Revolution II Stage 3 Installation

Instruction

006944.doc Page 2 of 29

Contents

Revolution II Stage 3 Installation Instruction......................................... 1

Contents ................................................................................................... 2

Important information - read this first .................................................... 3

Icons ......................................................................................................... 3

1. Safety............................................................................................. 4

2. Bail/Cabinet Part Numbers........................................................... 5

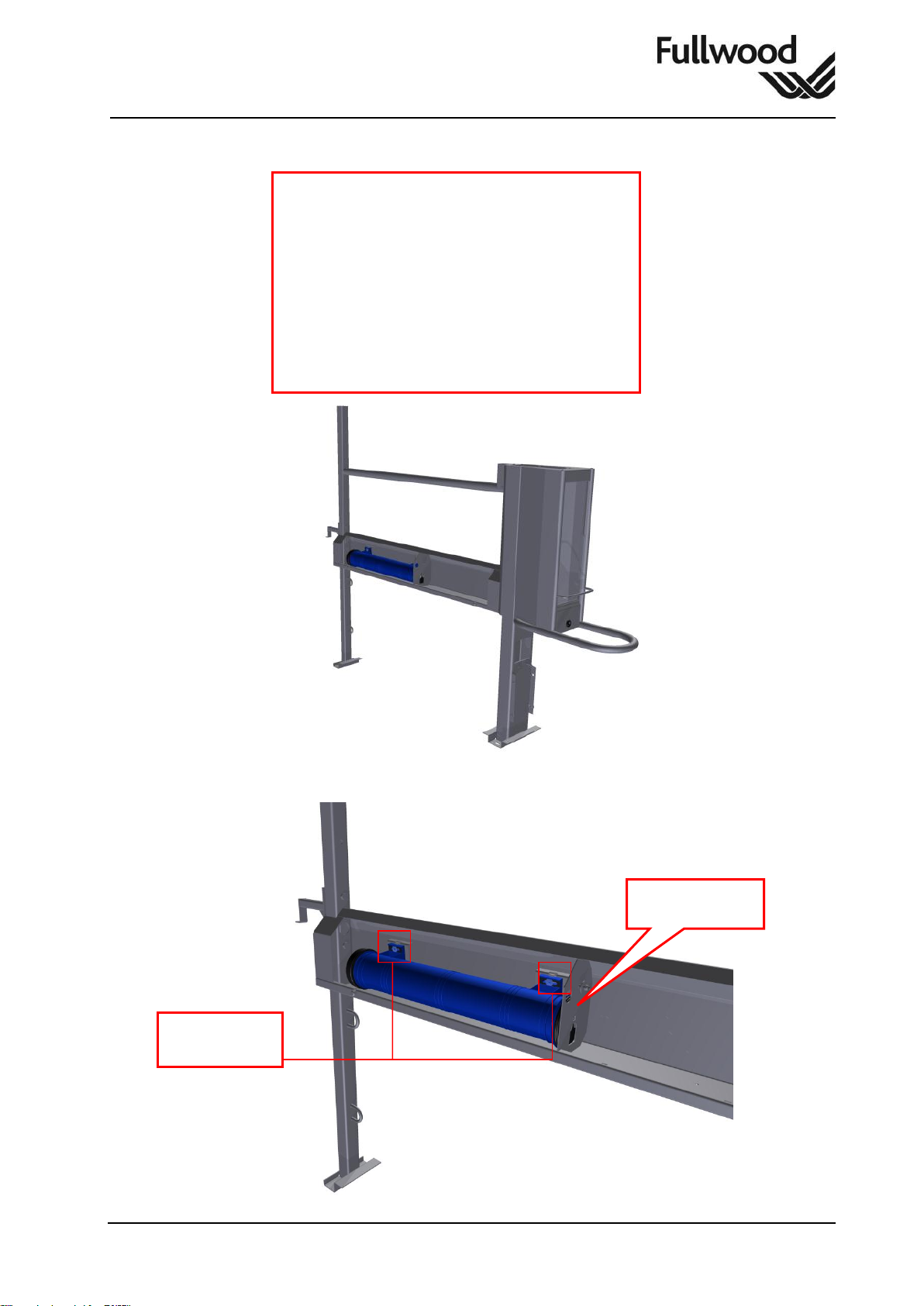

3. Bail Assembly ............................................................................... 6

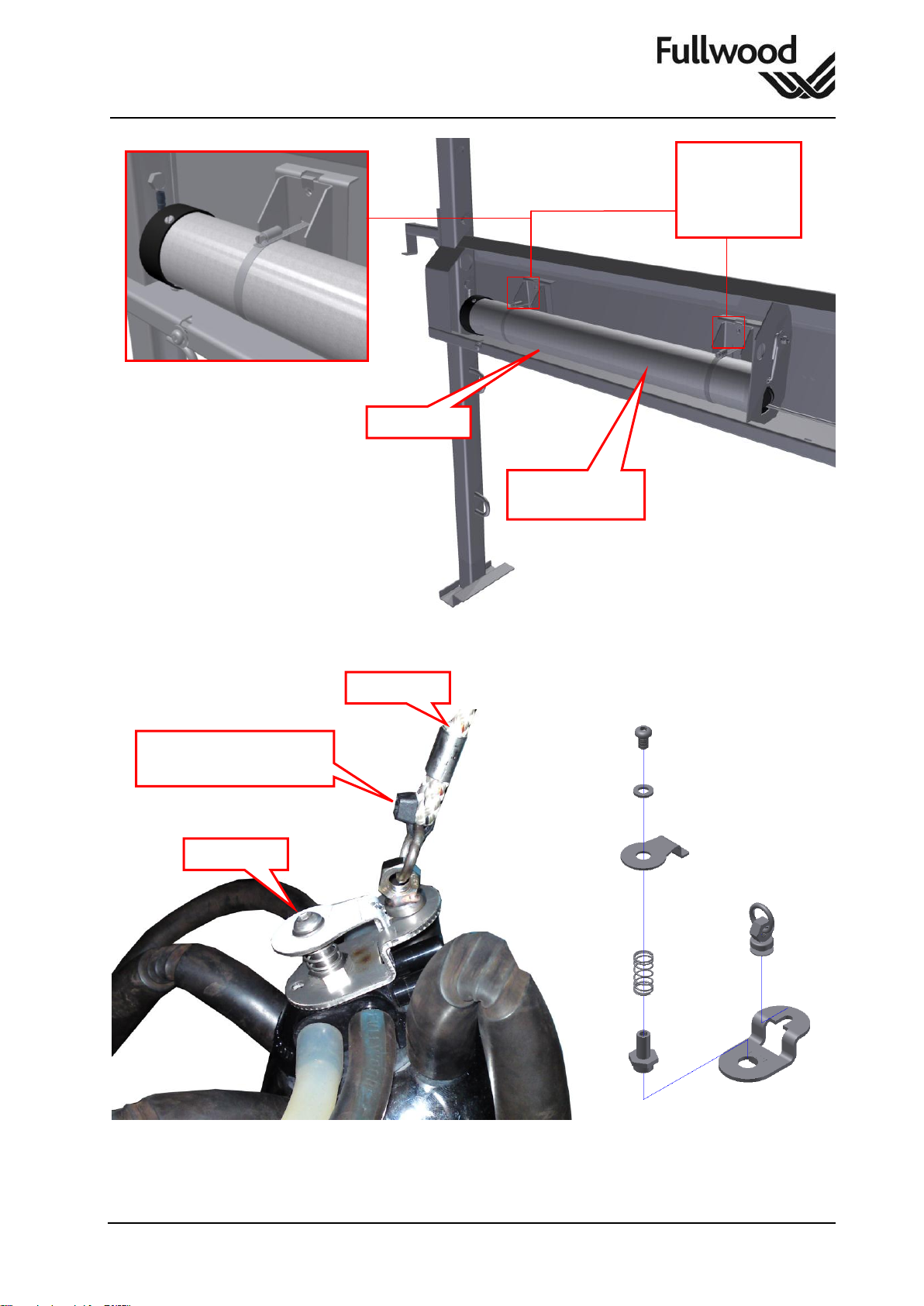

3.1 Rope Guide Plate...............................................................................................6

4. ACR Cylinders............................................................................... 7

4.1 SS ACR Cylinder................................................................................................7

4.2 DVC 1000 ACR Cylinder....................................................................................9

5. Aflilite System Installation ......................................................... 11

6. Afiflo 2000 System Installation .................................................. 13

7. Milk Meter Installation................................................................. 15

7.1 AfiLite and Afiflow individual Gate Wiring Diagram...........................................15

7.2 AfiLite and Afiflow Fullstart Wiring Diagram......................................................16

7.3 Milk Meter Combination Fixing .........................................................................18

8. Milk Plate Variations................................................................... 21

9. Flip Down Jetter.......................................................................... 24

10. Fixed Jetter Installation.............................................................. 25

11. Arm Assembly Variations and Installation................................ 26

12. Milk and Pulsation Tube Fitting................................................. 27

13. Full Start System......................................................................... 28

14. Disclaimers.................................................................................. 29

Copyright © 2007, Fullwood Limited reserves the right to change the contents of this manual if

necessary, without warning. Fullwood Limited has taken every precaution to avoid errors and

omissions on the manual and equipment but does not accept any responsibility or liability for

damage of any kind arising from the use of this manual or Fullwood equipment; whether this

damage is direct or indirect. If you discover any inaccuracies please inform Fullwood Limited or

one of its agents and we will make corrections for the next release.