ii

Ice Quality........................................................................................................................................................... 5-2

Adding Refrigerant.............................................................................................................................................. 5-2

Chapter 6 Electrical Controls and Their Functions ..................................................................................6-1

Vogt 450 Controller ............................................................................................................................................ 6-8

Variable Frequency Drive (50-Hz Machines Only)............................................................................................ 6-14

Chapter 7 Maintenance ........................................................................................................................7-1

Cleaning .............................................................................................................................................................. 7-1

Sanitizing ........................................................................................................................................................ 7-2

Water Distributors.......................................................................................................................................... 7-3

Water Tank..................................................................................................................................................... 7-4

Freezer Cover ................................................................................................................................................. 7-4

Water-Cooled Condensers ............................................................................................................................. 7-4

Chemical Cleaning .......................................................................................................................................... 7-5

Mechanical Cleaning ...................................................................................................................................... 7-6

Compressor Lubrication ..................................................................................................................................... 7-7

Lubrication of the Cutter Motor Gear Reducer.................................................................................................. 7-9

Preventive Maintenance .................................................................................................................................... 7-9

Daily Checklist................................................................................................................................................. 7-9

Weekly Checklist........................................................................................................................................... 7-10

Monthly or Yearly Checklist.......................................................................................................................... 7-10

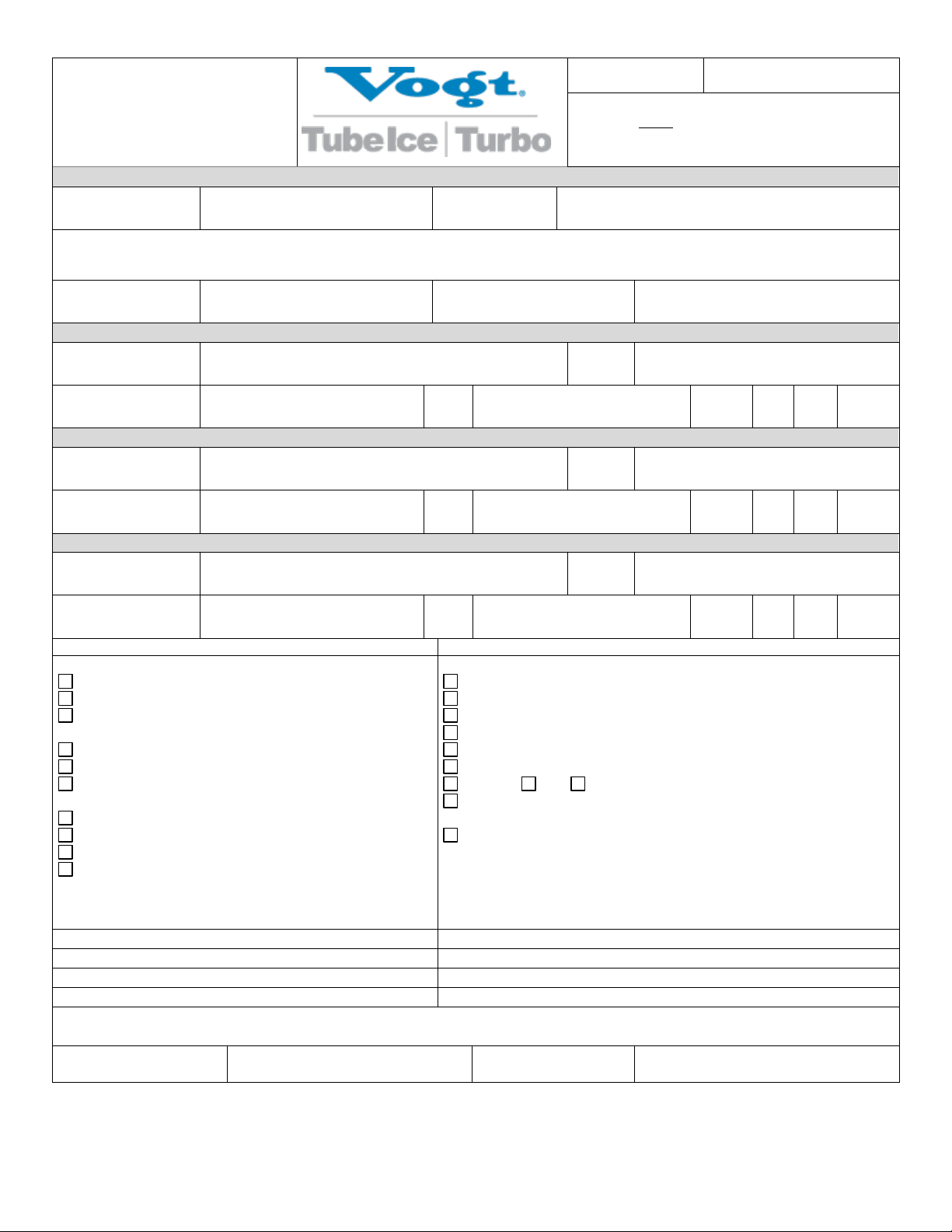

Preventive Maintenance Form......................................................................................................................... 7-11

Chapter 8 Troubleshooting ...................................................................................................................8-1

Machine Not Running......................................................................................................................................... 8-1

Freeze-Up from Extended Freeze Period ........................................................................................................... 8-2

Freeze-Up from Ice Failing to Discharge............................................................................................................. 8-3

Poor Ice Quality .................................................................................................................................................. 8-4

Low Ice Capacity ................................................................................................................................................. 8-4

High Head Pressure (Water-Cooled Machines).................................................................................................. 8-5

High Head Pressure (Air-Cooled Machines) ....................................................................................................... 8-6

Chapter 9 Servicing Operations.............................................................................................................9-1

Adjustable Blowdown (for Clearer Ice)............................................................................................................... 9-1

Automatic Blowdown......................................................................................................................................... 9-1

Makeup Water Float Valve................................................................................................................................. 9-1

Refrigerant Float Switch ..................................................................................................................................... 9-2

Hand Expansion Valve ........................................................................................................................................ 9-3

Freezer Pressure Switch (Vogt 450).................................................................................................................... 9-3

Low-Pressure Safety Switch (Vogt 450).............................................................................................................. 9-3

High-Pressure Safety Switch (Vogt 450)............................................................................................................. 9-3

Head Pressure (Vogt 450)................................................................................................................................... 9-3

Fan Cycling Switch (Air-Cooled Machines, Vogt 450)......................................................................................... 9-3

Water-Regulating Valve (Water-Cooled Machines) ........................................................................................... 9-4

Cleaning Water-Cooled Condenser .................................................................................................................... 9-4

Compressor Motor Protection ........................................................................................................................... 9-4

Compressor Motor Protection—Field Diagnosis................................................................................................ 9-5

Compressor Motor Burnout ............................................................................................................................... 9-5

Oil Level Safety ................................................................................................................................................... 9-6

Compressor Crankcase Heater (200 Watt)......................................................................................................... 9-6

Oil Separator....................................................................................................................................................... 9-6