATURES AND CAPABILITIES –(for specifications, please see Section 4)

The NB1 Neck Bander automatically produces and applies neckbands and full or partial body sleeves. It

is designed primarily for the pharmaceutical, nutraceutical and cosmetic industries. It is designed to

comply with FDA and GMP rules, using approved materials and methods to aid in cleanliness and

cleanability. All mechanical and electrical components are easily accessed for maintenance and service.

The clear, hinged guard door is electronically interlocked to stop the machine when opened. The

machine is self-contained and includes everything you need to position it over any conveyor and to

begin making bands in the shortest time possible.

The machine is controlled by a PLC (Programmable Logic Controller). The operator interacts with the PLC

via a touch screen HMI (human machine interface). The display screen gives prompts to aid the operator

each step of the way. All functions are accessed through an easy-to-use menu system. In addition to the

basic function of selecting manual or automatic operation, the menu includes features that aid in set-up

and testing, such as one-step jog operation and direct control of individual mechanical actions. The

control panel includes a mushroom-head, twist-to-unlock Emergency Stop Switch, which (when pressed)

cuts-off main electrical power and compressed air. There is also a rotary potentiometer that controls the

speed of the Spacing Wheel. An adjustable photo-electric start sensor is integrated into the machine,

which will detect the container and start a machine cycle.

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 6

Section 5 –GENERAL INFORMATION –(cont’d)

The NB1 Neck Bander is mounted on a manually-adjustable-height lift stand (LS-NB1), which includes an

air pressure regulator/filter and two brackets to connect the stand to a conveyor. Also mounted on the

lift stand is the roll Unwind Assembly and the motorized Spacing Wheel Assembly. The purpose of the

Spacing Wheel is to control the flow of containers into the machine, assuring a minimum gap between

containers.

3. OPTIONAL FEATURES - may be added to the machine at the factory or in the field. Please contact Deitz

company for more details

NB-VP Vertical Perforator Makes a continuous vertical perforated line in the band or sleeve to

ease removal of the seal by the end user.

NB-PR Print Registration For bands or sleeves with custom graphics, the NB-PR option adds a

sensor which detects the clear gap between print repeats and

assure that the cut is made at the gap.

NB-SBS Shoulderless Bottle System A conveyor-mounted system that allows bands and partial sleeves

to be applied to the upper portion of the bottle even if there is no

shoulder to hold the band or sleeve up. Combines a compact hugger

belt to hold the band up upon application and a heat gun to apply a

tack shrink to keep the band up, before it is released to go through

the heat tunnel.

LST-NB1 Tall Lift Stand For applications where the bottles or containers are all taller than

9” (23cm). Absolute high and low are 8” (20 cm) higher than a

standard LS-NB1 lift stand

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 7

Section 6 –INSTALLATION AND COMMISSIONING

NOTE: PLEASE RETAIN THE PACKING CRATE AND MATERIALS UNTIL THE MACHINE IS FULLY OPERATIONAL,

TESTED AND APPROVED.

1. Unpacking

a. Carefully remove the cardboard cover from the pallet.

b. Remove all packing materials and any small items that may be inside, such as:

•Cardboard box containing the spacing wheel assembly

•Cardboard box containing the operator manual, tooling and accessories

•Large clear plastic bag containing a packing check list and important set-up information

c. Cut the plastic straps that hold the NB-LS Lift Stand to the pallet.

d. Remove the Lift Stand from the pallet and place it on the floor.

e. Cut the plastic straps that hold the banding machine to the pallet.

f. Place the NB1 Neck Bander on a working surface (typically a table or sturdy cart).

g. Remove any shrink-wrap, bubble wrap and/or protective cardboard inserts from the Lift Stand and Neck

Bander.

h. Inspect all supplied equipment for damage.

i. If any damage is present, please notify DEITZ COMPANY immediately. If possible, send a photo.

j. Follow the procedures on the following pages to assemble and test the machine.

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 8

Section 6 –INSTALLATION AND COMMISSIONING (cont’d)

2. Set up the LS-NB Lift Stand

a. Remove the Lift Stand from the pallet.

b. Place lift stand on floor. The air filter/regulator is on the back side.

c. The Unwind Spool assembly is pre-installed.

d. Install the Spacing Wheel, where indicated by a white label, using the screws that are already in place.

e. Conveyor Alignment Bars are installed but must be repositioned prior to operation. Remove the free

socket head screw and loosen Conveyor Alignment Bars with provided socket driver and swing so “UP”

stickers are readable and horizontal. Reinstall previously removed socket head screw in available hole

on each Conveyor Alignment Bar (Note: The standard bars are made for a conveyor that is 5-1/2“wide.

Contact Deitz Company if you require a different size.)

TENSION BAR

UNWIND ASSEMBLY

AIR FILTER/REGULATOR

SPOOL

SPACING WHEEL

MOUNTING HARDWARE

BOTTLE SPACING WHEEL

CONVEYOR

ALIGNMENT

BARS

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 9

Section 6 –INSTALLATION AND COMMISSIONING (cont’d)

3. Install NB1 Neck Bander onto Lift Stand

a. Remove two (2) mounting screws and washers from top of lift stand.

b. Place NB1 Neck Bander on worktable.

c. Access mounting bar by loosening four (4) screws and removing Rear Access Panel.

d. Place the Neck Bander on top of the Lift Stand. Have a helper steady the machine (from the front).

e. Install the two (2) mounting screws with lock washers (from the back). Tighten securely.

f. Replace Rear Access Panel.

MOUNTING SCREWS

REAR ACCESS PANEL SCREWS

POWER CORD –LINE IN 115VAC

SPACING WHEEL

POWER CORD

MOUNTING SCREW –LEFT

MOUNTING SCREW –RIGHT

ZIP-TIE (CUT AND REMOVE)

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 10

Section 6 –INSTALLATION AND COMMISSIONING (cont’d)

4. Apply Electric and Air Service

a. Cut wire tie holding power cord and air supply tube.

b. Attach air supply to right side (as viewed from back) of the air filter/regulator.

•Attach compressed air from your in-house system to the left side of the air filter/regulator.

•Factory setting for regulator is 80 psi.

c. Plug in Spacing Wheel power cable to connector on short cord next to main power cord.

d. Before attaching to power, press Emergency Stop Button (E-stop) until latched.

e. Plug main power cord into 115 VAC outlet.

f. Release E-stop by twisting the red knob CW.

g. Confirm the that the HMI (front panel) lights up and after 4 seconds the display reads “Model NB1 Neck

Bander, Press Menu”

h. Confirm that there is the sound of air escaping from the vacuum generator (this is normal).

i. Open the guard door. Confirm that the HMI reads “Guard Door Open”.

j. Close the guard door. HMI reads “Press Menu” again.

k. Push E-stop. HMI will turn off, and air sound will go silent.

HMI UPON POWER UP –

MAIN MENU

HMI WITH GUARD

DOOR OPEN

EMERGENCY

STOP BUTTON

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 11

Section 6 –INSTALLATION AND COMMISSIONING (cont’d)

5. Integrate the assembled NB1 Neck Bander to the conveyor

a. Use the hand crank on the lift stand to raise the machine high enough to clear the conveyor and

conveyor guide rails. 10 turns = 1”(2.54cm).

b. Position machine next to the conveyor. Visually locate the blue suction cup under the knife.

c. Adjust the Conveyor Alignment Bars so that they hook underneath the conveyor body. Tighten the

mounting screws on the lift stand. (Note: The standard bars are made for a conveyor that is 5-1/2“wide.

Contact Deitz Company if you require a different size.) The blue suction cup is now directly over the

center of the conveyor belt and the machine is parallel to the conveyor

d. Loosen the black handle on the left (below the control panel) and swing down the optical start sensor

assembly a few inches so you can access it. Re-tighten the black handle. For now, we don’t care where

the black handle is positioned in the adjustment slot.

SUCTION CUP

HAND CRANK

START SENSOR

ADJUSTMENT

CONVEYOR

ALIGNMENT BARS

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 12

Section 6 –INSTALLATION AND COMMISSIONING (cont’d)

6. Conveyor Set Up Information with Heat Tunnel

•This is an example of a standard conveyor set up (NB1/ HT6/ CV4.5-HT). We recommend a

minimum of eighteen inches (18”) of space between the Neck Bander unit and the Heat

Tunnel. If the machines are too close, the hot air can adversely affect the application of the

seal, causing it to partially shrink before it comes to rest on the bottle.

•There must be no railings under the Heat Tunnel (they will get very hot). Railings under the

Neck Bander and between the Neck Bander and the Heat Tunnel are generally not needed.

•You must have a conveyor that can handle the high temperatures, like the CV4.5-HT conveyor,

which has brass wear strips on the starter section (motor end) which replace the standard

plastic wear strips. The heat tunnel should be positioned over the starter section.

•The heat tunnel can melt the plastic conveyor belt if the conveyor is stopped (or going very

slowly) while the heat tunnel is in operation down close to the belt. If you must stop the

conveyor with a hot tunnel, always move the tunnel away from the conveyor belt before

stopping. The HT6B can be ordered with the Emergency Auto Lift (EAL) option, which will

automatically lift the heat tunnel to its maximum height whenever the conveyor stops or is

going very slowly.

18“ minimum

Standard Wear Strip

Brass Wear Strip

EAL Emergency

Auto Lift Control

No railings under

heat tunnel

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 13

Section 6 –INSTALLATION AND COMMISSIONING (cont’d)

7. Basic operational test

a. Turn on the power by releasing the E-stop (twist). Wait for the display to read “Model NB1 Neck Bander,

Press Menu”

b. On the HMI (Human Machine Interface), press MENU. The display reads “Apply Bands /Adjust Settings /

Manual Control / One Step (Jog) / Technician Only”

c. Push “Apply Bands”. Push “Enter”. The display reads “Apply Bands Mode, Press Auto or Manual”

d. Push MANUAL. The machine will cycle once at normal speed. Confirm the following actions take place.

•Plunger extends and retracts.

•Knife opens.

•Feed rollers turn.

•Knife closes.

e. Push AUTO ON/OFF. The display reads “Auto Mode STAY CLEAR, Start Time .XX (F1)”

f. STAYING COMPLETELY CLEAR OF THE KNIFE, pass an object across the path of the optical START sensor.

The machine will cycle once at normal speed.

g. Push AUTO again.

h. Push CLEAR/ABORT. The display will return to the initial message. This completes the test.

HMI MAIN MENU

HMI –AUTO APPLY BANDS

MODE

2022-03-08 Pharmafill Model NB1

Deitz Company Inc. NB1 User Manual Page 14

Section 7 –CONTROLS

1.Control Panel –This is the panel at the front of the machine that contains the HMI, the E-stop and the

Spacing Wheel speed setting knob.

•HMI (Human Machine Interface) –this is a software-configured, touch screen interactive control panel.

All functions of the machine (other than the E-stop and Spacing Wheel speed) are controlled using this

unit. The display highlights only the buttons that are needed for the selected function and shows the

user interactive prompts as needed.

•E-STOP (Emergency Stop Button) - The control panel includes a mushroom-head, twist-to-unlock

Emergency Stop Switch, which (when pressed) cuts-off main electrical power and compressed air.

•Speed setting for Spacing Wheel –This is a rotary potentiometer that controls the speed of the Spacing

Wheel. The Spacing Wheel only turns on when the machine is in AUTO mode. The speed should be set in

conjunction with the conveyor speed to provide the container spacing and rate of entry that is

appropriate for the application.

EMERGENCY STOP BUTTON

HMI –HUMAN MACHINE INTERFACE

SPACING WHEEL SPEED SETTING

Table of contents

Other Deitz Industrial Equipment manuals