Milwaukee M18 ONEFHIWF1 User manual

Other Milwaukee Power Screwdriver manuals

Milwaukee

Milwaukee HEAVY DUTY M12 BDDX User manual

Milwaukee

Milwaukee M4 User manual

Milwaukee

Milwaukee IPWE 520 RQ User manual

Milwaukee

Milwaukee M4 User manual

Milwaukee

Milwaukee M18 BID-202C User manual

Milwaukee

Milwaukee CA 55 User manual

Milwaukee

Milwaukee DWSE 4000 Q User manual

Milwaukee

Milwaukee M12 Fuel User manual

Milwaukee

Milwaukee M12 BRAID User manual

Milwaukee

Milwaukee M12 2401-20 User manual

Milwaukee

Milwaukee M18 FHIWF12-502X User manual

Milwaukee

Milwaukee HD18HIWF-402C User manual

Milwaukee

Milwaukee C18 IW User manual

Milwaukee

Milwaukee M12 FPD2-402X User manual

Milwaukee

Milwaukee M12 FIR14LR User manual

Milwaukee

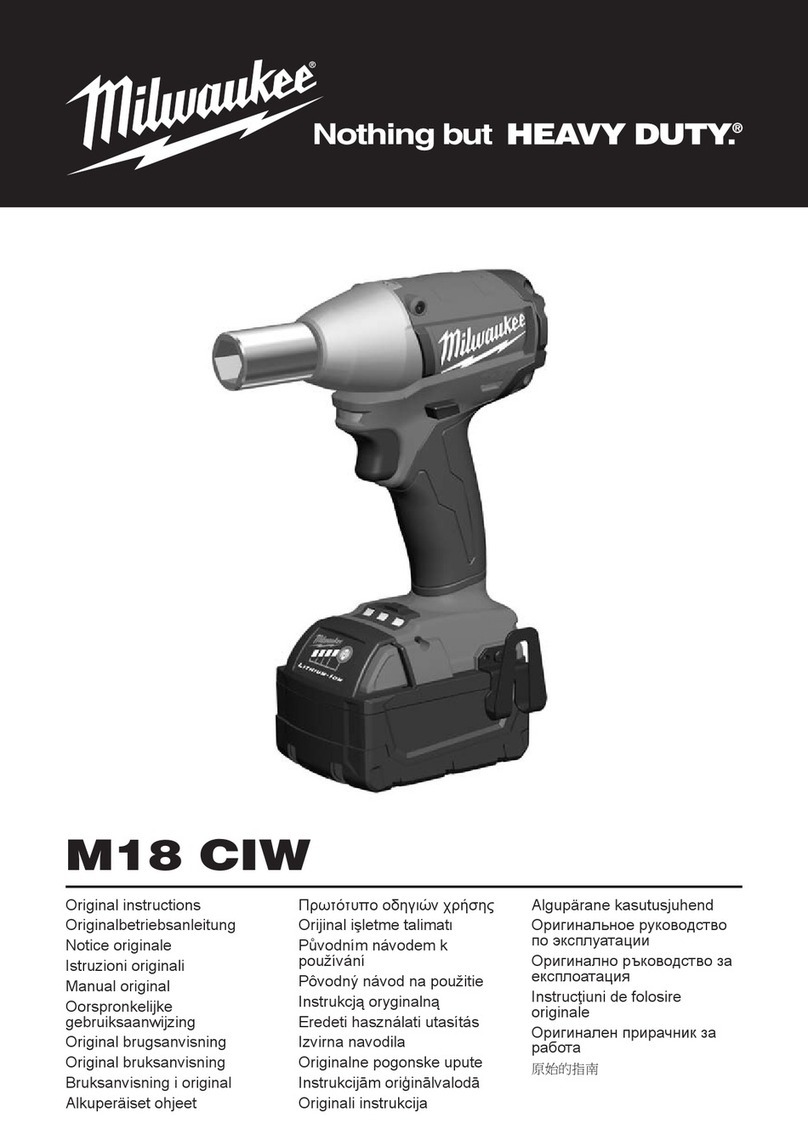

Milwaukee M18 CIW User manual

Milwaukee

Milwaukee M18 BLPD2-502X User manual

Milwaukee

Milwaukee 0490-20 User manual

Milwaukee

Milwaukee TQSE 1200Q User manual

Milwaukee

Milwaukee M12 FIR12 User manual