TABLE OF CONTENTS

SECTION 1: INTRODUCTION...................................................................................... 1-1

Guide to this Manual......................................................................................................... 1-1

For Your Safety................................................................................................................. 1-1

Safety Labels............................................................................................................... 1-1

Inspection and Warranty Registration .............................................................................. 1-

Standard/Optional Components................................................................................... 1-

Warranty Registration.................................................................................................. 1-

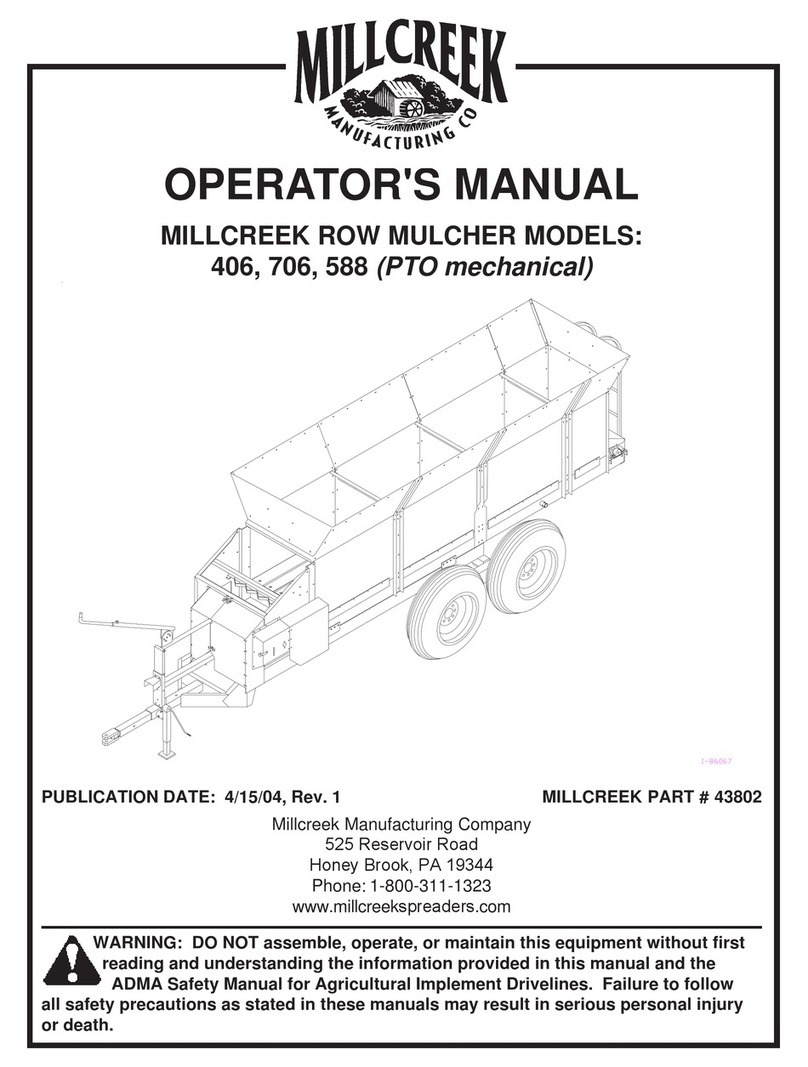

SECTION 2: ATTACHING THE ROW MULCHER TO THE TRACTOR.................... 2-1

Connecting the Row Mulcher Hitch to the Tractor Drawbar...........................................2-1

Attaching the Row Mulcher PTO to the Tractor PTO.......................................................2-2

Assembling the Safety Tow Chain....................................................................................2-2

SECTION 3: OPERATION & ADJUSTMENT............................................................. 3-1

Understanding Row Mulcher Operation...........................................................................3-1

The Row Mulcher Operating Components.................................................................3-1

Important Specifications for Row Mulcher Operation...............................................3-1

Guidelines for Loading the Row Mulcher..................................................................3-2

Operating the Row Mulcher..............................................................................................3-2

SECTION 4: MAINTENANCE.................................................................................... 4-1

Guidelines for Regular Maintenance.................................................................................4-1

General Maintenance..................................................................................................4-1

Wheel/Tire Maintenance.............................................................................................4-2

Wheel Bearing Maintenance.......................................................................................4-2

Drive System Maintenance.........................................................................................4-2

Hydraulic System Maintenance.........................................................................................4-4

APPENDIX A: PARTS REFERENCE.......................................................................... A-1

Parts Ordering Information...............................................................................................

Main Frame and Chassis..................................................................................................

Wheel and Hub Assembly...............................................................................................

Drive System Assembly..................................................................................................

Apron/Floor Chain Assembly..........................................................................................

Box Assembly................................................................................................................

Conveyor Assembly.......................................................................................................

Hydraulics.......................................................................................................................

A-1

A-2

A-4

A-6

A-8

A-10

A-12

A-14