CONTENTS

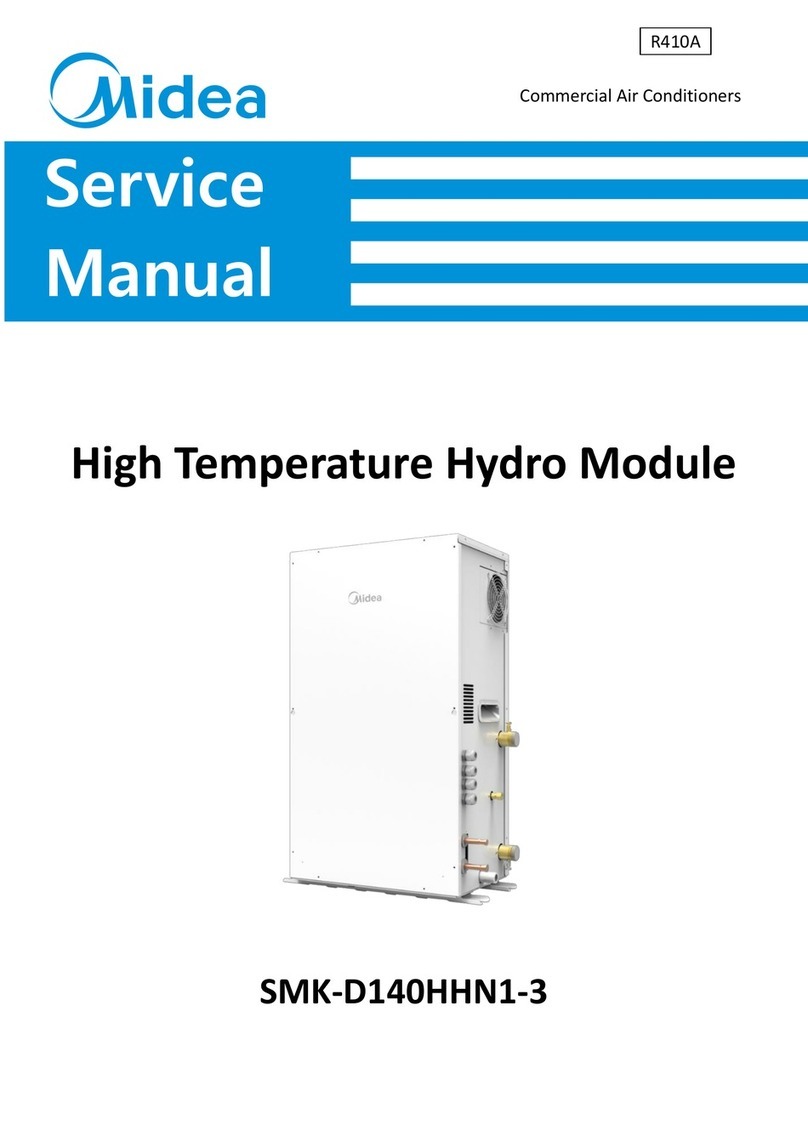

1 External Appearance.................................................................................. 3

2 Nomenclature............................................................................................ 3

3 System Schematic ...................................................................................... 4

4 Specifications............................................................................................. 5

5 BOM .......................................................................................................... 6

6 Dimensions................................................................................................ 8

7 Unit Installation ....................................................................................... 15

8 Application Examples............................................................................... 29

9 Pump Model Selection............................................................................. 42

10 Selection of Expansion Tank Volume and Preset Pressure ...................... 43

11 Final Check and Test Run........................................................................ 44

12 Piping Design ......................................................................................... 45

13 Wiring Diagram ...................................................................................... 46

14 Sound Levels .......................................................................................... 47

15 Accessories ............................................................................................ 49