Model T Electronically Cranked Coil Tester

V12 ©2019 Mictel LLC

10

4.4.2 Coil Test Results

The coil dwell time to fire and firing current must be within acceptable ranges for the coil to be

considered acceptable for use. The dwell time to fire value is displayed on the top scale of the

LED meter as Timing Error relative to a nominal value of 0 crank shaft degrees at 1000 RPM.

The possible coil test results are as follows:

Result Timing Error (Deg) Coil Current

Excellent 0 Ideal firing range

Good 0 +/- 1 Within acceptable range

Poor 0 +/- 2 or more Outside acceptable range

Table 2. Coil Test Results

IMPORTANT! – Good or Excellent Timing Error readings can still have a test result of Poor if

the coil firing current was outside the acceptable range. The Poor (Red LED) indicator will be

illuminated in this event even though Timing Error is 0 +/-1deg.

4.4.3 Coil Timing Error

The time required to charge the coil to the point of firing is known as dwell time to fire.

Nominal coil dwell time is 0.002 seconds (2ms) operating on 12VDC. This dwell time is

translated to ignition Timing Error and displayed on the ECCT lower scale calibrated in crank

shaft degrees with center value set to the nominal dwell time labeled as 0 degree Timing Error.

The scale is in 1 degree per division at 1000 RPM engine operation. The acceptable range of

Timing Error is 0 +/- 1 degree. Coils with Timing Error outside this range require adjustment

of the coil points covered in the next section.

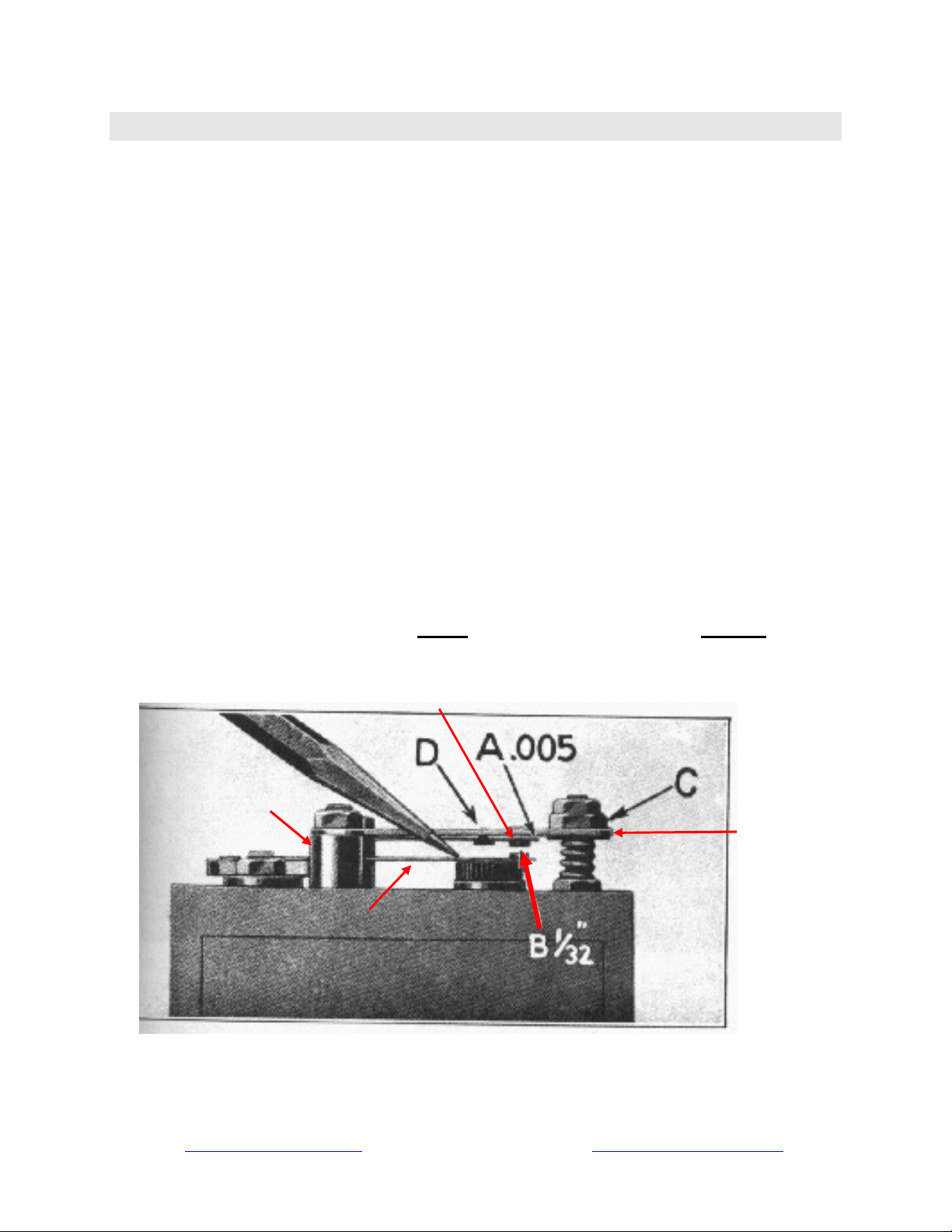

4.4.4 Coil Point Adjustment

The coil dwell time to fire is determined by many variables. The main variables are:

1. Vibrator Spring Tension

2. Cushion Spring Tension

3. Cushion Spring Travel

4. Point Gap

Attaining the desired dwell time to fire and firing consistency depends upon setting these 4

variables in the proper proportion with respect to each other. The ECCT coil test quickly

displays the Timing Error for a given set of these 4 variables. It is up to the operator to know

which of these variables to adjust to achieve the desired Timing Error and firing consistency.

Note that these 4 variables interact with each other which sometimes makes coil point adjustment

challenging to achieve the desired performance. Coil point adjustment requires patience and

experience for these reasons. It is highly recommended that new coil points be used when first

learning how to adjust and balance these 4 variables to achieve the desired result by avoiding

introduction of still more variables such as contact resistance and pitting. The next section

provides an introduction to the basics of coil point adjustment.