9

2.1.4 UI Checking (t04)

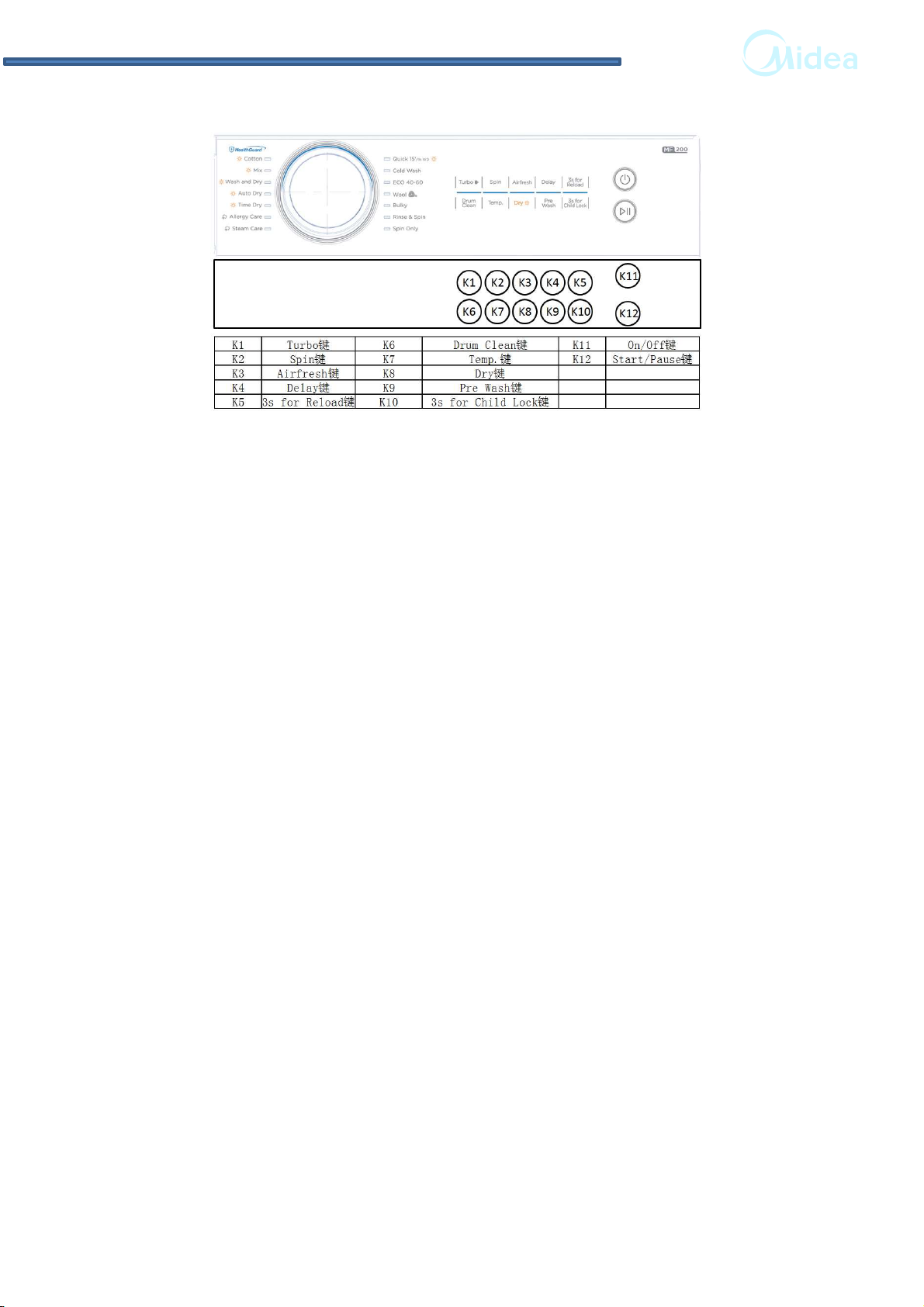

1) Press [K8] button to illuminate the whole LED display.

2) Press [K1] button, the whole LED display flashes.

3) Press [K8] to stop flash, LED display “t04”

3.2.5 Drain pump checking (t05)

1) Enter into service mode, LED displays “pup”.

2) Press [K8] button to drain out all the remaining water. If all water drained out, LED

displays “god”,and 6 minutes later ,if there is still water remains in it, LED displays

“FP”.

3) Press [K8] button to exit, LED displays “t05”

2.1.5 Pressure switch checking (t06)

1) Enter into service mode, drain out the water, LED displays LL.

2) Press [K8] button to activate inlet valve. LED displays level frequency once water

lever get the main wash level,after the water level reaching the overflow line, drain out

all the water.

2.1.6 Water temperature sensor and heater checking (t07)

1) Press [K8] button to activate the main inlet valve and get the water lever to heating

level then turn on the heater and 5 min later turned off automatically.

2) After heater turned on, LED displays the current temperature. Detect the real

temperature of inner drum and check with the numbers on the display.

3) Press [K8] button to exit, LED displays “t07”

2.1.7 Inlet valve checking (t08)

1) Enter into service mode, drain out the water, LED displays “UU”. Press [K8] button,

LED displays “out”.

2) Press [K1] button, LED displays “u2” and switch on prewash valve for 5s.

3) Press [K1] button, LED displays “u1” and switch on the main wash inlet valve

for5s.

4) Press [K1] button to switch on main wash and prewash valve and get the water

lever to setting level, then drain out the water.

2.1.8 Rotating checking (t09)

1) Enter into service mode, LED displays “tUB”

2) Press [K8] button, inner drum rotates in 45r/m clockwise for 10s and stop for 10s,

over and over again.

3) Press [K8] button to turn off the motor and exit, LED displays “t09”.

2.1.9 Spin speed checking (t10)

1) Press [K8] to enter into service mode, LED displays “spn”.

2) Press [K8] button again, the number on the display goes up in the same pace with

the real speed and when it reach 400rpm, you need to press [K1] button to get the

machine to reach its target speed.

( if declared speed ≥1000rpm, target speed is 1000rpm and if declared speed <

1000rpm,target speed is its declared speed)

3) Press [K8] button to exit and LED displays “t10”.

2 FACTORY PATTEN DETECTION