MIKRODEV PLC Series User manual

MP211

HARDWARE MANUAL

•MP211

PLC Series

06 / 2021

MIKRODEV_HM_MP211_EN

v1.5

1

MP211 SERIES –HARDWARE MANUAL

CONTENTS

FIGURES LIST ..................................................................................................................................2

Preface ...........................................................................................................................................3

About Mikrodev .............................................................................................................................4

WARNING!......................................................................................................................................5

1MP211 GENERAL INFORMATION ........................................................................ 6

1.1 Physical Interfaces .................................................................................... 6

1.2 General Device Specifications ..................................................................... 7

2INSTALLATION INFORMATION........................................................................... 8

2.1 Rail Installation ......................................................................................... 8

2.2 Expansion Installation................................................................................ 9

3CONNECTION DIAGRAMS ................................................................................10

3.1 Supply Connection....................................................................................10

3.2 Digital Inputs...........................................................................................11

3.3 Digital Outputs.........................................................................................12

3.4 Relay Outputs ..........................................................................................13

3.5 Analog Inputs ..........................................................................................14

3.6 Analog Outputs ........................................................................................15

3.7 RS485 Serial Port .....................................................................................16

3.8 RS232 Serial Port .....................................................................................17

2

MP211 SERIES –HARDWARE MANUAL

FIGURES LIST

Figure 1 Connector and Physical Interfaces ............................................................... 6

Figure 2 Mounting.................................................................................................. 8

Figure 3 Expansion Installation................................................................................ 9

Figure 4 Power Connection Diagram........................................................................10

Figure 5 Digital Input Connection Diagram...............................................................11

Figure 6 Digital Output Connection Diagram.............................................................12

Figure 7 Relay Connection Diagram ........................................................................13

Figure 8 Analog Input Connection Diagram ..............................................................14

Figure 9 Analog Output Connection Diagram ............................................................15

Figure 10 RS485 Serial Port Connection Diagram......................................................16

Figure 11 RS232 Serial Port Connection Diagram......................................................17

3

MP211 SERIES –HARDWARE MANUAL

Preface

Mikrodev MP211 PLC series are programmable control devices that are used in a wide

range of applications from process automation to building automation, from machine

automation to telemetry applications.

In this document, you can find information about the hardware specifications of Mikrodev

MP211 series PLCs.

Please follow our website www.mikrodev.com for the up to date version of the document.

4

MP211 SERIES –HARDWARE MANUAL

About Mikrodev

Since 2006, MIKRODEV has been developing and manufacturing industrial control and

communication products. MIKRODEV serves the system integrators in the public and

private sector, OEM and end users.

Our products are manufactured complying with the quality standards required by the

industrial automation industry and the quality of our products are proved on the field for

many years

MIKRODEV is one of the few companies in the world that has its own designed IEC

61131-3 compliant library for its programmable logic control devices. In addition, the

open, flexible, programmable SCADA solution developed by MIKRODEV is also available

to customers.

MIKRODEV products' performance and wide range of applications make them possible for

customers to achieve faster, simplified and cost-effective results.

5

MP211 SERIES –HARDWARE MANUAL

WARNING!

✓Please take care of the following issues when using Mikrodev devices.

✓Since the unit operates with 24 VDC (12-36 VDC) voltage, you should take care of

the voltage level that the unit is connected to. If a voltage above this voltage level

is applied, the device may be damaged and may be out of warranty.

✓Make sure that the energy connection of your device is connected to the ground

or to a properly grounded terminal.

✓Make sure that the environment in which your device is being used is free of

moisture, electric shock, vibration and dust.

✓Pay attention to the supply voltage and the connections of the product. Mikrodev

is not responsible for any issues due to power failure since there is no auxiliary

supply (UPS) on the device.

✓The fuse to be used must be a FF super fast type and current limit value 1A.

✓Do not use the device under conditions other than the environmental conditions

specified in the "Electrical Specifications" section (humidity, dust, liquid and

temperature, etc.)

✓Removing the warranty label on the product or removing the protective case will

void the warranty.

✓Products that are damaged, boxes have been changed and other brand labels are

affixed are not covered by the warranty.

✓The appliance must not be cleaned with solvents (thinner, benzine, acid etc.) or with

abrasive cleaning agents.

✓Only dry cloth should be used when cleaning the appliance.

✓Do not open the device by removing the case of the appliance, do not interfere

with the electronic components and circuits. There is no user-replaceable part

inside the device.

✓If there is a problem or malfunction on your device, it should only be repaired by

an authorized service. Installation and electrical connections must be made by

technical personnel in accordance with the instructions in the operating manual.

Failure to comply with these rules may result in death, serious injury or

property damage

6

MP211 SERIES –HARDWARE MANUAL

1MP211 GENERAL INFORMATION

1.1 Physical Interfaces

Figure 1 Connector and Physical Interfaces

1

Digital Input GND Connection

19

USB Port

2

Analog Output Connections

20

Relay Status Information LED

3

Analog GND Connection

21

Digital Output Status Information LED

4

Analog Input Connection

22

Digital Input Status Information LED

5

RS485 Connections

23

System Power LED

6

RS-232 GND Connections

24

System Running LED

7

Rs232 TX-RX Connections

25

Error LED

8

None

26

Protocol Data Transfer LED

9

None

27

Antenna Connection

10

Relay Connections

28

SIM Card Slot

11

CANBUS Connection

29

SD Card Slot

12

Digital Input Connections

30

LCD Screen

13

Digital Output Connections

31

LCD Screen Back Button

14

Digital Output Supply(Vin) Connection

32

LCD Screen Up Button

15

Digital Output GND Connection

33

LCD Screen Input Button

16

Device Power (V+) Connection

34

LCD Screen Forward Button

17

Device Power (V-) Connection

35

LCD Screen Down Button

18

Ethernet Port

7

MP211 SERIES –HARDWARE MANUAL

1.2 General Device Specifications

SPECIFICATION

ITEM

DESCRIPTION

Processor

Processor Architecture

ARM Cortex M4

Adressing Architecture

Little Endian Addressing

Electrical

Supply

24 VDC (12-36VDC)

Power

<13W @ 24V DC

Real Time Clock

Integrated

Input / Output

Digital Input

16 Channel

Digital Output

8 Channel, 2A@30V DC, PNP

Analog Input

4 Channel, 0-20 mA, 4-20 mA

Analog Output

2 Channel, 0-20 mA, 4-20 mA

Relay Output

4 Channel, 3A@30VDC - 5A@250VAC

Display

LCD Display*

2x16 Character

Enviromental

Conditions

Operating

Temperature

-20…+60 C

Storage Temperature

-25…+70 C

Humidity

5…95 RH

Memory

Retentive Memory

4 KB, 128 Block/Register

Program Memory

4 MBit

Communication Ports

Ethernet Port

10/100 Mbps

RS485

1 Port, 3 kV ESD Protection

RS232

1 Port

Wireless

Communication

GSM / GPRS*

Quad-Band 850/900/1800/1900 MHz

Wi-Fi*

IEEE 802.11 b/g/n

RF*

868 MHz, TX Power Up to 0,5 W

Expansion Capacity

DIN Rail Type-

CANBUS Expansion

Up to 1024 I/O Points

*May differ on some models

8

MP211 SERIES –HARDWARE MANUAL

2INSTALLATION INFORMATION

2.1 Rail Installation

DIN Rail Mountage

First, the upper part of the device is mounted on the DIN rail. Then, with the help of the

springs behind the device, when a lightly force is applied to the lower part, the device

locates into the DIN rail easily and the montage is completed. (See Figure 2)

DIN Rail Demountage

To demount the device, firstly it is pulled from the bottom using flexibility of the spring,

the device is removed from the DIN Rail and the demounting is completed.

Figure 2 Mounting

9

MP211 SERIES –HARDWARE MANUAL

2.2 Expansion Installation

The MP211 product and its extensions are mounted by sliding over the rail in such a way

that the connectors correponds.

Figure 3 Expansion Installation

10

MP211 SERIES –HARDWARE MANUAL

3CONNECTION DIAGRAMS

3.1 Supply Connection

Supply:

12-36 VDC, Protected

Power:

<13 W

Figure 4 Power Connection Diagram

11

MP211 SERIES –HARDWARE MANUAL

3.2 Digital Inputs

Module Input:

16 Channel

Voltage Range:

0-36V DC

ON Voltage Level:

12-36V DC

OFF Voltage Level:

0-10V DC

Input Impedance:

>2M

Isolation:

Optical

OFF to ON Response:

20 us

ON to OFF Response:

90 us

Fast Counter Inputs:

DI12, DI13, DI14, DI15

Fast Counter Inputs Max. Frekans

200 kHz

Figure 5 Digital Input Connection Diagram

12

MP211 SERIES –HARDWARE MANUAL

3.3 Digital Outputs

Module Output:

8 Channel, Mosfet Output

Voltage Range:

12-36V DC

Max. Output Current:

2A @ 30V DC

Isolation:

Optical

Pulse Width Modulation Output and Pulse Train Output:

DO1, DO2, DO3, DO4

Pulse Train Output Max. Frequency(PTO):

50 kHz

Pulse Width Modulation Output Max. Frequency(PWM):

65 kHz

Figure 6 Digital Output Connection Diagram

13

MP211 SERIES –HARDWARE MANUAL

3.4 Relay Outputs

Module Output:

4 Channel

Relay Contact Outputs:

NO(Normally Open) Contact

Contact Max. Current:

3A@30VDC –5A@250VAC

Isolation

Dry Contact

Figure 7 Relay Connection Diagram

14

MP211 SERIES –HARDWARE MANUAL

3.5 Analog Inputs

Module Input:

4 Channel

Analog Input Type:

0-20 mA, 4-20 mA

Analog Input Resolution:

12 Bit

Analog Input Precision:

%1 Precision

Common Input GND:

1 GND (4 Point / Common)

Figure 8 Analog Input Connection Diagram

15

MP211 SERIES –HARDWARE MANUAL

3.6 Analog Outputs

Module Output:

2 Channel

Analog Output Type:

0-20 mA, 4-20 mA

Analog Output Resolution:

12 Bit

Current Output Precision:

%1 Precision

Common Output GND:

1 GND (2 Point / Common)

Figure 9 Analog Output Connection Diagram

16

MP211 SERIES –HARDWARE MANUAL

3.7 RS485 Serial Port

RS485 Port Count:

1 Port, 3 kV ESD Protection

Maximum Slave Count

Limited to Hardware

Isolation:

Galvanic and Optical

Communication Distance:

1000 m

Data Bits:

7-8

Stop Bits:

1-2

Parity:

None-Even-Odd

Baudrate:

300 bps to 200 kbps

Figure 10 RS485 Serial Port Connection Diagram

17

MP211 SERIES –HARDWARE MANUAL

3.8 RS232 Serial Port

RS232 Port Count:

1 Port

Communication Distance:

10 m

Data Bits:

7-8

Stop Bits:

1-2

Parity:

None-Even-Odd

Baudrate:

300 bps to 200 kbps

Figure 11 RS232 Serial Port Connection Diagram

This manual suits for next models

1

Table of contents

Other MIKRODEV Controllers manuals

Popular Controllers manuals by other brands

Elan

Elan Z-880 installation manual

LMI Technologies

LMI Technologies Liquitron DC4000 Series instruction manual

Mircom

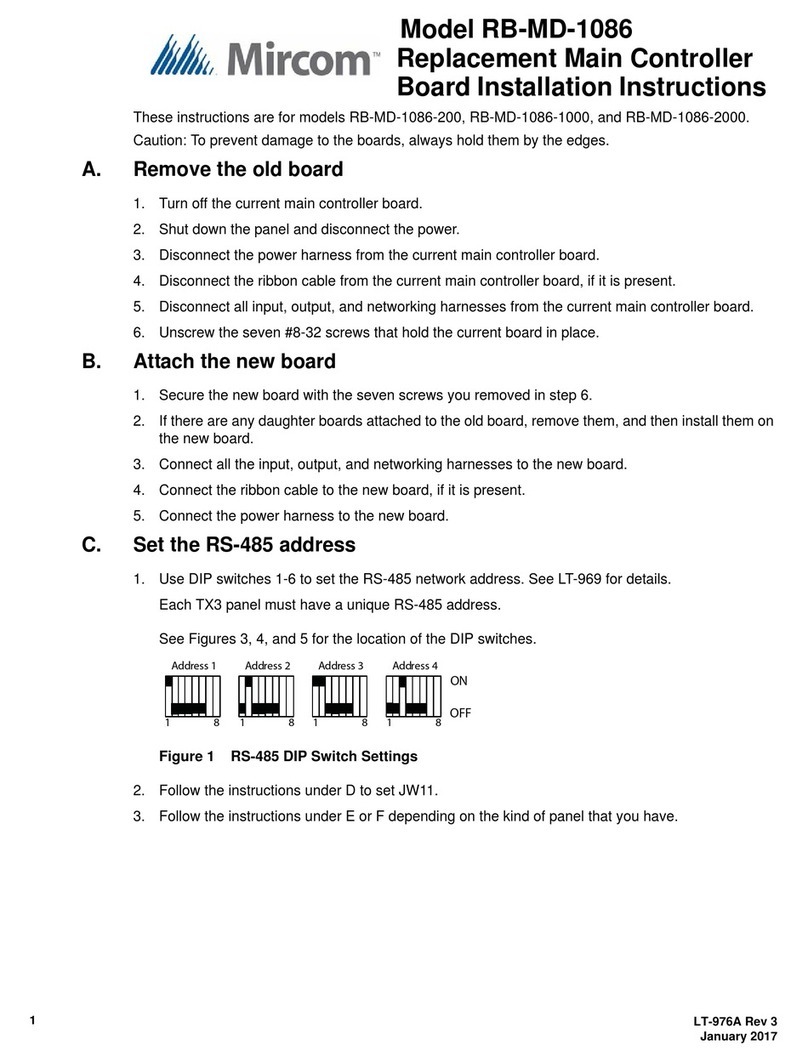

Mircom RB-MD-1086 Series installation instructions

Acuity Brands

Acuity Brands nLight rIO quick start guide

KE2

KE2 Evaporator Efficiency Condensed Quick Start Guide

Seikom Electronic

Seikom Electronic RLSW5 operating instructions

Leroy-Somer

Leroy-Somer UMV 2301 AS Series Installation and Maintenance

Snell Advanced Media

Snell Advanced Media 2460 user manual

Xylem

Xylem CentriPro Aquavar SOLO instruction manual

Johnson Controls

Johnson Controls Tyco KT-1 installation guide

EMKO

EMKO EZM-4950 instruction manual

Carel

Carel pCO3 series Technical leaflet