Fixed Hoist Test Facility Operation and Maintenance Manual ZOM-12000-4 rev 0

Page 2 of 33

This manual contains proprietary information and is not to be copied or disclosed without written

permission from Zephyr International LLC. Copyright 10-2-2006

Fixed Hoist Test Facility (FHTF)

Purpose: The FHTF when used in conjunction with the Mobile Rescue Hoist Ground

Support Equipment (RHGSE) provides the capability to operate the rescue hoist off of

the aircraft in order to perform intermediate level maintenance and troubleshooting.

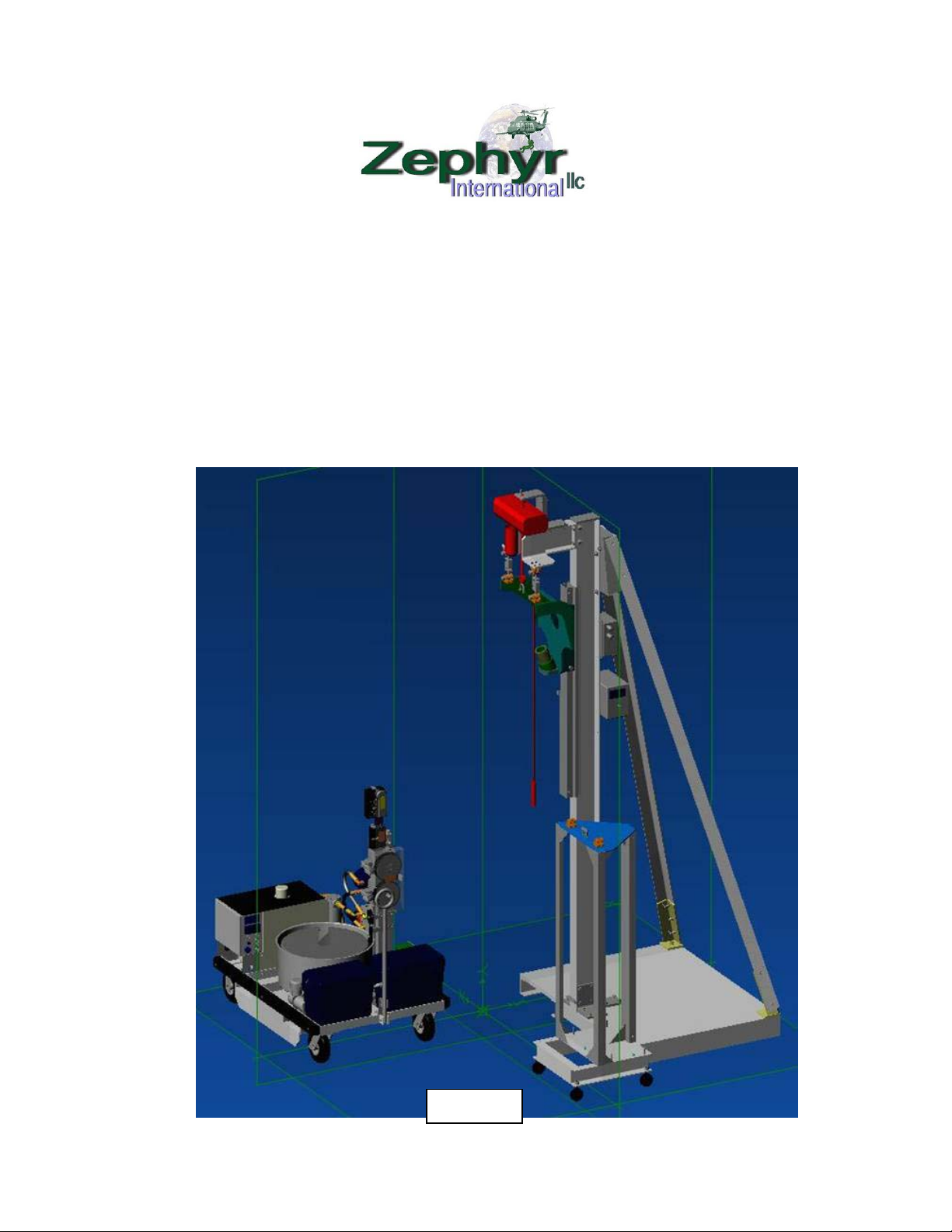

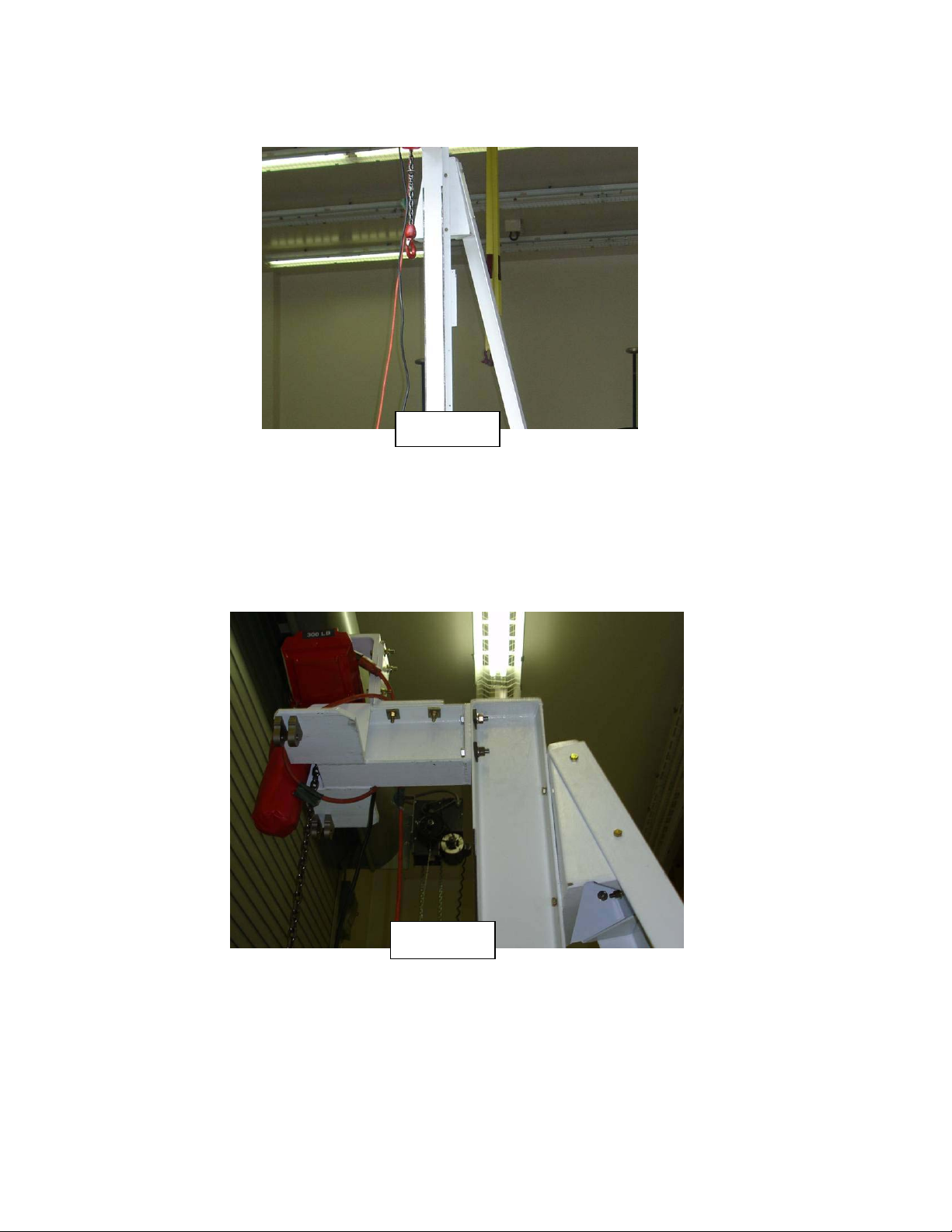

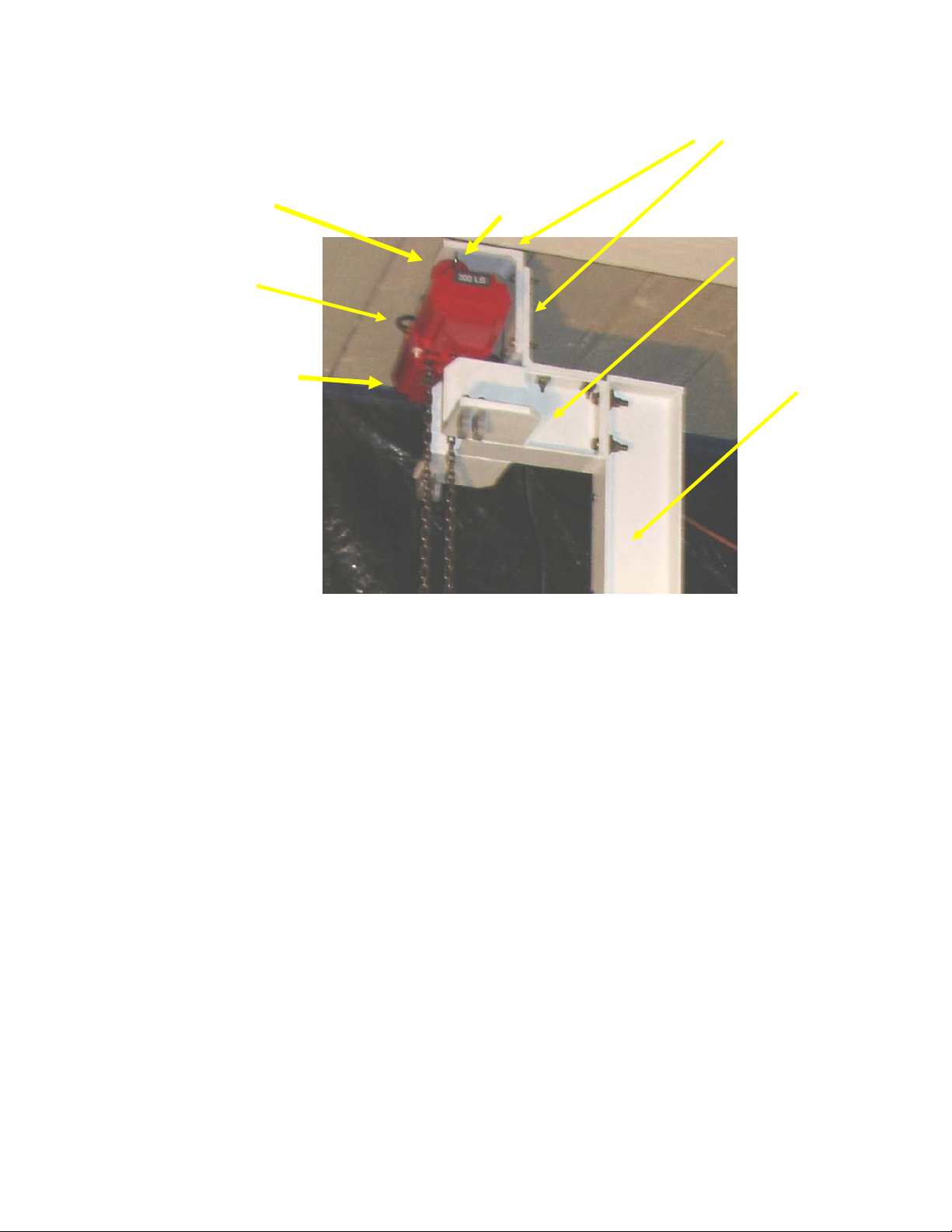

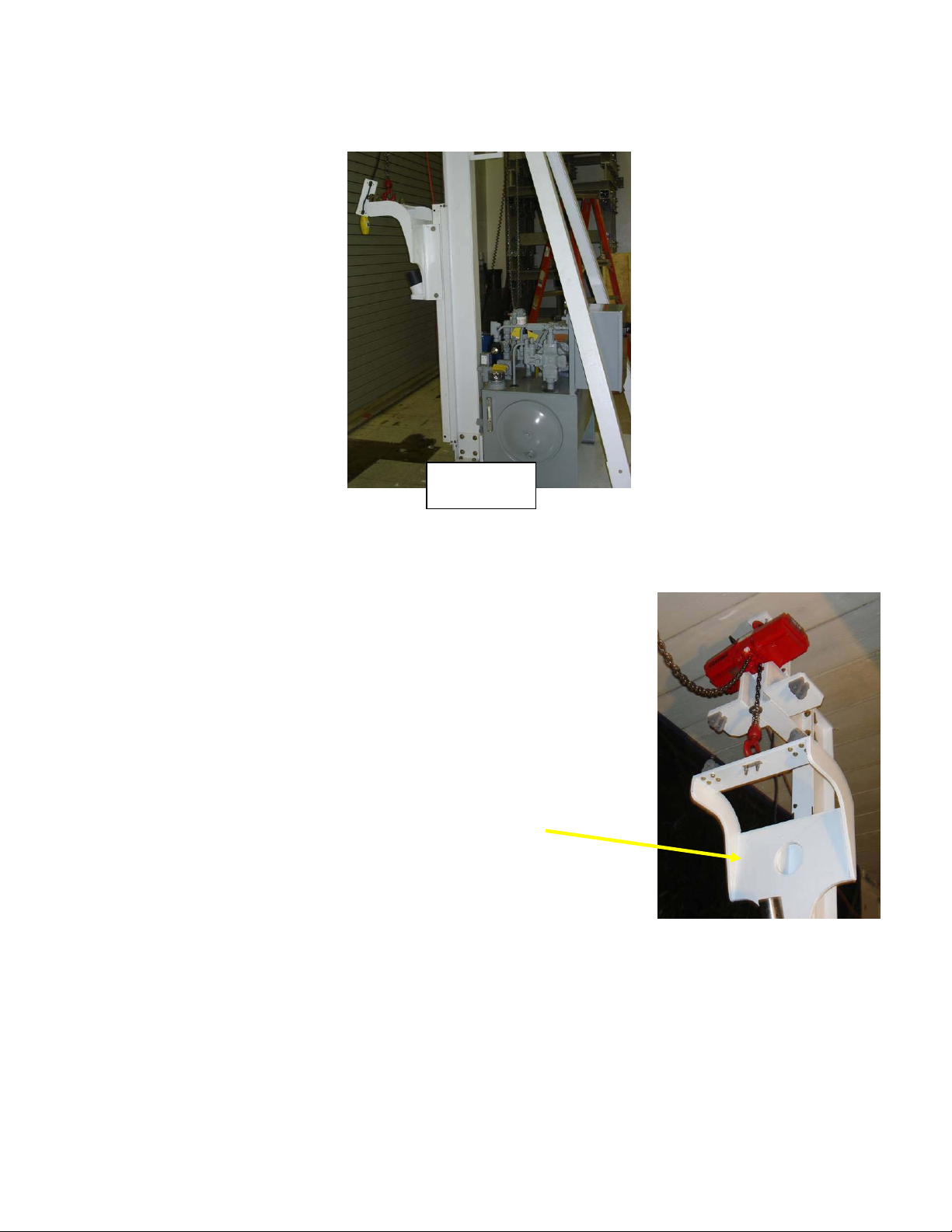

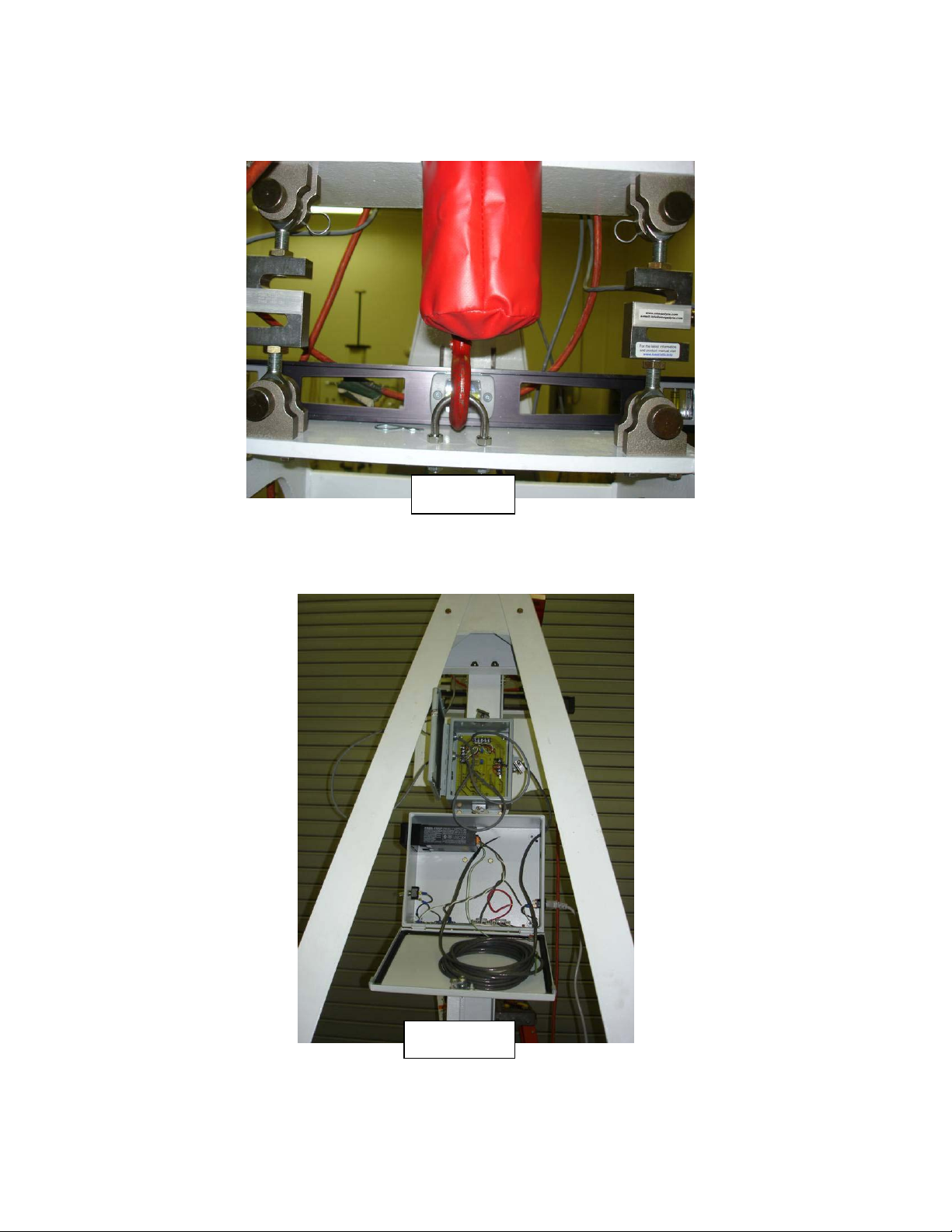

Description of FHTF: The FHTF consists of an upright structure, including an upper

weldment assembly, a hanging hoist mount, a chain hoist for raising and lowering the

unit under test (UUT), and a load weigh system. The UUT power and control signals

are provided by a customer supplied set of controllers and pendant and power supply.

Theory of Operation: The upright structure is equipped with a chain hoist to raise

the UUT up to the top of the structure where it is attached to two load cells. The two

load cells provide signals to a load cell summing box where the signals are summed

and sent to a display. The load readout can be set to zero to tare the readout with no

load applied to the rescue hoist hook.

The wire rope tensile load is provided by the RHGSE. The RHGSE provides the

capability to extend the wire rope under approximately 100 lbs. maximum load, and

provides the capability to retract the wire rope under approximately 600 lbs. maximum

load.

FHTF Limitations:

The FHTF is not intended to provide the capability to perform a complete acceptance

test as per the OEMs requirements but to allow the maintenance personnel to perform

checks of the system performance, set the hoist’s limit switches, adjust the levelwind,

and replace and condition the wire rope before the UUT is mounted onto the aircraft;

thus minimizing aircraft down time and flight time required if those procedures were

carried out on the aircraft.

Modifications to achieve full ATP capability

The FHTF has been supplied as requested without an auxiliary hydraulic power

supply, however with some modifications the FHTF and the RHGSE can be upgraded

to perform a complete ATP of the UUT. Please contact Zephyr International LLC for

details.