Mills TS MILLS Mounting instructions

TS MILLS

USE MANUAL

Infrastructure

USE MANUAL

TSMILLS

©Copyright 2016 Mills Estruturas e Serviços de Engenharia S.A.

The copying of this publication by any means or process is forbidden, even if

partially, without previous and written authorization both of the owners and the

intellectual authors.

THIS MANUAL WAS PRODUCED AT

ENGENHARIA NACIONAL

Mills Estruturas e Serviços de Engenharia S.A.

Estrada do Guerenguê, 1381 - Curicica

22713-001 - Rio de Janeiro | RJ

Tel: (21) 2132-4338

www.mills.com.br

SUPERVISED BY

Avelino Pinto da Silva Garzoni

ENGINEERING DIRECTOR

Vinícius Monteiro

ENGINEERING MANAGER

Claudinei Palma de Lima

TECHNICAL MANAGER

Miguel Henrique de Oliveira Costa

TECHNICAL COORDINATOR

Cardec Barcelos Lomeu Bastos

TECHNICAL COORDINATOR

Mário Luiz Sartorio Valiati

DESIGN COORDINATOR

TITLE

USE AND ASSEMBLY MANUAL | TS MILLS SYSTEM

ISSUE 2

Maio - 2016 | Edição 2 — 04.09.05.2016

TECHNICAL TEXT

Cardec Barcelos Lomeu Bastos

Claudinei Palma de Lima

Mário Luiz Sartorio Valiati

DESIGNS, ASSEMBLIES AND ILLUSTRATIONS

João Gabriel Coelho de Salles Victor

Laryssa da Cunha Macedo

Priscilla dos Santos Oliveira

Roberta da Costa Melo

DESIGNS, ASSEMBLIES AND ILLUSTRATIONS

André Durval de Andrade

Gustavo dos Santos Araújo

Jeisson Alves de Carvalho

Laryssa da Cunha Macedo

Marcelo Amancio Lages

Priscilla dos Santos Oliveira

Roberta da Costa Melo

Robson Ferreira das Neves

Thaís Cristina de Carvalho Araújo

Márcia Rita Santanna da Silva

TEXT EDITION

Laryssa da Cunha Macedo

Priscilla dos Santos Oliveira

Roberta da Costa Melo

COLLABORATORS

Wagner de Oliveira

Yuri de Amorim

REVISION

Cardec Barcelos Lomeu Bastos

Claudinei Palma de Lima

Bruno da Costa Ribeiro

Mário Luiz Sartorio Valiati

SUMMARY

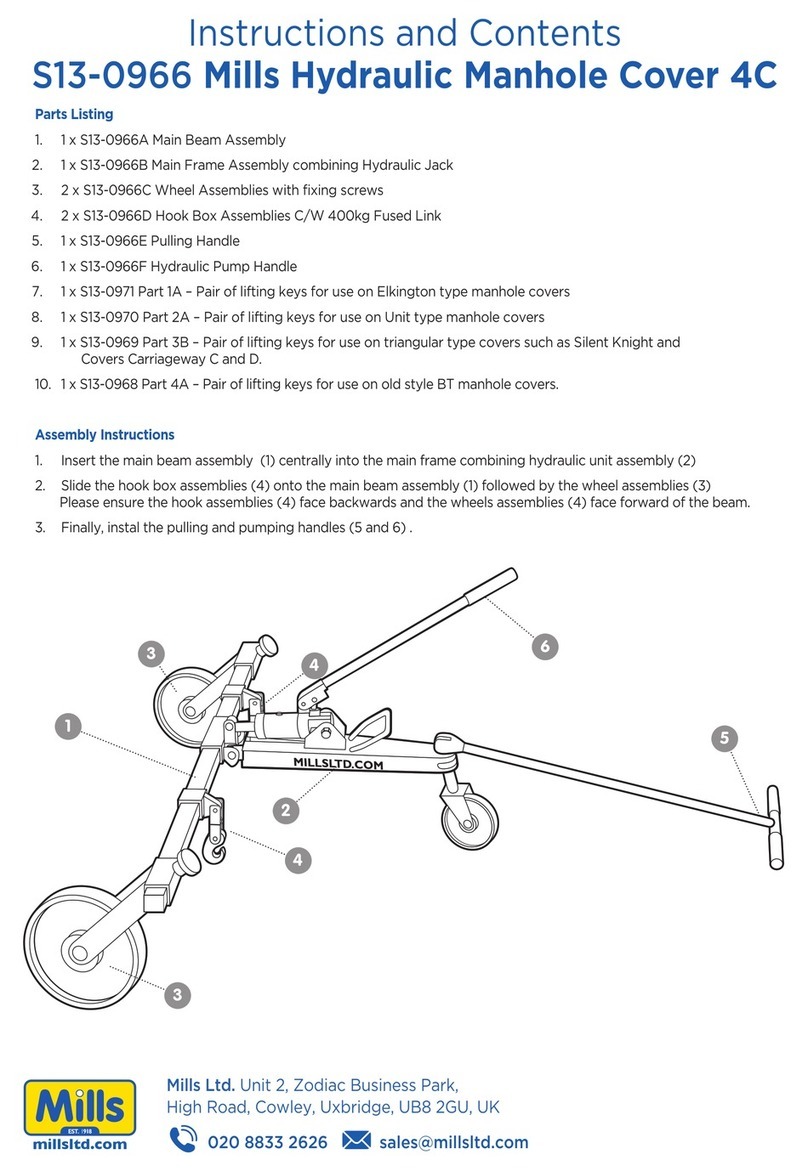

10 SYSTEM DESCRIPTION

11 POSSIBILITY OF USING THE TS MILLS SYSTEM

SLABS AND BEAMS

16 TS MILLS SYSTEM ELEMENTS

TS METALLIC TOWERS

18 TUBULAR FRAMES

TS3 AND TS4 FRAME

21 STANCHIONS

22 STANCHIONS ASSEMBLY

23 DX - “X” DIAGONALS FOR BRACING

25 DX VISUAL IDENTIFICATION

26 DTT TS - TRANSVERSE DIAGONAL FOR TS

28 DTT VISUAL IDENTIFICATION FOR TS

29 DTT USE RULE

31 SHOES

33 FIXED SHOE

34 ADJUSTABLE SHOE -TS

ELONGATED SHOE

35 USE OF ADJUSTABLE AND ELONGATED SHOES IN UNEVEN

SUPPORT

36 SUPPORTS FOR TS

37 SINGLE ADJUSTABLE SUPPORT TS

38 DOUBLE ADJUSTABLE SUPPORT TS

39 DOUBLE BASE FOR SUPPORT

40 RULE FOR USING THE DOUBLE BASE

41 KNEE BRACE

43 10T METALLIC TOWER

44 COMPONENTS OF THE 10T METALLIC TOWER

10T FRAME

45 10T STANCHION

46 DX 10T - “X” BRACING DIAGONALS

47 DTT 10T - TUBULAR TRANSVERSE DIAGONAL

48 10T ADJUSTABLE SHOE

49 10T ADJUSTABLE SUPPORT

50 ACCESSORIES FOR TS AND 10T TOWER

COUPLING ANGLE

52 METALLIC TOWER ASSEMBLY (TS OR 10T)

54 MILLSLOCK TOWER

55 MILLS TOWER

56 METALLIC STRUTS

57 METALLIC STRUT MODELS

59 TELESCOPIC SUPPORT I (WITH AND WITHOUT SHOE)

60 TELESCOPIC SUPPORT II (WITH AND WITHOUT SHOE)

61 2T STRUT

62 ALUMILLS STRUT

63 DECK STRUT

65 ACCESSORIES FOR FIXED SUPPORT STRUTS

66 TRIPODS

67 TUBULAR TRIPOD

68 ALUMILLS TRIPOD

69 UNIVERSAL TRIPOD

70 TRIPOD USE RULE

71 ALUMILLS PITCHFORK

72 CROSSHEADS AND SUPPORT T

CROSSHEAD I

73 CROSSHEAD II

74 SUPPORT T

75 METALLIC BEAMS

76 ALUMINUM BEAMS (VA 140, VA165, VA 165 DOUBLE CORE)

78 STEEL BEAMS (VJ2”, VJ3”, VJ5” AND VJ7”)

79 VJ2

80 VJ3

81 VJ5

82 VJ7

83 SUPPORT FOR BODYGUARD VJ5 AND VA 140

84 METALLIC SHAPES

SHAPE I (I 6”, I8”, I10” AND I12” AMERICAN STANDARD)

85 ALUMA RISER

86 RISER SPLICE PLATE

87 OTHER ELEMENTS

METALLIC YOKES

88 INNER YOKE

89 PERIPHERY YOKE

91 PERIPHERY YOKE BODYGUARD SUPPORT

GUIDE SYSTEM AND SUPPORTS FOR BUCKETS

GUIDES FOR REPROPPING RANGE

CONTINUOUS GUIDE

92 BUCKET SUPPORT

OPERATION PRINCIPLE OF THE COMPONENTS

93 ASSEMBLY STEPS

96 PIPES AND CLAMPS

MILLS PIPE

97 CLAMPS

1/49 AND 2/49 CLAMP

2/49/60 CLAMP

98 TYING COLUMN

99 FIXED AND HINGED CLAMP

100 PILLAR PLUMBER II

101 METALLIC CLIP, SUPPORT PLATE, TIE ROD AND WING NUT

102 TECHNICAL USE INSTRUCTIONS

PILLARS

PILLAR LOCKING AND PLUMBING

104 BEAMS

OUTER BEAMS / PERIPHERY / EDGE

STRUTS WITH CROSSHEADS AND T SUPPORT

105 PROPPING WITH TOWER

106 PROPPING USING BRACE

107 PERIPHERY YOKES

108 INNER BEAMS

PROPPING WITH CROSSHEADS AND T SUPPORT

109 PROPPING WITH TOWER

111 INNER YOKES

114 BEAM LOCKING

115 SOUND SLABS PROPPING

119 BRACING WITH STRUTS

120 BRACING WITH TOWERS

121 MIXED PROPPING

DOUBLE AND SINGLE BASE PROPPING

122 SAFETY RECOMMENDATIONS

SAFETY, PPE’S AND TOOLS

123 DESCRIPTION OF THE TS MILLS TS MILLS SYSTEM COMPONENTS

137 ANNEXES

MANUAL DE UTILIZAÇÃO |BALANÇO HIDRÁULICO

10 www.mills.com.br

1. SYSTEM DESCRIPTION

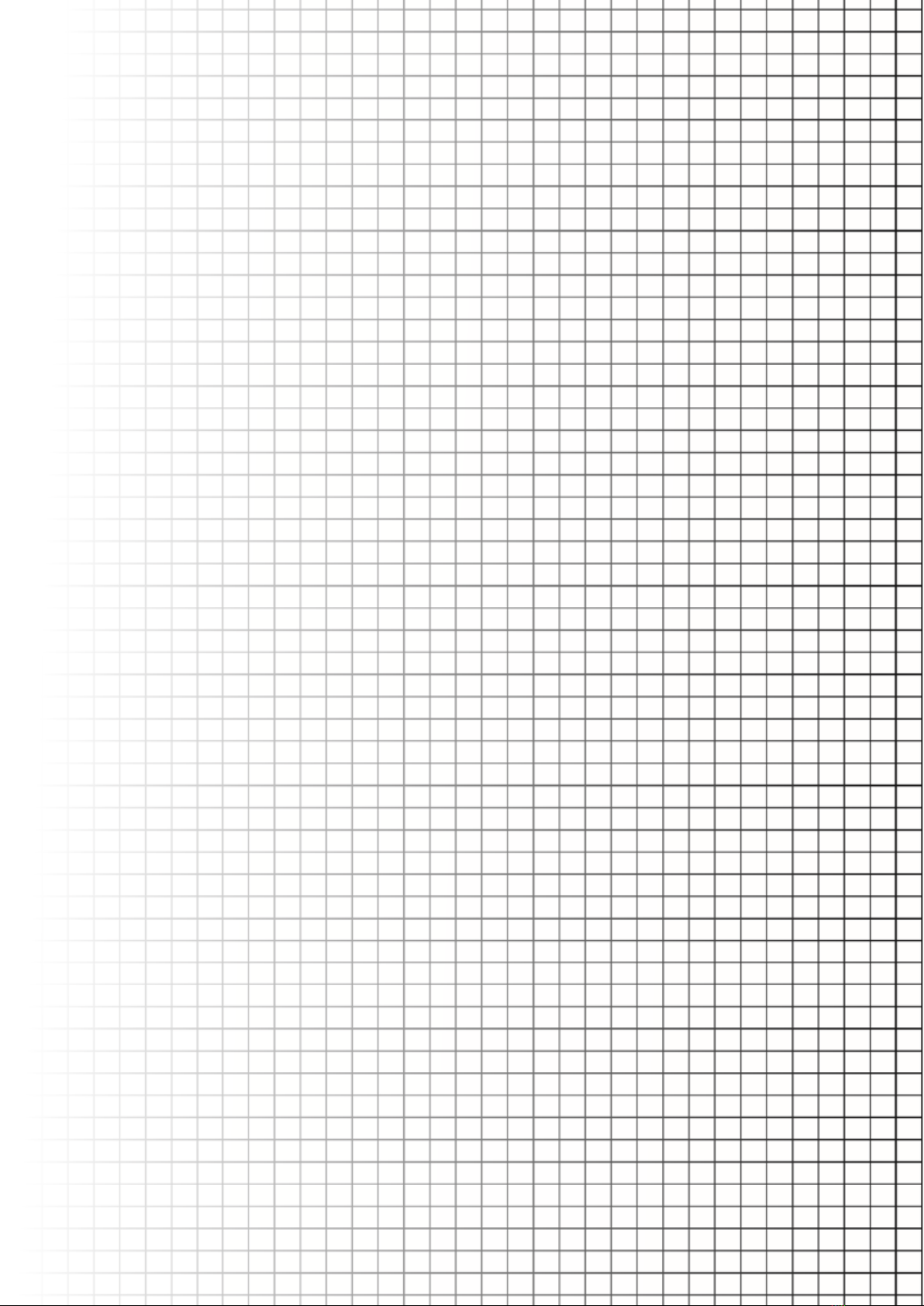

A light, quick and exible system, comprised by metallic towers, metallic (steel/aluminum) struts, metallic

(steel/aluminum) beams and accessories.

It is ideal for the propping of slabs and beams of building works (residential, commercial or industrial),

because it enables a high productivity index, due to the handling facility, the lightness of its components

and the system exibility, meeting all geometries.

METALLIC BEAMS

Page 75

METALLIC YOKES

Page 87

STRUTS

Page 57

BODYGUARD

Page 91

METALLIC TOWERS

Page 16

UNIDADE DE NEGÓCIOS INFRAESTRUTURA

11

MILLS ESTRUTURAS E SERVIÇOS DE ENGENHARIA S.A.

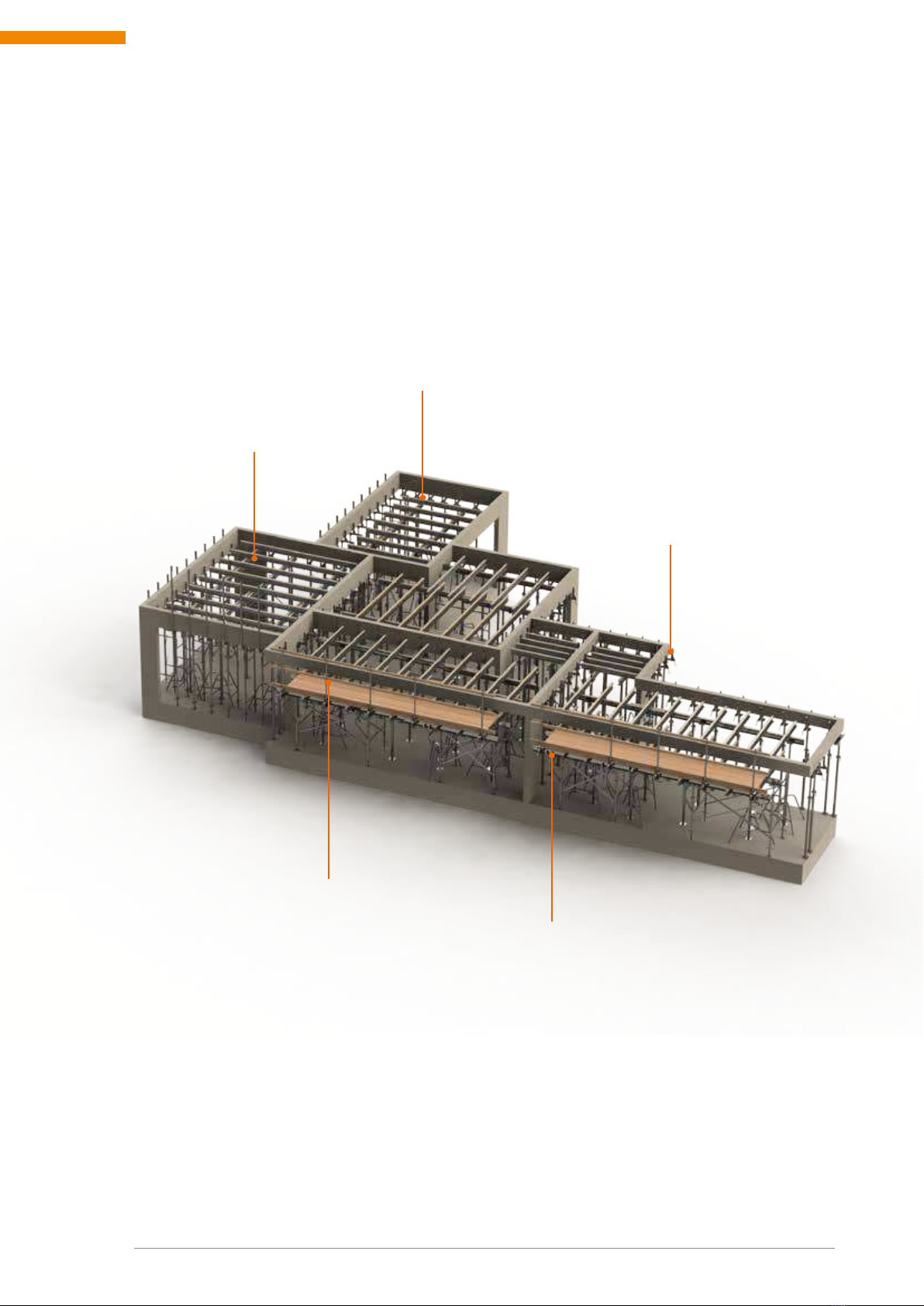

1.1. POSSIBILITIES OF USING THE TS MILLS SYSTEM

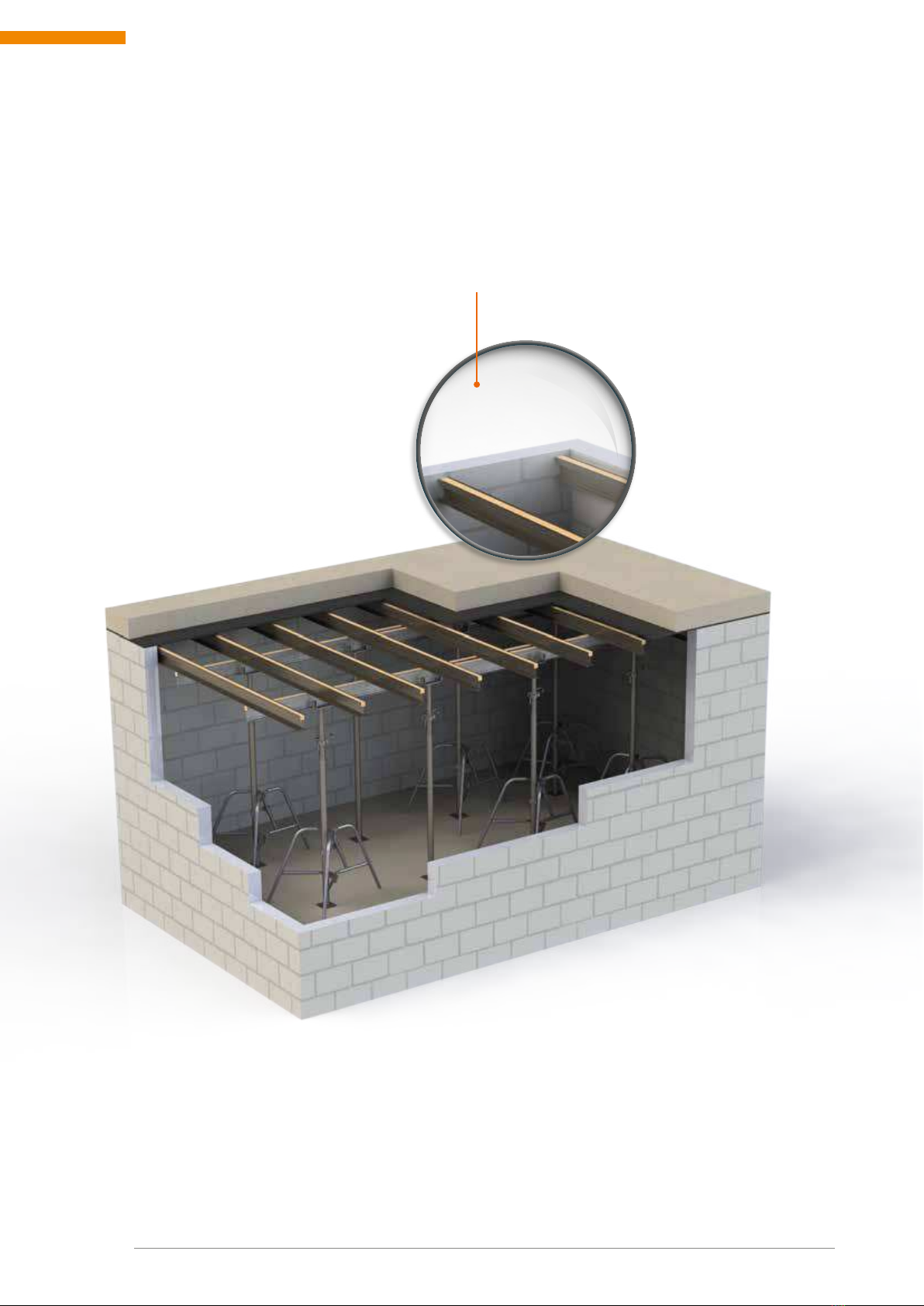

1.1.1. SLABS AND BEAMS

SITUATION 1

Propping of slabs and beams molded in loco

The TS Mills System has the right solution for your in-loco molded slab and beam independently of the

dimensions; we have a wide array of equipment and accessories, with varied possibilities of solutions

for your work, using metallic towers and struts.

DETAIL

Propping of slabs and beans

molded in loco

MANUAL DE UTILIZAÇÃO |BALANÇO HIDRÁULICO

12 www.mills.com.br

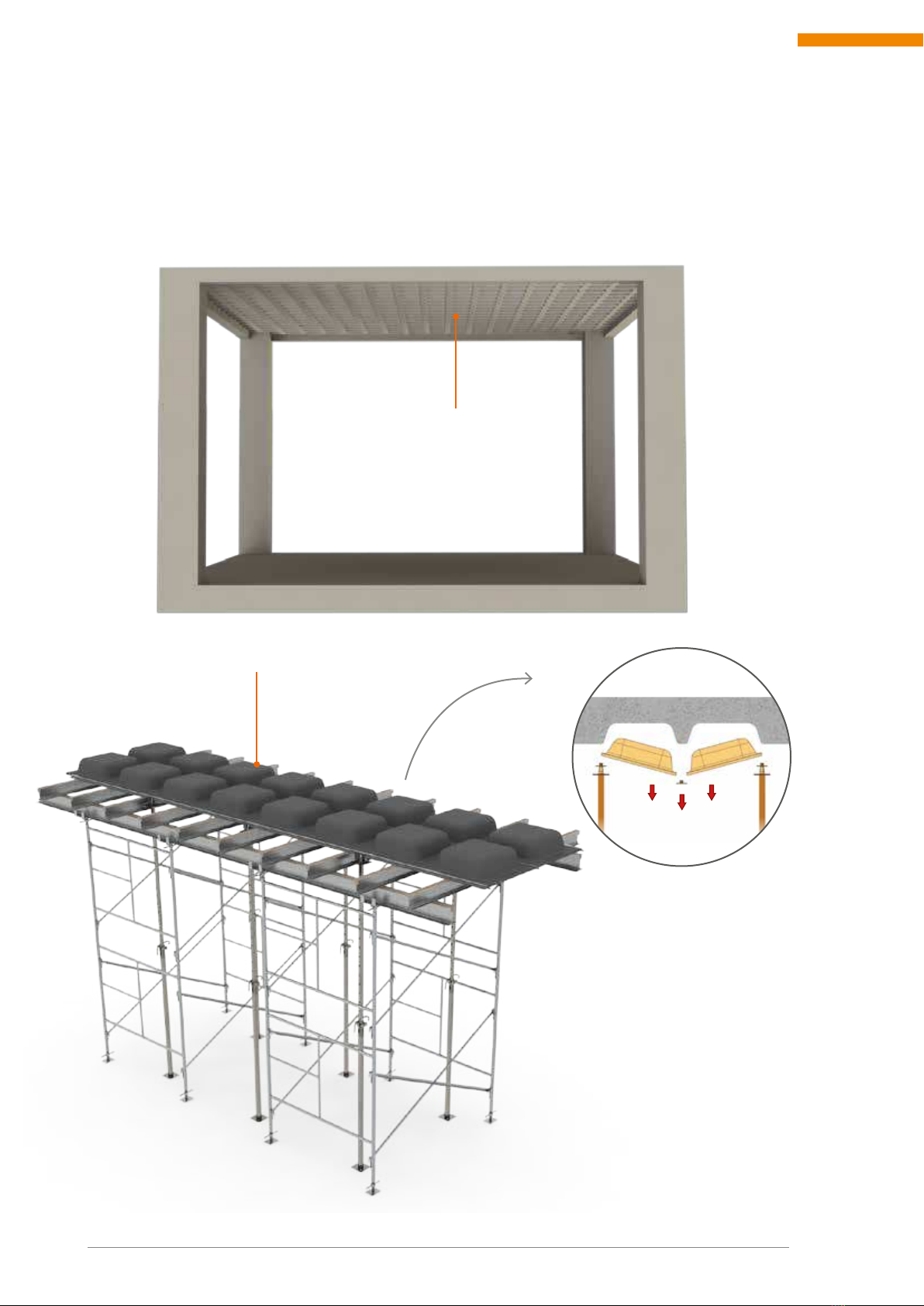

SITUATION 2

Prestressed slab propping

With a light propping comprised of struts and towers, we can give the practicality that your slab requires.

DETAIL

Propping of precast slabs

UNIDADE DE NEGÓCIOS INFRAESTRUTURA

13

MILLS ESTRUTURAS E SERVIÇOS DE ENGENHARIA S.A.

SITUATION 3

Propping of raft slabs

The TS Mills System has a line of equipment and accessories allowing using the same conventional

propping in at slabs, to comprise the repropping, providing more agility to the works, allowing the

entire horizontal and vertical propping to be assembled in the next oor.

BUCKET SYSTEM

Page 92

DETAIL

Raft slab

MANUAL DE UTILIZAÇÃO |BALANÇO HIDRÁULICO

14 www.mills.com.br

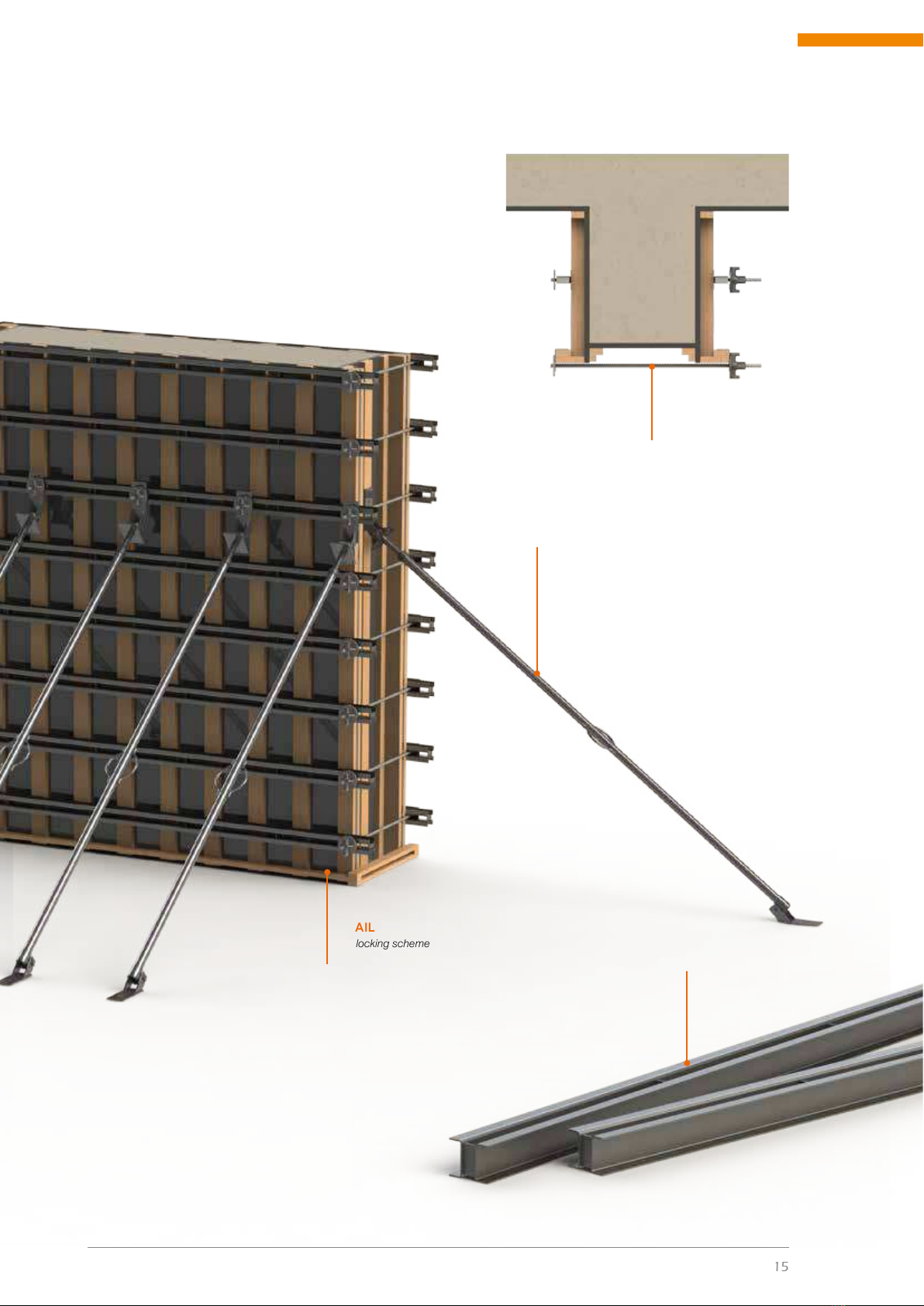

SITUATION 4

Slab propping with structural brickwork

With a light propping comprised of struts and towers, we can provide the agility that your work requires.

DETAIL

Beamwork for slab propping

UNIDADE DE NEGÓCIOS INFRAESTRUTURA

15

MILLS ESTRUTURAS E SERVIÇOS DE ENGENHARIA S.A.

SITUATION 5

Locking of pillars and beams

As an integrating part of the TS MILLS System,

we have a line of equipment directed to the locking

of Pillars and Beams, allowing more safety and

agility for your works.

DETAIL

Pillar locking scheme

RR TIE ROD

Page 102

DETAIL

VJ2 Beam

PILLAR PLUMBER

Page 101

MANUAL DE UTILIZAÇÃO |BALANÇO HIDRÁULICO

16 www.mills.com.br

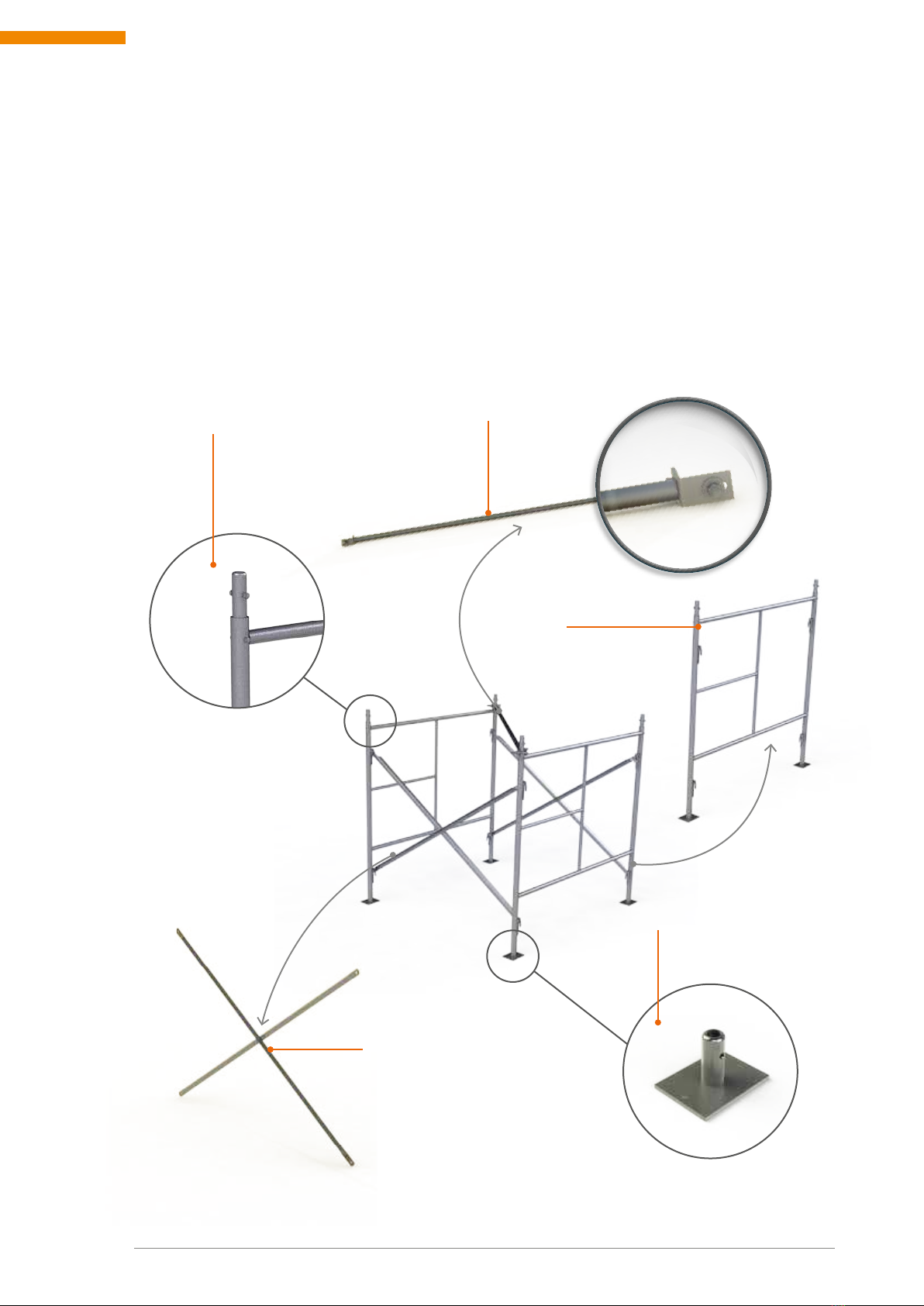

2. TS MILL SYSTEM ELEMENTS

2.1. TS METALLIC TOWERS

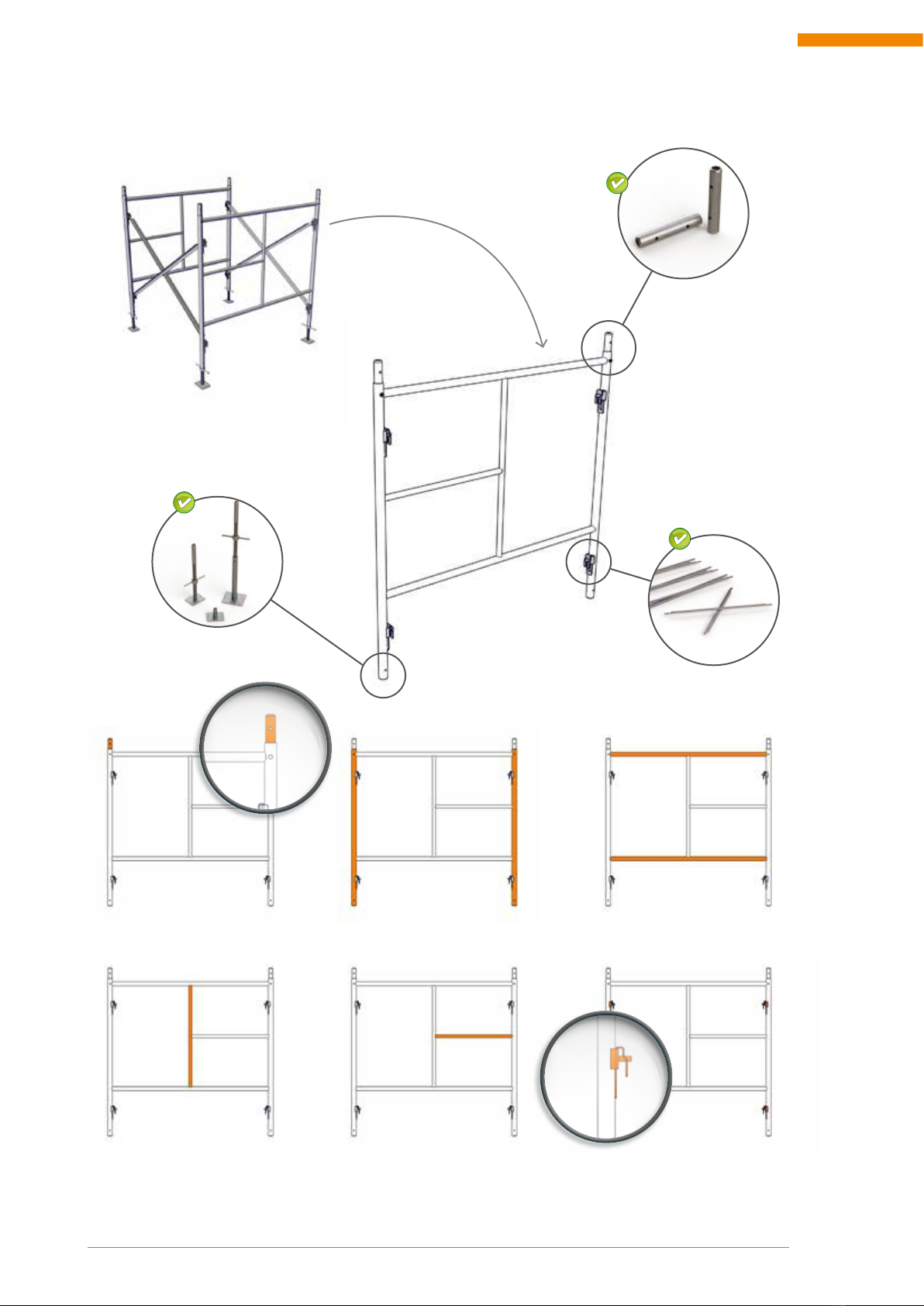

The TS metallic towers system is a composition of metallic structures formed by the tting of the

braced tubular frames by “X” diagonal elements. The assembly formed by two frames and two diagonal

elements (DX) is called module.

Its multiple models, measures and accessories offer assembly alternatives that meet several types of

works, mainly where a support structure is required as a way of accessing a certain height.

MAIN COMPONENTS OF THE METALLIC TOWER

DX

Page 23

STANCHION

Page 21

SHOES

Page 31

TS FRAME

Page 18

DTT/TS

Page 26

UNIDADE DE NEGÓCIOS INFRAESTRUTURA

17

MILLS ESTRUTURAS E SERVIÇOS DE ENGENHARIA S.A.

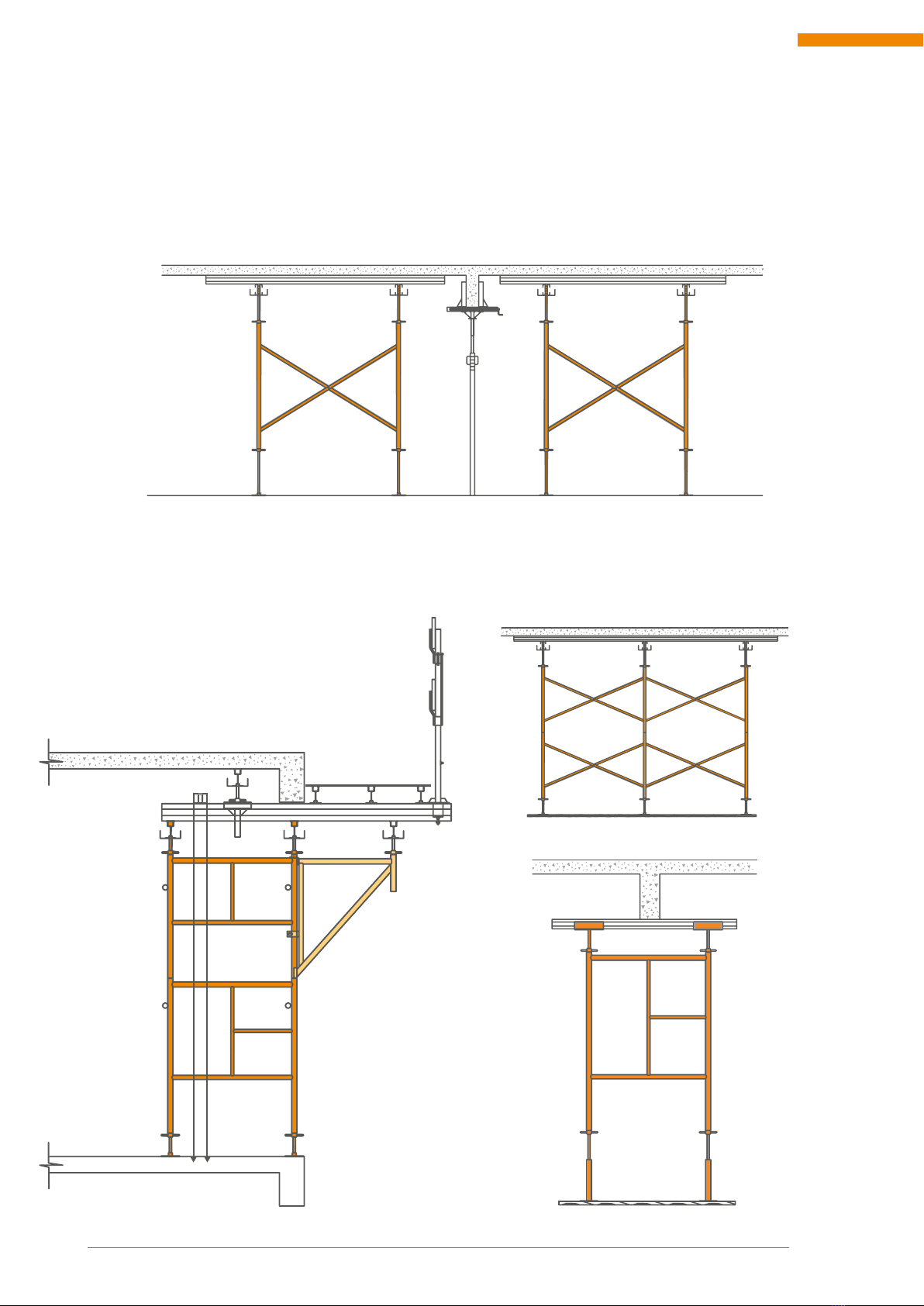

Periphery beam propping with

service platform.

▼

Slab propping with

one module tower.

►

Slab propping with two modules towers

interconnection.

▼

Inner beam propping with

tower with a module.

►

Since it is a practical, safe and easily assembled system, it does not require specialized labor. Therefore,

your system is part of the day to day of countless workers and foremen, such as load towers in the

propping of beams and slabs.

PROPPING EXAMPLES WITH TS METALLIC TOWER

MANUAL DE UTILIZAÇÃO |BALANÇO HIDRÁULICO

18 www.mills.com.br

2.1.1. TUBULAR FRAMES

This line of scaffolds is comprised of frames that differ from each other in width and in height. It is

compact and easily assembled.

Main element of the TS tower, responsible for transmitting the actuating loads to the support. It sets the

width (in the plant) of the tower: TS 3 = 1.50 m or TS 4 = 1.00 m.

01 - FRAME TS

Description Width (L) HEIGHT (H) Weight Load*

1TS-3A 1537 mm 1500 mm 18,600 kg 20 kN/post

2TS-3B 1537 mm 1250 mm 16,820 kg 20 kN/post

3TS-3C 1537 mm 1000 mm 14,100 kg 20 kN/post

4TS-4A 990 mm 1500 mm 16,050 kg 20 kN/post

5TS-4B 990 mm 1250 mm 14,280 kg 20 kN/post

6TS-4C 990 mm 1000 mm 11,920 kg 20 kN/post

(*) Load capacity per post.

(*) Review the load decrease chart

L

H

3

2

1

TS3 FRAME

5

6

4

Due to the number of modules, the allowable strengths of the posts

should be taken into account, according to the load decrease curve

chart. See page 144.

MAXIMUM LOAD PER POST

20 kN = 2000 kgf

2.1.1.1. TS3 AND TS4 FRAME

QUADRO TS4

UNIDADE DE NEGÓCIOS INFRAESTRUTURA

19

MILLS ESTRUTURAS E SERVIÇOS DE ENGENHARIA S.A.

STANCHIONS

UNION

LEGS

STEP

CROSSPIECES

DIAGONAL ELEMENTS

LOCKS

STANCHION

Page 21

SHOES

Página 31

DX DIAGONAL ELEMENTS

Page 23

NOMENCLATURE OF THE PARTS OF A FRAME

Other Mills Construction Equipment manuals