Millipore EZ-Pak Troubleshooting guide

EZ--PakTM

Membrane␣ Dispenser – Distributeur de membranes

Membran–Dispenser – Dispensador de membranas

Dispensatore di membrane – Membrane␣ Dispenser

Operation␣ and␣ Maintenance␣ Instructions – Manuel␣ d'utilisation␣ et␣ d'entretien

Betriebs-␣ und␣ Wartungsanleitung – Instrucciones␣ de␣ utilización␣ y␣ mantenimiento

Manuale␣ operativo␣ e␣ di␣ manutenzione

!"#$%&'

!"

http://www.millipore.com

For units produced from February 1997 to

present (cat. no. EZDI SP0 01)

View previous manual on Worldwide Web

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1

EZ--Pak

Membrane Dispenser

Operation and Maintenance Instructions

ENGLISH

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3

CONTENTS

Page

1-Introduction 4

2-Component Parts 5

3-Start-up 6 to 8

4-Using the Membrane Dispenser 9

5-Maintenance 10

6-Specifications 10

7-Troubleshooting 11 to 13

8-Replacing Wear Parts 14 to 16

9-Ordering Information 17

10 - Warranty 18

Millipore Offices Worldwide

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4

Congratulations for your choice of EZ-PakTM membranes and dispenser

for microbiological analysis of liquid samples.

The EZ-Pak system consists of sterile membranes packed in a special

pleated band within a cartridge and specially designed equipment to

allow individual membrane dispensing.

EZ-Pak is designed to be used under standard «clean conditions»

and with traditional membrane filtration methods.

With EZ-Pak, three delicate manipulations are eliminated: opening

individual sterile envelopes, separating the membrane from its protective

papers and removing the fragile membranes from their packaging.

The EZ-Pak cartridges contain 150 black or white gridded 47-mm or

50-mm diameter membranes, and should be used with the MicrofilTM

filtration system for maximum ease of use, speed and cleanliness. Of

course, EZ-Pak is also an ideal complement to traditional filtration

equipment.

1INTRODUCTION

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

5

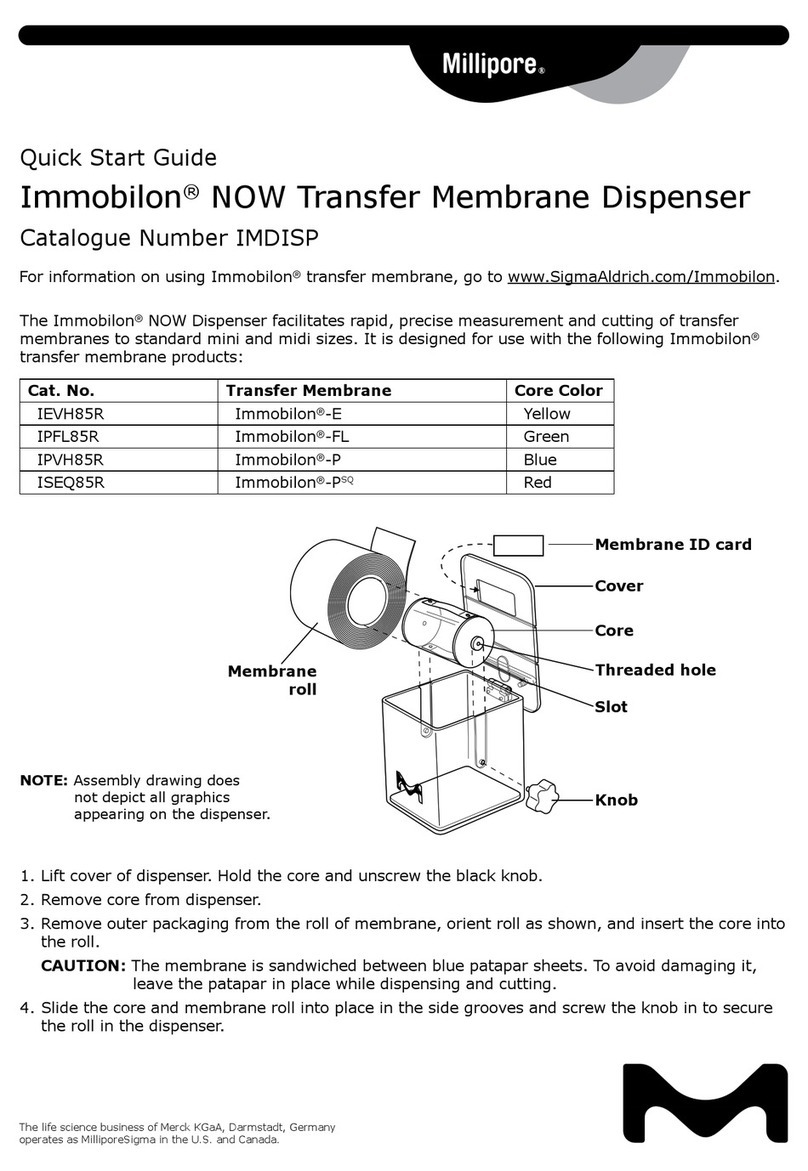

2COMPONENT PARTS

FIGURE 1 - Assembly and component parts

1- Paper spool

2- Film/paper spool clips

3- Paper guide

4- Drive roller

5- Actuator

6- Plate

7- Separating bar

8- Tensionning spring

(located under the back cover)

9- Film spool

10 - Metal cover

11 - Carrying handle

(moulded in the external case)

12 - Membrane cartridge holder

789210

6

5

4

3

2

1

11 12

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

6

3START-UP

1. Remove the dispenser from its packaging and place it on the work surface

with the dispensing mechanism facing you.

2. Check that all the component parts are undamaged and in place as shown

in Figure 1.

3. Open an EZ-Pak

membranes

cartridge

by detaching the pre-

cut top cover and folding it over

backwards (see Fig. 2).

4. Insert the

cartridge

in the

holder

so that the label is visible (see

Fig. 3).

5.

Important operation:

Fully depress the

actuator

before

proceeding to ensure correct

indexing of the

drive roller.

The

arrow on the

drive roller

must

point vertically upwards.

Caution:

Avoid letting the

actuator

spring back into place.

Slow the movement with the

finger.

6. Remove the

metal cover

by

separating the

cover

tab from

the

plate

tab (see Fig. 4).

Fig.␣ 2

Fig.␣ 3

Fig.␣ 4

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

7

7. Pull out the band until the first

cell containing a membrane is

visible (see Fig. 5).

Note:

The first cells on the band

do not contain membranes.

This

avoids wasting membranes

when installing the band.

8. Introduce the EZ-Pak band

under the

separating bar

. Pull

gently on the band to pass

3␣ empty cells under the

separating bar

.

9. Reinstall the

metal cover

by

inserting the pins in the

housings, then aligning the

cover

tab with the

plate

tab (see

Fig. 6). The locking ball should

audibly «snap» into place.

10. Peel away the transparent plas-

tic film from the paper backing

of the first cells up to the

separating bar.

11. Pull the backing paper through

the mechanism as shown in Fig-

ure 1.

Important operation:

Make sure the red arrow on the

paper after the second fold is

located above the vertical arrow

on the

drive roller.

Engage the

backing paper on the sprockets.

Fig.␣ 5

Fig.␣ 6

Fig.␣ 7

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

8

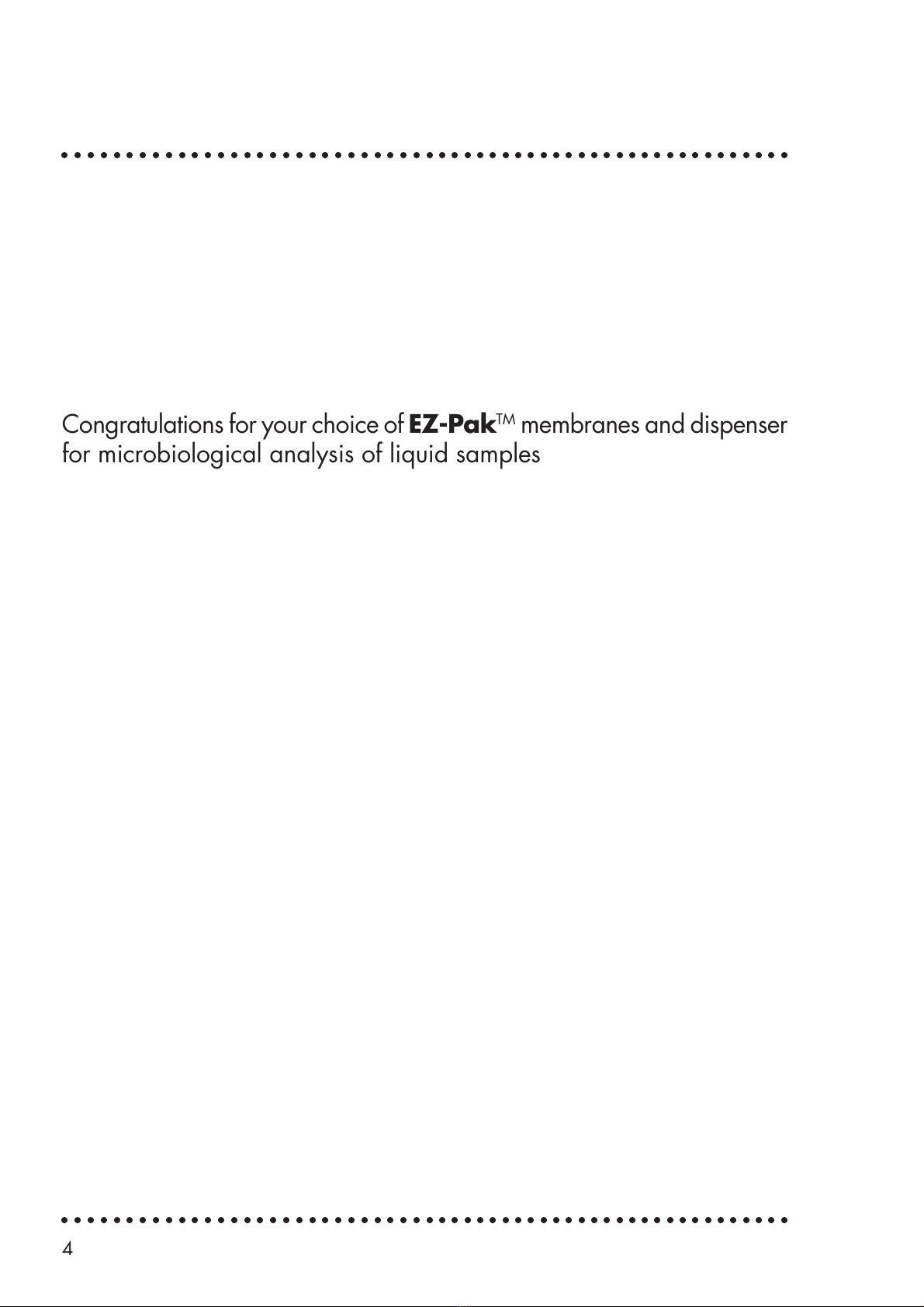

12. Rotate the

paper spool

until the

clip

is horizontal. Remove the

paper spool clip.

Place the

backing paper on the spool and

secure it with the

clip

. If

necessary, manually rotate the

paper spool

clockwise to take

up any slack.

13. If necessary, slightly pull the

backing paper back from the

cover

toward the

holder

until

there is no slack left in the paper

between the

separating bar

and

the

drive roller.

14. Remove the

film spool clip

, place the end of the

film

on the

film spool

and

secure it with the

clip,

being careful not to twist the film

.

The film should be

firmly held between the

clip

and spool.

Manually rotate the

film spool

clockwise to take up the slack (see Fig. 7).

15. Fully depress the

actuator

once then release it, slowing the upward movement

with the finger.

16. Verify that the membrane band is correctly installed by checking that the

cell dispensed is approximately one-third open (the bluish seal should be

peeled off around one-third of the edge) and that there is no slack in either

the film or the backing paper.

The EZ-Pak membrane dispenser is now ready for use.

Fig.␣ 8

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

9

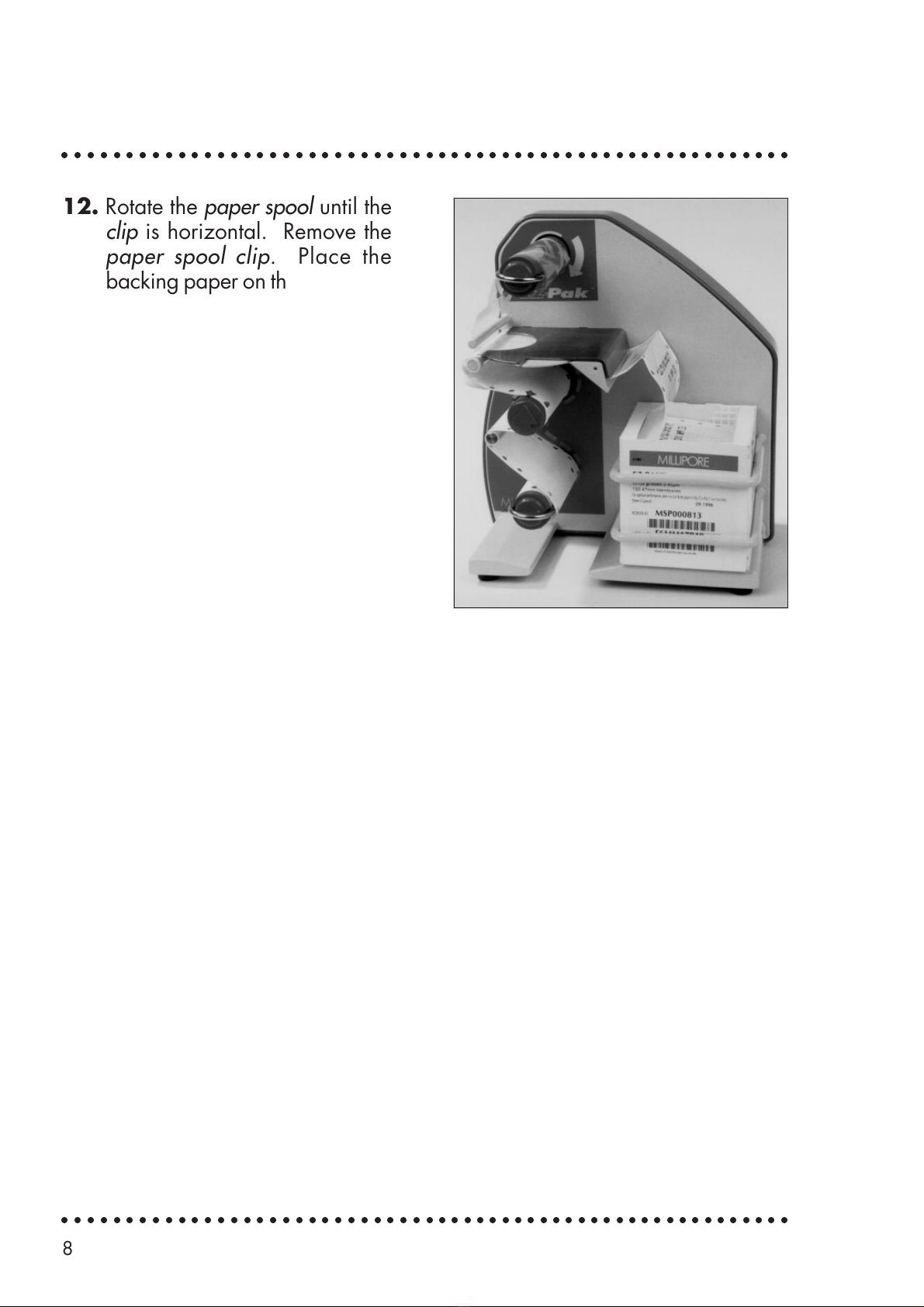

4USING␣ THE␣ MEMBRANE␣ DISPENSER

1. Position the dispenser on the left-hand side

*

of your workstation with the

Millipore logo directly facing you as shown in Figure 9.

2. To aseptically dispense a membrane, fully depress the

actuator

with your

left* hand. Repeat this step if the cell released does not contain a mem-

brane. The number 001 indicating the first membrane can be seen on the

film above the

separating bar

. During these operations, avoid letting the

actuator spring back into place. Slow the movement with the finger.

3. The membrane will be dispensed horizontally and held in place in the semi-

opened cell (see Fig. 9). Use a flamed and cooled forceps (see Fig.␣ 9) to

remove the membrane with the right hand

*

by pulling it straight out from the cell

and setting it on a Microfil or conventional Millipore filtration support.

4. Proceed with filtration in the normal manner.

5. After dispensing the last membrane, pull off the

clips

and remove the rolls of

used packaging.

* invert if the operator is left handed

Fig.␣ 9

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

10

The case surfaces may be cleaned using a mild detergent or decontaminated

with alcohol. No other maintenance is required.

If the outside case was exposed to UV rays often for relatively long periods, it

may have become slightly dull. Wiping it off with a cloth moistened with alcohol

will restore its original appearance almost completely.

Precautions

Avoid spraying liquids into the mechanism.

Do not autoclave.

Never use the

film spool

to lift or carry the dispenser. Use only the

carrying handle

for this purpose.

If it proves necessary to lubricate certain mechanical parts, use only thick

silicone grease, never oil, and be careful not to allow the grease to come

in contact with the spools and drive belts.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

6SPECIFICATIONS

Materials of construction

External case: Ultem®.

Internal case: Stainless steel.

Paint: Epoxy-baked.

Dimensions and Weight

Height: 240 mm. Width: 160 mm. Depth: 235 mm.

Weight empty: 2.4 kg.

5MAINTENANCE

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

11

7TROUBLESHOOTING

1. The film is not separated

from the paper backing

on the

plate

edge (the

film is pulled by the

backing).

2. The paper backing

catches on the sprockets

(slack in the backing

between

drive roller

and

paper spool).

3. There is slack in the

paper backing between

the

plate

and the

drive

roller:

The film is no longer

separated from the

backing at the

plate

edge.

The film is separated

from the backing at

the

plate

edge.

4. The

actuator

does not

drive the

drive roller:

The symptom persists,

but disappears when

the

actuator

is raised

all the way against

the stop.

The symptom persists

when the

actuator

is

depressed then raised

fully against the stop.

Separate the film from the

paper backing up to the

separating bar. If the fault

persists, the

film spool

driving belt is worn

The

film

spool driving belt

is worn.

The

film spool

driving belt

is worn.

The

tensioning spring

is

not taut enough.

The lever spring is no

longer taut enough.

The latch springs are

damaged.

Replace the driving belts

and the

tensioning spring

.

Replace the driving belts

and the

tensioning spring

.

Replace the driving belts

and the

tensioning spring

.

Replace the

tensioning

spring

and the driving belts.

Check whether the symptom

persists after fully

depressing the

pushbutton

all the way down against

the stop.

Replace the lever spring.

Replace the latch springs.

It is recommended that the

driving belts

and

tensioning

spring

be replaced at the

same time.

Symptom Probable cause Corrective action

Refer to Figures 10 and 11 on the page 13 for the list of component parts.

Membranes not dispensed correctly

Send E-mail to Technical Service

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

12

The locking ball is out of

adjustment. Adjust the position of the

locking ball with a

screwdriver.

Removing a partially used band from the spools and reinstalling

it after repair:

1. Rotate the

paper spool

counterclockwise by two turns to slacken the paper

backing.

2. Remove the

paper spool clip

.

3. Remove the paper backing by pulling it straight out of the

paper spool.

4. Take the paper backing off the sprockets on the

drive roller

and the

paper

guide

.

5. To remove the film, repeat steps 1 to 3 above on the film spool.

6. Lay the film on the paper backing.

7. Cut the film and paper off at the fourth empty cell (the fourth cell ahead of

the first membrane).

8. Repeat steps 11 to 16 (page 7–8) to reinstall the band. To position the

backing paper (step 11), the vertical arrow must be located two sprocket

holes ahead of a fold (the closest fold is located to the left of the

arrowhead).

For additional information, contact your nearest Millipore office, specifying the

catalogue number and serial number on the nameplate under the dispenser.

Symptom Probable cause Corrective action

The

metal cover

is difficult to install or is not securely held in the

housing.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

13

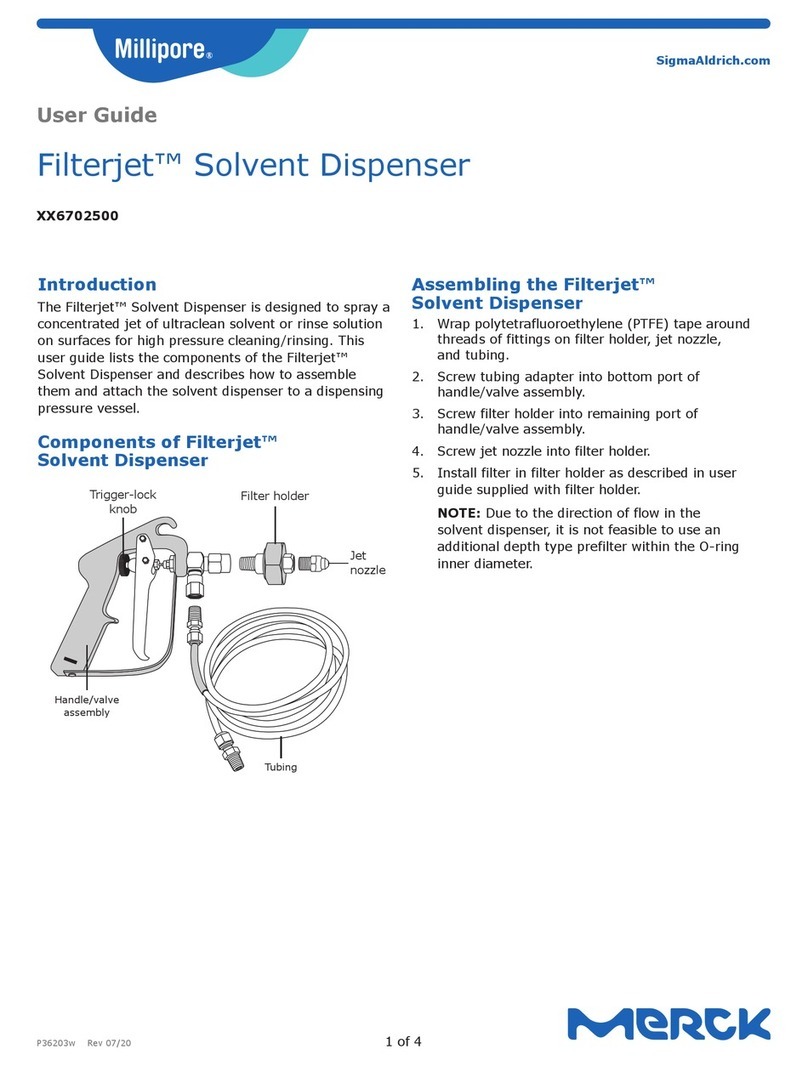

Feet

Actuator

FIGURE 10

Feet

Lever

Actuator

FIGURE 11

Lever

Driving belts

Lever spring

Rack bar clip

Latch nodule

Lever screw

Lever return

damper

Rack bar

Rack positioning screw

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

14

8REPLACING WEAR PARTS

Driving Belts and Latch Springs

These parts should be replaced together.

Tools

2.5 mm and 3 mm Allen keys

Latch spring installation tool

Set of latch belts and springs

Scissors or cutter

Cloth and cleaning agent

Procedure

1. Unscrew the 6 socket head screws with the 2.5 mm Allen key and

remove the inside cover (located on the side of the spools).

2. Remove the outside cover as follows:

Break the retaining tab located under the actuator with a screwdriver

or other strong pointed object and remove the actuator.

Remove the two feet by pushing the internal shaft and pulling on

the feet.

Unscrew the five socket head screws from the cover with the 3␣ mm

Allen key.

Push the lever down against the stop and hold it there.

Remove the cover.

3. Cut the two drive belts.

Replacing the Latch Springs

4. Lift the latch and cut the two retaining springs.

5. Remove the latch.

6. Engage the spring installation tool on the

drive roller

.

7. Fit two new springs on the tool to place them in their grooves.

8. Remove the installation tool.

9. Lift the two springs and fit the latch in its housing.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

15

Replacing the Driving Belts

10. Clean the spool grooves with a clean cloth slightly moistened with a

cleaning agent (e.g. acetone).

11. Set the two belts on a flat surface, one inside the other.

12. Engage the larger belt (the outside one) on the

film spool

and

drive roller

.

13. Move the belt along the spools, fitting it over the sprockets, until it is in

the grooves.

14. Engage the second, smaller belt on the

paper spool

and

drive roller

.

15. Move the belt along the spools, fitting it over the sprockets, until it is in

the grooves.

16. Install the inside and outside covers by carrying out steps 1 and 2 of

page 14 in reverse order.

17. Check that the belts are correctly positioned by operating the

actuator

several times.

Tensioning Spring

The

tensioning spring

should always be replaced at the same time as the latch

belts and springs.

Tools

Adjustable wrench

Tensioning spring

Procedure

1. Unscrew the spring-nut and lock-nut located under the

plate

. Remove the

two washers and the old spring.

2. Install a new spring, the flat washer then the self-locking washer, the nut

and the lock-nut.

3. Check that the spring does not rub against the sides of the oblong hole.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

16

Lever Spring

Tools

2.5 mm Allen key

3 mm Allen key

Lever spring

Procedure

1. Unscrew the 6 socket head screws with a 2.5 mm Allen key and remove

the inside cover (located on the side of the spools).

2. Remove the outside cover as follows:

Break the retaining tab located under the actuator with a screwdriver

or other strong pointed object and remove the actuator.

Remove the two feet by pushing the internal shaft and pulling on

the feet.

Unscrew the five socket head screws from the cover with the 3 mm

Allen key.

Push the lever down against the stop and hold it there.

Remove the cover.

3. The spring is then accessible and can be replaced without using any

tools.

4. Install the inside and outside covers by carrying out steps 1 and 2 on in

reverse order.

For additional information, contact your nearest Millipore office, specifying

the catalogue number and serial number on the nameplate under the dispen-

ser.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

17

Ordering Information

Description Catalogue No.

EZ-Pak membrane dispenser (Qty 1) EZDI SP0 01

Kit of spare parts including: EZDI KIT 01

- 3 actuators

- 1 clip

- 4 feet

- 2 sets of latch springs

- 2 sets of driving belts

- 2.5 mm and 3 mm Allen keys

- latch spring installation tool

- latch

- cover attaching screws

- 2 tensioning springs

EZ-Pak Membranes (4 cartridges, each containing 150 membranes)

EZ-Pak membranes, 0.45 µm, white, MSP0 008 13

gridded, 47 mm diameter, Q 600

EZ-Pak membranes, 0.45 µm, black, MSP0 008 14

gridded, 47 mm diameter, Q 600

EZ-Pak Membranes (150 membranes with 150 Microfil funnels)

EZ-Pak membranes, 0.45 µm, white, MZHA WG1 01

gridded, diameter 47 mm, Q150

and 6 packets of 25 Microfil funnels, 100 ml

EZ-Pak membranes, 0.45 µm, white, MZHA WG2 51

gridded, diameter 47 mm, Q150

and 5 packets of 30 Microfil funnels, 250 ml

EZ-Pak membranes, 0.45 µm, black, MZHA BG1 01

gridded, diameter 47 mm, Q150

and 6 packets of 25 Microfil funnels, 100 ml

EZ-Pak membranes, 0.45 µm, black, MZHA BG2 51

gridded, diameter 47 mm, Q150

and 5 packets of 30 Microfil funnels, 250 ml

The range of available membranes is growing rapidly. Contact your nearest

Millipore office for further information on the other types of EZ-Pak membra-

nes or to place an order.

9ORDERING INFORMATION

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

18

10 WARRANTY

Millipore warrants its products against defects in manufacturing and workmanship

for a period of one (1) year from the date of delivery, provided that they have

been used under the conditions described in this manual.

Millipore offers no other warranty neither explicit nor implicit, in particular no

warranty of merchantability or fitness for a particular purpose. The terms of this

warranty, as well as information, characteristics and descriptions of Millipore

products shown on brochures and catalogues published by the Company may

not be modified without express authorization signed by a duly qualified Millipore

representative. Any written or oral interpretation not in accordance with this

warranty or to the said publications shall be considered null and void.

In case of non-respect of the terms of the above-mentioned warranty, Millipore’s

sole obligation shall be to repair or replace, at its discretion, all or part of a

product found to be defective during the period of warranty, due to defects in

workmanship or manufacturing, on condition that the customer notifies the fault

immediately.

The present service obligation cannot be considered as not having been fulfilled

if Millipore has demonstrated its good faith in repairing or replacing any defective

Millipore product or part.

Millipore cannot be held responsible for prejudice due to non-operation or

damage to property where its products could have been the cause, nor

consequently be required to award indirect damages.

The terms of this warranty do not affect the buyer’s statutory rights.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Millipore␣ Worldwide␣ –␣ Millipore␣ dans␣ le␣ monde␣ –

Millipore␣ weltweit␣ –␣ Millipore␣ en␣ el␣ mundo␣ –

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Millipore␣ nel␣ mondo – !"#$$%&

AUSTRALIA

Millipore Australia Pty. Ltd.

A.C.N. 001 239 818

Private Bag No. 18

87–89 Mars Road

Lane Cove, N.S.W.2066

Tel. Toll-Free: (008) 222–111

In Sydney Area (02) 428–7333

FAX (02) 427–0611

AUSTRIA, CENTRAL EUROPE,

C.I.S., AFRICA, MIDDLE EAST

AND GULF

Millipore Ges.m.b.H.

Hietzinger Hauptstraße 145

A–1130 Wien, Austria

Tel. (43) 1 877 8926

Telex 131464 miliv a

FAX (43) 1 877 1654

BALTIC REPUBLICS

Millipore Oy

Lanttikatu 2

FIN–02770 Espoo

Finland

Tel. 358-0-804 51 10

FAX 358-0-859 66 16

BELGIUM AND

LUXEMBURG

Millipore S.A.–N.V.

Rue de la Fusée 60

Raketstraat 60

B–1130 Bruxelles–Brussels

Tel. (02) 726.88.40

FAX (02) 726.98.84

BRAZIL

Millipore Indústria

e Comércio Ltda.

Rua Prof. Campos

de Oliveira, 430

CEP 04675

São Paulo–SP

Tel. (011) 548–7011

Telex (011) 57751 MILY BR

FAX (011) 548–7923

CANADA

Millipore (Canada) Ltd.

36 Antares Drive/

Suite 700/

Nepean, Ontario, K2E 7W5

Tel. Toll-Free 1–800 Millipore

FAX (613) 225–9366

CHINA

PEOPLE’S REPUBLIC OF

Millipore China Ltd.

Room 302 Office Bldg.

Asia Jinjiang Hotel

8 Xinzhong Xijie Gongti

Bei Lu, Beijing (100027)

Tel. (86–1) 5008063

FAX (86–1) 5007372

Millipore China Ltd.

Room 615

China Hotel Office Tower

Linhua Lu

Guangzhou

Postal Code 510015

Tel. (86) 20–686217

CHINA

PEOPLE’S REPUBLIC OF

Millipore China Ltd.

Suite 2806, Union Building

100 Yan An Road (E)

Shanghai 200002, P.R.C.

Tel. (86) 21–3737256

FAX (86) 21–3200236

CZECH REPUBLIC

Millipore spol.s.r.o

Obchodní Zastoupení

Rícanova 21

CZ–169 00 Praha 6

Tel. 42-2 205 13841

FAX 42-2-235 2375

DENMARK

Millipore A/S

Baldersbuen 46

DK–2640 Hedehusene

Tel. 46 59 00 23

FAX 46 59 13 14

FINLAND

Millipore Oy

Lanttikatu 2

FIN–02770 Espoo

Tel. (90) 804 51 10

FAX (90) 859 66 16

FRANCE

Millipore S.A.

BP 307

F–78054 Saint–Quentin

Yvelines Cedex

Tel. 01.30.12.70.00

Telex 698 371 F

FAX 01.30.12.71.80

GERMANY

Millipore GmbH

Hauptstraße 87

D–65760 Eschbom

Tel. 49-6196494 0

Telex 40 72 704 mil d

FAX 49-6196 439 01

HONG KONG

Millipore China Ltd.

Millipore Asia Ltd.

1406 Cityplaza 4

12 Taikoo Wan Road

Hong Kong

Tel. (852)-2-803 9111

Telex 331 40 MWBHK HX

FAX (852)-2-513 0313

HUNGARY

Millipore kft

Andor u. 47–49

H–1119 Budapest

Tel. (1) 166 86 74

(1) 185 11 22

Telex 22 30 57

FAX (1) 185 32 36

INDIA

Millipore (India) Pvt. Ltd.

50–A, 2nd Phase,

Ring Road Peenya

Bangalore 560 058

Tel. 91 (808) 394657, 396320

Telex 845–5089 MLPR IN

Cable: Millipore

FAX 91 (808) 396345

ITALY

Millipore S.p.A.

Via B. Buozzi, 4

I–20090 Vimodrone MI

Tel. (02) 25078.1

FAX (02) 2650324

Millipore S.p.A.

Via D. Sansotta 100

I–00144 Roma

Tel. (06) 5203600

FAX (06) 5295735

JAPAN

Nihon Millipore Ltd.

Dai 5 Koike Bldg. 3–12

Kitashinagawa 1–Chome

Shinagawa-Ku

Tokyo 140

Tel. (03) 3474–9111

Telex 24948 MILLIPOR J

FAX (03) 3474–9130

KOREA

Millipore Korea Ltd.

13F, Yusung Bldg.

706-25, Yoksam-Dong

Kangnam-Ku, Seoul 135–080

Tel. (82–2) 5386211

FAX (82–2) 5636253

MALAYSIA

Millipore Asia Ltd.

Malaysia Branch

B4 – 05/06, PJ. Industrial Park

Section 13 Jalan Kemajuan

46200 Petaling Jaya, Selangor

Tel. (603) 757 1322

FAX (603) 757 1711

MEXICO

Millipore S.A. de C.V.

Avenida Ingenieros Militares 85–PB

México 11230 D.F.

Tel. (525) 576–96–88

FAX (525) 576–87–06

THE NETHERLANDS

Millipore B.V.

Penningweg 33

Postbus 166

NL–4870 AD Etten-Leur (N.B.)

Tel. (076) 5022000

Telex 54 840 milwa nl

FAX (076) 5022436

NORWAY

Millipore AS

Postboks 39, Simensbraten

N–1107 Oslo

Tel. (47) 22 67 82 53

FAX (47) 22 68 53 15

POLAND

Millipore Sp.z.o.o.

Oddzial w Warszawie

Ul. Jasnodworska 7

PL–01–745 Warszawa

Tel. 22 669 12–25/663 70 31

Telex 825 422

FAX 22 663 70 33

PUERTO RICO

Millipore Corporation

Puerto Rico Branch

P.O. Box 11977

Cidra, Puerto Rico 00739

Tel. (809) 273–8495

FAX (809) 747–8449

SINGAPORE

Millipore Asia Ltd.

Singapore Branch

#07–01/02 Jumbo Industrial Bldg.

19 Kim Keat Road

Singapore 328804

Tel. (65) 253–2733

FAX (65) 254–4056

SPAIN AND PORTUGAL

Millipore Ibérica, S.A.

Avda. del Llano Castellano, 13–3°

E–28034 Madrid

Tel. 91–729 03 00

FAX 91–729 29 09

Millipore Ibérica, S.A.

Entenza, 28°

E–08015 Barcelona

Tel. 93–325 96 16

FAX 93–325 98 96

SWEDEN

Millipore AB

Box 7090

S–172 07 Sundbyberg

Tel. 08–628 69 60

FAX 08–628 64 57

SWITZERLAND

Millipore AG

Chriesbaumstrasse 6

CH–8604 Volketswil

Tel. (01) 908 30 60

Telex 82 94 08 MILAG CH

FAX (01) 908 30 80

Millipore SA

Avenue de Maillefer 43

CH–1052 Le Mont-sur-Lausanne

Tel. (021) 648 51 18

FAX (021) 648 51 37

TAIWAN

Millipore Asia Ltd.

Unit #707, 7/th, fl

136 Jen-Ai Road, Sec. 3

Taipei Tawai R.O.C.

Tel. (886–2) 7001742

FAX (886–2) 7553267

U.K. AND IRELAND

Millipore (U.K.) Ltd.

“The Boulevard”

Blackmoor Lane Watford,

Hertfordshire WD1 8YW

Tel. (01923) 816375

Telex 24191 milpor g

FAX (01923) 818297

U.S.A.

Millipore Corporation

P.O. Box 255

Bedford, MA 01730

Tel. Toll-Free

(including Massachusetts)

1-800 Millipore

or 1-800-645-5476

In Western States,

Alaska & Hawaii

800–632–2708

In Puerto Rico (809) 273-8495

IN ALL OTHER COUNTRIES

Millipore Intertech

80 Ashby Road

Bedford, MA 01730

U.S.A.

Tel. 1-617 275 9200

FAX 1-617 275 5550

Cat. No. PF 05600. Printed in France, 11/96. Copyright © 1996, Millipore Corporation, Bedford, MA, U.S.A., or affiliated company. Millipore is a registered

trademark of Millipore Corporation or an affiliated company. EZ-Pak and Microfil are trademarks of Millipore Corporation or an affiliated company.

Table of contents

Other Millipore Dispenser manuals