Miller-Leaman Ulra-Pure ML-01-8 User manual

E-mail : sales@millerleaman.com

www.millerleaman.com

OPERATING

MANUAL

ML-01-8 - ML-50-8

Electrical: {208-230/460V/60Hz/Single or Three Phase}

MLModel Number: __________

E-mail : sales@millerleaman.com

www.millerleaman.com

2

CONTENT

Pages

1 Brochures and information

Ultra-Pure ML860 membrane cartridge

Ultra-Pure ML systems

2 - 3

2 Process and Plant Setup Diagram 4

3 Process Description

Filtration, Air Scouring, Air Scouring & Backflush 5 - 9

4 Membrane Regeneration

Functional EBF (FEBF)

Enhanced Backflush (EBF)

Clean In Place (CIP)

10 - 15

5 System / Electrical Control and Schematics

16 - 49

6

7

8

Storage and Usage

Trouble Shooting

System Parameter Record Chart

50

51

52

9

Attachments

53

E-mail : sales@millerleaman.com

www.millerleaman.com

3

Specifications

Operating Process

Configuration Hollow Fiber ( Out to In Filtration )

Material Hydrophilic modified PAN

Fibre Size 2.0mm OD

Surface Area 520 sq ft

Cartridge Housing 8 “ Diameter x 60 “ Length

Weight 40 kg / 80 lbs

Operating Temperature < 50 °C / 104 °F

Operating Pressure (TMP) < 8 psi (Feed); <14 psi (Backflush)

pH 3 ~ 9 (Operating); 2 ~ 11 (Washing)

Flow/Flux Rate:

City Water

River/ Bore

Treated Wastewater

4.0 m³/h (48gfd)*

2.5 m³/h (30gfd)*

1.5 m³/h (18gfd)*

Filtration

(Out to In) Re-generation

(In to Out)

Dead End Mode Air Scouring with

Backflushing

Note: Miller-Leaman reserves the right to make any changes to the information provided above without prior notice.

* Subject to feed water condition

E-mail : sales@millerleaman.com

www.millerleaman.com

4

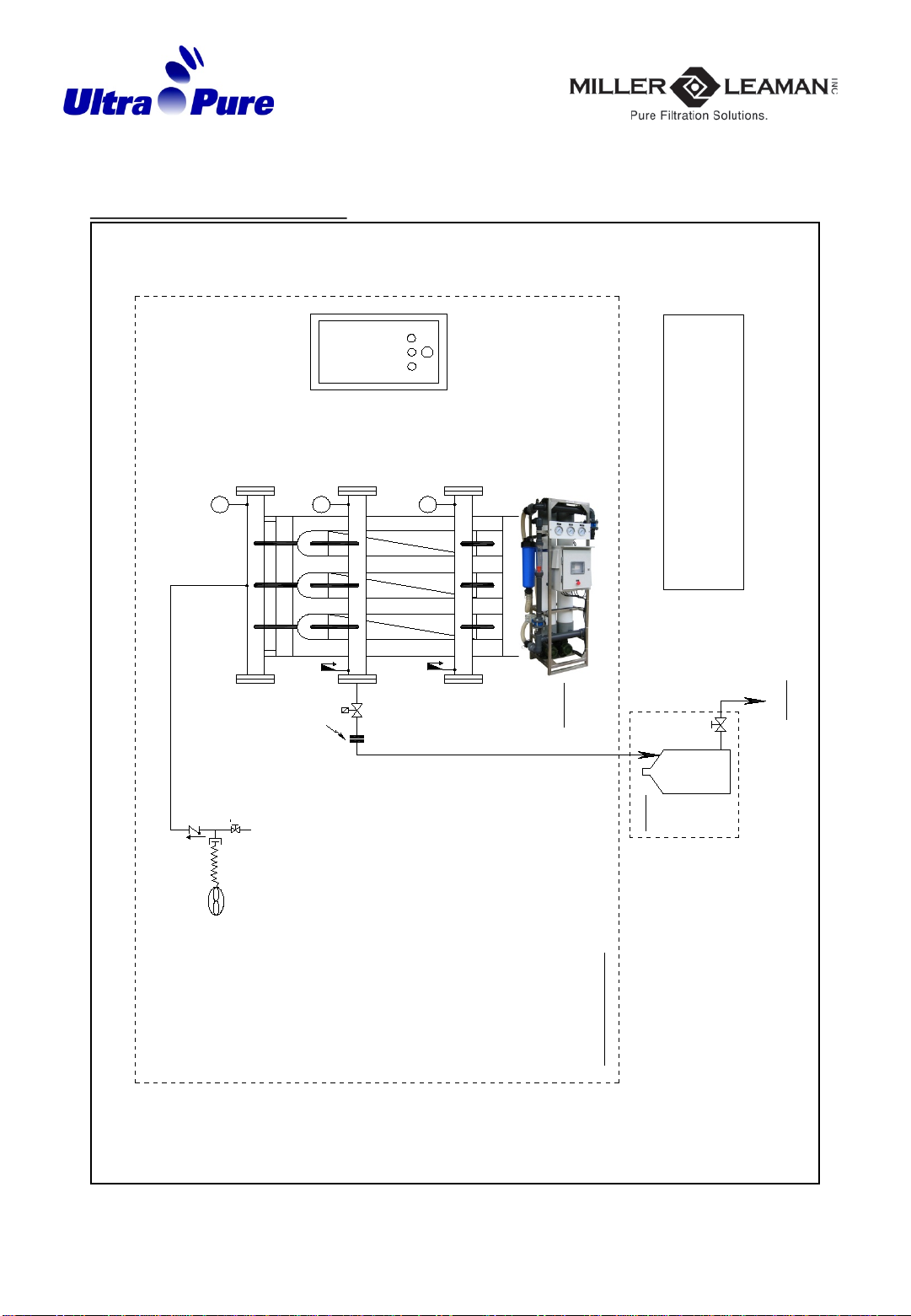

2. Process and Plant setup Diagram

P1

P3

P2

Product Out

(>95% Volume)

Product/Backflush Tank

Tank Volume : Depends on usage pattern.

FEED

Feed

Flow

P0

Guard Filter

CV-1

Product

Flowmeter

Connecting

Point

Control

Panel

(Electrical)

Product Flow PRODUCT

Ultra-Flo Membrane Module

Membrane Skid

SCOPE OF SUPPLY

Guard-Filter Bag size selection :

Filtration : 100 um size.

CIP : 50 um size

H

L

Pressure

Relief Valve

REJECT

to drain

(<5% Volume)

(Keep this pipeline big & short)

EBF

Tank

Drain

Connecting

Flange

Backflush Pump

Check

Valve Backflush

Flow

BACKFLUSH

(Keep this pipeline big & short)

Backflush Tank

Valve

EBF Feed

Valve

Tank Volume:

150L/membrane

CV-2

Feed Tank

Valve

Feed Tank

Tank Volume : 20 ~ 30 mins holding time.

Check Valve

Connecting

Flange

Connecting

Flange

L

Feed Pump

Dosing

Tank

Dosing

Pump

CIPV-1

MV-1

Optional

Air Blower

Check

Valve

1

4

" Drain

Valve

Hose

Pressure

Relief Valve

CIP Feed

Valve

DRAIN

Reject/CIP

Tank

Optional

Optional

MV-2

CIPV-2

Drain

Valve

E-mail : sales@millerleaman.com

www.millerleaman.com

5

3. Process Description: (2-Valve Control)

Start process in ‘Auto’. Select SS-1 to “Auto”, depress PB-1 “System On/Off” once to

start. The system will go through the following sequence.

P1 – Feed Pressure

P2 – Air Scouring Pressure

P3 – Backflush Pressure

1. Filtration cycle ( T1 ) (Refer to Filtration Flow Diagram Page 8)

Aim : Produce Filtered Water

CV-1 Close, CV-2 Open, Feed Pump On, Backflush pump Off, Blower Off

Outside to inside flow, on a dead-end configuration.

Filtration cycle will pump feed water through the Guard-strainer to the membrane

cartridges. Filtered product water will flow through the flow-meter to the Product /

Backflush Tank.

Filtration Pressure (P1 – P3 = TMP1), maximum at 8 psi (Default setting at 3 psi)

Filtration Pressure / product flow rate can be increase or decrease by adjusting from the

frequency controller (refer to inverter operating manual).

(Start filtration at low pressure first, example at 1 psi for a few cycles and records

down the parameters before increasing to higher pressure/flow.)

Time duration is set in the PLC, ‘Filtration’(T1). (Default is at 5 minutes)

Timer duration can be set longer according to the feed water condition.

2. Air Scouring cycle ( T2 ) (Refer toAir Scouring Diagram Page 9)

Aim : Dislodge Suspended Solids from Membrane

CV-1 Open, CV-2 Close, Feed Pump Off, Backflush pump Off, Blower On

Air scouring is a process of releasing air bubbles into the membrane cartridge via the

Blower.

When the Blower is activated, air scouring pressure gauge (P2) should read 1.5 ~ 2.0 psi

above the gauge reading.

This will dislodge suspended solids from the membrane surface. Time duration is set in

the PLC, ‘Air-Scouring’ (T2). (Default is at 30 seconds)

Timer duration is set according to the feed water condition.

E-mail : sales@millerleaman.com

www.millerleaman.com

6

3. Air Scouring + Backflush cycle ( T3 ) (Refer toAir Scouring + Backflush Flow Diagram

Page 10)

Aim : Membrane Regeneration

CV-1 Open, CV-2 Close, Feed Pump Off, Backflush pump On, Blower On

Inside to outside flow, on a dead-end configuration.

Backflush cycle will pump product water through the membrane cartridges through Reject valve CV-1

for disposal.

Backflush Pressure (P3 – P1 = TMP2) maximum of 14 psi (When Blower is Activated)

Backflush pressure or flow rate can be either increase or decrease by adjusting from the frequency

controller (refer to the inverter operating manual).

Time duration is set in the PLC, ‘Backflush’(T3). (Default is at 30 seconds)

Timer duration is set according to the feed water condition.

Backflushing flow rate during this cycle is much higher relative to the filtration cycle, 6-7m3/h per

membrane. Important to keep the following pipelines big in diameter and short in length:

- suction pipe line from tank to backflush pump.

- reject pipe line after CV-1, to open drain.

Important Instructions:

Flushing Instructions:

Membrane contains preservatives such as sodium meta-bisulphite or glycerine. Flush the membrane

with clean water (normally city water) for about 10mins before operating the system.

Bag Filter:

It is a routine operational procedure to monitor and to ensure that the bag filter is not clogged. If the

flowrate decreases or if the differential pressure between the bag filter and feed pressure (P0-P1)

exceeds 10psi, changing or cleaning the filter bag must be done immediately.

System startup procedure:

Start operating this system with clean water (normal city water supply) in the feed tank. Operate the

system for 30 minutes with this feed water. Record the operating parameters and keep this as the

reference for this plant.

Long term usage:

During long term usage, it will be useful to add a shock level of biocide into the feed water on a once a

day basis. Chlorine can be applied at a dosage below 20 ppm. Other forms of non-oxidizing biocide

can be applied at higher levels.

Testing of Free Chlorine:

Free Chlorine concentration in the water can easily be measured by using a simple comparison of a

colour scale with a test strip. Recommended chlorine test strips - Chlorine Test

Cat No. Measuring Range – mg/l/Cl2

1.17924.0001 25 ~ 500

1.17925.0001 0.5 ~ 20

E-mail : sales@millerleaman.com

www.millerleaman.com

7

Filtration Flow Diagram

P1

P3

P2

Product Out

(>95% Volume)

Product/Backflush Tank

Tank Volume : Depends on usage pattern.

FEED

Feed

Flow

P0

Guard Filter

CV-1

Product

Flowmeter

Connecting

Point

Control

Panel

(Electrical)

Product Flow

PRODUCT

Ultra-Flo Membrane Module

Membrane Skid

SCOPE OF SUPPLY

Guard-Filter Bag size selection :

Filtration : 100 um size.

CIP : 50 um size

H

L

Pressure

Relief Valve

CV-2

Feed Tank

Valve

Feed Tank

Tank Volume : 20 ~ 30 mins holding time.

Check Valve

Connecting

Flange

Connecting

Flange

L

Feed Pump

MV-1

Pressure

Relief Valve

MV-2

E-mail : sales@millerleaman.com

www.millerleaman.com

8

Air Scouring Diagram

P1

P3

P2

CV-1

Control

Panel

(Electrical)

Ultra-Flo Membrane Module

Membrane Skid

SCOPE OF SUPPLY

Guard-Filter Bag size selection :

Filtration : 100 um size.

CIP : 50 um size

Pressure

Relief Valve

REJECT

to drain

(<5% Volume)

(Keep this pipeline big & short)

Connecting

Flange

Air Blower

Check

Valve

1

4

" Drain

Valve

Hose

Pressure

Relief Valve

DRAIN

Reject/CIP

Tank

Optional

Drain

Valve

E-mail : sales@millerleaman.com

www.millerleaman.com

9

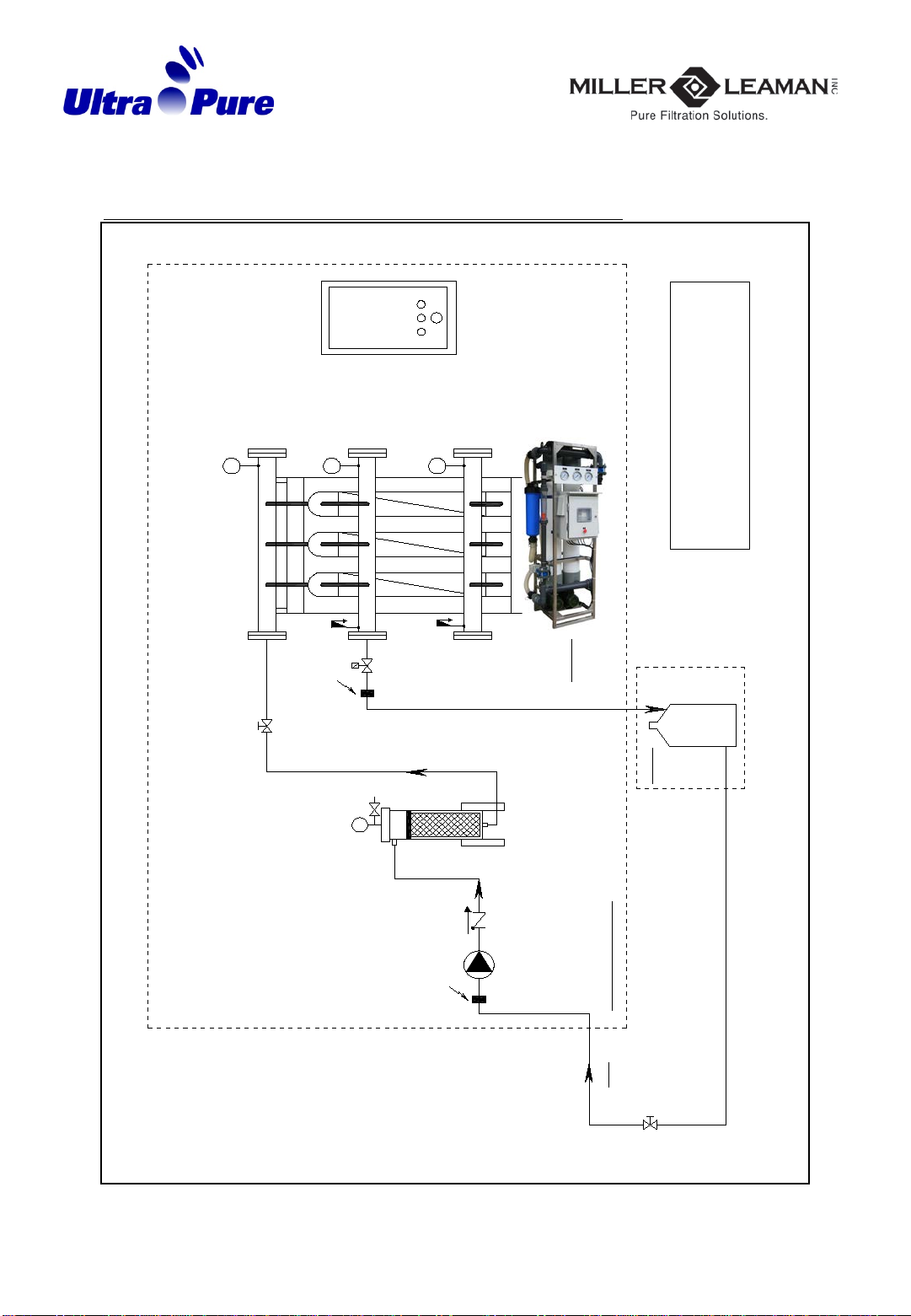

Air Scouring + Backflush Flow Diagram

P1

P3

P2

Product/Backflush Tank

Tank Volume : Depends on usage pattern. CV-1

Control

Panel

(Electrical)

Ultra-Flo Membrane Module

Membrane Skid

SCOPE OF SUPPLY

Guard-Filter Bag size selection :

Filtration : 100 um size.

CIP : 50 um size

H

L

Pressure

Relief Valve

REJECT

to drain

(<5% Volume)

(Keep this pipeline big & short)

Connecting

Flange

Backflush Pump

Check

Valve Backflush

Flow

BACKFLUSH

(Keep this pipeline big & short)

Backflush Tank

Valve

Connecting

Flange

Dosing

Tank

Dosing

Pump

Optional

Air Blower

Check

Valve

1

4

" Drain

Valve

Hose

Pressure

Relief Valve

DRAIN

Reject/CIP

Tank

Optional

Drain

Valve

E-mail : sales@millerleaman.com

www.millerleaman.com

10

4. Membrane Regeneration

After some time of usage, and depending on the feed water conditions, the membrane

cartridges may experience fouling. This will result in a drop in product flow rate and/or

an increase in filtration pressure. Aregeneration procedure can be performed to

reverse this situation.

4.1 *Optional : Functional EBF (T4)

(Default frequency of Fuctional EBF is set at every 24hrs)

(Refer to Page 10)

Aim : Membrane Regeneration

(Enhance Backflushing at Periodic Time to Prevent Further Fouling)

A shock level of free chlorine at 20ppm is added into the backflushing stream during the

backflushing cycle. This is done automatically by having an optional dosing system

(Pump and Chemical Tank) to pump in the required amount of chlorine.

According to the feed water condition, the frequecy of dosing can be determined in PLC

‘FEBF’ (Timer T4). The default frequency is once every 24hrs. To activate or deactivate

the dosing simply by connecting or disconnecting the power plug provided.

E-mail : sales@millerleaman.com

www.millerleaman.com

11

4. Membrane Regeneration

4.2 Enhanced Backflush “EBF” (Refer to EBF Flow Diagram Page 13)

EBF is a process of backflushing the membrane cartridges

with a preferred chemical for cleaning purpose. This regeneration process will

reverse the fouling issue. It should be implemented as a routine during the usage

of this system. Depending on the feed water conditions and system performance,

it can be performed on a daily, every 2 or 3 days, or even weekly basis.

Before starting the EBF. Step 1 and 2 will put the system through a normal Air

Scouring + Backflush cycle to reduce some loading before chemical usage.

1 Air Scouring + Backflush the system once, depress PB-2 ‘Backflush’ button.

2 Stop the system, depress PB-1 ‘System on/off’ button.

3 Fill-up the ‘Backflush Tank’ with reference amount of clean water (prefer

from its own product water or directly from the utility water).

Add chemical to EBF tank (selection depends on fouling conditions)

Select to Backflush from EBF tank by setting manual valve.

• 20-100 ppm of chlorine, Cl2( Organics and Biological ), Or

•pH 2 for acid cleaning ( Inorganic and scaling ), Or

•pH 11 for alkaline cleaning (Organics and Biological )

4To commence EBF. Select SS-1 to “EBF” depress PB-1 “System On/Off” once

to start the EBF process. The system will go through one cycle of Air

Scouring + Backflush. Depress PB-1 “System On/Off” again to stop the

system.

5Soak the membrane cartridges for about 10-20 mins.

6 Repeat Step 4 & 5 if necessary.

7 Select Backflush from Product / backflush tank, by setting manual valve.

8Select SS-1 to ‘Auto” start filtration by depress PB-1 “System On/Off” once.

Air Scouring + Backflush the system once, depress PB-2 ‘Backflush’ button.

This will help to neutralize the residual chemical in the system

9 End of EBF

E-mail : sales@millerleaman.com

www.millerleaman.com

12

4.2 Membrane Regeneration (EBF) Flow Diagram

P1

P3

P2

CV-1

Control

Panel

(Electrical)

Ultra-Flo Membrane Module

Membrane Skid

SCOPE OF SUPPLY

Guard-Filter Bag size selection :

Filtration : 100 um size.

CIP : 50 um size

Pressure

Relief Valve

REJECT

to drain

(<5% Volume)

(Keep this pipeline big & short)

EBF

Tank

Drain

Connecting

Flange

Backflush Pump

Check

Valve Backflush

Flow

BACKFLUSH

EBF Feed

Valve

Tank Volume:

150L/membrane

Connecting

Flange

Air Blower

Check

Valve

1

4

" Drain

Valve

Hose

Pressure

Relief Valve

DRAIN

Reject/CIP

Tank

Optional

Optional

E-mail : sales@millerleaman.com

www.millerleaman.com

13

4.3 Clean In Place “CIP” (Refer to page 15 & 16)

CIP is a process of cross flowing the membrane cartridges with the preferred Chemicals for

cleaning purpose. This regeneration process will reverse the fouling issue.

It should be implemented as a routine during the usage of this system. Depending on the feed

water conditions and system performance, it should be performed on a routine basis.

Before starting the CIP; Step 1 will put the system through a normal Air Scouring + Backflush

cycle to reduce some dirt loading before chemical usage.

1 Air Scouring + Backflush the system once, depress PB-2 ‘Backflush’ button.

2 Stop the system, depress PB-1 ‘System on/off’ button.

3Close the drain valve to convert the Reject tank as CIP tank.

4 Fill-up the CIP Tank with reference amount of clean water (prefer its own product

water or directly from utility water supply). Add chemical to CIP tank (selection depends

on fouling conditions)

•50-100 ppm of chlorine, Cl2( Organics and Biological ),Or

•pH 2 for acid cleaning ( Inorganic and scaling ), Or

•pH 11 for alkaline cleaning (Organics and Biological )

5 Close manual valve from feed tank (MV-2) and open manual valve to CIP tank (CIPV-2).

Open manual valve to air manifold (CIPV-1), close manual valve to feed manifold (MV-1).

Change filter bag to 50/100µm.

6 To commence CIP. Select SS-1 to “CIP”, then depress PB-1 “System On/Off” once to start

the CIP process. Adjust the feed pump frequency to 45Hz in order to achieve a good circulation

flowrate.

7 In CIP mode, the system will go through an alternate process of cross flow and air

scouring for 5mins (TT6A) and 20secs (TT6B) respectively. There will be 5 cycles, at the

end of 5th cycle, the cartridges will be soaked for 10mins. At the end of 10mins of

soaking, the above 5 cycles will be repeated. After which the system will automatically

off. End of CIP.

8 Reverse the actions in above step 3 to 5.

9 Reset the feed pump frequency back to normal. Start filtration. Select SS-1 to “Auto”,

depress PB-1 “System On/Off” once. Air Scouring + Backflush the system once, depress PB-2

‘Backflush’ button. This will help to neutralize the residual chemical in the system.

10 Process in ‘Auto’.

E-mail : sales@millerleaman.com

www.millerleaman.com

14

4.3 Membrane Regeneration (CIP) Flow Diagram

P1

P3

P2

FEED

Feed

Flow

P0

Guard Filter

CV-1

Control

Panel

(Electrical)

Ultra-Flo Membrane Module

Membrane Skid

SCOPE OF SUPPLY

Guard-Filter Bag size selection :

Filtration : 100 um size.

CIP : 50 um size

Pressure

Relief Valve

REJECT

to drain

(<5% Volume)

(Keep this pipeline big & short)

Check Valve

Connecting

Flange

Connecting

Flange

Feed Pump

CIPV-1

Pressure

Relief Valve

CIP Feed

Valve

CIP

Tank

Optional

CIPV-2

E-mail : sales@millerleaman.com

www.millerleaman.com

15

Reject/CIPTank Connection Drawing

6" PVC SCH 80

Pipe

3" PVC SCH 80

Pipe

3" PVC Manual

Valve

Feed Tank

4"

Backflush Tank

Drain Valve

Drain

Valve to feed manifold (MV-1) Valve to air manifold (CIPV-1)

MV-2

CIPV-2

E-mail : sales@millerleaman.com

www.millerleaman.com

16

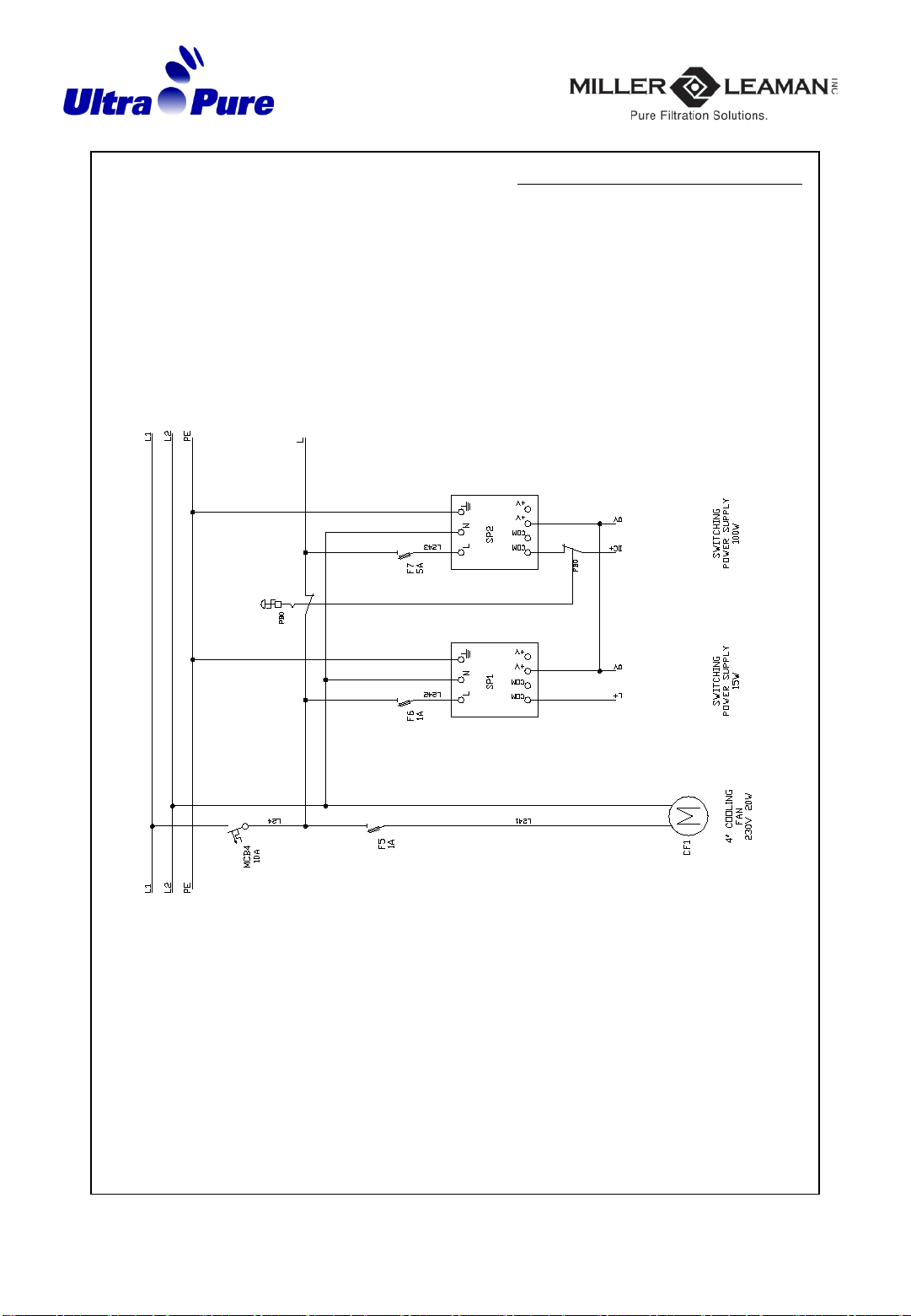

5. System / Electrical Control & Schematics

E-mail : sales@millerleaman.com

www.millerleaman.com

17

Basic controls on Starting and Stopping the System

Level switches controls on the System

Contact close (level above switch): System run

Contact open (level below switch): System will

skip ONE backflush cycle, system will stop on

SECOND backflush cycle

Product / Backflush Tank Low Level

Switch

(TB-24, 25)

3

Contact close (level above switch): System run

Contact open (level below switch): System stop

Product / Blackflush Tank High

Level Switch

(TB-22, 23)

2

Contact close (level above switch): System run

Contact open (level below switch): System stop

Feed Tank Low Level Switch

(TB-20, 21)

1

1 Release “Emergency Stop” Switch (PB-0)

(turn red knob clockwise) Connect power supply to PLC,

Control Valves, Flow-switches, etc.

2 Select Selector switch SS1 to ‘AUTO’

3 Press “System On/Off” button ONCE (PB-1) Step 1 : Filtration

(Start process) Step 2 : Air Scouring only

Step 3 : Air Scouring & Backflush

Return to Step 1

4 Press “Backflush” button ONCE (PB-2) Jump to

(enabled only during Filtration cycle) Step 2 : Air Scouring only

Step 3 : Air Scouring & Backflush

Return to Step 1

5 Press “System On/Off" button ONCE (PB-1) System Stop

(Stop process) (Filtration time stopped at last

count)

E-mail : sales@millerleaman.com

www.millerleaman.com

18

PLC settings, changing timer on Filtration, Air scouring, Air scouring + Backflush, FEBF,

Air Scouring frequency during CIP & Air Scouring duration during CIP.

Warning : Do not change other parameters or settings, except TT1, TT2 ,TT3, TT4, TT6A &

TT6B

Press ▲to increase or ▼to decrease timing

6

Press MENU/OK and then select Yes to save new

setting

7

Press MENU/OK to return to Run screen8

Time setting will “blink”

Press MENU/OK once then ►to change set time

5

Press ▲/ ▼to TT1(Filtration), TT2 (Air scouring), TT3

(Air Scouring + Backflush), TT4 (FEBF Frequency),

TT6A (Air Scouring frequency during CIP), TT6B (Air

Scouring duration during CIP)

4

Press MENU/OK once to enter parameter setting3

Press ▲/ ▼to select ‘PARAMETER’

2 Press MENU/OK once to enter Mode page1

Inverter settings, changing Filtration & Backflushing pump frequency setting

Warning : Do not change other parameters or settings, except for 3-10-0 & 3-10-1

3-10-0 – FEED PUMP FREQUENCY 25 Hz (25%)

3-10-1 – B/F PUMP FREQUENCY 35 Hz (35%)

1.To enter the Main Menu,press [MENU] key unti

indicator in display is placed above

Main Menu.

1.Use ▲/ ▼to browse through the parameter

groups 3-10-0 & 3-10-1.

1.Press [OK] to select a parameter group.

2.Use ▲/ ▼to browse through the parameters in the

specific group.

3.Press [OK] to select the parameter.

4.Use ▲/ ▼to set/change the parameter value.

5.Press [OK] to accept the value.

6.To exit, press either [BACK] twice to enter Quick Menu,

or press [MENU] once to enter Status.

E-mail : sales@millerleaman.com

www.millerleaman.com

19

ML-02 - 4 Electrical Drawing (a)

E-mail : sales@millerleaman.com

www.millerleaman.com

20

ML-02 - 4 Electrical Drawing (b)

This manual suits for next models

1

Table of contents

Other Miller-Leaman Water Filtration System manuals

Popular Water Filtration System manuals by other brands

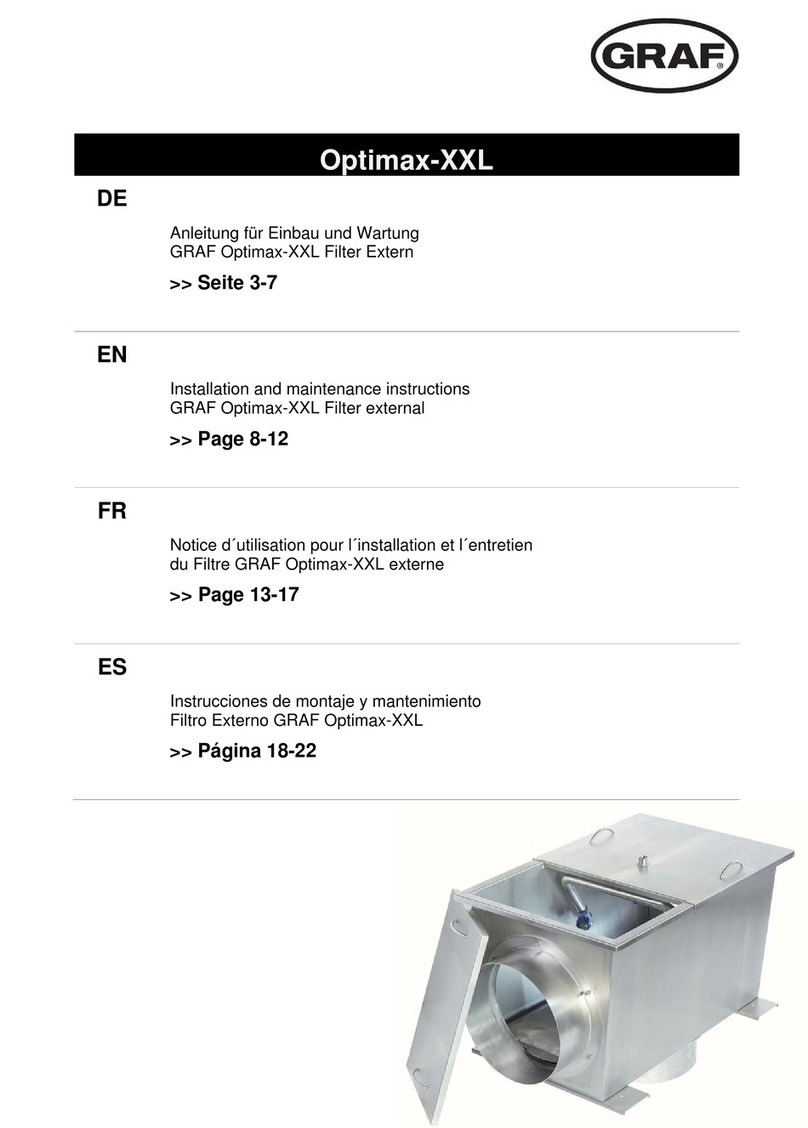

Graf

Graf Optimax-XXL DN300 Installation and maintenance instructions

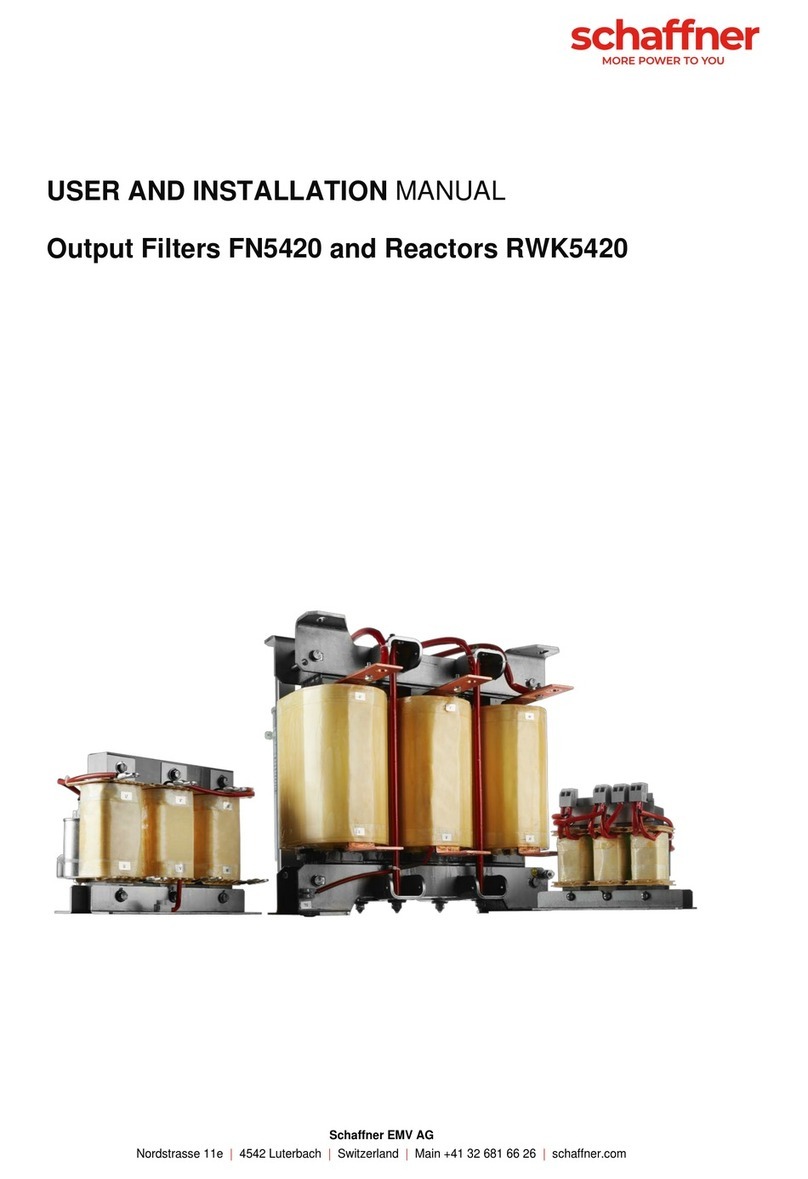

Schaffner

Schaffner FN5420 User and installation manual

Grunbeck

Grunbeck pureliQ:K Operation manual

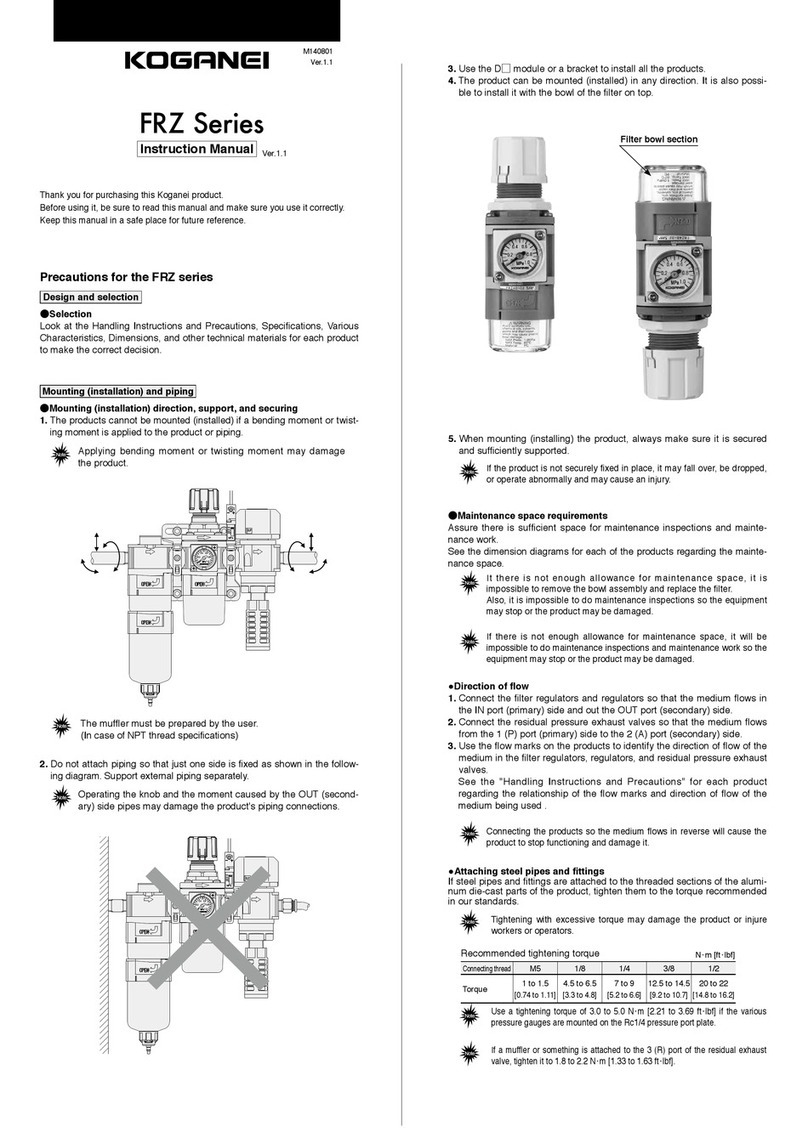

KOGANEI CORPORATION

KOGANEI CORPORATION FRZ Series instruction manual

Vizion

Vizion UF-216 series owner's manual

Philips

Philips AUT7006 user manual