Microcanner PAK TECH Instruction Manual

Other Microcanner Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Parat

Parat PARAPROJECT TROLLEY U40 WOL user manual

Bosch

Bosch RA1171 Operating/safety instructions

Rath

Rath RGD Series Installation & operating manual

Festo

Festo EHPS LK Series operating instructions

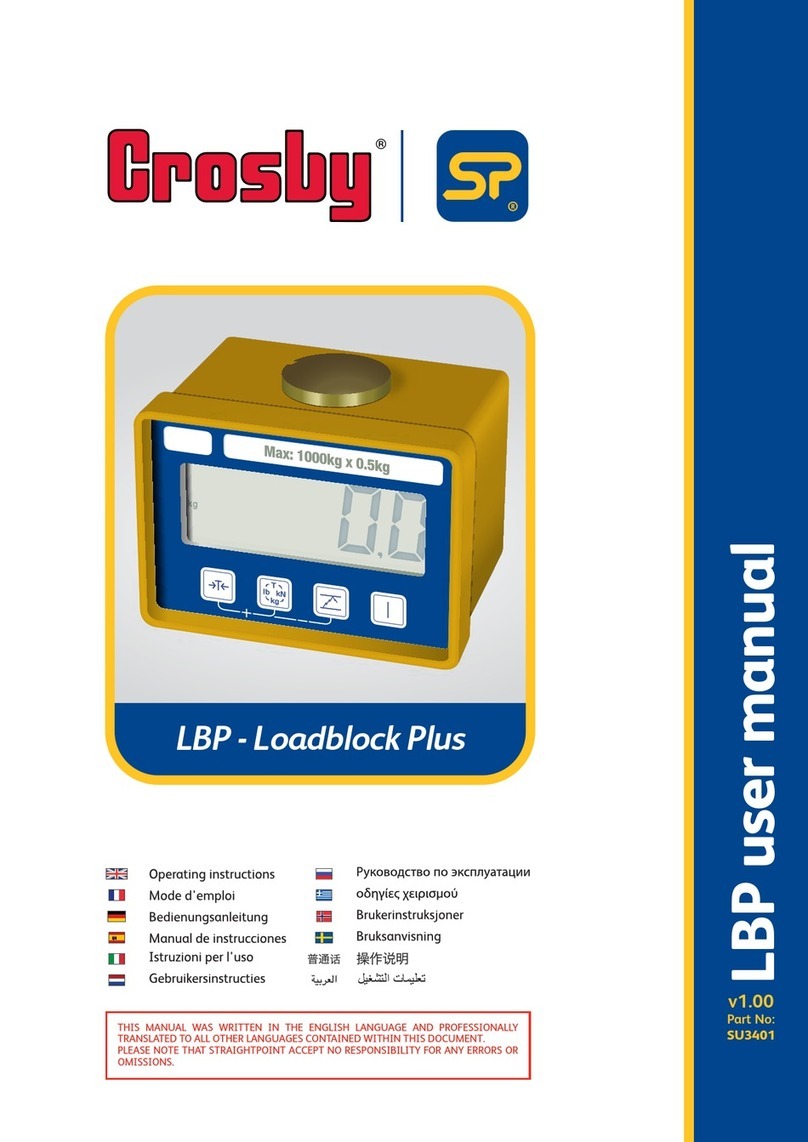

Crosby

Crosby Loadblock Plus operating instructions

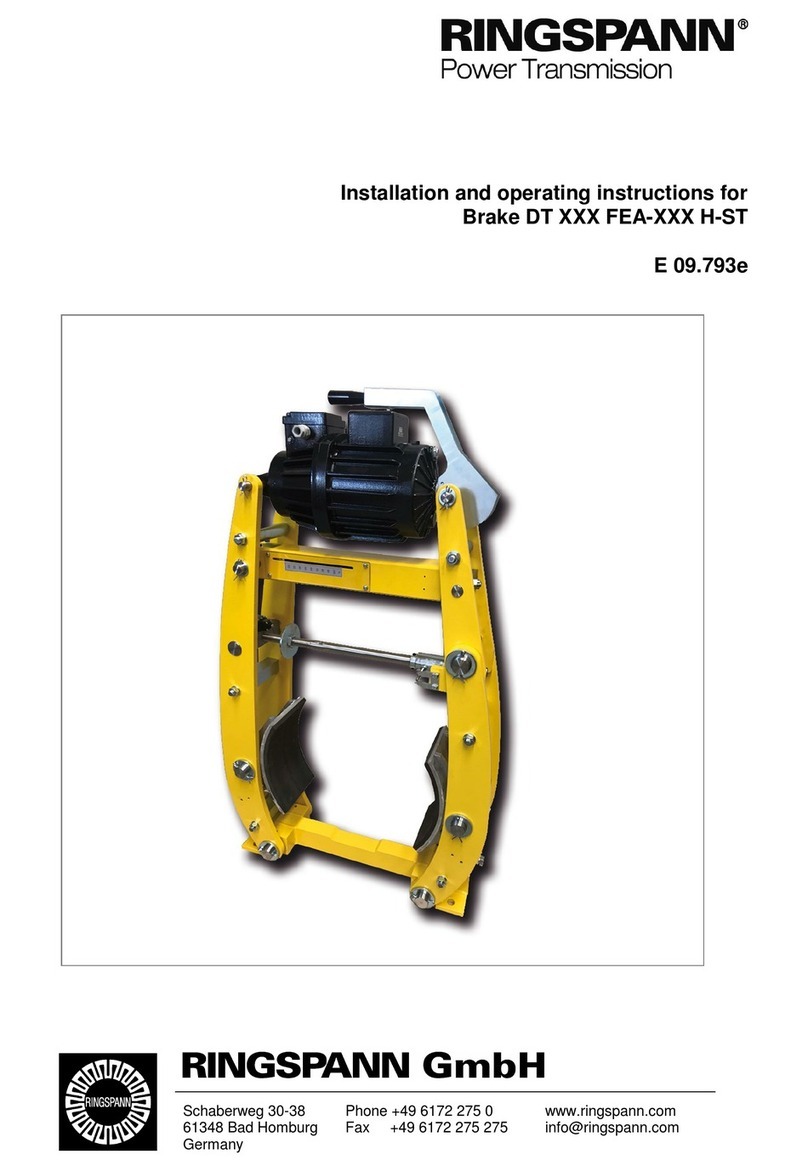

RINGSPANN

RINGSPANN DT FEA H-ST Series Installation and operating instructions