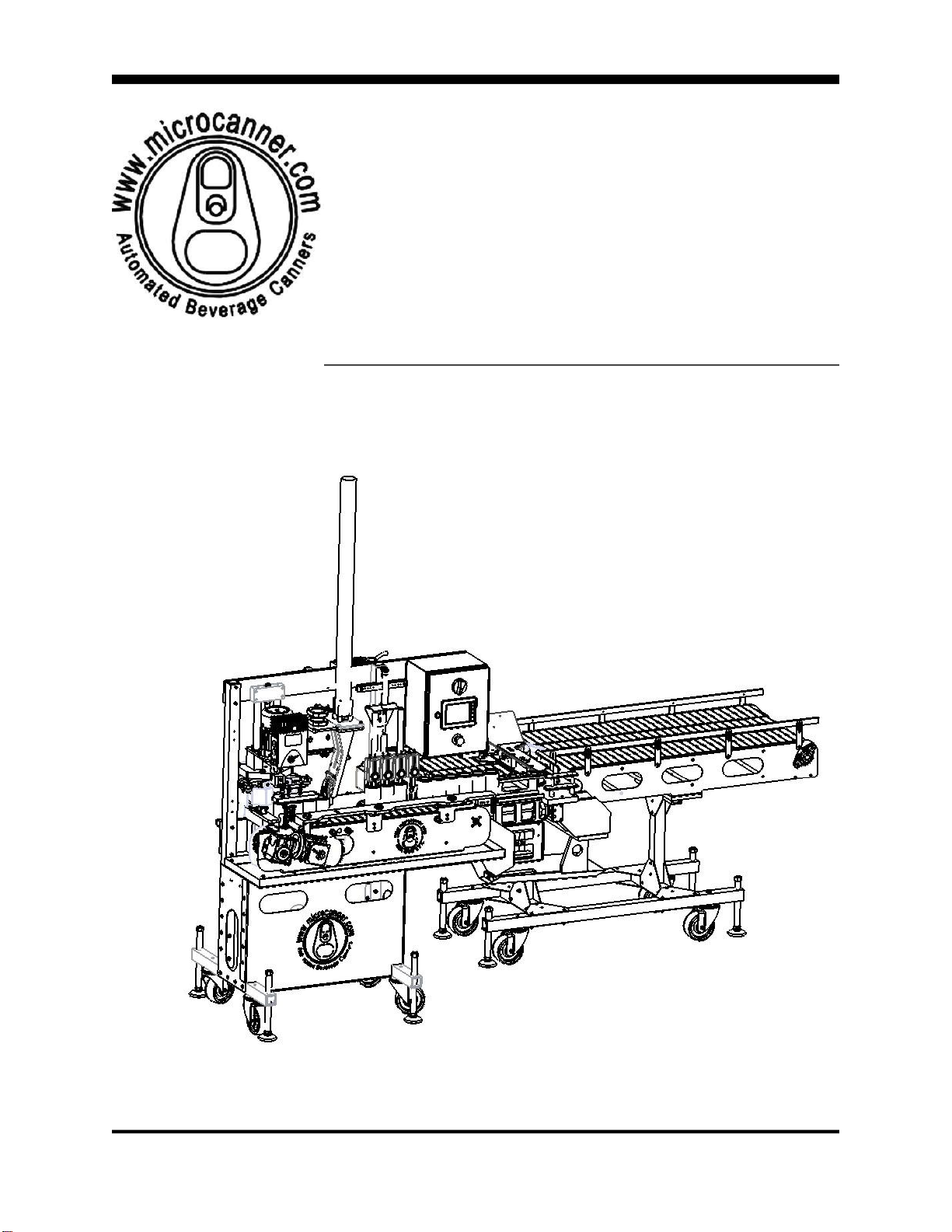

Microcanner MC CRAFT User manual

microcanner MC CRAFT

OPERATING INSTRUCTION

MANUAL

Version 1.0

Date 070220

microcanner MCCRAFT

MC CRAFT (V1.0) Page 2 of 19

WARNING!

OPERATING AUTOMATED EQUIPMENT IS DANGEROUS. DO NOT

OPERATE

THE MC CRAFT CANNING SYSTEM UNTIL YOU HAVE READ THIS

MANUAL AND HAVE RECEIVED PROPER TRAINING. PRECAUTIONS MUST

BE TAKEN TO SAFEGUARD OPERATORS. OPERATORS MUST BE

TRAINED AND AWARE OF DANGER POINTS, IF SOMEONE FAILS TO

FOLLOW SAFETY RULES, INJURY OR DEATH COULD RESULT.

IMPORTANT SAFETY PRACTICES

●Conveyors are dangerous and present entanglement hazards. Loose clothing,

hair, and jewelry should be avoided at all costs. Never place hands near or

inside of a moving conveyor.

●NEVER permit children, or un-trained operators anywhere near an operating

machine.

●In the event of an emergency, hit the E-stop.

●Never perform adjustments without being in E-Stop mode, or unplugging.

●Never plug into an outlet that is not GFCI. Water and electricity do not mix.

●Never open the control panel while powered up / plugged in.

●Keep clear of all moving parts.

●Clear machine jams only when in E-stop mode or fully powered down.

●It is recommended that you wear safety glasses anytime during operation of

the MC CRAFT canning system.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 3 of 19

TABLE OF CONTENTS

1 INTRODUCTION.......................................................................................3

2 MACHINE REQUIREMENTS ..................................................................4

3 GENERAL MACHINE SERVICE.............................................................4

4 START UP PROCEDURE.......................................................................6

5 SEAM SETUP GUIDE.............................................................................9

6 CHANGE OVER PROCEDURE ............................................................12

7 HMI OPERATIONS ................................................................................14

8 TIPS FOR A SUCCESSFUL RUN.......................................................19

1 INTRODUCTION

●Thank you for purchasing a microcanner MC CRAFT canning system. This

manual is written for your benefit to help you fully understand how to operate

and service your machine. With proper operation and service your machine will

offer you years of service.

●The MC CRAFT canning system is designed to run 8,12,16oz 202 series cans

and Sleek Series cans with a few simple changeover steps. This machine can

be special ordered to run Slim series cans. The machine will run up to 75

cases per hour, this will vary from product to product based on carbonation

and/or specific gravity along with temperature of the product.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 4 of 19

2 MACHINE REQUIREMENTS

●For safety purposes you should plug your machine into a 110v 20 amp GFCI

outlet. Please note that the motors use a V.F.D. (variable frequency drive) to

convert 110v single phase to 220 volt, 3 phase power. The type of GFCI

commonly purchased in a big box store will not work. A licensed electrician with

experience in motor control should be contracted to perform the work.

●Clean dry air supply to the machine. Below is one we would suggest.

o http://www.smcusa.com/products/idfb-refrigerated-air-dryer.aspx o Model IDF

B3E-11N should be adequate. Consult your local SMC representative prior

to purchase.

o Failure to provide dry air will destroy valves and void the warranty.

o The Air Regulator on the machine is to be set at 80 P.S.I. If your

pressure needle jumps around during operation, you will need to supply

a surge tank near the machine.

●CO 2delivery system that is regulated to 18 P.S.I. This line should have

a standard quick connect for hooking up to the filler head.

●Water supply for rinse tunnel, and pre-rinse if applicable. Simple garden hose

connection. Water supply should not exceed 55 psi.

●1 ½ Tri-clamp product supply line from brite tank, preferably insulated

●34°F product @ 2.64 Co2 @ 15 PSI head pressure (head pressure will vary

and a longer line set may be required when running high gravity, high IBU

double IPA beer)

●1 ¹⁄ ” Tri-clamp with sanitizer to rinse filler valves (pump kit is supplied)

3 GENERAL MACHINE SERVICE

Like any other piece of equipment, like a new car or tractor, your canning

machine needs to be cleaned, lubricated and periodically serviced. Screws

loosen, Filters plug up with contaminates, sensors vibrate out of adjustment

and seam tooling wears. It is important to assign a technician to learn the

system and take good care of it.

●Prior to each use, all screws and sensors should be checked for tightness.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 5 of 19

●During each use seams should be checked at least every 200 cans to assure

that bad cans are not being made due to worn out or loose tooling.

●Drain beer from the fill line and run sanitizer through it after use. Thoroughly

clean fill level sensors and spray with alcohol.

●Following each use, the entire machine should be hosed off (no pressure

washers). A bucket of warm water and dawn soap should be prepared, and

the machine be scrubbed with a soft plastic bristled brush. All water spots

should be polished off using vinegar and rags.

●After cleaning a food grade zero weight grease

( https://www.mcmaster.com/1445K41/)needs to be applied to all conveyor

bearing zerc fittings. There are 4 conveyor bearings on the feeder line

and 2 zercs on the main line at the end of the shafts.

●Grease must also be applied to 1 st operation and 2 nd operation

tooling. While greasing, spin the form wheel. Stop pumping when you just

start to notice the rpm of the wheel drop from the grease contact.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 6 of 19

●Grease Shaft Zerc behind the cap in place sensor thoroughly between canning

runs.

●Prior to running the machine check to see if any water has accumulated in

the catch bowl of the filter regulator to the right, or the water separator to

the left.

o To empty the catch bowl, push down on the grey thumb slide, then

turn and pull down to take the bowl off. Empty the bowl of any water.

4 START UP PROCEDURE

1. Put the machine into desired location.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 7 of 19

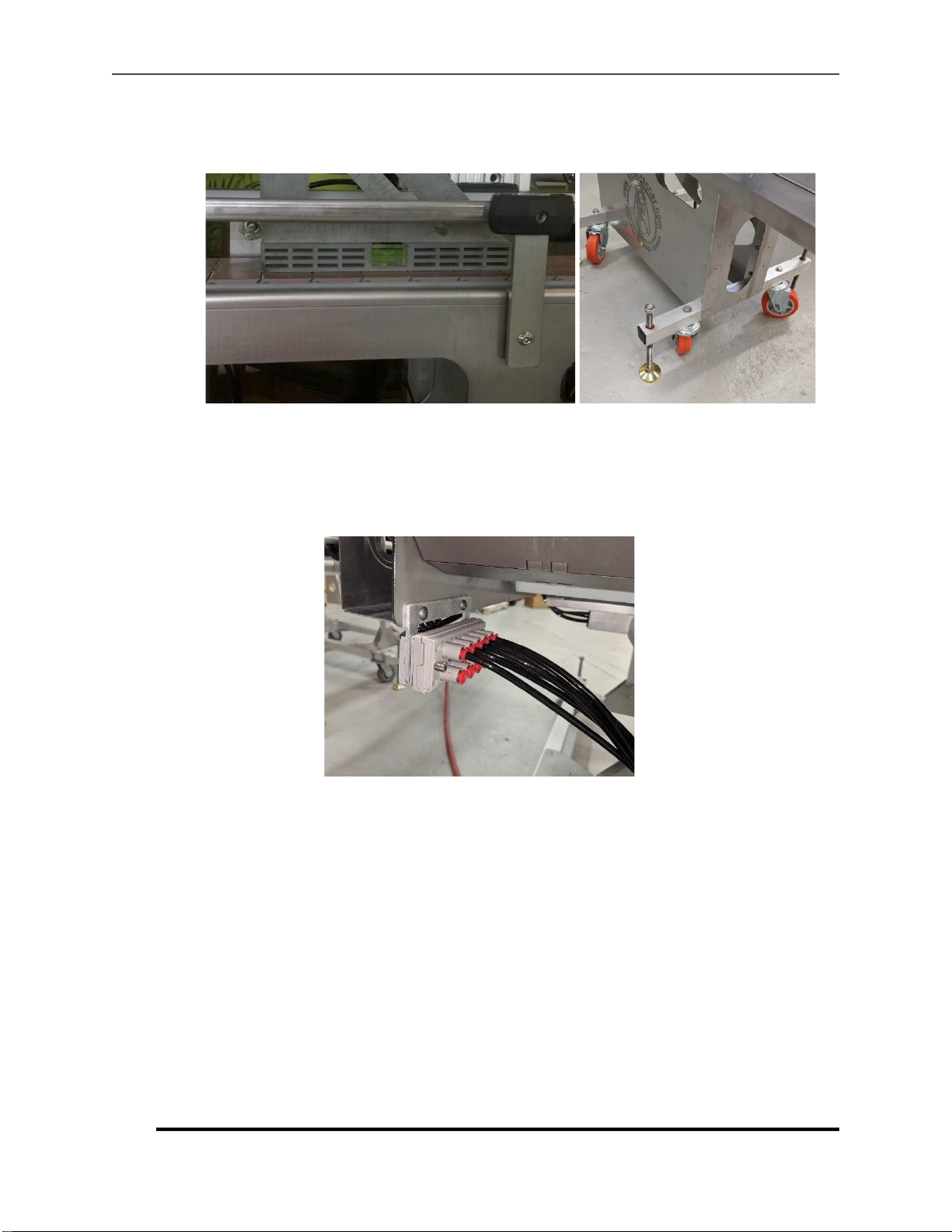

2. With a bubble level on the bed of the conveyor, raise the machine by

lowering the threaded foot pads by hand until the machine is completely level.

3. Place and level add-on rinse / feed system, if applicable

a. Start by adjusting foot pads to adjust until rinse platform and print track are

aligned.

b. Connect the proximity cable sensor and the multi-port manifold

4. Verify that the machine and feeder is setup to run the desired size.

5. Verify that the cap shedder is at the appropriate running height. Run a can

by hand under the shedder to verify the end catches and falls on top of the

can.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 8 of 19

6. Plug in the machine power, infeed power, hook up the air supply, connect

Co2 on the quick connect fitting located behind the filler head, attach cold

water supply to both the line and the rotary feed / rinse package, and attach

supply of sanitizer to the filling station.

7. With the machine on, e-stop button off, and the fill station raised, put the

machine into paused mode. On the fill station screen (F3) on the HMI hit

the on/off button to open the valves and let the sanitizer flow completely

through the fill lines.

a. During this process leave 4 cans under the filling station so they will

fill with sanitizer.

b. Make sure sanitizer has fully made it through the system.

c. Using the fill station screen, lower the fill station so that the fill tubes

and float switches can be soaked with sanitizer.

d. On the HMI turn the fill valves off.

e. Let sit for desired amount of time.

f. Raise the fill station.

g. Remove the 4 cans filled with sanitizer.

h. Fully purge system with product.

8. Load ends into cap feeder station.

9. Turn machine to automatic mode.

10.Engage the “hold back cans” button on the first screen.

microcanner MCCRAFT

MC CRAFT (V1.0) Page 9 of 19

11.Load cans

*Be sure to check the seam dimensions (5.4) on the first few cans, and

periodically throughout the run.

5 SEAM SETUP GUIDE

5.1 GETTING STARTED

●Prior to getting started review seam setup dimensions (7.3) and

controls (7.6) in the HMI operations section (7).

●Your machine will be setup prior to shipment, but you will want to

verify that the seams are still in spec prior to every run, and

periodically while running.

5.2 GENERAL SEAMING INFORMATION

●There are 3 main components to the operation.

1. The center chuck is what the can is pressed into and holds the

can in place for seaming.

2. The 1st operation form tool is to the right of the chuck, and

starts the seam by curling the end around the lip of the can.

3. The 2nd operation form tool is to the left of the chuck, and acts

more as an anvil to flatten and seal the seam

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 10 of 19

●Check out http://www.doubleseam.com/ for a wealth of great

information.

5.3 how to adjust seam form tooling

1. You should read this section 5.3 and the next 5.4 to get a good

understanding of the necessary steps required to properly setup your

tool prior to adjusting any tooling.

2. It is recommended that any step in this section 5.3 be done with the

air powered down, turned off, and the seaming arms moved manually

to verify fit and function. Failure to follow this step could result in

damage to tooling and voiding warranty of the tooling.

3. Unless your chuck becomes loose, or a bearing fails, there is never

any need to adjust it.

4. When setting up the 1st and 2nd op form tools you want to have

about a paper thickness of air gap (.003”) between the shoulder of

the chuck, and the shoulder of either form tool.

5. To adjust the height on either form tool you first need to loosen the

2 jam nuts, then the two set screws that lock the threads of the form

tools. Never use a set screw that is not brass or brass tipped as you

risk damaging the threads of the form rolls. You then turn the form

tools clockwise to raise the tool, or counter-clockwise to lower the tool.

Once in position, retighten the 2 set screws, and jam nuts. Take care

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 11 of 19

to make sure the form tools do not move while retightening the clamp

screws.

1. To adjust the depth of the 1st op form tool you will need to first

loosen the jam nut on the cylinder rod on the rear of the cylinder. Then

put a wrench on the rod of the cylinder and turn the wrench clockwise

to increase depth, and counter-clockwise to reduce depth. Retighten the

jam nut once in desired position.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 12 of 19

2. Adjusting the 2nd op form tool is the same except you turn the

wrench in the opposite direction. Counter-clockwise to increase depth,

and clockwise to reduce depth.

5.4 HOW TO TEST AND MEASURE SEAMS

1. Prior to make sure to complete the steps in section 5.3 to roughly position

the seam tooling to avoid damage to the tooling.

2. Start with the machine on, and in manual mode. ( reference 7.2 for manual

mode)

3. Take a can and fill it with water to give it structural rigidity. The can will get

crushed without fluid in it running through the seaming station.

4. Place an end on the can, and place it on the conveyor prior to the seaming

station

5. The following steps will be done using the seam setup controls screen (7.6).

6. Index the can into position

7. Hit op 1 for op1 test / measure

8. Hit op2 for op2 test / measure

9. Hit op 1 & 2 to check both combined / measure

10.Measure the seam and compare to seam dimensions on the F2 screen.

If dimensions are out of tolerance adjust the tooling until within spec.

11.Do operation 1 until good, then proceed to operation 2, then check a

sequential run

6 CHANGE OVER PROCEDURE

6.1 ADJUSTING THE FILLER

1. Fill 4 cans with water or product to the desired volume/weight, and

place them under the filling station.

2. Go to the filling station screen on your HMI panel, and lower the

filling station so that the fill tubes and float switches are inside the

cans.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 13 of 19

3. Loosen the knob on the switch plate. Move the plate up or down

until the sensor light is activated on the HMI screen. Then tighten

the knob.

4. Use the HMI screen to raise the fill station.

5. Remove setup cans so the machine will be ready to run.

6.2 ADJUSTING THE MAIN HEAD

1. Crack the jam nut on the seamer head

2. In manual mode place a can on the lift puck and using the F3

screen lift the can. Adjust the main bolt until the can has about

1/16” stroke to go (can in firm compression).

3. Retighten the jam nut

6.3 ADJUSTING THE FOAM RAIL

1. Place a can on the conveyor with a lid on it.

2. Using the two screws, set the foam plate about .01 inch above the

can and lid assembly

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 14 of 19

3. Once the rail height is set, put a can with an end on it under the

Cap in Place Sensor. This is the sensor directly above the next can

waiting to go into the seam station.

4. With a can and end directly under the Cap in Place Sensor, Turn the

sensor to adjust its position. Adjust the sensor until the sensor lights

up orange meaning it sees the can. Repeat this step whenever

necessary.

7 HMI OPERATIONS

7.1 HMI BASIC OPERATIONS

●There are 5 menu screens on your HMI F1-F5, which we will get

into in this section. You navigate through each screen by pushing the

corresponding button on the right.

●Most menu screens have buttons on the touch screen tht perform

certain tasks, that will be described in the sections below.

●Below the touch panel, you will see a red emergency stop button.

This E-stop button will shut the entire machine off, and is a vital piece

of safety equipment. Familiarize yourself with this button and its

operations prior to running the machine.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 15 of 19

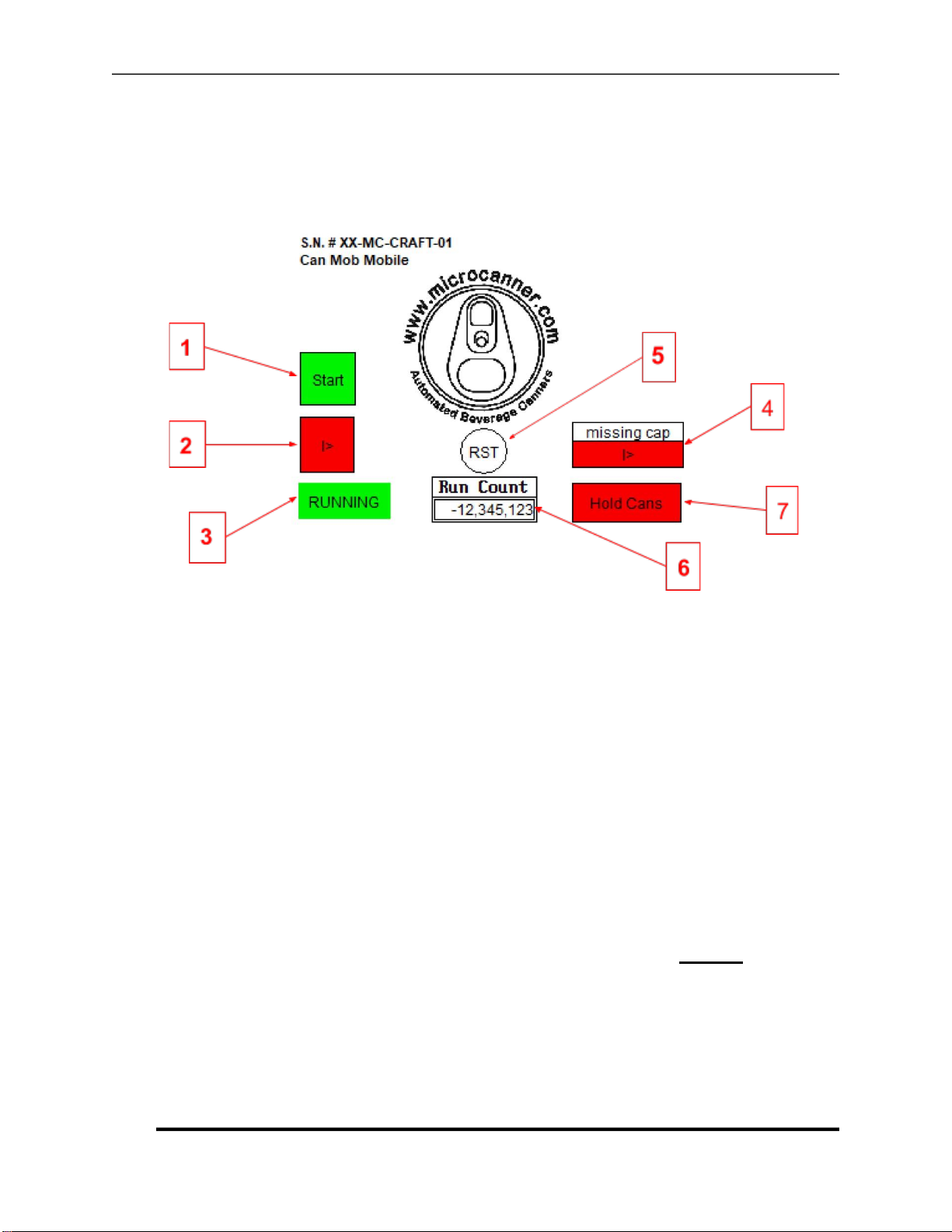

7.2 F1: MAIN SCREEN

●The numbers on the picture below correspond with the numbering in this

section

1. Start: this button will start the convery, and will by default start the

machine in manual mode.

2. Pause (II): Also referred to as the manual button. This button pauses

the entire machine. It can be used as a brief stop of the machine. It

should not be used to do machine maintenance. Always press the

e-stop button prior to doing any maintenance.

3. Running/Paused Icon: This is not a button, but is shown to display

if the conveyor is running or paused mode.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 16 of 19

4. Missing Cap Pause (II): This button should be used when a can with

a missing end has made it under the cap in place sensor. If this

button is not pushed before placing an end on the can, the machine

may actuate early and send a can into the seaming station. After

replacing a missing end, hit the button again to unpause the machine.

5. Run Counter Reset: This button resets the run counter. You can

reset this counter prior to each run.

6. Run Counter: Displays the amount of cans run per session.

7. Hold Back: Use this button to run cans out while holding new ones

from entering the fill station. This is helpful while setting fill weights

or when taking a break.

7.3 F2: SEAM SETUP DIMENSIONS

● These dimensions are for LOE can end. You can also consult your supplier for

manufacturer specific dimensions.

7.4 F3: FILL STATION SETUP

●This screen is to be used for the sanitation of the machine before and after

running product through the machine, and also to set the float valves on

the filling station if they ever need to be adjusted.

●Reference step 7 of startup procedure for sanitation procedure.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 17 of 19

●Reference section 6.1 on how to adjust the filler.

●There are only two buttons on the fill station setup screen

1. Fill Valves on/off: Turns the fill valves on or off.

2. Co2 sanitizer: Use to force sanitizer through the gas valves

3. Fill Lifter: Raises or lowers the fill station.

There are 4 icons at the bottom of the screen that will light up when the

corresponding float valve on the filling station is activated. This is a visual

cue used to set the fill level in each can.

7.5 F4: TOP OFF MODE

●This screen can be used if at any time an additional amount of product

needs to be added to any individual can.

●If you are standing at the front of the machine at the HMI V1 controls the

valve farthest from you, or farthest left, and V4 controls the valve closest to

you, or farthest right.

●Each button push will add an additional 1 /16 of a second. The number

displayed is in milliseconds, where 1000=1 second.

●The Purge timer and the Delay timer can be used to adjust the CO2 can purge

cycle. Use the PURGE to adjust the amount of time that CO2 is being purged into

the can. Use the DELAY to adjust the amount of time between the start of CO2

flow and the start of product flow.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 18 of 19

●It is important to note that these values can reset to 0 if the machine is left without

power for an extended period of time. Always check that these values match the

default values displayed on the screen.

7.6 F5: SEAM SETUP CONTROLS

●This screen is a simple way to be able to run a single can through the

seaming station to test and measure seams.

●Reference the seam setup guide (5) on how to test and measure seams.

●Below is a quick overview of the buttons and how they function.

1. Lift Can: Either lifts or lowers the lift puck depending on the position

it is already in.

2. Motor on/off: Turns the seam chuck motor on or off.

3. Index Can: Indexes the rotary actuator that will let you feed a can

in or out of the seaming station.

4. Opp 1: Extends the 1st operation tooling. This button needs to be

held to keep the form tooling in position.

5. Opp 2: Extends the 2nd operation tooling. This button needs to be

held to keep the form tooling in position.

microcanner MCCRAFT

MC

CRAFT (V1.0) Page 19 of 19

8 TIPS FOR A SUCCESSFUL RUN

● When canning you want the temperature of your product to be as close to

32°F as possible for your first run. The key to low dissolved oxygen levels

is to have a perfect mushroom of foam when the cans leave the fill head.

To achieve this, tank pressure, temperature and carbonation rates must be

experimented with on each beer until this desired condition is met. When

starting out, only can the beer you know will sell in a couple of weeks.

TRAINING VIDEO:

https://drive.google.com/file/d/15lYzGAO0vqxMuBtbdCOSRqZ4sKJ-

cA8C/view?usp=sharing

Table of contents

Other Microcanner Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Zephyr

Zephyr ZGS-12000-4 Operation and maintenance manual

Harbor

Harbor CENTRAL 60738 Owner's manual & safety instructions

ESAB

ESAB GASARC GPE 400 Series Installation & operating instructions

Electrolux

Electrolux UNIC AURA Programming Maintenance Troubleshooting

Siemens

Siemens GCP5000 instruction & installation guide

Eaton

Eaton Airflex WCBD Series Installation, operation and maintenance manual