Toho Electronics TTM-339 User manual

- 1 -

TOHO ELECTRONICS INC.

Program Controller

TTM-339

Operation Manual

Thank you for purchasing Toho Electronics’TTM-339 series.

Before using the products, thoroughly read this manual for a better understanding of them.

Ensure to store this manual and use it whenever needed.

Contents

1.Precautions on the use of the products・ P2

2.Parts indication and Installation ・・ P4

3.Terminal connection diagram・・・ ・・・ P7

4.Terms and various functions ・・・・・・ P8

5.Flow of mode change operation and run operation P18

6.Measurement range and indicator resolution P28

7.List of models・・・・・・・・・・・・・ P29

8.Standard specifications ・・・・・・・・ P29

9.Maintenance and Inspections ・・・・・・ P31

- 2 -

1.Precautions on the use of the products

Ensure to read this manual before using the equipment. Take care to understand the following for the safe use of the equipment.

Ensure this manual to be in hands of a person using the equipment.

★Precautions on safety

Alarms are defined and categorized into either one of four groups in this manual, depending on degrees of importance or risk

in terms of the safe use of the equipment or prevention of accident or damage on the equipment. For each alarm, symbol is

assigned as shown below.

★Alarm symbols

Danger

Improper handling of the equipment

may cause fatality or serious injury for

an impending reality.

Caution

Improper handling of the equipment

may cause injury or physical damage

on it.

Warning

Improper handling of the equipment

may cause fatality or serious injury.

Reminder

Care should be taken for ensuring

safety.

An alarm categorized in the group of Caution may still yield to serious result, depending on circumstances.

Any symbol for the four groups intends to raise user’s attention for important description. Carefully observe it.

General caution, warning or

prohibition without

particularity

.

Instruction on ground connection

for the equipment with safety

grounding terminals

.

Hazard of pinched fingers on a

particular portion of the

equipment

.

Possible injury caused by touching a

particular portion of the equipment

under specific conditions

.

Unspecific behaviors

of general users.

Hazard of injury such as an electric

shock due to disassembling or

modification of the equipment

Hazard of an electric shock

under specific conditions

Hazard of injury due to high

temperature under specific conditions

Hazard of burst under

particular conditions.

Warning

Improper wiring to the equipment may cause a failure, such as fire. Upon completion of wiring, ensure to verify the

proper wiring before turning on electricity.

Do not turn on electricity until all wiring is complete. Do not touch portions of high voltages such as power supply

terminals, as an electric shock may be resultant.

Install appropriate protective circuits externally if a failure or abnormality of the equipment may seriously affect related

sys

tems.

Do not use the equipment out of the specified range, as it may fail or catch fire.

Do not under any circumstance to modify or disassemble the equipment, as a failure may be caused, resulting fire or an

electric shock.

Do not use the equipment in ambience of flammable or explosive gases.

Caution

Do not use the vacant terminals for wiring.

Do not use a pointed object to operate keys.

Do not turn on the power supply until wiring is fully complete in order to prevent an electric shock, failure or

malfunctioning. For replacing a component connected on the equipment, ensure to turn off the power supply. For

turning back on the power supply, do so after all wiring is complete.

Ensure not to trap heat in the space surrounding the equipment in order to provide sufficient heat release.

Do not put a metal piece or similar inside the equipment. A fire, an electric shock or failure may be caused.

The equipment is designed for instrumentation. For its use in environments of high voltages or intense noises, take

appropriate measures on the side of user’s equipment.

The equipment is designed for controlling physical values, such as temperatures, on general industrial facilities. Do not

use it for subjects of control that may seriously affect human life.

- 3 -

Turn off the power supply before cleaning the equipment, and wipe it with a soft dry cloth. Do not use thinners, as they

may cause deformation or discoloration of the equipment.

The equipment may cause radio disturbances in domestic settings. User is required to take appropriate measure.

Ensure to tighten terminal screws at specified torque. Insufficient tightening the screws may cause an electric shock or

fire.

Ensure to observe precautions listed in this manual for the use of the equipment.

Reprinting or duplicating this manual is prohibited.

This manual may be revised without prior notice.

Precaution regarding Export Trade Control Ordinance

Investigation on client or application by an appropriate party is required so that the equipment is not used for mass destruction

weapons and such (military application, military facilities, etc.).

Notation convention in this manual

★Summary notation

Abbreviations in alphabetical characters are used for the diagrams and text in this manual. Some major examples are as

follows.

Abbreviation

Term

PV

Present value

SV Setting value

AT

Auto

-

tuning

MV1

Primary operating amount

MV2

Secondary operating amount

CT Current transformer

0

1

2

3

4

5

6

0 1 2 3 4 5 6

7 8 9

Minus

Period

Slash

7 8 9 - . /

A

B

C

D

E

F

G

A B C D E F G

H

I

J

K

L

M

N

H I J K L M N

O

P

Q

R

S

T

U

O P Q R S T U

V

W

X

Y

Z

V W X Y Z

- 4 -

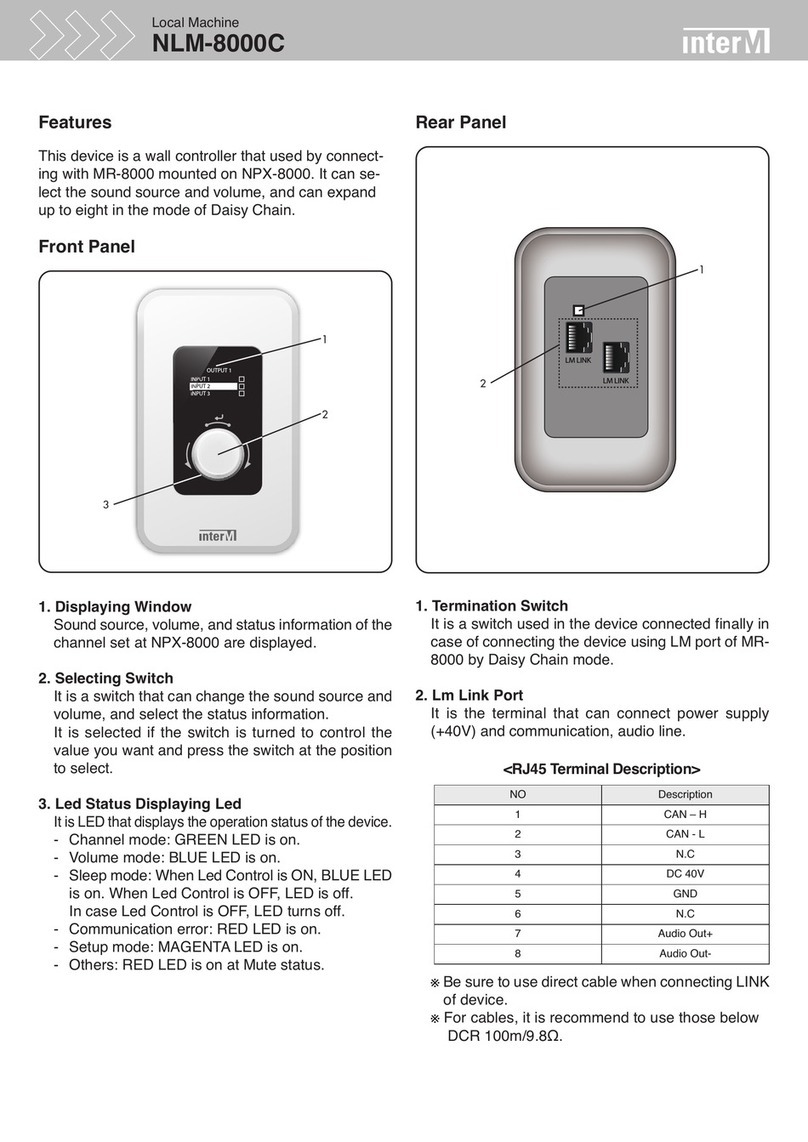

2. Parts indication and Installation

2.1 Full panel face

2.2 Segment display section

No.

Segment character

Content

①

PV (5 digits in the upper row)

Displays PV, etc.

②

SV (5 digits in the lower row)

Displays SV, etc.

Fixed to 0 during a stop.

Displays

“

TIME

”

during

a timer run.

③

Pattern digit (2 digits in the lower row left)

Displays the pattern No., etc. presently in selection.

④

Step digit (2 digits in the lower row right)

In a stop: Displays the number of steps of the pattern

presently in selection.

In a r

un: Displays the step No., etc. presently in progress.

⑤

Operating status (lower row center; 6 segments)

Indicates the program operating status.

2.3 Key

No.

Name

Content

A

RUN/STOP key

Used for run start/stop, temporary stop, etc.

B

DSP.CHG key

Us

ed for display switchover, etc.

C

Dig.MOVE key

Shifts the set digit leftward during setting.

D

AUTO/MAN key

Switches over MANU/AUTO.

E

RESET key

Used for screen return, etc.

F

MODE key

Used for changing a setting item, etc.

G

key

Used for decreasing

a numerical value, etc.

H

key

Used for increasing a numerical value, etc.

RUN/STOP DSP.CHG D i g..MOVE AUTO/MAN

RESET M O D E

▽ △

RUN

OUT

EV1

EV2

EV3

EV4

TS1

TS2

TS3

TS4

AUTO

MANU

AT

END

TIME

SV

PV

PTN STP

①

②

③

④

⑤

D

GH

F

E

C

B

A

- 5 -

2.4 Lamp display section

Lamp character

Content

PTN

Lights up while a pattern in display.

STP

Lights up while a step in display.

RUN

Lights up during a program run.

OUT

Lights up at the heating output ON.

EV1

Lights up at occurrence of Event 1.

EV2

Lights up at occurrence of Event 2.

EV3

Lights up at occurrence of Event 3.

EV4

Lights up at occurrence of Event 4.

TS1

Lights up at Time Signal 1 ON.

TS2

Lights up

at Time Signal 2 ON.

TS3

Lights up at Time Signal 3 ON.

TS4

Lights up at Time Signal 4 ON.

AUTO

Lights up during an automatic run.

MANU

Lights up during a manual run.

AT

Lights up during an auto

-

tuning.

END

Lights up at the output ON while End

Signal in use.

TIME

Lights up at the time being set.

2.5 Lamp display section

2.6 Outer Dimensions

- 6 -

2.7 Precautions on installation

Warning

Ensure to turn the power supply off before beginning removal or reinstallation of the equipment in order to

prevent an electric shock or equipment failure.

★Ambient temperature and humidity (the equipment to be used in the specified range as listed below)

(1) Temperature range: 0 - 50 °C

(2) Humidity range: 20 - 90% PH (no dew condensation allowed)

(3) Installation gradient: Base plane ± 10 degrees

★Do not install the equipment in the following places.

(1) Where temperature abruptly changes to generate dew

(2) Where corrosive or flammable gases are generated

(3) Where water, oil, steam or chemicals splatter

(4) Where vibration or noise is directly applied

(5) Where dusty or salty ambience, or many iron scraps is present

(6) Where direct sunlight is received

(7) Where circuits may negatively be affected by static electricity, noise or magnetism

(8) Where direct warm or cool air is received from an air-conditioner

★Precautions on installation

(1) Provide sufficient space for ventilation so that the ambient temperature does not rise to 50 °C or higher. In case that the

temperature of 50 °C or higher is suspected, use a fan or air-conditioner to cool the ambience.

Take care that no cold air flows directly on the equipment.

(2) Do not install the equipment on a device that may generate large heat, such as heater and transformer.

(3) Install the equipment away as much distant as possible from high-voltage devices, power lines or power equipment.

(4) Do not block off the ventilation opening on the equipment. Ensure a sufficient gap between stacked units of equipment.

2.8 How to install or remove the equipment

★Installation on a panel

(1) Make an opening on the panel.

(2) Insert the equipment into the opening.

(3) Install the mounting attachment from behind the panel.

(Ensure that the equipment is securely fixed)

* Conduct wiring after the equipment is installed.

* Turn on the power after the wiring.

★Removal from the panel

(1) Turn off the power.

(2) Disconnect the wiring.

(3) Insert a flat-head screw driver into the clearance

formed between gabs on the equipment and attachment.

Turn the screw driver clockwise or counterclockwise to

dislocate the gabs to remove the attachment from

the equipment.

(4) Remove the equipment from the panel.

* Ensure to conduct removal work after

turning off the power.

- 7 -

3. Terminal connection diagram

Power supply

100 to 240 VAC

①

X

A

Communications RS-485

⑬

+

EV4

Open collector

output

②

B

⑭

+

TS1

Not in use

③

Pattern 1

No-voltage

contact input

⑮

+

TS2

OUT1

(Relay/SSR/4 -20

mADC)

−

C

④

Pattern 2

⑯

+

TS3

+

NO

⑤

Pattern 3

⑰

+

TS4

OUT2(None/Relay/

SSR/

4 -20 mADC)

−

C

⑥

Pattern 4

⑱

+

TIME

+

NO

⑦

RUN/RDY

⑲

−

COM

Not in use

⑧

Operation

switchover

⑳

CT input

Relay contact

output

EV1

⑨

Step feed

EV2

⑩

COM

Sensor input

* See below.

EV3

⑪

END signal

Relay contact

output

C

OM

⑫

Y

COM

RTD

TC/10 mV

Current/voltage

b

+

B

−

−

A

+

Precautions on wiring

Warning

Do not turn on the power until all wiring is complete in order to prevent an electric shock

or equipment failure.

★For inputs from a thermocouple, use the specified wires or compensating leads.

★For inputs from a resistance temperature detector, use wires that the wire resistance of leads is small and no resistance difference

is present among 3 wires (3-wire type).

★Provide input signal lines distant from power supply lines, power lines or load lines so as not to affect input signal lines with

noise induction.

★Wire the power supply for instruments such that they do not receive noises from the power supply for power devices.

The use of a noise filter is recommended in case that the equipment is vulnerable to noises.

Take care the following when a noise filter is used.

◎Install the noise filter as close to a temperature controller as possible.

Wire the instruments in as short a distance as possible to output lines (secondary side) of the noise filter and power

terminals for the temperature controller.

◎Isolate the noise filter input line (primary side) from its output line (secondary side).

High-frequency elements of noises may be induced, resulting in no provision of much noise attenuation effect as expected,

in case of input and output wires being close one another, such as being bundled together or installed in a same duct or

tube.

◎Wire the grounding wire of the noise filter in as short a distance as possible.

A long grounding wire is equivalent to insert of an inductance, resulting in deteriorated high-frequency characteristics.

◎Before installing the noise filter, peel off the paint applied on a mounting plate of the noise filter as appropriate, in order to

reduce the contact resistance between the noise filter and equipment housing.

★For the power supply, use and twist wires that cause less voltage drop.

★For the equipment being activated, it takes about 4 seconds after its power turns on. Use delay relays when using the

equipment for generating signals for interlocking circuits.

★The equipment is not attached with power supply switch fuses. Separately install fuses in proximity of the equipment, as

needed.

◎Recommended fuse rating: Rated voltage of 250 V and rated current of 1 A

★Use crimping terminals that match screw sizes.

◎Size of crimping terminal: Terminal width of 6 mm or smaller

Crimping terminal recommended

Manufacturer: NICHIFU

Model: ICTV-1.25Y-3N (Y terminal)

ICTV-1.25-3S (round terminal)

◎Tightening torque recommended: 0.5 N⋅m

◎Applicable wire

Use wires in sizes suitable for the terminals.

- 8 -

The use of shielded wires is recommended.

For Pt100 (resistance temperature detector), use identical wires of low lead resistance and no resistance difference among

3 wires.

4. Terms and Various Functions

4.1 Program run

* The following number of steps is fixedly set, depending on the number of patterns.

Pattern No. 1 2 3 4 5 6 7 8

Step No. 99 49 33 24 19 16 14 12

Pattern No. 9 10 11 12 13 14 15

Step No. 11 9 9 8 7 7 6

To make control, SV is changed parallel to the temperature and time set for each pattern.

If a setting is made to the lower limit within [a setting range - 1] (“----” to be displayed) in the temperature setting for

each step, steps following the said step is ineffective and no setting parameter is displayed.

The pattern run ends at one step prior to the step set as “----.”

Neither the step temperature nor the step time in a run can be changed.

If the setting temperature of the step 1 is set at SLL for a PV start, the time of step 1 is effective and a timer run begins.

(The normal PV start begins with the step 2.)

“TIME” is displayed in the SV display frame.

If the setting temperature for all steps is 0, setting a temperature for a step results in the next step automatically being set

to the same temperature (only at key operation).

If the step time is set above the upper limit within the setting range (“~~~~~” to be displayed), the step continuously runs

at the setting temperature.

Each pattern repeats for the number of times that has been executed. When the setting is set to “0”, it will continue to

repeat until it is stopped with key operation. (max. 9999 times)

During a run, the TIME output is ON.

For display during the program run, see Section 5.3.2 “Auto run (normal mode).”

The following is displayed upon termination of the program.

RUN

OUT

EV1

EV2

EV3

EV4

TS1

TS2

TS3

TS4

AUTO

MANU

AT

END

TIME

PTN STP

• The screen shown in the left is the normal one.

4.2 Step feed/step return

Holding the “” key pressed for 3 seconds during a run results in the step feed to transfer to the next step.

Holding the “” key pressed for 3 seconds results in the step return to transfer to the step one previous to the current

step.

In the case of the external drive signal selection being ON, the step feed is executed when open of the step feed DI

changes to closed.

Only the timer is reset when the step return is executed at step 1 (or the leading step).

If the step feed is executed at the step for the endless setting, END is established.

*When the External Drive Signal Selection is set to ON, Step Forward/Reverse with key operation will not be

effective.

4.3 Elapsed time increase/decrease

During a program run, pressing the /key on the elapsed time screen results in an increase/decrease of the elapsed

time.

The unit of the elapsed time is minute. Counting the number of seconds continues.

The change range of the elapsed time is 0 to [the setting time in a run - 1].

The change range of the elapsed time for a wait zone is 0 to [the setting time in a run + the wait time - 1].

Execution of an increase/decrease in the wait zone results in an increase/decrease of the elapsed time; however, setting

the elapsed time below the setting time results in a return to the normal step run but not to the wait zone.

This function is ineffective for an end signal.

- 9 -

4.4 Wait function

For the current step transferring to the next step, the next step does not begin if PV has not reached the wait zone

(similarly, if PV has overreached) after the step time elapsed.

However, if the wait time elapses, the next step begins at that point.

The above operation is executed by selecting 0 to 4 for each step, or by setting value for 1 to 4.

Selecting 0 indicates no function.

In the case of [the wait zone setting = 0], in-a- wait is effective until PV goes beyond SV.

Wait zone

Wait zone

Present step Next step

SV PV

In a wait

As PV enters into the wait zone, a transfer to

the next step is made.

Even if PV does not enter into the wait

zone, a transfer to the next step is

made when the wait time elapses.

4.5 Three-zone PID function

Numerical values of P, I, D and PC are switched over at each of the low, intermediate and high temperatures.

The ranges of the three zones are as follows:

- Low temperature (PID No. 1): SLL to intermediate point 1

- Intermediate temperature (PID No. 2): Intermediate point 1 to intermediate point 2

- High temperature (PID No. 3): Intermediate point 2 to SLH

4.6 Auto tuning function

Auto tuning starts at each of low, intermediate and high temperatures.

Auto tuning starts when the temperature at which the auto tuning is to be performed is set on each startup screen and the

RUN/STOP key is pressed or by an Auto tuning start command of the communication.

During the auto tuning, AT-1 (to 3) and SV are alternately displayed in the SV display digit ,andATALL and PV are

alternately displayed in the PV display digit.

Re-pressing the RUN/STOP key results in a stop of the auto tuning.

If the auto tuning has not terminated 3 hours after its start, an AT error is established and the run stops, displaying

“ERR2.”

Attempting an auto tuning during an automatic run results in first a temporary stop and then start of the auto tuning.

During a manual run, the auto tuning is not possible.

4.7 PV start/SV start

At a start of the program run after selecting the PV start and SV start, the start SV indicates the following:

PV start:

The run starts from the ramp step of upward slope in which the measurement temperature is included.

In addition, the run starts from the elapsed time, of which amount is assumed to elapse to come to the start point.

The calculation is made with the start point of 0°C /0 digit.

For below 0°C /0 digit, the calculation is made with the elapsed time of 0 minute.

SV start: The program run starts from the SV start temperature setting.

- 10 -

4.8 Time signal output

At starting each step, the time signals 1 to 4 are turned on upon elapse of the time set on the ON delay timer.

Then, the output is turned off upon elapse of the time set on the OFF delay timer.

During the time signal output ON, corresponding lamps of TS1 to TS4 light up.

Select the function selection among 0 to 5 of TS 1 to 4 at each step; if either one of 1 to 4 is selected, the above

operation is performed with the setting; if 0 is selected, no function is available; if 5 is selected, ON is always set

during the selection step.

If the time is set backward by using the or key, even after elapse of time, the output returns to the one

corresponding to the point at which the time set backward and time counting starts at that point, i.e., in the middle

of the way.

Example: If the elapsed time is returned by 5 minutes by using the key 3 minutes after the OFF delay

terminates, the output turns on and the OFF delay counts for 2 minutes.

ON time

OFF time

Output

△

Step start

4.9 Time output

During a program run, the Time output is always ON as in-a-run signal output.

4.10 In-a-run signal output/end signal output selection function

The use purpose of one relay output is selected from either in-a-run signal output or end signal output.

4.10.1 When selecting the in-a-run signal output

During a run, the relay output is always ON as in-a-run signal output.

4.10.2 When selecting the end signal output

At termination of the program run, the output as the end signal output is turned on or off according to the

following flow.

If the setting is above the maximum value within the setting range (“~~~~~” to be displayed), the output remains

turned on until the reset status described in Section 5.3.1 is established.

Also, the END lamp lights up.

ON time

Output

△

Termination of the program run

4.11 DI (external input)

Operation including run can be performed via DI through the external drive signal selection.

For the function of each DI, see Sections 4.10.1 to 4.10.4.

No operation is performed for [external drive signal = OFF].

4.11.1 Run/reset DI

The following operation is performed when ON continues for 2 seconds after the external contact open (OFF)

changes to the external contact closed (ON):

During a run: The run stops.

During a stop: A run starts.

4.11.2 Hold DI

The following operation is performed when ON continues for 2 seconds after the external contact open (OFF)

changes to the external contact closed (ON):

During a run: The run stops momentarily.

During a momentary stop: The run restarts.

4.11.3 Step feed DI

- 11 -

The step changes when the external contact open (OFF) changes to the external contact closed (ON) during a

program run.

4.11.4 Patterns 1 to 4 DI

A pattern is selected from 1 to 15, which are configured by combination of the external contacts 1 to 4 closed (ON)

and open (OFF).

No switchover of a pattern No. is possible during a run.

If all external contacts 1 to 4 are open (OFF), choose the pattern No. selected in the pattern No. setting mode.

Pattern 1 DI: 1

Pattern 2 DI: 2

Pattern 3 DI: 4

Pattern 4 DI: 8

Example: If both pattern 1DI and pattern 3DI are ON, selected pattern No. is: 1 + 4 = 5.

4.12 Auto run (AUTO)/manual run (MANU)

The base of a run is the auto run (AUTO); the auto run, however, changes to the manual run (MANU) by

holding the AUTO/MANU key pressed for 3 seconds.

No control is performed during a manual run, but the operation amount is output in a display.

The displayed operation amount is identical to the SV displayed in the lower row on the PV/SV screen in the

normal mode.

Pressing the /key in this status results in a change of the operation amount to be output.

The operation amount and step time are as follows at the start of a manual run:

−Operation amount

In the case of in-a-stop: Starts with the operation amount of 0.0%.

In the case of in-a-run: Starts with the operation amount at the time of switchover

−Step time

In the case of in-a-stop: Remains in a stop (no step time counting begins).

In the case of in-a-run: The step time elapses (remains in a stop during a momentary stop).

Re-holding the AUTO/MANU key pressed for 3 seconds results in a return to the auto run.

The AUTO and MANU lamps lights up as follows:

During an auto run: The AUTO lamp turns on and the MANU lamp turns off.

During a manual run: The AUTO lamp turns off and the MANU lamp turns on.

The output interval during a manual run is fixed to 10 seconds.

4.13 Operation amount limiter

By using the operation amount function selection, “no limit function” can be set or two types of operation

amount limiters can be effective.

In addition, two types of limiters can be effective by using the other operation amounts limiter setting described

in Section 4.13.3.

4.13.1 Operation amount limiter

The operation amount is limited by using the primary/secondary control operation amount upper limiters and

Primary/secondary control operation amount lower limiters selected by the operation amount limiter function

selection at each step.

If the operation amount limiter function selection is 0, then 0.0 to 100.0 % is applicable.

- 12 -

4.13.2 Operation amount current limiter

The operation amount and current value are limited at each point obtained by dividing SLL to SLH into 10.

At the operation amount limiter points 1 to 11, the operation amount resulted from calculation is limited.

At the current value limiter points 1 to 11, the operation amount is limited by the operation amount at the

current value limiter point determined from a measured current value and present operation amount if the

measured current value at each point exceeds the value [setting value - current limiter sensitivity].

This operation amount changes each time when measuring the current value.

The final operation amount is limited by using either smaller limit of the above two.

The function is effective when [OUT 2 selection = 4 to 20mA], CT existent, [CNT = 1] and operation amount

current limiter effective. OUT2 outputs MV1 (equivalent to OUT1).

100%

Operation amount

0

Temperature

0℃

=SLL

1200℃

=SLH

120℃ 240℃ 360℃ 480℃ 600℃ 720℃ 840℃ 960℃ 1080℃

30A

Current

0

- For an input below the table range, the SLL operation amount and the current value are used for calculation.

- For an input above the table range, the SL operation amount and the current value are

used for calculation.

Temperature

0℃

=SLL

1200℃

=SLH

120℃ 240℃ 360℃ 480℃ 600℃ 720℃ 840℃ 960℃ 1080℃

AHC

* The limiter on the current side is at the location indicated by

([setting value - sensitivity]) at each point.

- 13 -

Example:

Assume the following for various settings and PV:

PV = 120 °C, operation amount limiter point 2 = 75.0%, current value limiter point 2 = 10.0 A, present operation

amount = 60.0% and AHC = 1.0 A.

−If measured current valued = 15 A:

Based on the relation [0 to present operation amount (60.0%) = 0.0 to measured current value (15.0 A)], the

operation amount [current value limiter point 2 (10.0 A) - current limiter sensitivity (1.0 A)] is to be determined.

The calculation results in the operation amount of 36.0%.

15A

Current

0% 60.0%

15A

Current

0% 60.0%36.0%

(10A-1A =)9A

0A0A

Operation

amount

Operation

amount

* The operation limiter point 2 = 75.0%; as this amount is larger than the operation amount resulted from the

calculation, the operation amount is eventually limited at 36.0%.

4.14.3 Other operation amounts limiter setting

4.14.3-1 Primary/secondary control operation amount change limiter increase setting

Setting items:

Primary/secondary control operation amount change limiter increase setting: 0.0 to 549.9 [%] (no function by

setting at 0.0 [%])

Operation description:

The increase rate of variation of a calculated operation amount is limited.

The operation amount allowed to increase for a second is set in percent.

The setting is effective during AT.

If the setting is changed, control results also changes; redo AT.

If the setting is 100%, the variation increases only up to 20 % for input sampling (200 ms).

To increase up to 100% for input sampling (200 ms), set at 500%.

(1 second ÷200 ms) ×100% = 500%

Calculated operation

amount

Limited operation

amount

100%

100%

0%

0%

Time

- 14 -

4.14.3-2 Primary/secondary control operation amount increase time

Setting items:

Primary/secondary control operation amount increase time: 0 to 3600 [second] (no function by setting at 0

[second])

Operation description:

For a remote run, apply a limit on the operation amount such that the ratio of the operation amount to the

calculated operation amount is from 0% at the start to 100% at the setting time.

The setting is effective also during AT.

If the setting is changed, control results change; redo the AT.

Operation is performed only at the control start (RDY to RUN or MAN orAT)

Care must be used, as no limit applies by the operation amount increase time after the setting time.

100%

Operation amount

Time

0

oHtM

Calculated operation amount

Limited operation amount

0%

oHtM

RDY RUN

* No compensation applies

after the setting time.

Calculated operation

amount

Limited operation

amount

100%

100%

0%

0%

Time

4.15 Key lock

When a change of each parameter is attempted in a lock after lock ON/OFF is elected, “LOC” is displayed in the

SV display section.

RUN

OUT

EV1

EV2

EV3

EV4

TS1

TS2

TS3

TS4

AUTO

MANU

AT

END

TIME

PTN STP

- 15 -

4.16 PV filter setting

4.16.1 PV filter setting

This setting is a function to achieve the CR filter effect on the software by performing a primary delay

calculation on the PV of the input 1.

The filter effect is set with the damping time constant [t].

(Damping time constant is defined as time when PV reaches about 63% in a stepwise change of input.)

* CR filter: Filter of first order lag

Application of a PV filter:

(1) By elimination of high-frequency noise, effect of noise is mitigated when electric noise applies to input.

(2) Response can be delayed for an abrupt change of input.

Input signal

0%

100%

100%

0%

100%

0%

Damping time constant (PdF1)

63%

Read-in input

(No filter)

Read-in input

(With a filter)

4.16.2 B thermocouple/PR40-20 special PV filter setting

This setting is a function for the input 1 to add the PV filter setting time further with a limitation of a particular

range on the B thermocouple and PR40-20.

Filter effect is set by the damping time constant [t].

The effective range of the set filter is as follows:

(1) B thermocouple: In the case of 400°C or below

(2) PR40-20: In the case of below 800°C

100%

0%

100%

0% Damping time constant (PdF1 + PdFS)

63%

63%

Damping time constant (PdF1)

Normal PV filter

(PV filter setting only)

Special PV filter

Time added for PdFS

Input signal

0%

100%

- 16 -

4.17 Event alarm

By setting the events 1 to 4 function setting, outputs of EV 1 to 4 are turned on if PV is located within the alarm range.

Corresponding EV1 to EV4 lamps light up.

By switching over the events 1 to 4 polarities, selection of open/closed is possible at the turn-on.

Output is also turned on at occurrence of a loop abnormality when the events 1 to 4 function 2 setting is effective.

* For loop abnormality, see Section 8.17 “ Loop abnormality.”

The setting can be released by using the key or reset DI, provided that the following condition is met:

(1) Normal status at the release

(2) Standby existent even if abnormality status at the release

Judgment process is performed only during a run (no judgment made during a stop).

Restoration from a power outage is made for the status previous to the outage.

4.18 Loop abnormality

When the primary/secondary control loop abnormality PV change amount setting is not 0, the PV change amount is

determined every loop abnormality time setting time if the present step is a soak.

Consequently, “loop abnormality” occurs if the following condition is met: ⊿PV ≤Primary/secondary control loop

abnormality PV change amount setting.

Function OFF is established if the primary/secondary control loop abnormality PV change amount setting is 0.

4.19 Blind Function

RUN

OUT

EV1

EV2

EV3

EV4

TS1

TS2

TS3

TS4

AUTO

MANU

AT

END

TIME

PTN STP

RUN

OUT

EV1

EV2

EV3

EV4

TS1

TS2

TS3

TS4

AUTO

MANU

AT

END

TIME

PTN STP

RUN

OUT

EV1

EV2

EV3

EV4

TS1

TS2

TS3

TS4

AUTO

MANU

AT

END

TIME

PTN STP

Press the MODE key.

Hold the MODE key pressed as is although a

change is made to the common parameter

setting 3 seconds after pressing the MODE key.

Holding the MODE key pressed for 10

seconds on the PV/SV screen results in

blinking display. Pressing the MODE key

and then the RESET key results in a change

to the blind mode.

MODE key

Input 1 type

MODE key

△・▽ key △・▽ key △・▽ key

△・▽キー

To PID To PV-SV

To SET 3

to SET 11

To the following

items

Three-second prolonged

press of the MODE key

MODE key

function setting

MODE key

To the following

items

Setting temperature

MODE key

−Holding the MODE key pressed for 10 seconds on the PV/SV screen results in the blind mode.

−In the blind mode, “ON” and “OFF” are displayed in the lower row for each character (SV display section). “ON”

indicates display and “OFF” indicates no display (blind). Note that a batch setting applies for the PV/SV screen,

elapsed time screen and operation amount screen.

−For a character change in the blind mode, use the DSP.CHG key.

−To terminate the blind setting mode, either turn off the power or hold the MODE key pressed for 10 seconds on the

PV/SV screen.

−For blind items, see “L/B” in the column of “Command” in Operation Specifications “List of communications

items.”

- 17 -

4.20 Electric Power Outage Function

−Upon recovery of the electric power after its outage during a run, the status at the time of the outage is restored

under the following conditions. Note that, if the PV at restoration is out of the range of [PV ±electric power

outage restoration temperature width], the restoration is made as a stop.

−Alarm statuses of the event function are also restored.

1) If the step 1 is in the status of a timer run (SV=SLL):

→Restored at the location at the time of the outage.

2) In the case of in-a-ramp of SV increase or in-a-soak:

→Restored with the PV start.

Restored with the run end “END” if no SV present.

3) In the case of in-a-ramp of a SV decrease or in-a-soak after the decrease:

→Restored with the PV start at the step of the decrease if PV >decrease point.

Restored with the run end “END” if PV ≤decrease point.

4) In the case of in-“END”:

→Restored to “END.”

5) Restored with a temporary stop for the items 1 through 3 if a power outage occurs during a temporary stop.

6) In the case of in-a-manual-run:

→Restored with a stop status.

1) 2) 3)

During

END

4)

During a

timer run

PV

Time

- 18 -

5. Flow of Mode Change Operation and Run Operation

5.1

Primary Power Source in

the OFF status

5.2

Initial mode

Primary power

source ON

5.3

Normal mode

5.4

Pattern No. setting mode

5.5

Program setting mode

4 seconds

elapsed In a stop: Display switchover key only

In a run: Display switchover key: 3

seconds

5.6

Common parameter setting

mode

5.7

Alarm temperature setting

mode

5.8

PID setting mode

Reset

MODE key

Reset

MODE key: 3 seconds

Reset

MODE key +▽key: 3 seconds

Reset

MODE key + △key: 3 seconds

Reset

5.3.1

Reset

5.3.2

Auto run

5.3.3

Temporary stop

< Normal mode >

RUN/STOP key: 2 seconds

RESET key: 2 seconds

RUN/STOP key

5.3.4

Manual run

AUTO/MAN key: 3 seconds

AUTO/MAN key: 3 seconds

It takes about 2 seconds from the primary

power source ON until the initial mode.

Primary power

source OFF

- 19 -

Flow of the program setting mode

Pattern No. setting mode

MODE key

Step 1 temperature

setting

Step 1 time setting

Step 2 temperature setting

Step 2 time setting

MODE key

Step □temperature setting

Step □time setting

Similarly make settings up to the

maximum step.

(Varies, depending on the number of

patterns.)

□

□

MODE key

END signal ON time setting

DSP.CHG key +

MODE key

MODE key MODE key

Step 1 wait function

existence/nonexistence

setting

Step 1 time signal 4

function existence/

nonexistence setting

MODE key MODE key

MODE key

MODE key

MODE key MODE key

□ □

MODE key

Step 1 operation

amount limiter function

setting

MODE key

MODE key

□

MODE key + △key

MODE key + △key

MODE key + △key

MODE key + △key

MODE key

Step 1 time signal 1

function existence/

nonexistence setting

MODE key

MODE key

□

* There are time signals 1 to 4.

MODE key MODE key + △key

DSP.CHG key +

MODE key

DSP.CHG key +

MODE key

Step 2 wait function

existence/nonexistence

setting

Step 2 time signal 4

function existence/

nonexistence setting

Step 2 operation

amount limiter function

setting

Step 2 time signal 1

function existence/

nonexistence setting

Step □wait function

existence/nonexistence

setting

Step □time signal 4

function existence/

nonexistence setting

Step □operation

amount limiter function

setting

Step □time signal 1

function existence/

nonexistence setting

- 20 -

Flow of the Common parameter setting mode

Normal mode

△ key

MODE key

MODE key

MODE key

MODE key: 3 seconds

MODE key

MODE key

MODE key

MODE key

MODE key

MODE key

MODE key

MODE key

▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

△ key▽ key

MODE key

MODE key

△ key▽ key

To settings of

SET1

To settings of

SET2

To settings of

SET3

To settings of

SET4

To settings of

SET5

To settings of

SET6

To settings of

SET7

To settings of

SET8

To settings of

SET9

To settings of

SET10

To settings of

SET11

To settings of

SET12

To settings of

SET13

Flow of the Alarm temperature Flow of the PID setting mode

setting mode

Normal mode

MODE key

MODE key

MODE key

MODE key

MODE key

MODE key

MODE key

MODE key

Event 1 upper limit setting

Event 1 lower limit setting

MODE key + ▽key: 3 seconds

Event 2 upper limit setting

Event 2 lower limit setting

Event 3 upper limit setting

Event 3 lower limit setting

Event 4 upper limit setting

Event 4 lower limit setting

Normal mode

MODE key

MODE key

MODE key

MODE key

Proportional band setting of PID No. 1 (low temperature)

Integral time setting of PID No. 1 (low temperature)

MODE key + △key: 3 seconds

Derivative time setting of PID No. 1 (low temperature)

Intermediate point 1 setting for the PID range

MODE key

MODE key

MODE key

Proportional band setting of PID No. 2 (intermediate temperature)

Integral time setting of PID No. 2 (intermediate temperature)

Derivative time setting of PID No. 2 (intermediate temperature)

Intermediate point 2 setting for the PID range

MODE key

MODE key

MODE key

MODE key

Proportional band setting of PID No. 3 (high temperature)

Integral time setting of PID No. 3 (high temperature)

Derivative time setting of PID No. 1 (high temperature)

Table of contents

Other Toho Electronics Controllers manuals

Toho Electronics

Toho Electronics TTM-00BW User manual

Toho Electronics

Toho Electronics TTM-P4W Series User manual

Toho Electronics

Toho Electronics TTM-200 Series Use and care manual

Toho Electronics

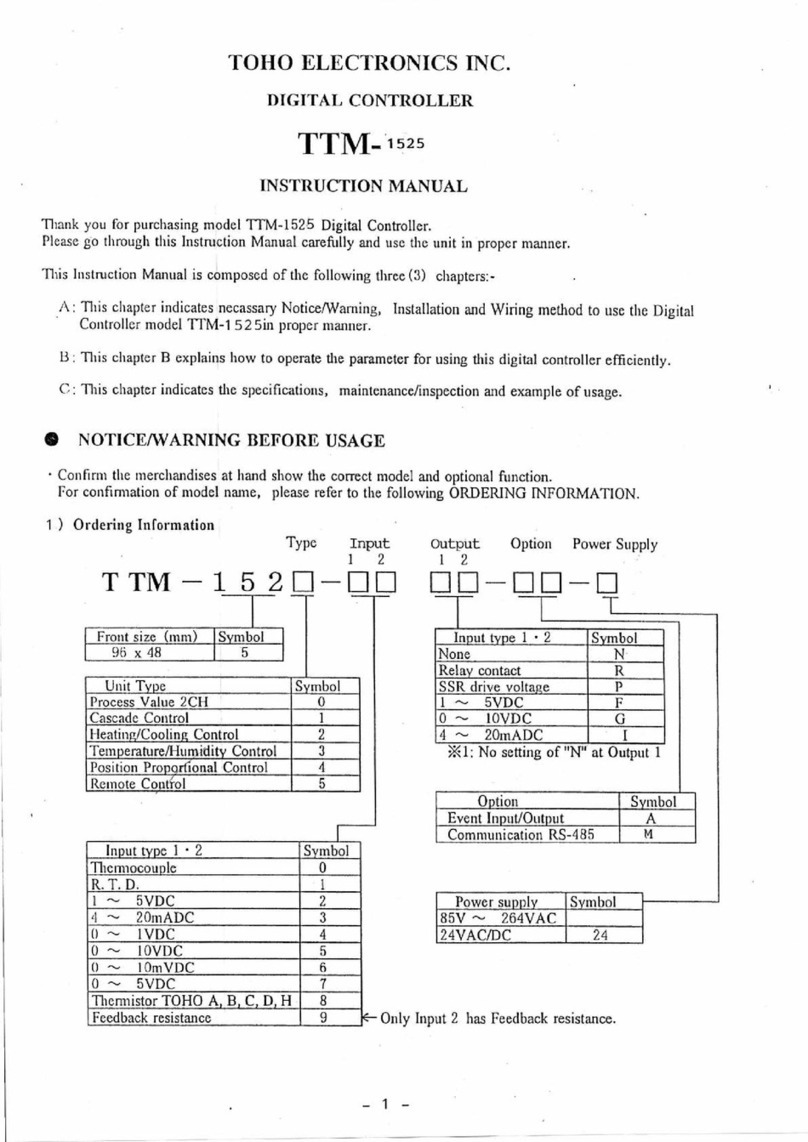

Toho Electronics TTM-1525 User manual

Toho Electronics

Toho Electronics TTX-800 User manual

Toho Electronics

Toho Electronics TTM-300 Series User manual

Toho Electronics

Toho Electronics TTM-210 Series Use and care manual

Toho Electronics

Toho Electronics TRV1-C015 User manual