TABLE OF CONTENTS

1. Preface

2. Applications, Warnings, Power Transmission of Machine

3. Warning Symbols

4. Safety Precautions

5. Specifications

6. Appearance

7. Inspection Before Operation

8. Operation

9. Stopping the Machine

10. Transportation

11. Storage

12. Regular Check and Adjustment

13. Troubleshooting

4-1 General Precautions

4-2 Refueling Precautions

4-3 Location and Ventilation Precautions

4-4 Precautions Before Starting

4-5 Precautions During Work

4-6 Lifting Precautions

4-7 Transportation and Storage Precautions

4-8 Maintenance Precautions

4-9 Labeling Positions

4-10 Description of Symbols Used on Warning Labels

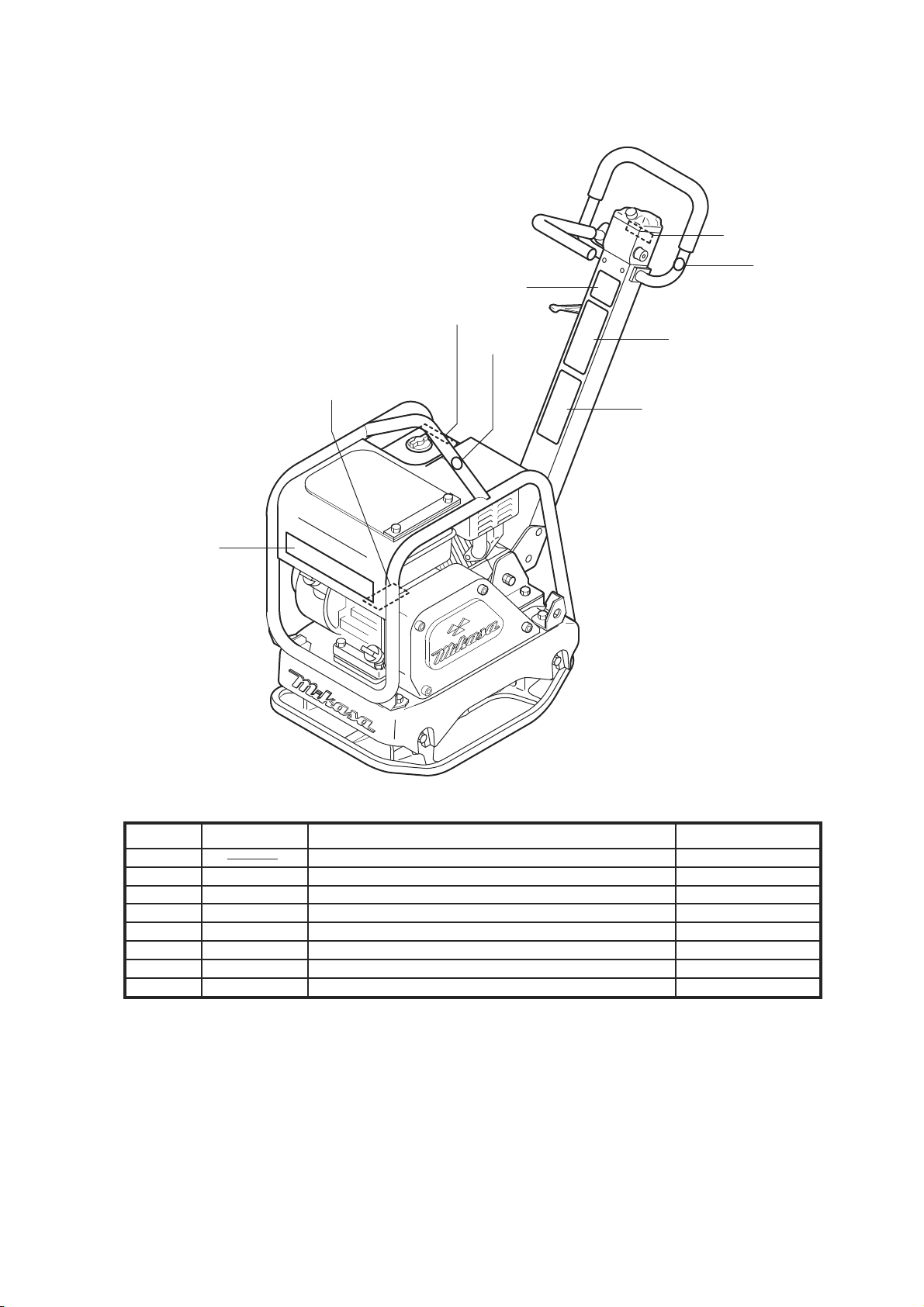

6-1 Outside Dimensions

6-2 Parts and Component

8-1 Starting

8-2 Operation

10-1 Loading and Unloading

10-2 Transportation Precautions

12-1 Inspection and Maintenance Schedule Table

12-2 Changing the Engine Oil

12-3 Cleaning the Air Cleaner

12-4 Checking/Changing the V-belt and Clutch

12-5 Checking/Changing the Vibrator Oil

12-6 Checking/Changing the Hydraulic Oil

13-1 Gasoline Engine

13-2 Main Body

.................................................................................... 1

....... 1

.................................................................... 3

.................................................................. 3

.................................................... 3

.................................................. 4

........................... 4

....................................... 4

............................................. 4

....................................................... 4

.................... 5

........................................... 5

....................................................... 6

...... 7

.......................................................................... 9

.............................................................................10

.....................................................10

................................................ 11

.................................................. 12

............................................................................... 13

..................................................................... 13

.................................................................. 16

............................................................ 17

....................................................................... 18

............................................ 18

...................................... 18

.................................................................................. 18

............................................ 19

........... 19

........................................... 20

........................................... 20

................ 20

......................... 21

....................... 21

.................................................................... 23

....................................................... 23

................................................................ 24