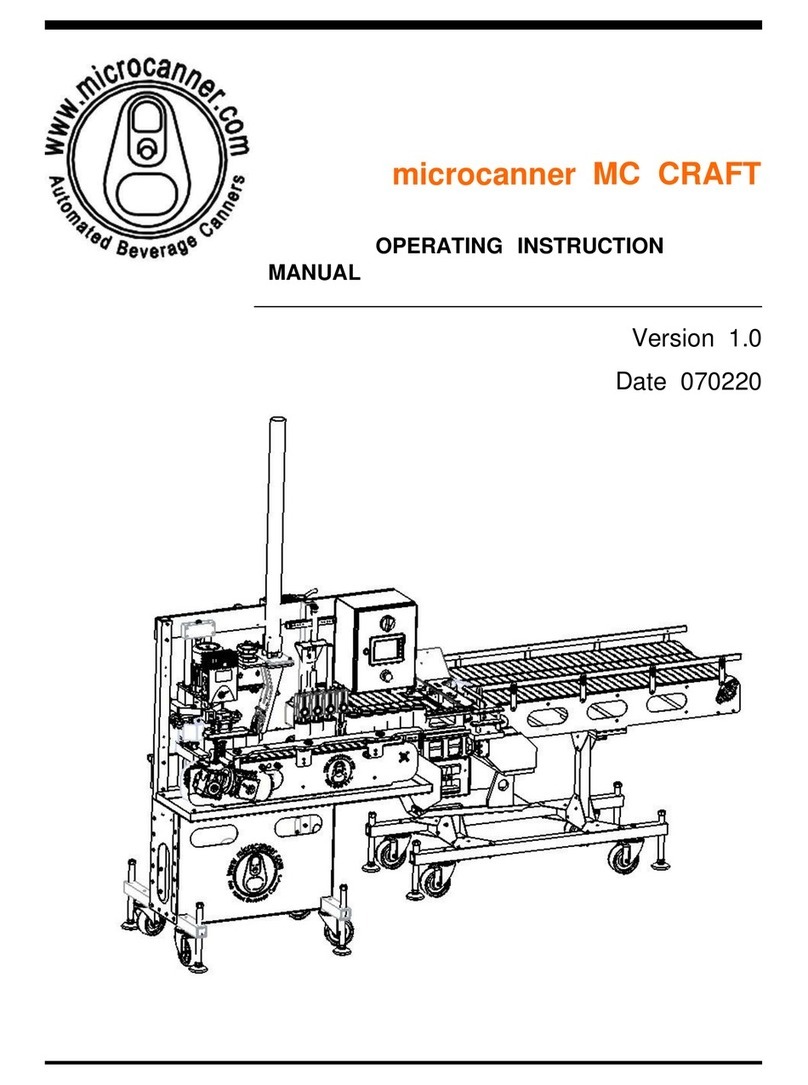

Microcanner MC ATOMIC Instruction Manual

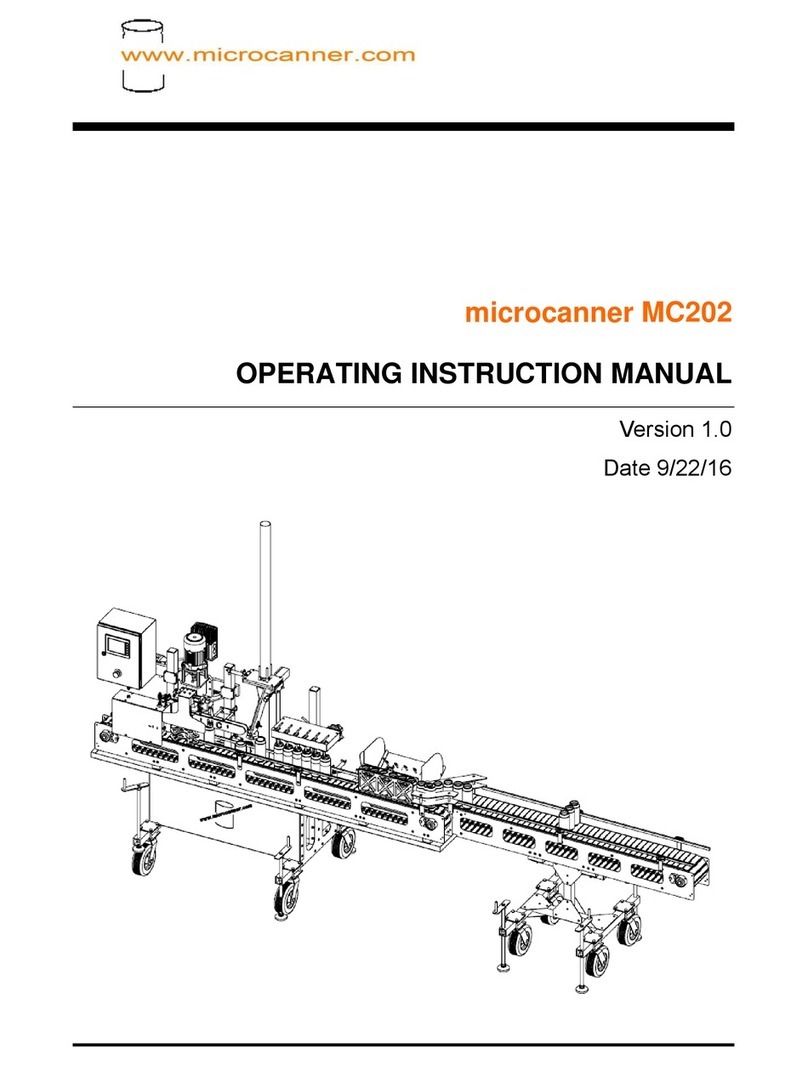

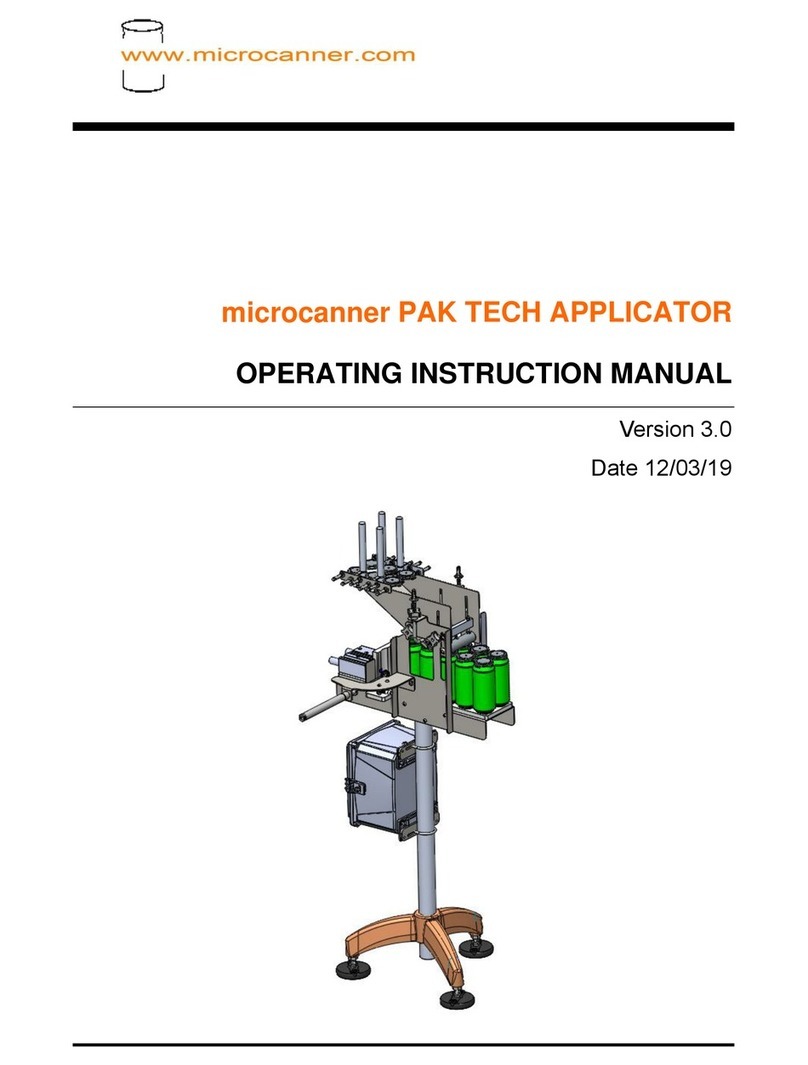

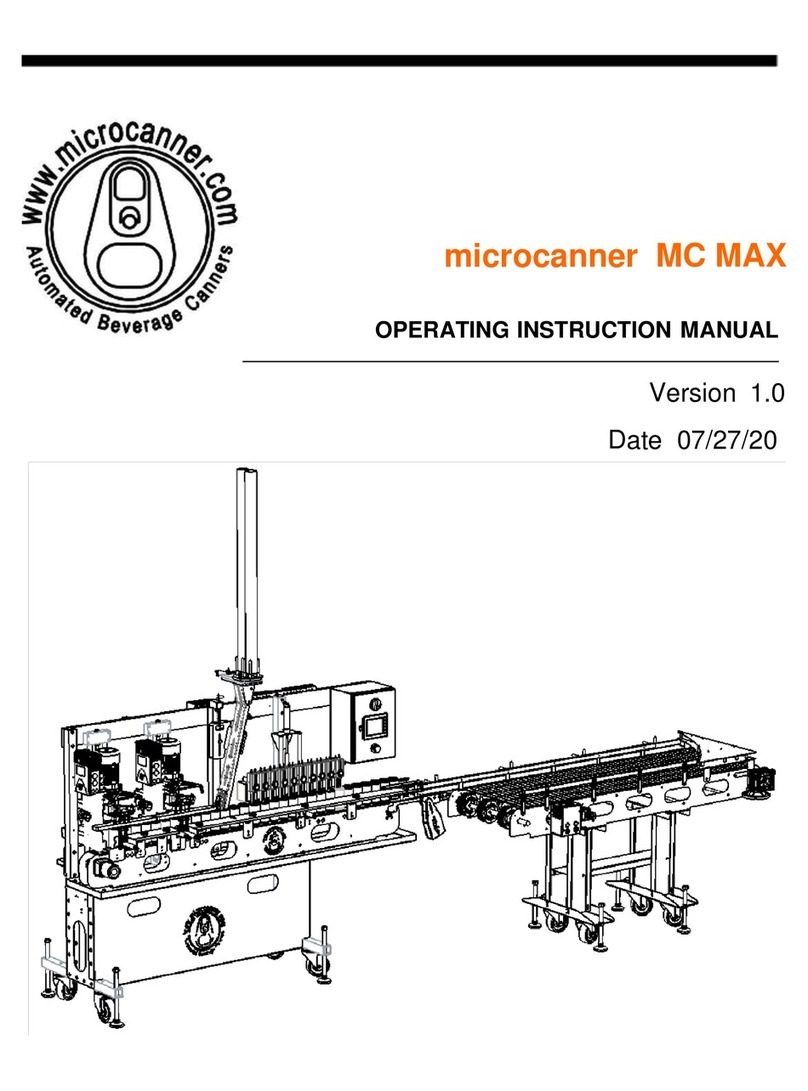

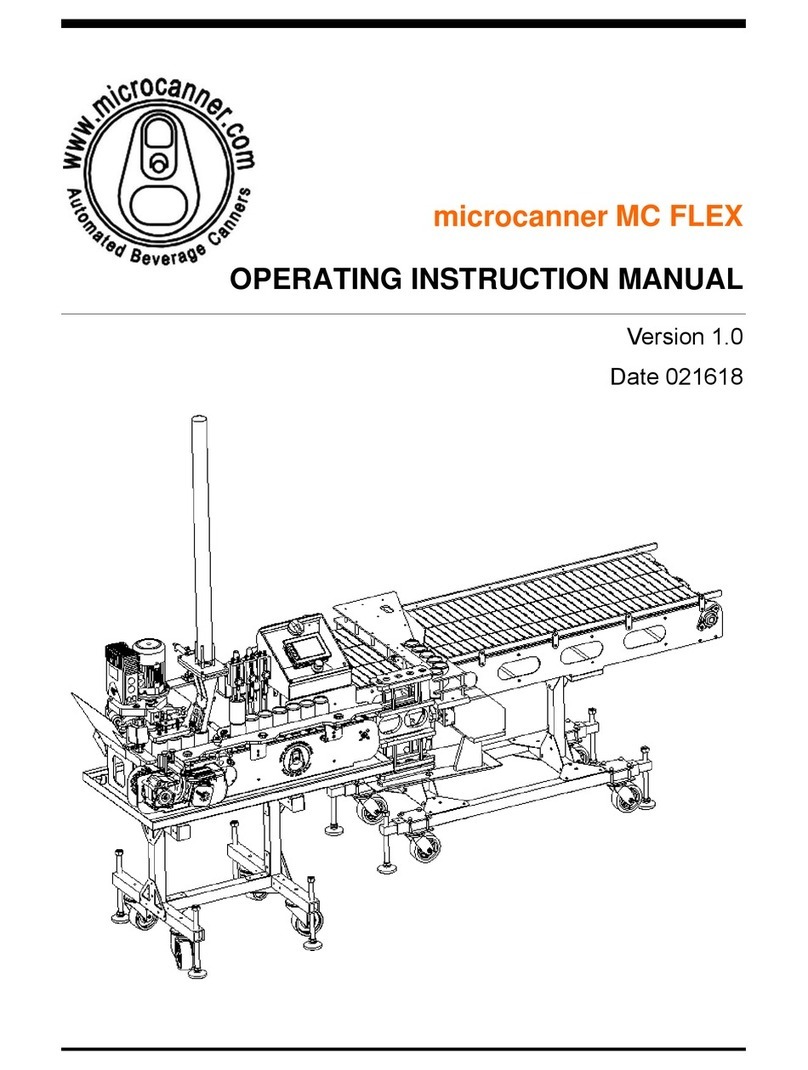

Other Microcanner Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Greenbroz

Greenbroz 215 CannaGin user manual

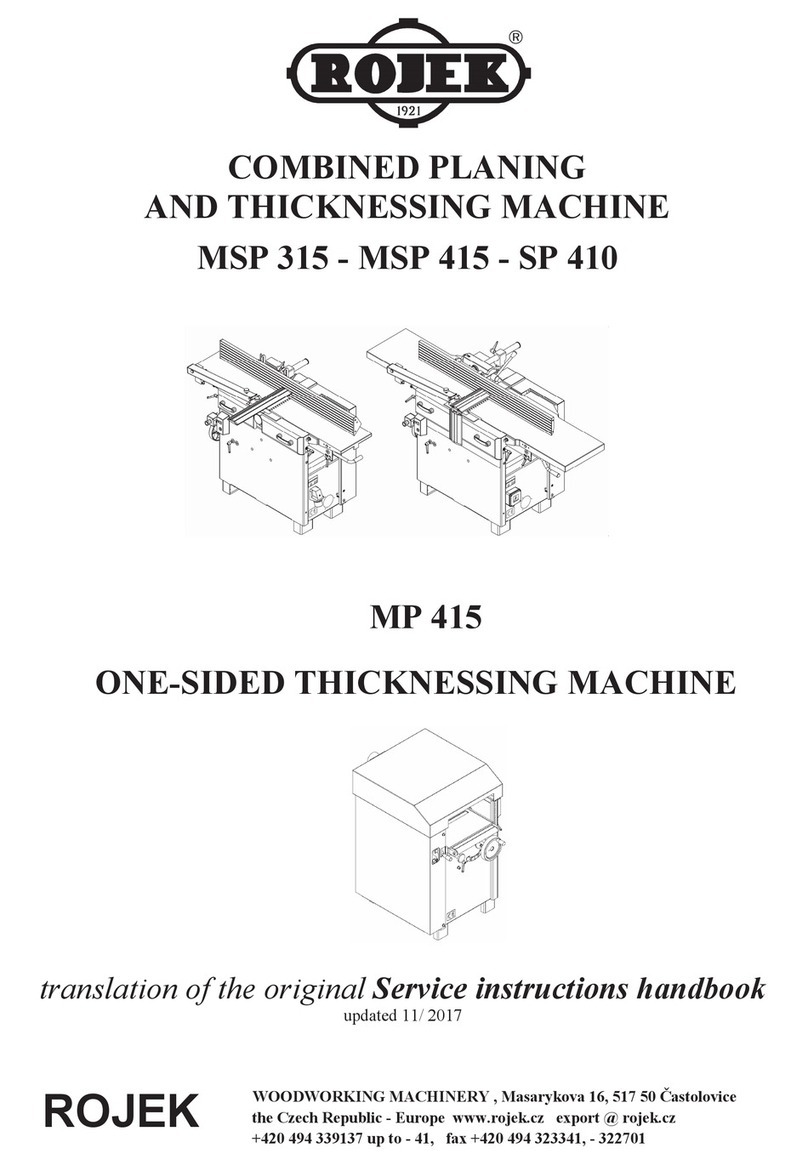

ROJEK

ROJEK MSP 315 Service instructions

Siebeck

Siebeck MK III Series Translation of the original operating manual

Kobelt

Kobelt 5022-SA Owner's Operation, Installation & Maintenance Manual

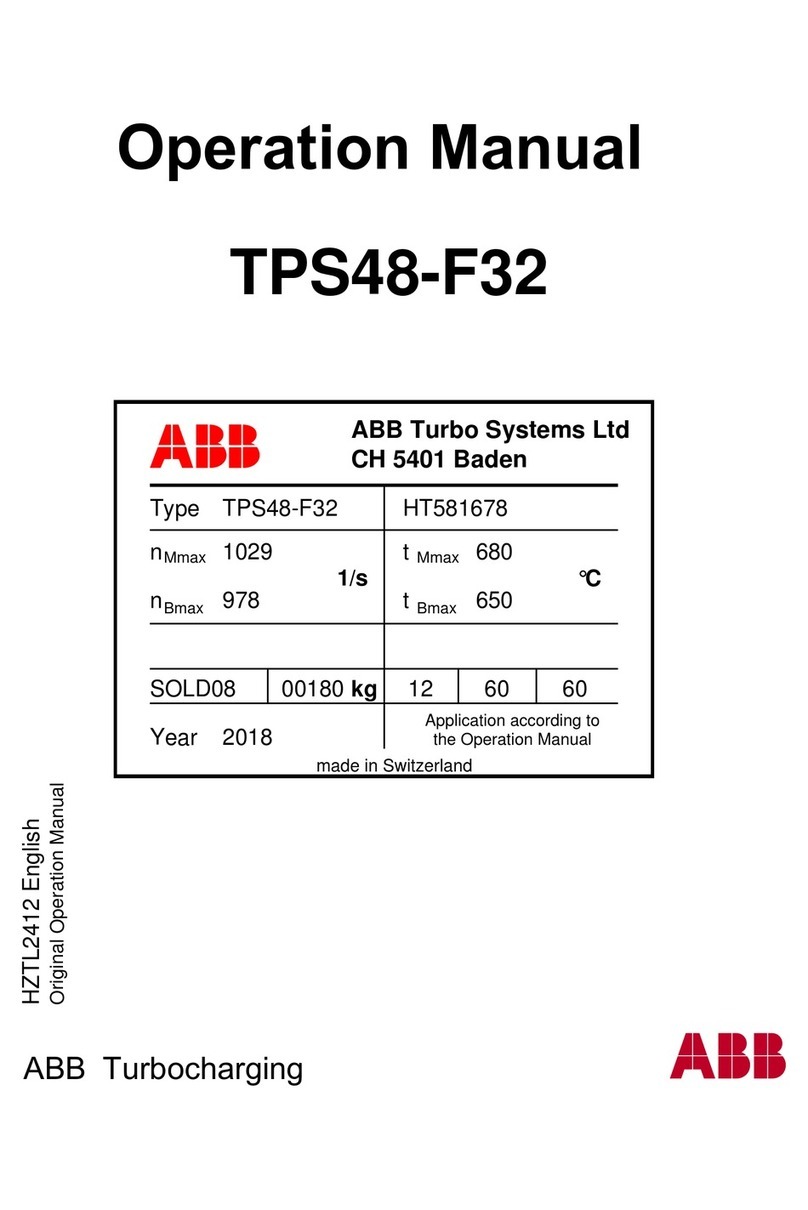

ABB

ABB HT581678 Operation manual

Greenlee

Greenlee 658 Operation, service and parts instruction manual

Time Electronics

Time Electronics 1053 Technical manual

Westermo

Westermo RedFox Industrial Rack Series user manual

YASKAWA

YASKAWA Motoman DX200 Maintenance manual

Rockwell Automation

Rockwell Automation Allen-Bradley 1606-XLSREDS40HE Reference manual

Vestil

Vestil HOOK-BASE instruction manual

SAINT-GOBAIN

SAINT-GOBAIN CertainTeed Volu-Matic 200 Operation Manual and Safety Information

CertainTeed

CertainTeed Volu-Matic 300 Operation Manual and Safety Information

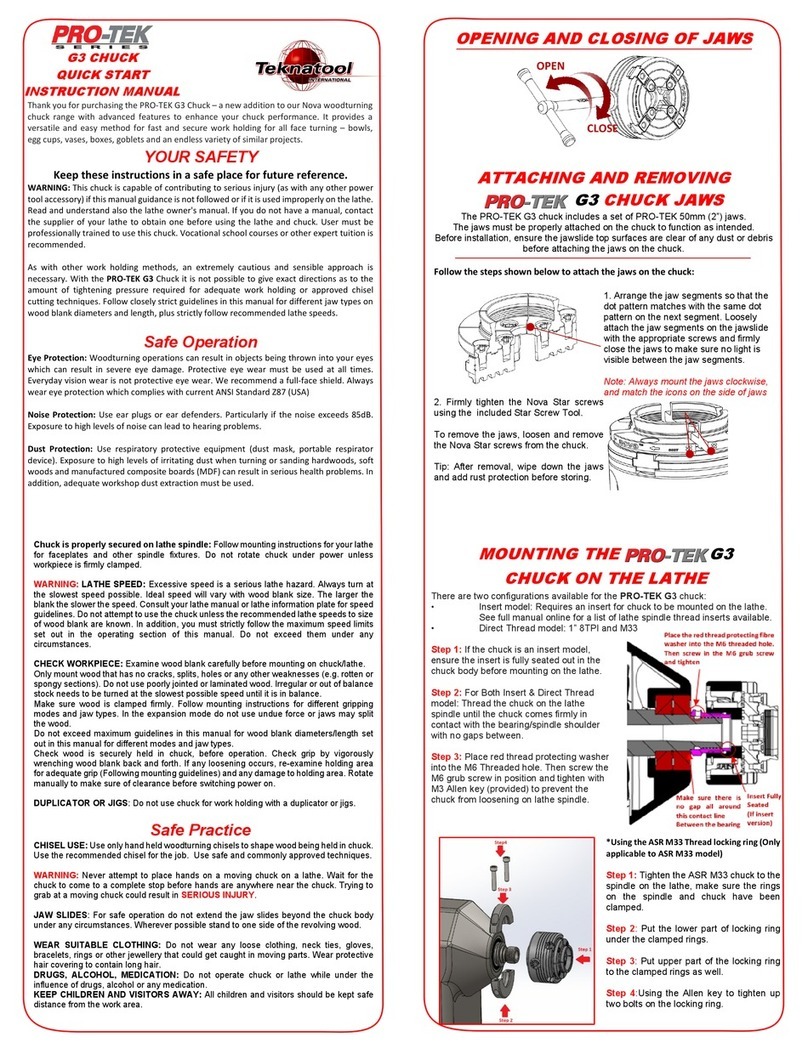

Teknatool

Teknatool PRO-TEK G3 Quick start instruction manual

Halfen

Halfen HLB Series Assembly instructions

Optex

Optex TSC-10-D instruction manual

Ideal Heating

Ideal Heating IMAX XTRA 2 manual

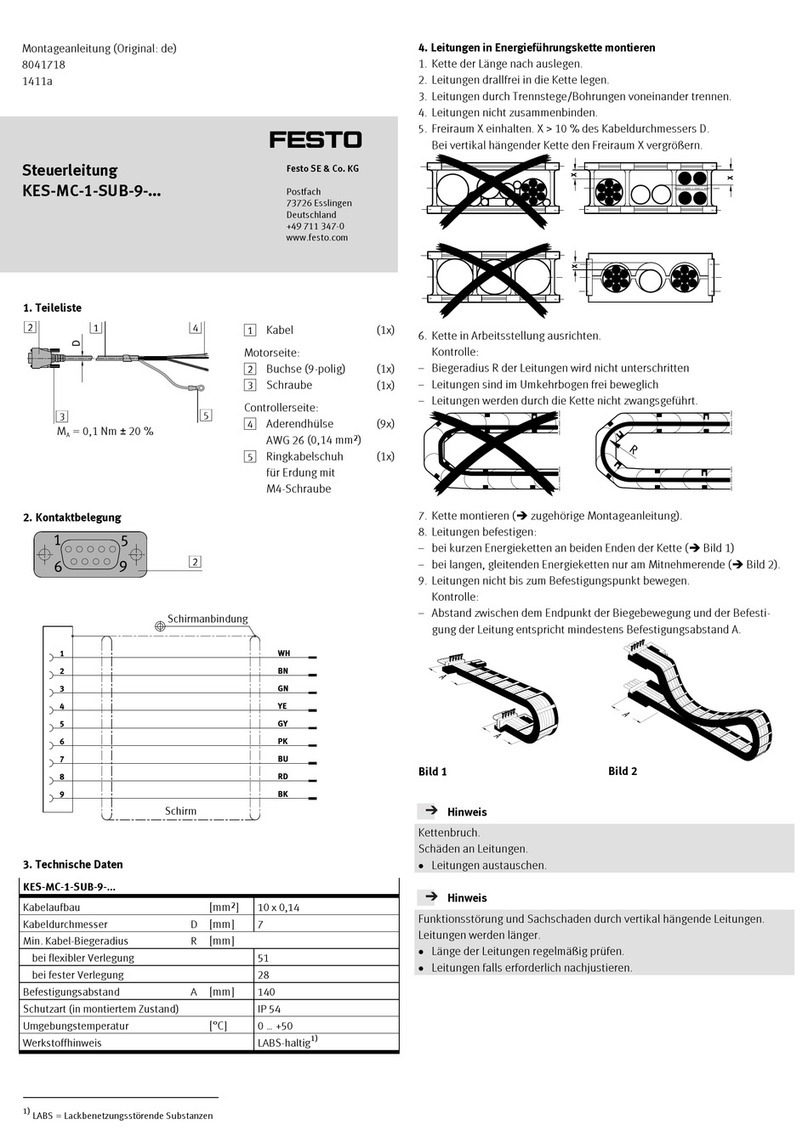

Festo

Festo KES-MC-1-SUB-9 Series Assembly instructions