B. STARTING UNDER NORMAL CONDITIONS

1. Take all necessary precautions previously stated, and ensure the workpiece can rotate fully without obstruction.

2. Put the manual & auto feeding Clutch to right or left side, depending upon whether or not auto feeding is required.

IMPORTANT: This should ALWAYS be a deliberate, conscious action.

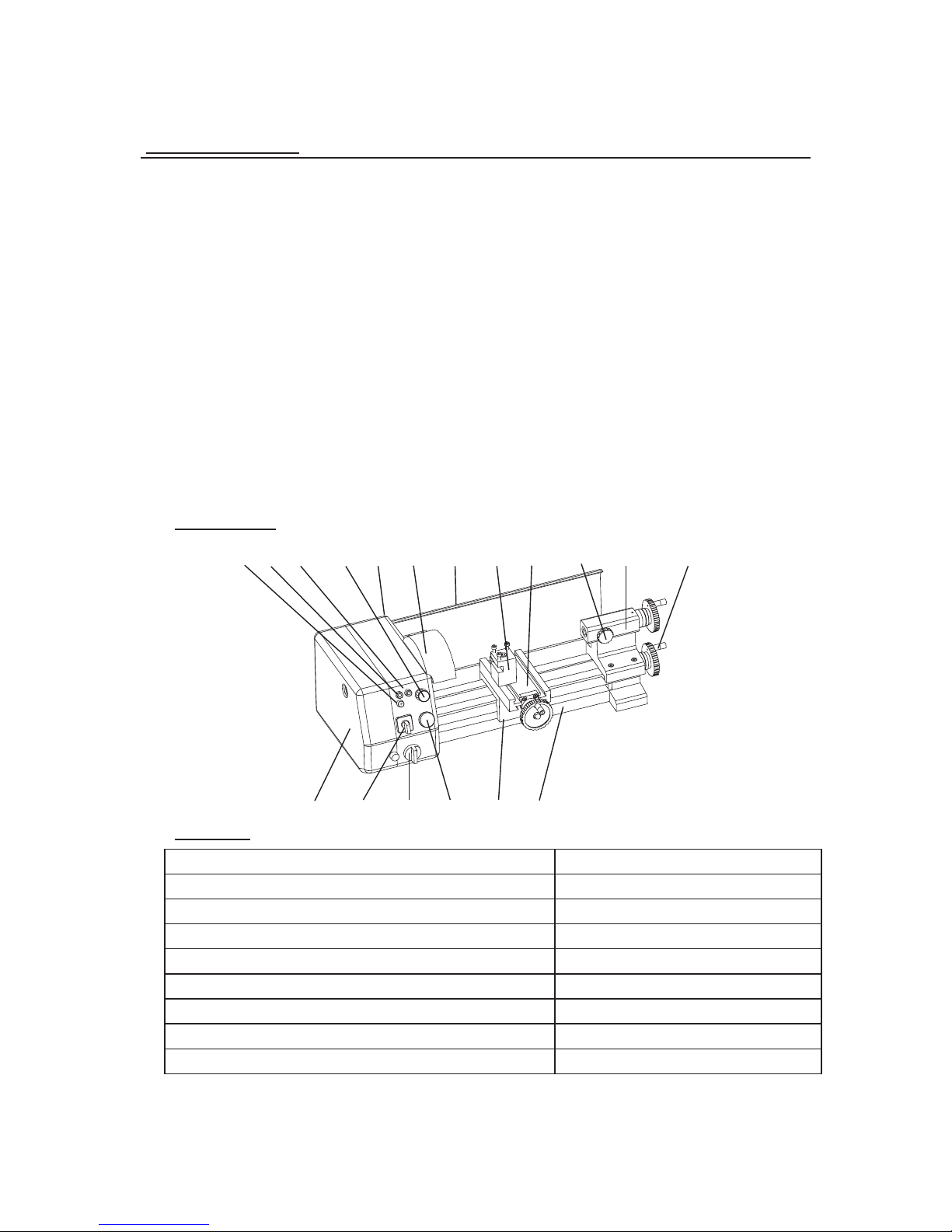

3. To prevent damage, the carriage drive screw clutch must be engaged with the motor off. To engage the clutch,

turn the clutch control knob (1) gently clockwise while, at the same time, rotating the lead screw hand wheel (13)

until the clutch fully engages (you’ll feel this in the knob as it goes all the way “over”). Before starting the lathe,

you’ll want to make sure there is plenty of clearance for the carriage to move unobstructed. The carriage drive

may be disengaged while the lathe is either running or stopped. To do so, rotate the control knob with a swift, firm

motion counterclockwise to the disengaged position. Remember to stop the lathe before attempting to re-engage

the carriage drive screw clutch.

4. Proceed to start the machine as described in Section A.

5. If the machine is finished with or is to be left unattended, turn the F/O/R switch to the OFF position then

disconnect from the main supply.

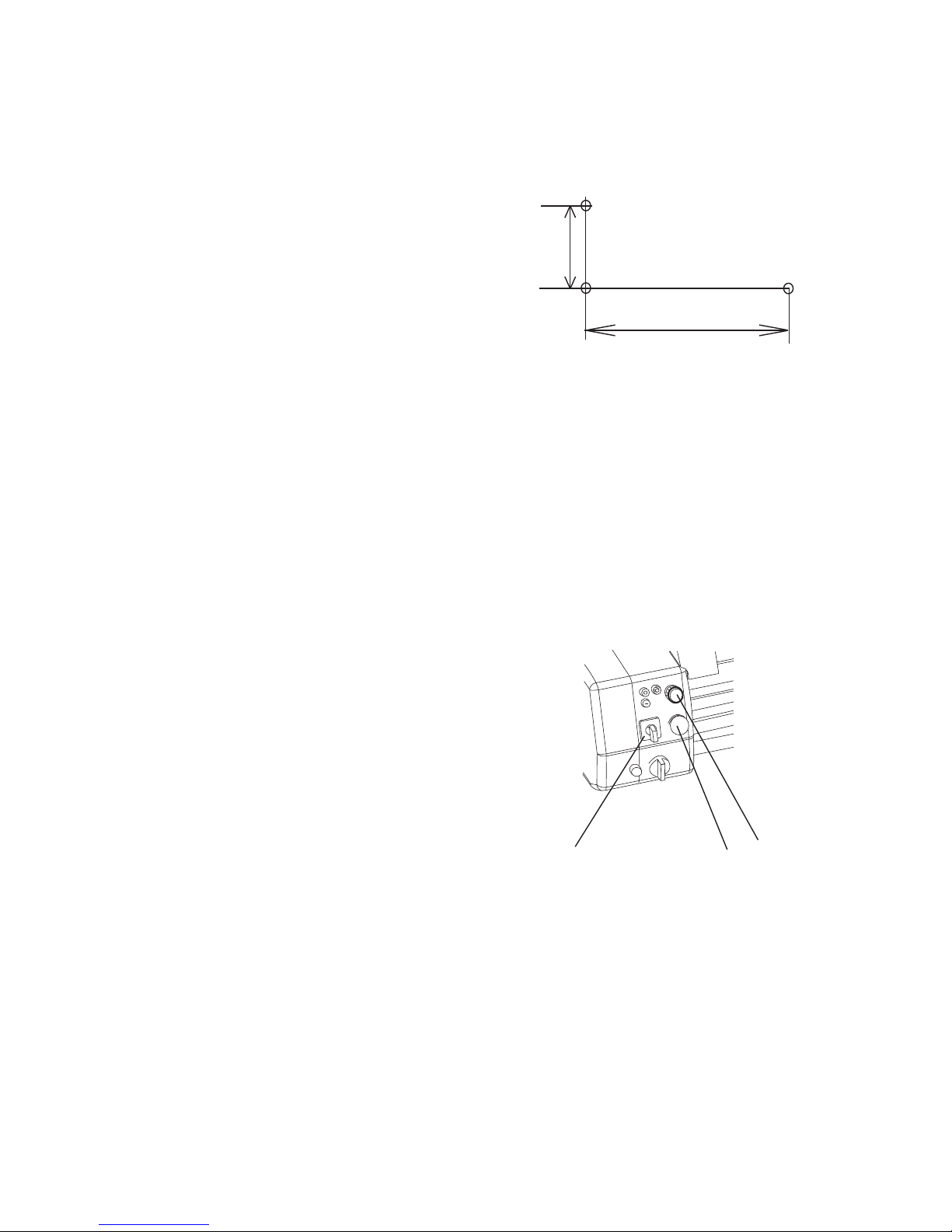

ATTENTION: The power supply system of this machine has an automatic overload protective device. If cutting or

drilling too deep, the system will stop working, and a yellow lamp (C, on the main panel) will light. Just turn down the

Variable Speed control knob (E) and move directional switch (A) to neutral and then turn on again. The system will

work again and the yellow lamp will go off automatically.

OPERATION

SIMPLE TURNING

Before starting the machine, as described above, it is imperative that the setup for the type of work to be carried out

is fully checked.

The following notes are guidelines as to how to set up the lathe in order to carry out a simple turning operation.

ALWAYS plan your work. Have drawings or a plan on hand together with any measuring instruments you may

require, such as micrometers / verniers / calipers etc.

Select a cutting tool that will produce the desired cut and mount in the tool rest, with as little overhang as possible,

secure it using the hex socket head screws (ideally, the overhang should be approximately 6mm but not more than

8mm for a straight tool).

lt is IMPORTANT to ensure that the tip of the cutting tool is on the center line of the work, or very slightly below it.

On no account should it be above the center line.

Where necessary, shims should be used beneath the tool in order to achieve the correct height or, if the tip is too high

or too low, you may find the rocker side useful, and the last recourse is to select another tool or grind down the tip.

To ch e ck th e tip i s at th e c or r ect h eig ht, p o si t ion t he to ol so t h at t h e tip i s alm ost t ouc h ing t he po int o f the t a ils toc k

center. They should coincide. If necessary make adjustments using shims or grind down the cutting tip or select

another tool.

When satisfied, mount the work, either in the chuck or on a faceplate, and if necessary, use the tailstock center

for additional support(if the work cannot be adequately secured by the chuck, or if it is a long piece, or of small

diameter). Additionally, ‘Steady rest’may be used.

If the tailstock is not to be used you may remove it completely by slackening off the securing screws at its base, and

sliding it free of the bed.

Mark the surface of the work at the point where the cut is to end, i.e. the shoulder, using a scriber or similar means,

and move the saddle so that the cutting tool is directly opposite the mark, then wind in the cross-slide so that the tool

touches the surface of the work.

While carrying out these maneuvers, rotate the chuck by hand to ensure that nothing will come into contact with it

when turning takes place, i.e. there is adequate clearance between the saddle, cross-slide, tool post or cutting tool,

and the chuck.

7