MILLART MACHINE TOOLS SS-18 User manual

Popular Tools manuals by other brands

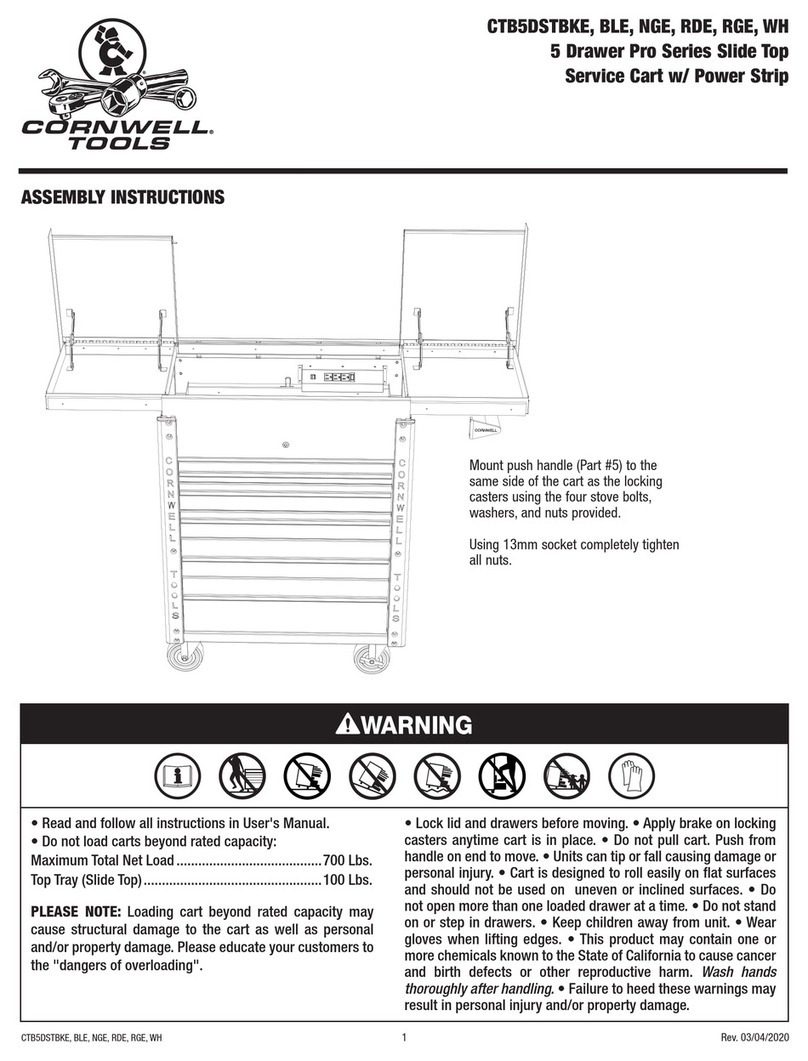

Cornwell Tools

Cornwell Tools Pro Series Assembly instructions

Dexter Power

Dexter Power PC1300RT Original instructions

Cornwell Tools

Cornwell Tools CTG-SSAGG operating instructions

Parkside

Parkside PSS 65 A1 Translation of the original instructions

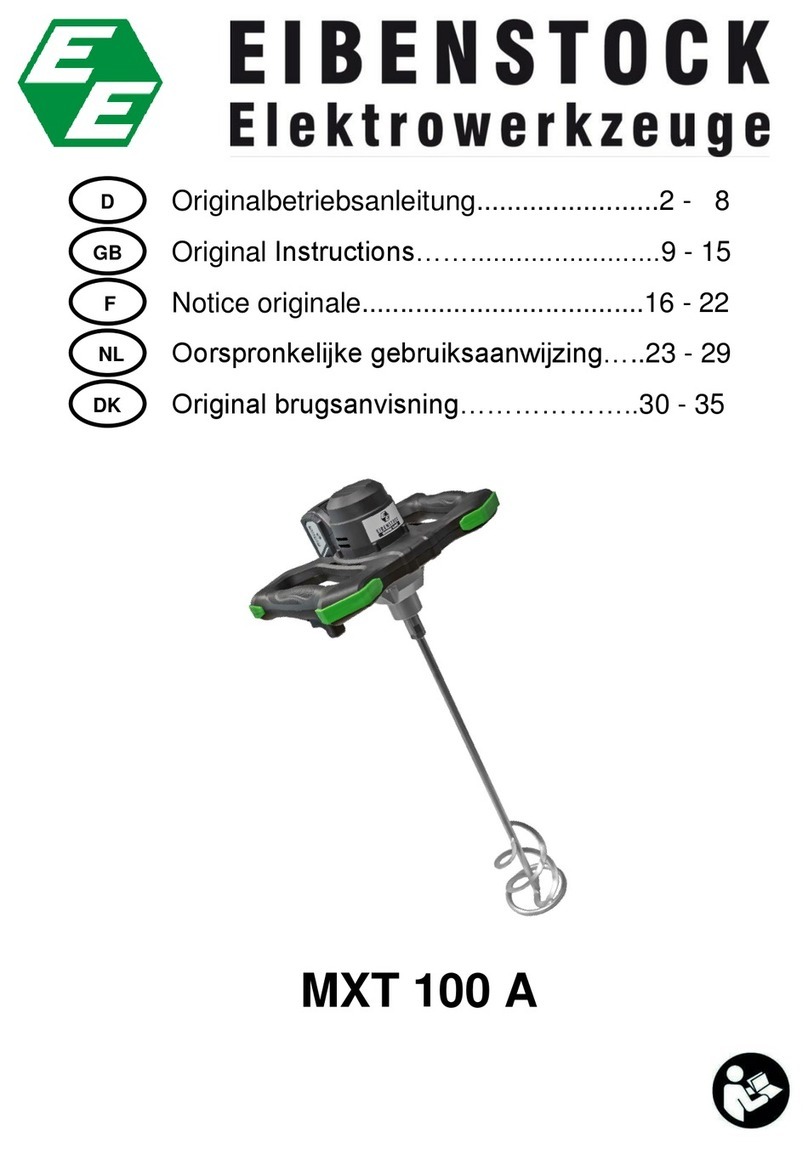

EIBENSTOCK

EIBENSTOCK MXT 100 A Original instructions

EINHELL

EINHELL DTA 25/2 Original operating instructions

B-K lighting

B-K lighting AGI2 manual

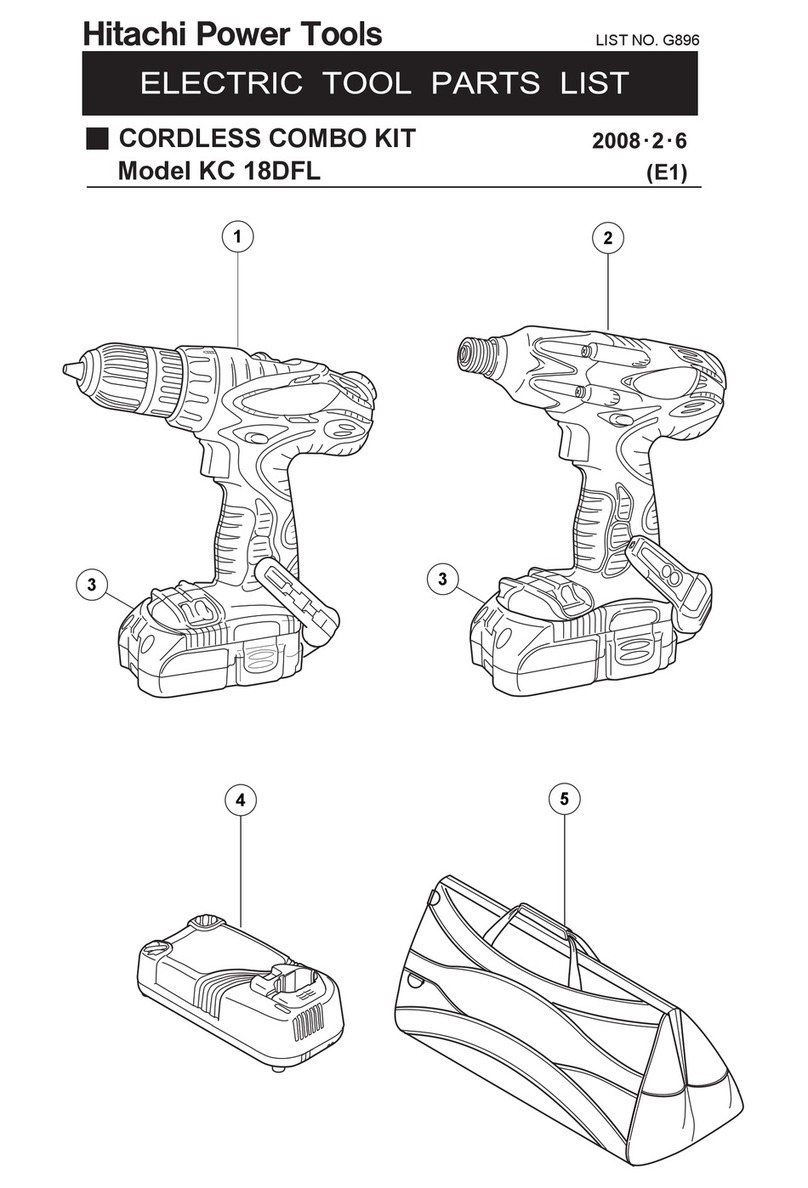

Hitachi

Hitachi KC18DFL - 18V Cordless Lithium Ion Two Piece... parts list

Tapepro

Tapepro CORNER BOX manual

Retra

Retra REALEZY 320 Series Owner's operation and maintenance manual

SUHNER ABRASIVE

SUHNER ABRASIVE LBC 16 manual

Huck International

Huck International SF20 instruction manual