Millipore Filterjet 6702500 Series User manual

SigmaAldrich.com

P36203w Rev 07/20 1 of 4

User Guide

Filterjet™ Solvent Dispenser

XX6702500

Introduction

The Filterjet™ Solvent Dispenser is designed to spray a

concentrated jet of ultraclean solvent or rinse solution

on surfaces for high pressure cleaning/rinsing. This

user guide lists the components of the Filterjet™

Solvent Dispenser and describes how to assemble

them and attach the solvent dispenser to a dispensing

pressure vessel.

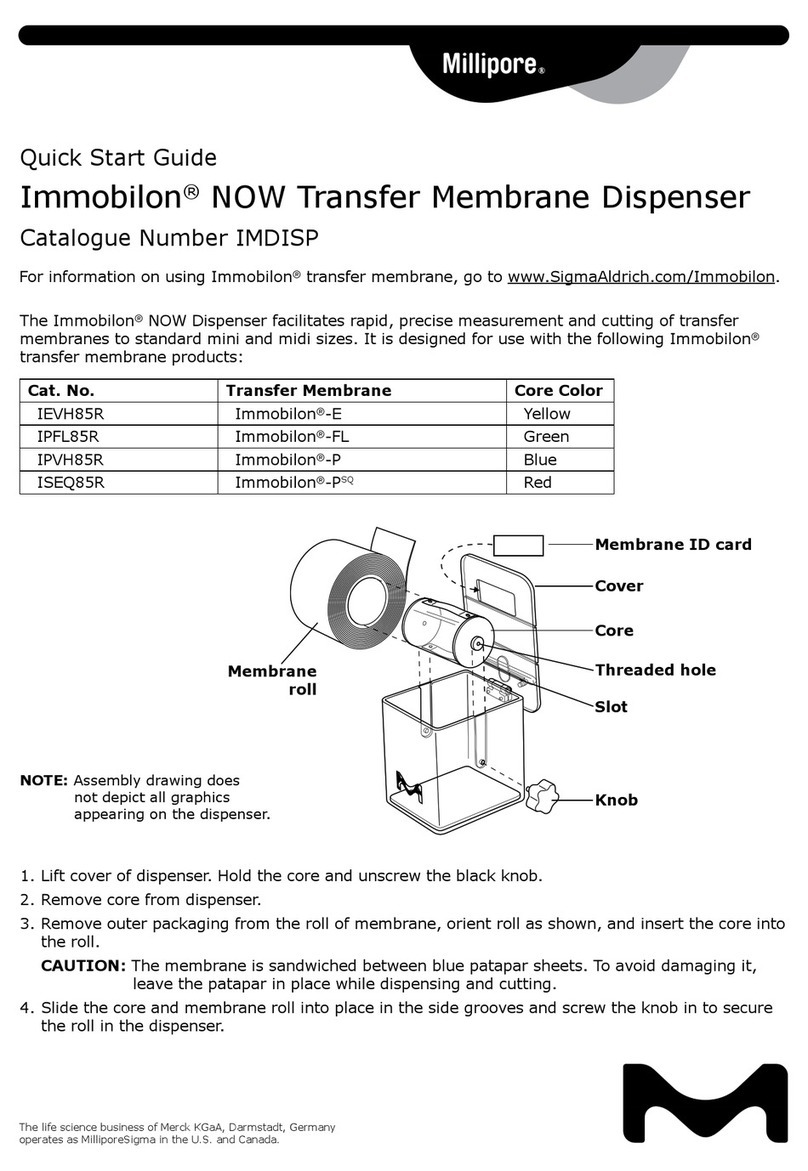

Components of Filterjet™

Solvent Dispenser

Handle/valve

assembly

Filter holder

Trigger-lock

knob

Jet

nozzle

Tubing

Assembling the Filterjet™

Solvent Dispenser

1. Wrap polytetrafluoroethylene (PTFE) tape around

threads of fittings on filter holder, jet nozzle,

and tubing.

2. Screw tubing adapter into bottom port of

handle/valve assembly.

3. Screw filter holder into remaining port of

handle/valve assembly.

4. Screw jet nozzle into filter holder.

5. Install filter in filter holder as described in user

guide supplied with filter holder.

NOTE: Due to the direction of flow in the

solvent dispenser, it is not feasible to use an

additional depth type prefilter within the O-ring

inner diameter.

P36203w Rev 07/20 2 of 4

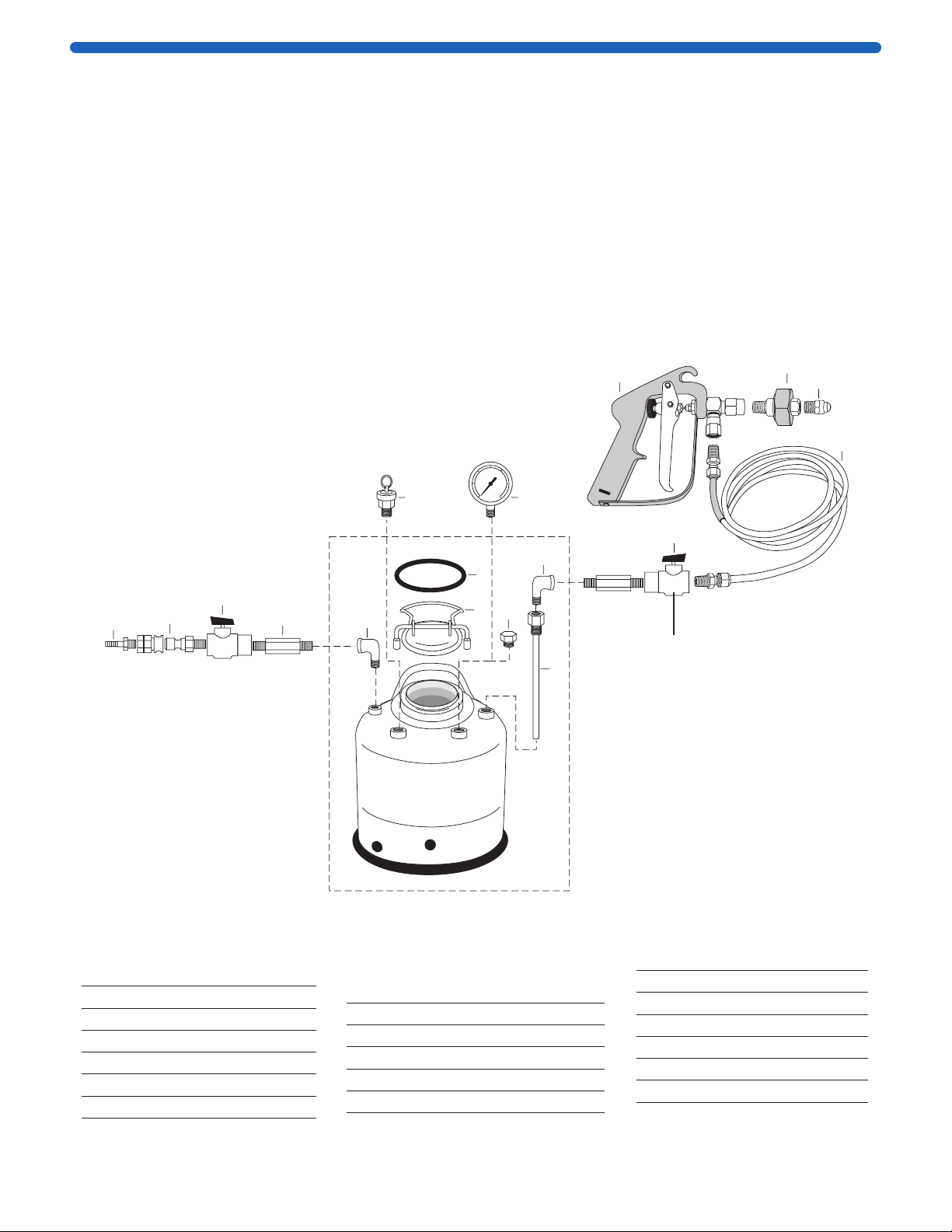

Attaching the Filterjet™ Solvent Dispenser to a Dispensing Pressure Vessel

To attach the Filterjet™ Solvent Dispenser to a

Dispensing Pressure Vessel, the following additional

products are required:

• Dispensing Pressure Vessel:

Cat. No. XX6700P05, XX6700P10, XX6700P20,

or XX6700P01

• Dispensing Pressure Vessel Fitting Kit:

Cat. No. XX67000PK

NOTE: XX67000PK components listed below can be

purchased separately. Refer to “Product Ordering”

for catalogue numbers. Items Fand Gare required;

other Dispensing Pressure Vessel Fitting Kit items

are optional.

1. Assemble the Dispensing Pressure Vessel

components as indicated in the user guide.

2. Assemble the Dispensing Pressure Vessel fitting

components as indicated in the user guide, except

do not install a quick-disconnect nipple and coupling

(J) and tubing adapter (K) on the fitting assembly

attached to the pressure vessel outlet port.

3. Instead, attach the free end of the Filterjet™ tubing

to the ball valve (I) on the outlet port.

KJ

I

HC

C

L

M

N

O

I

A

B

D

E

FG

Optional: For quick-disconnect

capability, install quick-disconnect

nipple (item J) here.

Dispensing Pressure Vessel

Fitting Kit,

Includes items F – K, outside dashed

outline: Cat. No. XX67000PK

F vent/relief valve (required)

G pressure gauge (required)

H hex nipple

I ball valve

J quick-disconnect nipple

K tubing adapter

Dispensing Pressure Vessel

Includes items A – E, inside dashed

outline: Cat. No. XX6700P05 (5 L),

XX6700P10 (10 L), XX6700P20 (20 L),

or XX6700P01 (1 gal).

A outlet dip-tube

B pipe plug

C elbow

D vessel cover

E O-ring

Filterjet™ Solvent Dispenser

Includes items L – O, upper right:

Cat. No. XX6702500

L handle/valve assembly

M filter holder

N jet nozzle

O tubing

J quick-disconnect nipple

K tubing adapter

P36203w Rev 07/20 3 of 4

Rules for Safe Operation

• The high pressure fluid dispensed by the Filterjet™

Solvent Dispenser can cause injury. Never aim the

solvent dispenser at yourself or another person.

• To prevent accidental discharge, use the trigger-lock

feature when the solvent dispenser is not in use.

• Consult appropriate Safety Data Sheet (SDS) when

working with potentially hazardous chemicals.

• Wear Personal Protective Equipment (PPE)

appropriate for the fluid being dispensed.

• Apply grounding and/or bonding measures

appropriate for the fluid being dispensed.

• Before use, make sure that all connections

are secure.

Using the Filterjet™ Solvent Dispenser

1. Close the trigger-lock knob by turning it

fully clockwise.

2. Pressurize the dispensing pressure vessel.

WARNING: Do not exceed 3.4 bar (50 psi).

3. Release the trigger-lock by turning the knob

fully counter-clockwise.

4. Squeeze the trigger handle to spray.

Cleaning and Maintenance

After use, purge tubing and solvent dispenser of fluid.

Remove jet nozzle. Disassemble and clean the filter

holder components and jet nozzle as indicated in the

supplied filter holder user guide.

12345

6

78910

11 12 13 15

14

19

18

20

16

17

Cup PackingValve Seat

If leakage occurs

from handle/valve

assembly, replace

the PTFE valve seat

(item 3) and PTFE

cup packing (item 7)

using replacement

kit XX6702502.

Specifications

Maximum Inlet Pressure 3.4 bar (50 psi)

Filter Diameter 25 mm

Tubing Adapter

1/4 in. tubing to 1/4 in.

national pipe thread (NPT) male

Dimensions

Nozzle tip to end of

dispenser handle: Approximately 22.9 cm (9 in.)

Tubing : 1/4 in. outer diameter (OD)

× 1.8 m (6 ft)

Weight: 696.4 g (1.5 lb)

Materials of construction

Filter holder

Inlet head and outlet body: 304 stainless steel

Filter support screens: 316 stainless steel

Locking nut: Anodized aluminum

Locking nut washer: PTFE

O-ring: Fluoroelastomer

Jet nozzle Stainless steel

Handle/valve assembly

(Nylon-coated aluminum, nickel-plated steel, stainless steel)

Valve seat:

Stainless steel/carbon-filled PTFE

Cup packing: PTFE

Tubing:

Polyethylene with stainless

steel adapters,

Tygon®tubing sleeve

Statement Regarding Compliance

with the Pressure Equipment

Directive, 2014/68/EU

We certify that this product complies with the European

Pressure Equipment Directive, 2014/68/EU of 15

May 2014. This product is classified under Article 4

§ 3 of the Pressure Equipment Directive. It has been

designed and manufactured in accordance with sound

engineering practices to ensure safe use. The product is

accompanied by user instructions and bears markings

to permit identification of EMD Millipore Corporation as

the manufacturer or authorized representative of this

product within the European Community. In compliance

with Article 4 § 3 of the Pressure Equipment Directive,

this product does not bear the CE mark.

P36203w Rev 07/20 4 of 4

The life science business of Merck operates

as MilliporeSigma in the U.S. and Canada.

Merck, Millipore, Filterjet, and Sigma-Aldrich are trademarks of Merck KGaA, Darmstadt, Germany

or its affiliates. All other trademarks are the property of their respective owners. Detailed

information on trademarks is available via publicly accessible resources.

© 2020 Merck KGaA, Darmstadt, Germany and/or its affiliates. All Rights Reserved.

Product Ordering

Purchase products online at SigmaAldrich.com/products.

Description Cat. No.

Filterjet™ Solvent Dispenser, 25 mm (1/pk)

XX6702500

Replacement nozzles for Filterjet™ Solvent

Dispenser: Jet, Fan, Cone Spray Nozzles XX67025RK

Filterjet™ handle/valve assembly (1/pk) XX6702501

Filterjet™ valve seals

Includes 1 valve seat, 3 cup packings XX6702502

Pressure tubing (polyethylene) with

1/4 in. NPT adapters, 1.8 m (6 ft) XX6702506

Adapter, 1/4 in. NPT male to 1/4 in.

OD tubing (1/pk) XX6702507

Tubing (polypropylene),

1/4 in. (6 mm) OD × 3 m (10 ft) XX6702508

Filter holder (25 mm) for Filterjet™

Solvent Dispenser (1/pk) XX4002500

Replacement parts for 25 mm filter holder

(see filter holder user guide) XX40025RK

Dispensing Pressure Vessels (1/pk)

5-Liter XX6700P05

10-Liter XX6700P10

20-Liter XX6700P20

1-Gallon XX6700P01

Dispensing Pressure Vessel Fitting Kit

Includes components listed below:

XX67000PK

Vent/relief valve (1/kit, item F), (1/pk) XX6700L24

Pressure gauge (1/kit, item G), (1/pk) XX6700L15

Hex nipple (2/kit, item H), (1/pk) XX6700125

Ball valve (2/kit, item I), (1/pk) YY2029348

Quick-disconnect nipple (2/kit, item J)

(1/pk) XX6700030

Tubing adapter (2/kit, item K) XX6700L11

PTFE tape,

1.3 cm (0.5 in.) × 660 cm (260 in.) TP0001326

Notice

We provide information and advice to our customers

on application technologies and regulatory matters

to the best of our knowledge and ability, but without

obligation or liability. Existing laws and regulations are

to be observed in all cases by our customers. This also

applies in respect to any rights of third parties. Our

information and advice do not relieve our customers of

their own responsibility for checking the suitability of

our products for the envisaged purpose.

The information in this document is subject to change

without notice and should not be construed as a

commitment by the manufacturing or selling entity, or

an affiliate. We assume no responsibility for any errors

that may appear in this document.

Contact Information

For the location of the office nearest you, go to

SigmaAldrich.com/offices.

Technical Assistance

Visit the tech service page on our web site at

SigmaAldrich.com/techservice.

Standard Warranty

The applicable warranty for the products listed in this

publication may be found at SigmaAldrich.com/terms.

Other Millipore Dispenser manuals

Popular Dispenser manuals by other brands

Johnson Plastics Plus

Johnson Plastics Plus SOAPDISP18 quick start guide

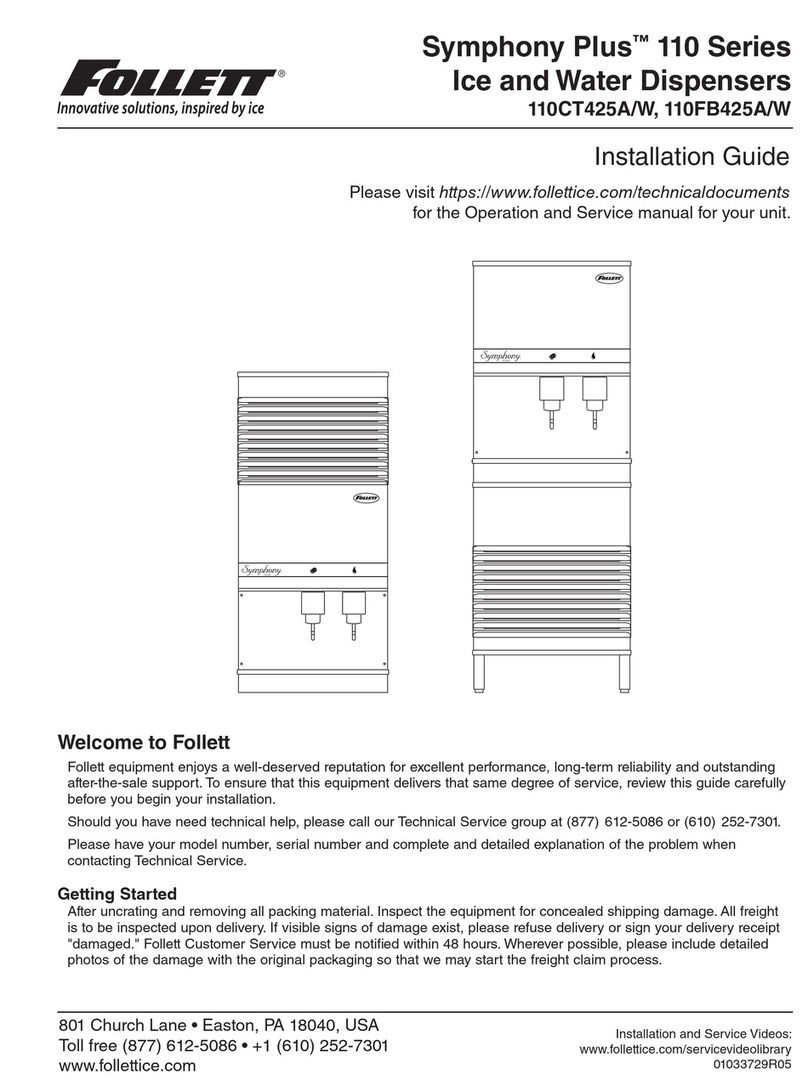

Follett

Follett Symphony Plus 110 Series installation guide

Kold-Draft

Kold-Draft AKD-125 Installation & operation instructions

Bras

Bras QUARK 1 Operator's manual

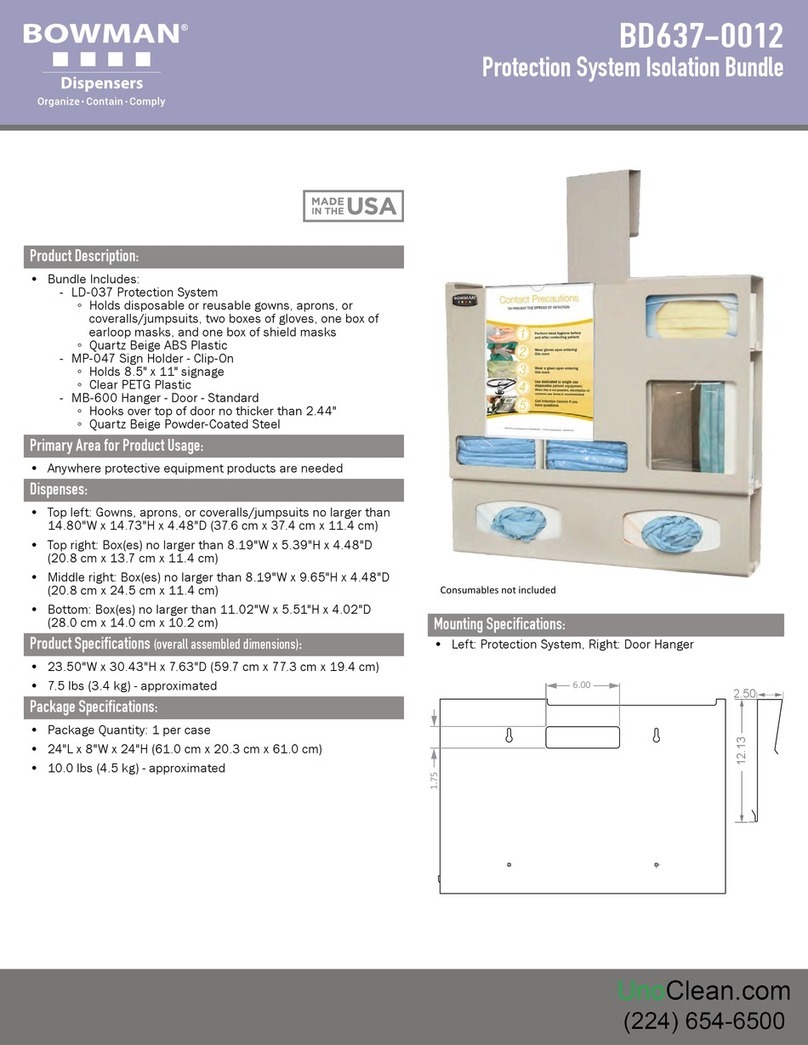

BOWMAN

BOWMAN BD637-0012 quick start guide

Franke

Franke RODAN RODX600ME Installation and operating instructions

Kimberly-Clark PROFESSIONAL

Kimberly-Clark PROFESSIONAL ICON 53696 Installation

Sanela

Sanela SLZN 71E Instructions for use

Go

Go PIUSI CUBE MC Instructions for installation, use and maintenance manual

Franke

Franke STRATOS STRX637 Installation and operating instructions

Solaris

Solaris LoCor Recessed Electronic Dispenser user guide

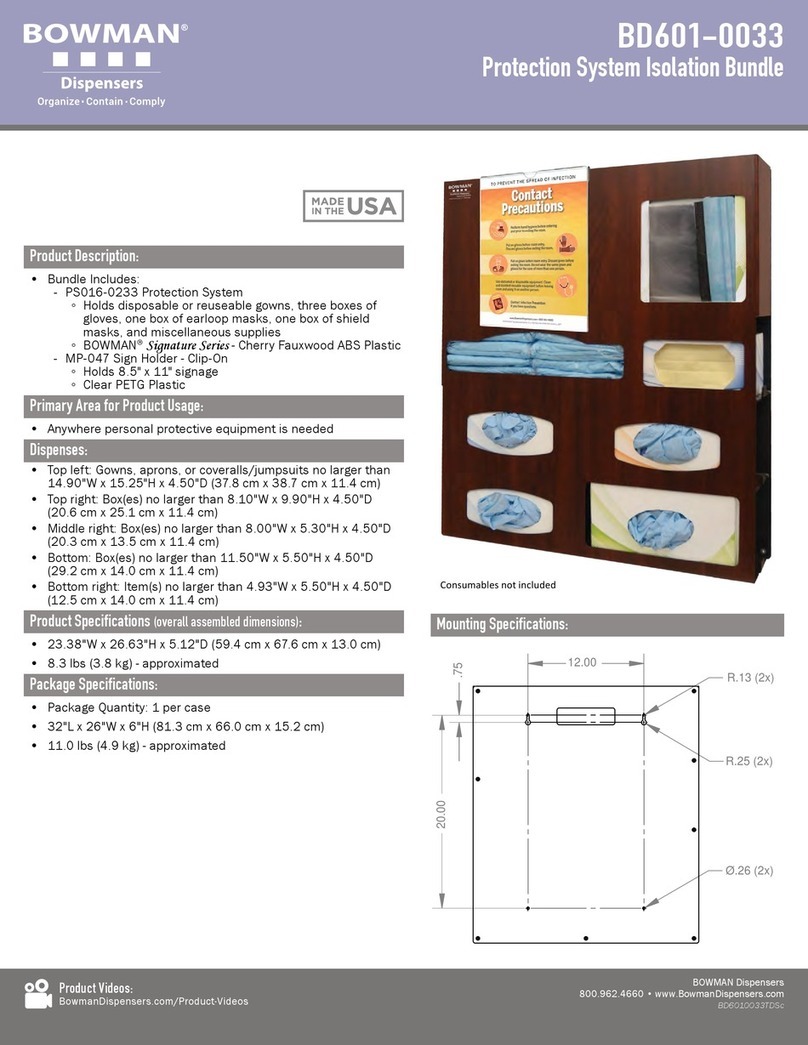

BOWMAN

BOWMAN BD601-0033 quick start guide