Page 2

IMPORTANT SAFETY INSTRUCTIONS / INSTRUCTIONS IMPORTAANTES SUR LA SÉCURITÉ

SAVE ALL INSTRUCTIONS / CONSERVER CES INSTRUCTIONS

CAUTION/ATTENTION and the exclamation point within an

equilateral triangle is intended to alert the user to the possibility of

damaging or destroying the equipment if the instructions are not

followed.

Attention et le point d'exclamation dans un triangle équilatéral est

destiné à alerter l'utilisateur de la possibilité d'endommager ou de

détruire l'équipement si les instructions ne sont pas suivies.

WARNING/AVERTISSEMENT and the exclamation point within an

equilateral triangle is intended to alert the user to the possibility of

serious injury or death if the instructions are not followed.

Avertissement et le point d'exclamation dans un triangle équilatéral

est destiné à alerter l'utilisateur de la possibilité de blessures

graves ou la mort si les instructions ne sont pas suivies.

WARNING: Failure to read, understand and follow the following information can result in seri-

ous personal injury, damage to the equipment or voiding of the warranty.

AVERTISSEMENT: Ne pas lire, comprendre et suivre les informations suivantes peut entraîner

des blessures graves, des dommages à l'équipement ou de la nullité de la garantie.

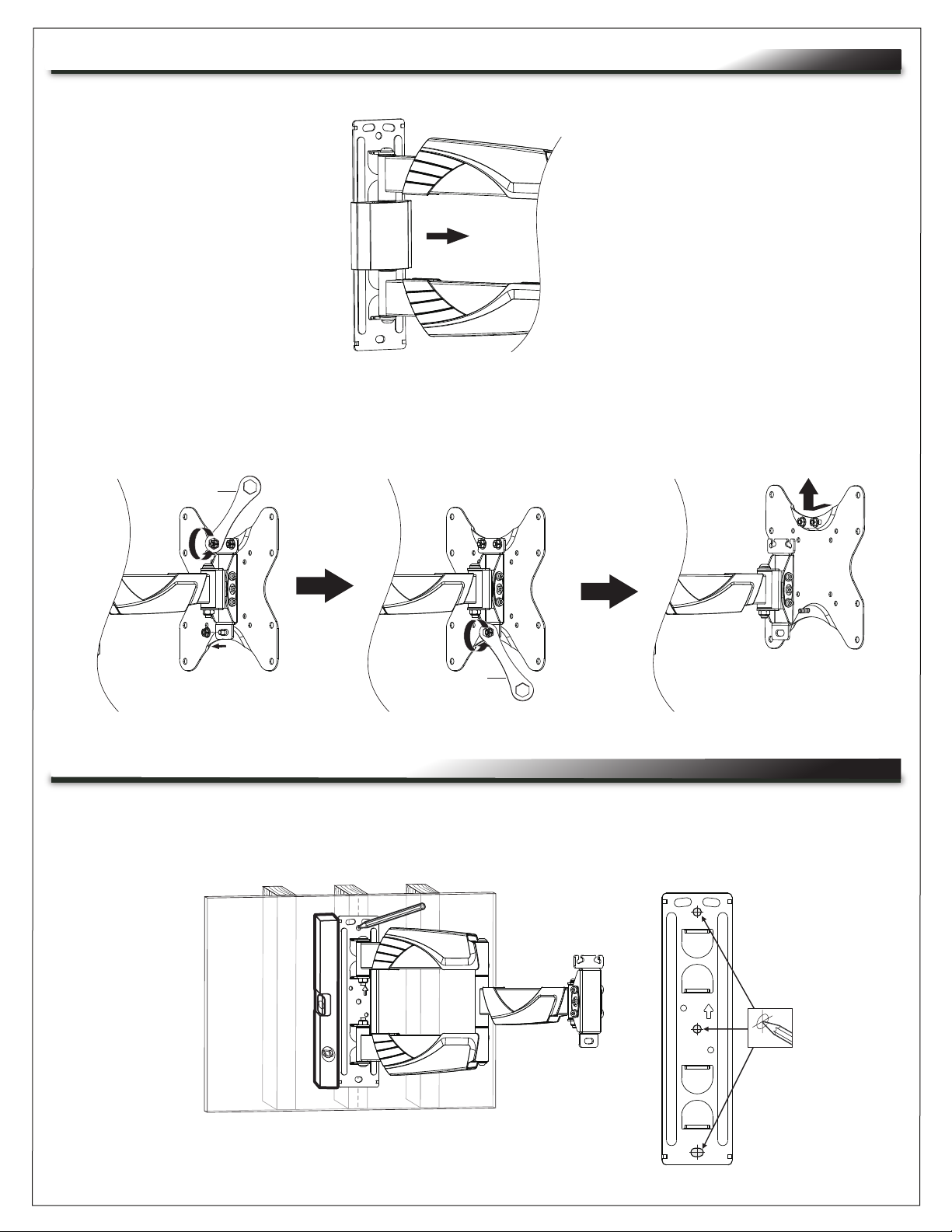

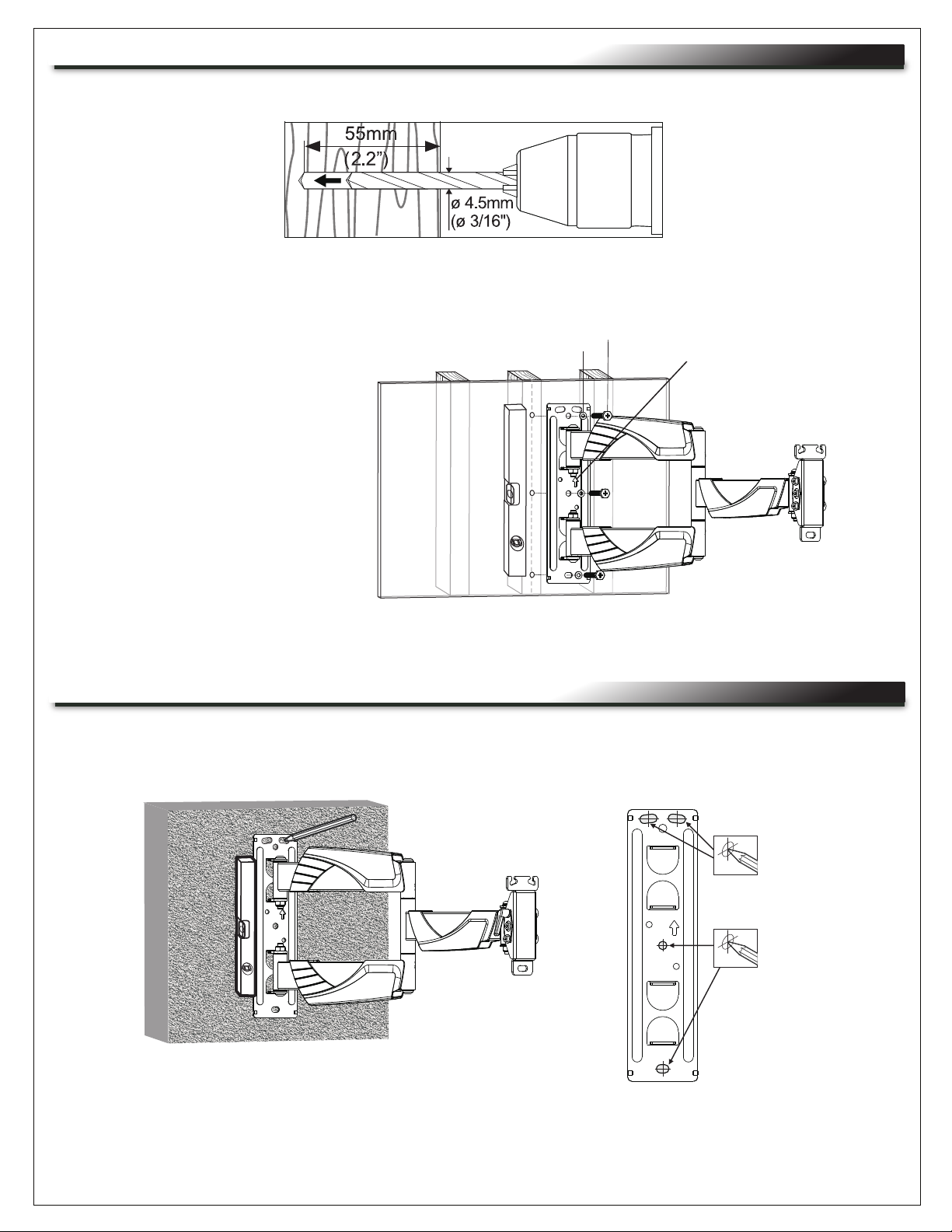

WARNING: Failure to provide correct structural strength for the component may result in seri-

ous personal injury or damage the equipment. The 2x4 stud wall to which the component is

being attached may have a maximum drywall thickness of 5/8” (1.6 cm).

AVERTISSEMENT: Le défaut de fournir une résistance structurelle correcte pour le composant

peut entraîner des blessures graves ou endommager l'équipement. Le goujon de 2x4 auquel le

composant mur est connecté peut avoir un maximum de 1.6 cm (5/8”) d'Épaisseur cloison

sèche.

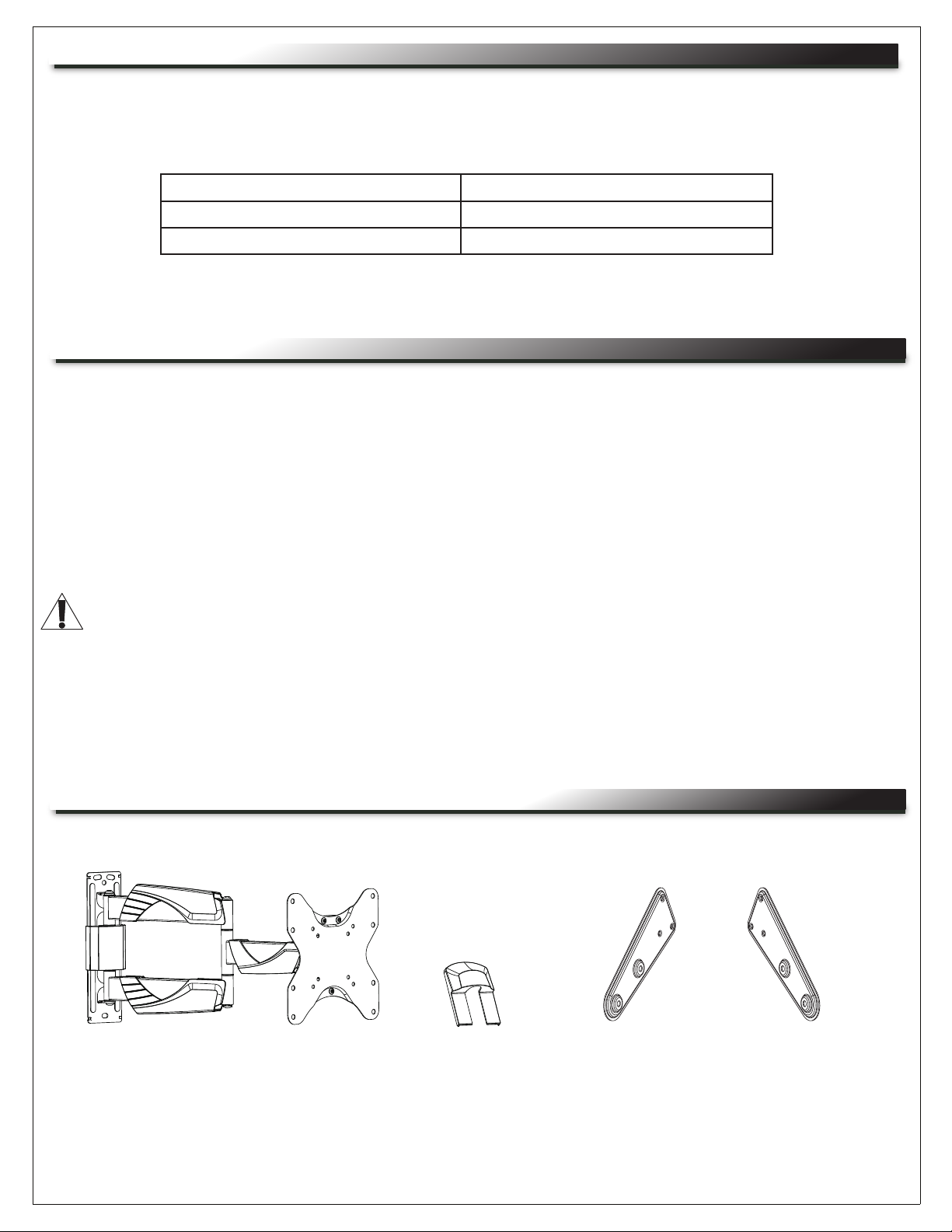

WARNING: Exceeding the weight capacity may result in personal injury or equipment damage.

The combined weight of all components attached to the mount must not exceed weights listed

on page 3.

AVERTISSEMENT: Dépasser la capacité de poids peut entraîner des blessures ou des dom-

mages matériels. Le poids combiné de tous les composants reliés au support de montage ne

doit pas dépasser les grammages indiqués à la page 3.

WARNING: Be aware of pinch points and do not place fingers in between moving parts.

AVERTISSEMENT: Soyez conscient des points de pincement et de ne pas placer les doigts

entre les pièces mobiles.

WARNING: Use this product for its intended use and only use attachments recommended by

the manufacturer.

AVERTISSEMENT: Utilisez ce produit pour son utilisation prévue et utiliser uniquement les

accessoires recommandés par le fabricant.

WARNING: Do not use a damaged product. Return damaged products to a qualified service

center for repair.

AVERTISSEMENT: Ne pas utiliser un produit endommagé. Retour produits endommagés à un

centre de service qualifié pour la réparation.

WARNING: Not intended for outdoor use.

AVERTISSEMENT: Non destiné à une utilisation en extérieur.