6

3 – TEN KEY POINTS FOR USERS

The following list is intended to be referred to prior to commencing each

spraying operation, to remind users of the key points for the safe and

efficient use of the MICROMAX atomiser.

1SAFETY: Always refer to the product label for specific

recommendations for each product, and to Section 4 ‘Safety and

En ironmental Considerations’ before commencing any spraying

operation.

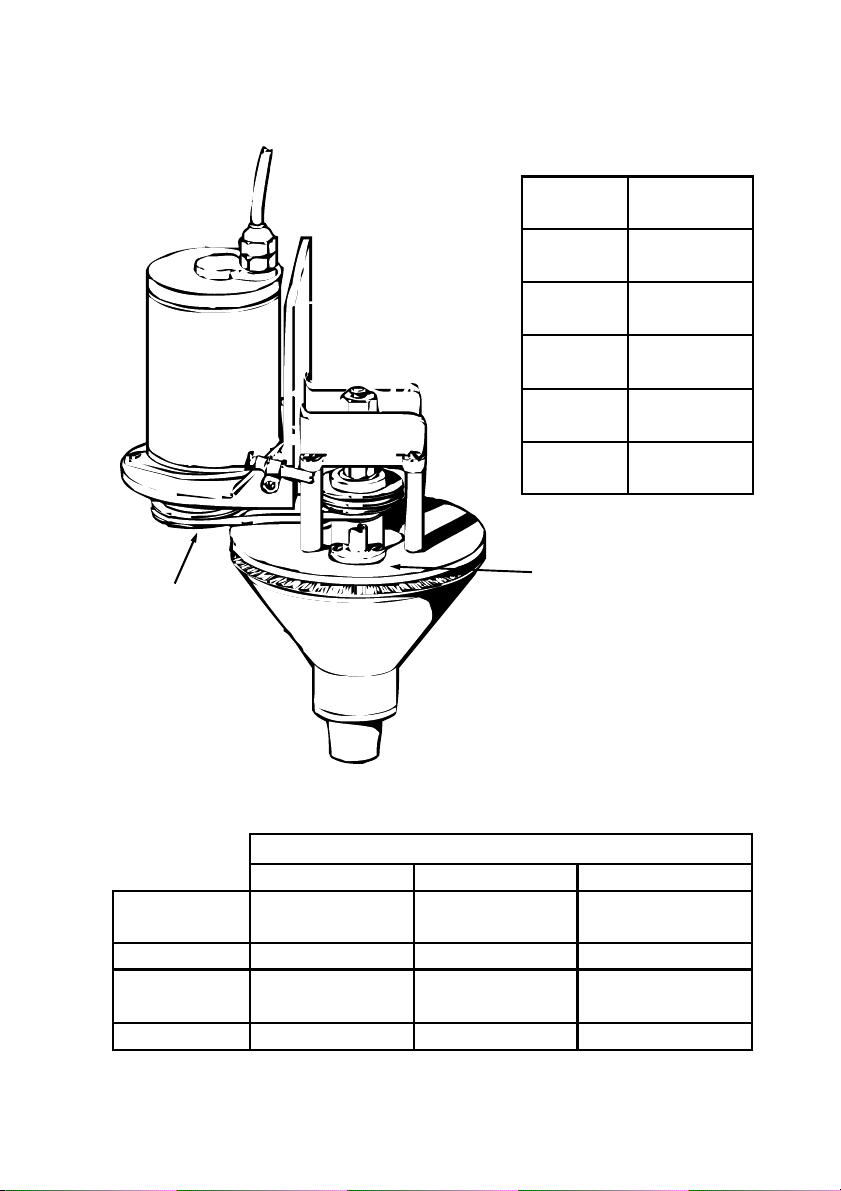

2 Check that all atomisers rotate freely. If binding or roughness is felt,

inspect the motor, belt dri e and disc bearings.

3 Check that the pulleys and belts are clean and free from damage

and that the appropriate gear is selected, see Section 7 ’Calibration

and Adjustment’.

4 Check that the atomiser discs are secure and free from damage or

blockage by dried chemical.

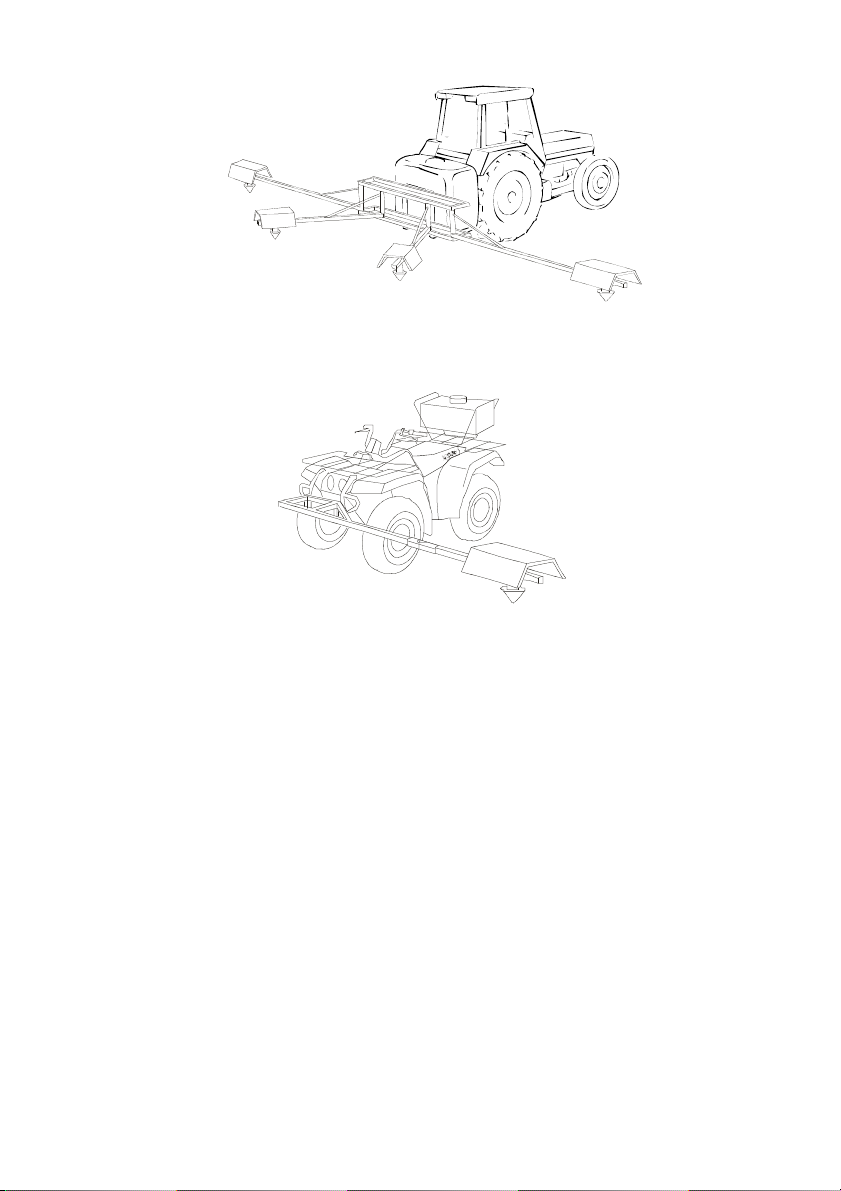

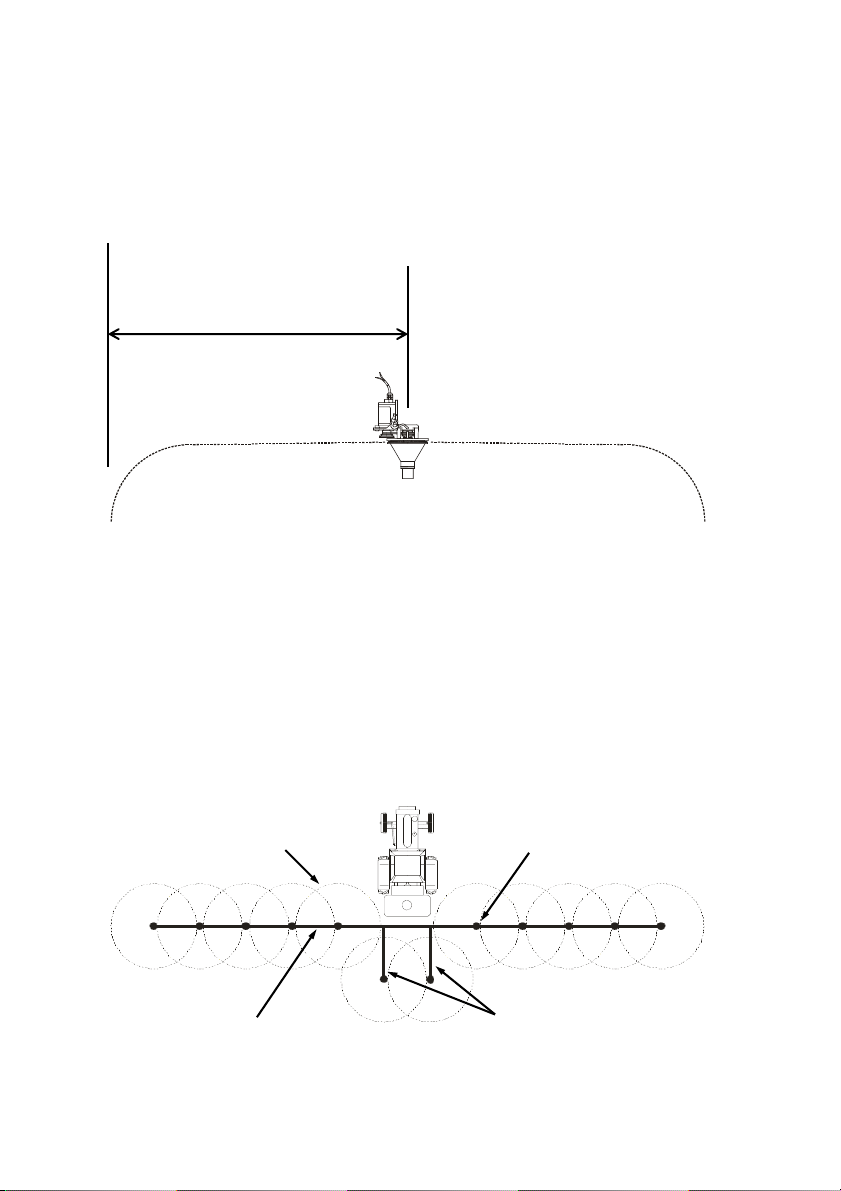

5 Ensure that the atomisers are securely and correctly positioned on

the boom or support structure, and are set to the correct distance

from the crop/target to be sprayed, see Section 5 ‘Installation’.

6 Inspect the entire sprayer for damaged or twisted hoses, leaks in the

chemical system, or damaged wires.

7 Check that the correct nozzles and flow restrictor orifices are fitted,

and that the correct system pressure is set to pro ide the required

liquid feed rate, see Section 7 ‘Calibration and Adjustment’.

8 Turn the atomiser motors on, to ensure they are rotating and at the

correct speed, see Section 7 ‘ Calibration and Adjustment’.

9 Whilst spraying, isually ensure that each atomiser is working, and

erify the accuracy of the calibration of the sprayer by checking the

olume of liquid used against the area being sprayed.

10 After use, always flush out the entire system with clean water or a

suitable sol ent. Never lea e chemical residues in the tank or pipe

work. Wash off outer surfaces of atomisers, booms, etc. to a oid

build up of pesticide residues.

3 – TEN KEY POINTS FOR USERS MICROMAX