7ML19981CM01.1 MERCAP – INSTRUCTION MANUAL Page 1

Table of Contents

Introduction

IntroductionIntroduction

Introduction

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

....................................

........

.... 3

33

3

Identifications and Abbreviations..............................................................................................3

Technical Specifications

Technical SpecificationsTechnical Specifications

Technical Specifications

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..............................................

............................

.............. 5

55

5

Electrodes.........................................................................................................................................5

Wetted Parts....................................................................................................................................5

Transmitter.......................................................................................................................................5

Electrodes and Process Connections

Electrodes and Process ConnectionsElectrodes and Process Connections

Electrodes and Process Connections

................................

................................................................

................................................................

................................................................

........................................................

................................................

........................ 7

77

7

Handling of Electrodes..................................................................................................................7

Characteristics ................................................................................................................................7

General Design Principles ...........................................................................................................8

Mercap Configurations.................................................................................................................9

Examples of Mercap Level Instruments ................................................................................10

Interface and Level Version (Mercap MCP 02)....................................................................15

Flanges ............................................................................................................................................17

Flange Standards .........................................................................................................................17

Applications Examples................................................................................................................19

Flow-Through Electrode

Flow-Through ElectrodeFlow-Through Electrode

Flow-Through Electrode ................................

................................................................

................................................................

................................................................

................................................................

................................................................

..............................................

............................

.............. 21

2121

21

FTS Series ......................................................................................................................................21

FTF Series.......................................................................................................................................22

MST9500 Transmitter

MST9500 TransmitterMST9500 Transmitter

MST9500 Transmitter

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..................................................

....................................

.................. 24

2424

24

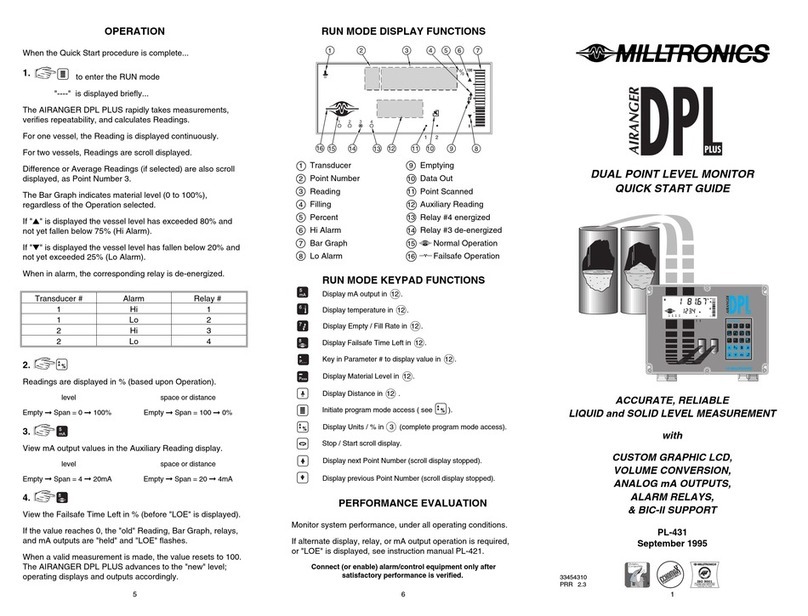

Operating Principles ....................................................................................................................24

Installation

InstallationInstallation

Installation

and Interconnection

and Interconnectionand Interconnection

and Interconnection................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................ 25

2525

25

Interconnection.............................................................................................................................26

Connection Diagrams..................................................................................................................27

Factory settings ............................................................................................................................29

Applications

ApplicationsApplications

Applications

and Grounding

and Groundingand Grounding

and Grounding ................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................

..............

....... 30

3030

30

Start-up

Start-upStart-up

Start-up

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................

..................

......... 35

3535

35

Push-Button Adjustment............................................................................................................35

Adjustment using HARTTM ..........................................................................................................36

Maintenance

MaintenanceMaintenance

Maintenance

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................ 39

3939

39

Test function ..................................................................................................................................39

Appendix A: HART

Appendix A: HARTAppendix A: HART

Appendix A: HARTTM

TMTM

TM Documentation

DocumentationDocumentation

Documentation

................................

................................................................

................................................................

................................................................

........................................................

................................................

........................ 41

4141

41

HARTTM info.....................................................................................................................................41

HARTTM Conformance and Command Class .........................................................................41

MST9500 DD Menu/Variable Organization ..........................................................................43

HARTTM Response Code information.......................................................................................44

General transmitter information...............................................................................................44

Siemens Automation