Installationsplan PT 7251 EL

Stand: 23.09.2004 Seite 8

Nominal air throughput in vented mode m³/h 510Vented

Permissible pressure attenuation Pa 200

Machine vent connection (da× s × l) [DN 150] mm 150 × 0.6 × 78

On-site vent connection (interior diameter) mm 150

Max. temperature °C 80

As relative humidity can be as high as 100%, suitable

measures must be taken to prevent a backflow of condensate

into the machine.

If the machine fan is unable to transport air over the on-site

vent ducting distance, an additional fan with a suitable

capacity must be installed either in the ducting or at the point

of discharge to atmosphere.

Standard connection:

=> Air intake from installation site

Air intake

Direct air intake recommended cm² 531

(to prevent draughts)

Sufficient air intake should be available to replace the

displaced volume of air.

Alternative connection: (cf. Detail Y)

=> Direct air intake

Machine connection (di × s × l) [NW160] mm 161 × 4.0 × 16

On-site connection (external diameter) mm 160

Lid removal exposes live components! For safety reasons,

the pipe connected for central air intake should be at least

900 mm long and secured using two screws.

2 × screws DIN 571 (Ø × length) mm 6 × 40

2 × rawl plugs (Ø × length) mm 10 × 50

Fittings (supplied)

The machine should be bolted to the floor.

Fixing materials for floating screed floor to be provided on site

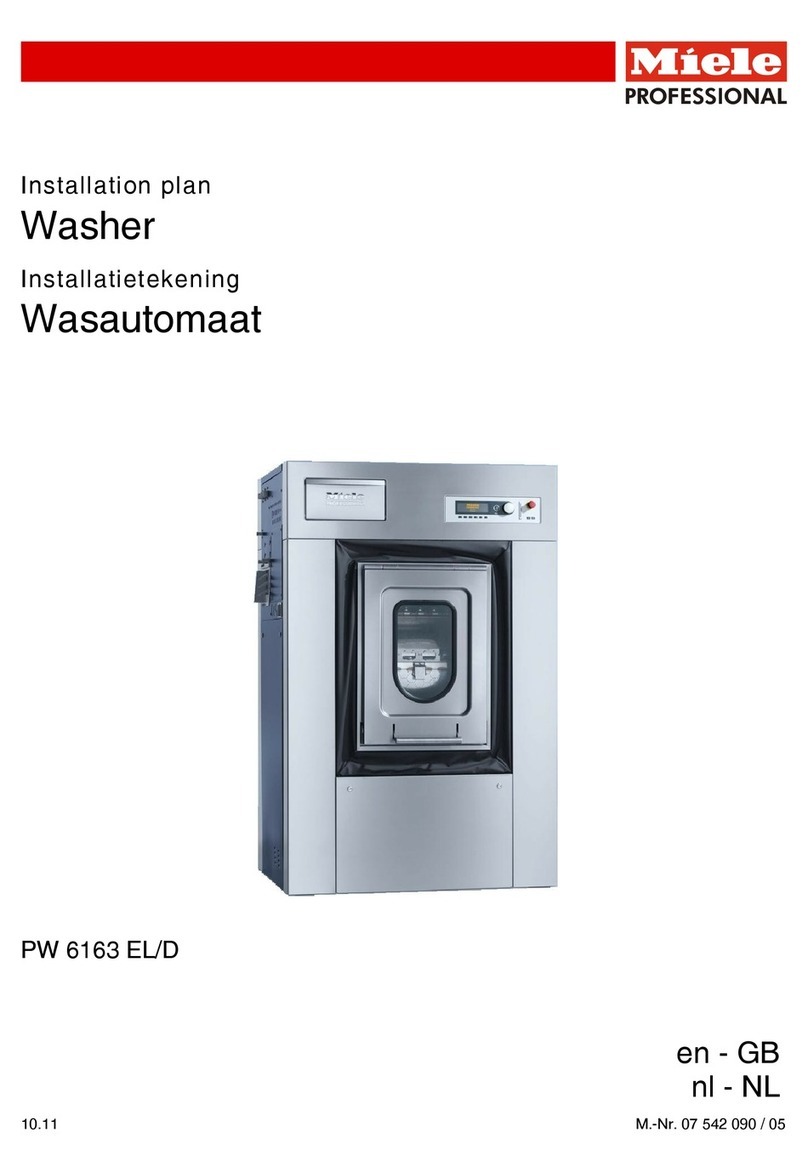

Machine data Width mm 900

Depth mm 836

Height mm 1400

Knocked-down dimensions (W × H) mm 900 x 1500

Rear wall gap (measured to front of machine) mm 1100

Net weight kg 160

Dynamic floor load, max. N 1716

Average heat dissipation

(dependent on ambient room temperature and programme

selected)

W 500

Acoustic power level (re1 pW) dB (A) 68

Sound pressure level dB (A) not yet available

(measured at a distance of 1 m from the machine and at a

height of 1.6 m)

Installation should only be carried out by authorised fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved!