Contents

1. Product Introduction.................................................................................................................................4

1.1 Overview...........................................................................................................................................4

1.2 Features............................................................................................................................................4

2. Hardware Introduction............................................................................................................................. 4

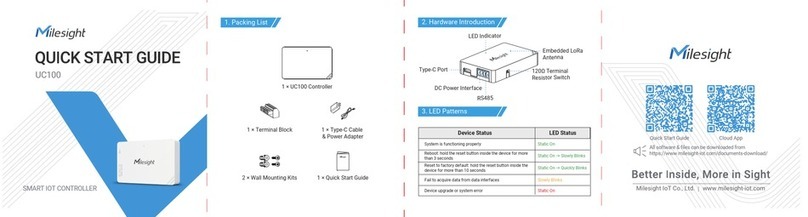

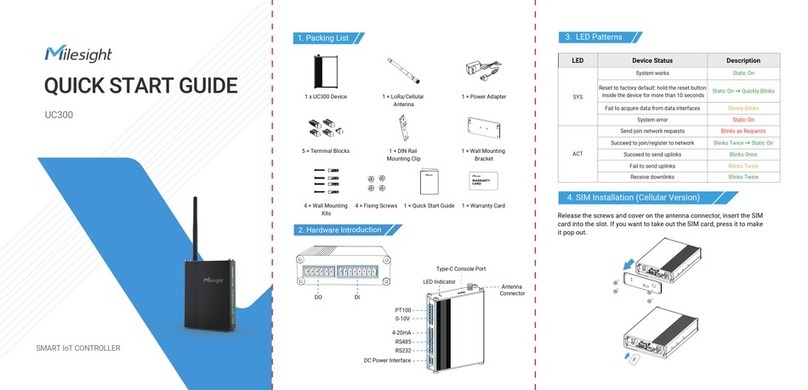

2.1 Packing List..................................................................................................................................... 4

2.2 Hardware Overview........................................................................................................................ 4

2.3 Internal Interfaces...........................................................................................................................5

2.4 Dimensions(mm)............................................................................................................................ 6

3. Hardware Installation............................................................................................................................... 6

3.1 Hardware Switch.............................................................................................................................6

3.2 UC500 Installation.......................................................................................................................... 7

4. Operation Guide.........................................................................................................................................8

4.1 Log in the ToolBox..........................................................................................................................8

4.1.1 NFC Configuration...............................................................................................................8

4.1.2 USB Configuration.............................................................................................................10

4.2 LoRaWAN Settings....................................................................................................................... 11

4.3 Interface Settings......................................................................................................................... 14

4.3.1 RS485 Settings.................................................................................................................. 14

4.3.2 RS232 Settings.................................................................................................................. 17

4.3.3 GPIO Settings.....................................................................................................................18

4.3.4 AI Settings.......................................................................................................................... 20

4.4 Maintenance..................................................................................................................................21

4.4.1 Upgrade.............................................................................................................................. 21

4.4.2 Backup................................................................................................................................ 22

4.4.3 Reset to Factory Default.................................................................................................. 23

5. Milesight IoT Cloud Management........................................................................................................24

5.1 Add a Milesight Gateway.............................................................................................................24

5.2 Add UC500 to Milesight IoT Cloud............................................................................................ 26

6. Device Payload........................................................................................................................................27