Midwest TeeJet Mid-Tech ARC 6000 User manual

1

There is no substitute for understanding your equipment’s

specifications, instructions and capabilities.

Do NOT try to modify or lengthen any of the 3

Speed Sensor or Encoder cables. Please call

Newton Crouch Inc. for extension cables

ALWAYS disconnect battery from console prior

to jump starting, welding, or charging battery.

The TeeJet ARC 6000 User Guide is available online in

pdf format at www.teejet.com

Products...Application Control and Equipment

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

2

BE SURE THE CONSOLE IS SELECTED TO THE

CORRECT APPLICATION PROGRAM

There are 5 choices total

Liquid or Dry

Programming for your Mid-Tech ARC 6000 Console Granular

Console calibration is a one-time procedure that, once it has been performed, does not

have to be repeated. Turning the POWER ON/OFF switch does not affect the console’s

memory—all data is retained.

Turns the console

power ON or OFF

Mode Selector Switch

selects either Operate

or SetUp mode

INC/DEC Switch

changes values in

display

Display Selector Function Knob is

used for Operate or SetUp in both

Granular and Liquid

Boom Switch ON / OFF

Indicators

Displays

Data

1. Liquid Pressure—normal pressure based spraying

2. Liquid Standard—normal flow based spraying

3. Liquid Reflow—used on some European sprayers

4. Granular Standard—single conveyor spreader

5. Granular Split Drive—dual conveyor spreader

The control console must be calibrated & programmed before it is ready to be used.

4. C Stnrd

5. C SPL

1.L PSI

2.L Stnrd

3.L rEFLO

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

Logo on console may vary due to the

age of the console. They work exactly

the same regardless of logo

3

A

Mark the correct selection here and have this sheet with you as you program

your console. It will make programming your console much easier. The most

commonly used selections are indicated by

Prime: __________ Step 1

This is your application type.

(single conveyor)

(dual or split chain conveyor)

Distance: __________ Step 2

This is a calibration number that must be checked.

The radar constant will vary with the type of radar.

Mid-Tech Compact Radar start at 780

DickeyJohn Radar start at 1000

Implement Width: __________ Step 3

This is your swath in INCHES.

50 ft swath = 600 in

60 ft swath = 720 in

80 ft swath = 960 in

Total Applied: __________ Step 4

This is your spreader constant from the chart

Have to know chain type & width plus encoder type

It must match the gate height.

Application Rate: __________ Step 5

This is your product in lbs/cu ft.

If the product density is not correct,

the application rate will not be correct.

PD should be measured & entered with each load.

% Rate: __________ Step 6

Change rate by 10% increments.

This is a personal choice.

Product Volume: __________ Step 7

Enter as a constant In pounds

This is the total weight of product

in your hopper

12 ft body—14000 lb max capacity

10 ft body—12000 lb max capacity

C Stnrd

C SPL it

B

E

D

C

F

G

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

4

Total ARea: ___Err____ Step 8

Err

Field Area: __________ Step 9

You set this # to get an audible alarm

When you reach that level spreading.

Example: Can get an alarm every 1 acre

or 5 acres. This is a personal choice.

Speed: ____0_____ Step 10

Set GSO (Ground Speed Override)

to 0 (zero) on dry

Scan: ___Err____ Step 11

Err

Test Speed: __________ Step 12

This is a personal choice.

7—10 mph are common.

This number is for testing only

With these selections you are now ready to enter the data into your console.

H

I

J

K

L

Move switch down

Change Console to Set Up

Turn ARC console on

Move switch up

Getting Started

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

5

A Initial Programming ARC 6000

Twist Display Selector to

Prime

Using switch labeled INC. / DEC.

Push switch up or down and hold.

Don’t worry if the selection does not

change immediately. You may have

to hold for 10 or more seconds before

the next choice pops up. .Screen will

scroll through selections:

4. C Stnrd

5. C SPL it

1.L PSI

2.L Stnrd

3.L rEFLO

Liquid Dry

Be sure you are

in the correct

mode!! These

selections look

very similar!

Look for the C!

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

6

B

Using switch labeled INC. / DEC.

Push switch up or down . Number

will increase or decrease accordingly.

Twist Display Selector to Distance

This is a calibration number that must be

checked. The radar constant will vary with the

type of radar.

Mid-Tech Compact Radar start at 780

DickeyJohn Radar start at 1000

C Twist Display Selector to Implement Width

Using switch labeled INC. / DEC.

Push switch up or down . Number

will increase or decrease accordingly.

The number one should light red.

This is your dry swath.

Numbers 2—9 should have a ZERO value.

1

your swath is entered in INCHES.

50 ft swath = 600 in

60 ft swath = 720 in

80 ft swath = 960 in

When you are in the OPERATE mode,

your Implement Width (swath) will be

shown in FEET!

A minimum of 400 ft should be driven to calibrate this number.

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

7

D Using switch labeled INC. / DEC. Push

switch up or down . Number will increase

or decrease accordingly.

Twist Display Selector to Total Applied

The spreader constant number must be

checked. The gate height must match the

constant chosen.

Using conveyor width & type plus encoder

type NCI has a chart to obtain this number.

E Twist Display Selector to Application Rate

Using switch labeled INC. / DEC. Push switch up or

down . Number will increase or decrease accordingly.

Product density should be measured & entered

with each load.

NCI sells a density scale

(SM-DS-50895)that will

give you the correct

number for your load.

This is the amount of deviation from your

desired application rate that you allow. It

changes in increments of 10.

Usually, it is not desirable to have your

spread rate deviate substantially.

F Twist Display Selector to % Rate

This is your product density entered in lbs/cu ft.

Incorrect product density will cause your application rate to be incorrect

ALWAYS return to 100% in the Operate Mode or your entire job will be incorrect!!

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

This setting allows for

110% I—the desired rate

plus 10%

8

This is the amount of product

in your hopper. It is entered

as a constant in pounds.

G

H

I

K L

Twist Display Selector to

Product Volume

Twist Display Selector to Field Area

Twist Display Selector to

Test Speed

This is commonly used for testing only, however, it can

be used for stationary unloading.of the hopper.

J

NCI 10 ft body holds

approximately 12000

Twist Display Selector to Scan

Display will show Err

This number is discretionary. It will

cause the console to sound an audible

and visible notification whenever that

threshold is passed. It is usually 1 acre

Twist Display

Selector to

Total Area

Display will show Err

This number is a cumulative total

of all jobs you have spread since

you last cleared the console. It

will show Err in Set Up mode.

NCI 12 ft body holds

approximately 14000

Twist Display

Selector to

Speed

This is the Ground Speed Override. Set it to Zero

1/2 acre

1 acre

5 acres

This is a cycle through

some of the major

functions.

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

9

Here is an abbreviated “Cheat Sheet” from NCI

PRIME 1. BLANK

DISTANCE 2. FT. Covered After 5280 FT. Switch to MILE

IMPLEMENT WIDTH 3. Boom Switch Box OFF –0

Boom Switch ON –Swath in FEET

Must set Flow Control (LIQ) AUTO RANGE –HOLD

See Note (2) (DRY) HYD. VALVE –CLOSED

TOTAL APPLIED 4. 0 to Start Total LBS/AC Applied—Spread

APPLICATION RATE 5. Desired LBS/AC will oscillate

% RATE 6. 100 ALWAYS, if other than 100 change Target Rate –LBS/AC

PRODUCT VOLUME 7. Enter full capacity from Constant in Set Up (GC). Weight to match ma-

terial in unit. Then number shows how much material remains in unit.

Beeps at 10% of entered weight. See Note (3)

TOTAL AREA 8. 0 to start May require special instruction

DO NOT ZERO OUT UNTIL END OF DAY or INTERVAL OF CHOICE

FIELD AREA 9. 0 to start Change Finish Job

SPEED 10. MPH travel 0 is still

SCAN 11. Totals and setting of some selector functions

TEST SPEED 12. 10 MPH –Blinks during testing only

PRIME A. C –Stnd

DISTANCE B. Calibration Number See Note (1) This must be checked

IMPLEMENT WIDTH C. Swath in inches 50’ = 600‖; 60’ = 720‖

Lock in position with conveyor interface master on (Number 1 lit

with single switch is dry swath)

*Must fill out all Slots 2—9 with a value ―0‖

TOTAL APPLIED D. Spreader Constant must match gate height for unit

GET OUT of the truck and check!

APPLICATION RATE E. Must match density in LBS/CU FT

% RATE F. 10% Change rate by increments of + or - 10%

PRODUCT VOLUME G. LBS Enter as constant 12’ Body = 14000 lb / 10’ Body = 12000 lb

TOTAL AREA H. ERR

FIELD AREA I. ―0‖ - Enter acre to hear audible alarm

SPEED J. Set GSO to ―0‖ on dry—ALWAYS

SCAN K. ERR

TEST SPEED L. 10 MPH Steady suggested for testing

OPERATE

SET UP Under Set Up most displays blink.

NOTES

(1) Radar constant will vary with radar type: Mid-Tech Compact Radar - Start at 780 or DickeyJohn Radar - Start at 1000

(2) Check Valve Setting—Dry—Closed

(3) Enter by constant in setup. (G) To go to a higher number, must go down then back up.

Highlighted Items MUST be performed at the beginning of each job. All other fields

are for information and should be reset at your discretion.

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

Table of contents

Popular Controllers manuals by other brands

Emerson

Emerson Control Link Installation and operation manual

YASKAWA

YASKAWA Motoman DX200 instructions

Honeywell

Honeywell ControLinks R7999C manual

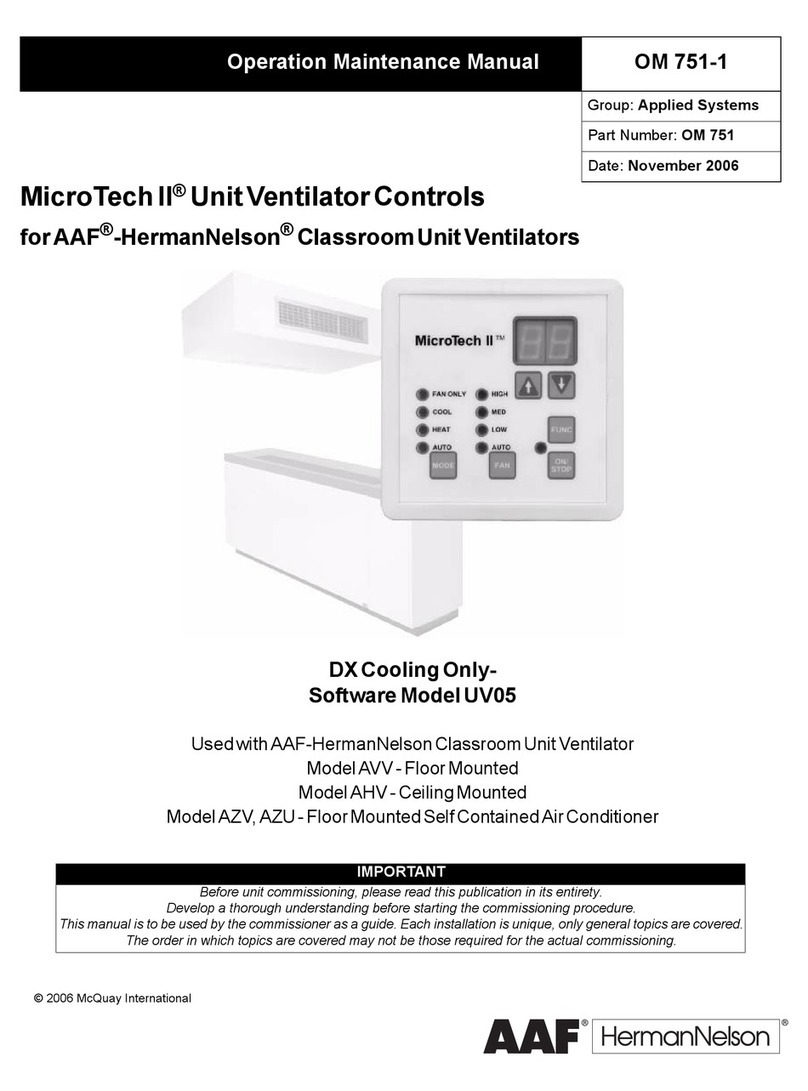

AAF

AAF UV05 Operation & maintenance manual

Toho Electronics

Toho Electronics TTM-339 Operation manual

Delta Electronics

Delta Electronics AH500 Operation manual