Minco TT519 User manual

2-WIRE PROGRAMMABLE TRANSMITTER TT519

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

1

2-WIRE PROGRAMMABLE TRANSMITTER TT519

CONTENTS

Application .........................................................................................................2

Technical characteristics .....................................................................................2

Mounting / Installation.......................................................................................2

Applications........................................................................................................3

Order: TT519.......................................................................................................4

Electrical specifications .......................................................................................4

Connections........................................................................................................8

Programming......................................................................................................9

Mechanical specifications .................................................................................10

Mounting of sensor wires .................................................................................10

Appendix ..........................................................................................................11

IECEx Installation Drawing ..........................................................................11

ATEX Installation Drawing...........................................................................13

InNMETRO Instruções de Segurança ...........................................................15

2

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

2-WIRE PROGRAMMABLE TRANSMITTER TT519

•TC input

•High measurement accuracy

•Galvanic isolation

•Programmable sensor error value

•For DIN form B sensor head mounting

Application

•Linearized temperature measurement with TC sensor.

•Amplification of bipolar mV signals to a 4…20 mA signal, optionally linearized according

to a defined linearization function.

Technical characteristics

•Within a few seconds the user can program the TT519 to measure temperatures within

all TC ranges defined by the norms.

•Cold junction compensation (CJC) with a built-in temperature sensor.

•Continuous check of vital stored data for safety reasons.

Mounting/installation

•For DIN form B sensor head mounting. In non-hazardous areas, the TT519 can be

mounted on a DIN rail with the AC807 Minco DIN rail adapter.

4

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

Order TT519:

Electrical specifications

Specifications Range:

-40°C to +85°C

Common specifications:

Supply voltage, DC ………………………………………………… 7.2…30 VDC

Internal consumption…………………………………………….. 25 mW…0.7 W

Voltage drop …………………………………………………………. 7.2 VDC

Isolation voltage, test/operation ………………………….. 1.5 kVAC/50VAC

Warm-up time ………………………………………………………. 5 min

Communications interface ……………………………………. Loop Link with AC205817

Signal /noise ratio …………………………………………………. Min. 60 dB

Response time (programmable) ……………………………. 1…60 s

EEprom error check ………………………………………………. < 3.5 s

Signal dynamics, input ………………………………………….. 18 bit

Signal dynamics, output ……………………………………….. 16 bit

Calibration temperature………………………………………… 20…28°C

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

5

Accuracy:

Calibration

Type

Accuracy

Temperature

Coefficient

Nominal

Type E, J, K, T, N

<±1°C

<±0.05°C/°C

Type B, R, S

<±2°C

<±0.2°C/°C

Voltage

<±10µV

<±1µV/°C

EMC immunity influence ………………………………………………………………………………… < ± 0.5% of span

Extended EMC immunity:

NAMUR NE 21, A criterion, burst ……………………………………………………………………. < ± 1% of span

Effect of supply voltage variation ……………………………. < 0.005% of span/VDC

Vibration ………………………………………………………………… IEC 60068-2-6:2007

2…25 Hz………………………………………………………±1.6 mm

25…100 Hz………………………………………………….±4 g

Max. wire size ……………………………............................... 1x1.5 mm2stranded wire

Screw terminal torque …………………………………………….. 0.4 Nm

Humidity …………………………………………………………………. < 95% RH (non-cond.)

Dimensions ……………………………………………………………… ø44 x 20.2 mm

Protection degree (enclosure / terminal) ………………… IP68 / IP00

Weight ……………………………………………………………………. 50 g

6

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

Electrical specification, input:

Max. offset ……………………………………………………………… 50% of selec. max. value

TC input:

Type

Min

temperature

Max

temperature

Min span

Standard

B

+400°C

+1820°C

100°C

IEC584

E

-100°C

+1000°C

50°C

IEC584

J

-100°C

+1200°C

50°C

IEC584

K

-180°C

+1372°C

50°C

IEC584

L

-100°C

+900°C

50°C

DIN 43710

N

-180°C

+1300°C

50°C

IEC584

R

-50°C

+1760°C

100°C

IEC584

S

-50°C

+1760°C

100°C

IEC584

T

-200°C

+400°C

50°C

IEC584

U

-200°C

+600°C

50°C

DIN 43710

W3

0°C

+2300°C

100°C

ASTM E988-90

W5

0°C

+2300°C

100°C

ASTM E988-90

LR

-200°C

+800°C

50°C

GOST 3044-84

Cold junction compensation ……………………………. < ±1.0°C

Sensor error detection …………………………………….. Yes

Sensor error current:

When detecting …………………………………. Nom. 33 µA

Else ……………………………………………………. 0 mA

Voltage input:

Measurement range ……………………………………….. -12…150mV

Min. span ………………………………………………………… 5 mV

Input resistance ………………………………………………. 10 MΩ

Output:

Current output:

Signal range ……………………………………………………. 4…20 mA

Min. signal range ……………………………………………. 16mA

Updating time ………………………………………………… 440 ms

Output signal at EEprom error ……………………….. ≤ 3.5 mA

Load resistance ………………………………………………. ≤ (Vsupply – 7.2)/0.023 [Ω]

Load stability ………………………………………………….. ±0.01% of span/100 Ω

Sensor error detection:

Programmable ……………………………………………….. 3.5…23 mA

Namur NE43 Upscale ……………………………………… 23 mA

Namur NE43 Downscale …………………………………. 3.5 mA

Of span = Of the presently selected range

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

7

Approvals

EMC ………………………………..……………..………….. 2014/30/EU

CCOE…………………………………………………………… P337392/1

RoHS .............................................................. 2011/65/EU

EAC................................................................. TR-CU 020/2011

Marine approval:

DNV-GL, Ships & Offshore.................................... Standard for Certification No. 2.4

Ex:

ATEX 2014/34/EU………………………………………. KEMA 06ATEX0062 X

IECEx………………………………………………………….. DEK 13.0035X

INMETRO………………………………………………….… DEKRA 16.0013 X

CCOE………………………………………………………….. P337392/2

EAC Ex TR-CU 012/2011……………………………… RU C-DK.GB08.V.00410

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

9

Programming

•Loop Link is a communication interface that is needed for programming the TT508,

TT509, TT510, TT511, TT518, TT519, TT520 & TT521.

•Use Minco AC205817.

•For programming please refer to the drawing below.

•Loop link is not approved for communication with modules installed in hazardous (Ex)

areas.

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

11

Appendix

IECEx Installation Drawing

For safe installation of the TT519 the following must be observed. The module shall only be

installed by qualified personnel who are familiar with the national and international laws,

directives and standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

ATEX Certificate IECEx DEK 13.0035X

Marking

Ex ia IIC T4…T6 Ga

Ex ia IIIC Da

Ex ia I Ma

Standards EN 60079-0 : 2011, EN60079-11 : 2011, IEC 60079-26 : 2006

12

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

Installation Notes:

The sensor circuit is not infallibly galvanic isolated from the input circuit. However, the galvanic

isolation between the circuits is capable of withstanding a test voltage of 500Vac during 1

minute.

In a potentially explosive gas atmosphere, the transmitter shall be mounted in a metal form B

enclosure in order to provide a degree of protection of at least IP20 according to IEC60529. If

however the environment requires a higher degree of protection, this shall be taken into

account

If the transmitter is installed in an explosive atmosphere requiring the use of equipment

protection level Ga, Ma and Mb, and if the enclosure is made of aluminum, it must be installed

such, that ignition sources due to impact and friction sparks are excluded.

For installation in a potentially explosive dust atmosphere, the following instructions apply:

For explosive dust atmospheres, the surface temperature of the outer enclosure is 20 K above

the ambient temperature.

The transmitter shall be mounted in a metal enclosure form B according to DIN43729 that is

providing a degree of protection of at least IP6X according to IEC60529, that is suitable for the

application and correctly installed.

Cable entries and blanking elements shall be used that are suitable for the application and

correctly installed.

For an ambient temperature ≥ 60ºC, heat resistant cables shall be used with a rating of at least

20 K above the ambient temperature.

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

13

ATEX Installation Drawing

For safe installation of the TT519 the following must be observed. The module shall only be

installed by qualified personnel who are familiar with the national and international laws,

directives and standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

ATEX Certificate KEMA 06ATEX 0062 X

Marking

II 1 G EX ia IIC T4…T6 Ga

II 1 D Ex ia IIIC Da

II M1 Ex ia I Ma

Standards EN 60079-0 : 2012, EN60079-11 : 2012, EN 60079-26 : 2007,

EN 60079-15 : 2010

14

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

Installation notes:

The sensor circuit is not infallibly galvanic isolated form the input circuit. However, the galvanic

isolation between the circuits is capable of withstanding a test voltage of 500Vac during 1

minute.

In a potentially explosive gas atmosphere, the transmitter shall be mounted in an enclosure in

order to provide a degree of protection of at least IP20 according to EN60529.

If the transmitter is installed in an explosive atmosphere requiring the use of equipment of

category 1 G, 1 M, or 2 M, and if the enclosure is made of aluminum, it must be installed such,

that even in the event of rare incidents, ignition sources due to impact and friction, sparks are

exclude: if the enclosure is made of non-metallic materials, electrostatic charging shall be

avoided.

For installation in a potentially explosive dust atmosphere, the following instructions apply:

The transmitter shall be mounted in a metal enclosure form B according to DIN43729 that is

providing a degree of protection of at least IP6X according to EN60529, that is suitable for the

application and correctly installed.

Cable entries and blanking elements shall be used that are suitable for the application and

correctly installed.

For an ambient temperature ≥ 60°c, heat resistance cable shall be used with a rating of at least

20 K above the ambient temperature

The surface temperature of the enclosure is equal to the ambient temperature plus 20 K, for a

dust layer with a thickness up to 5 mm.

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

15

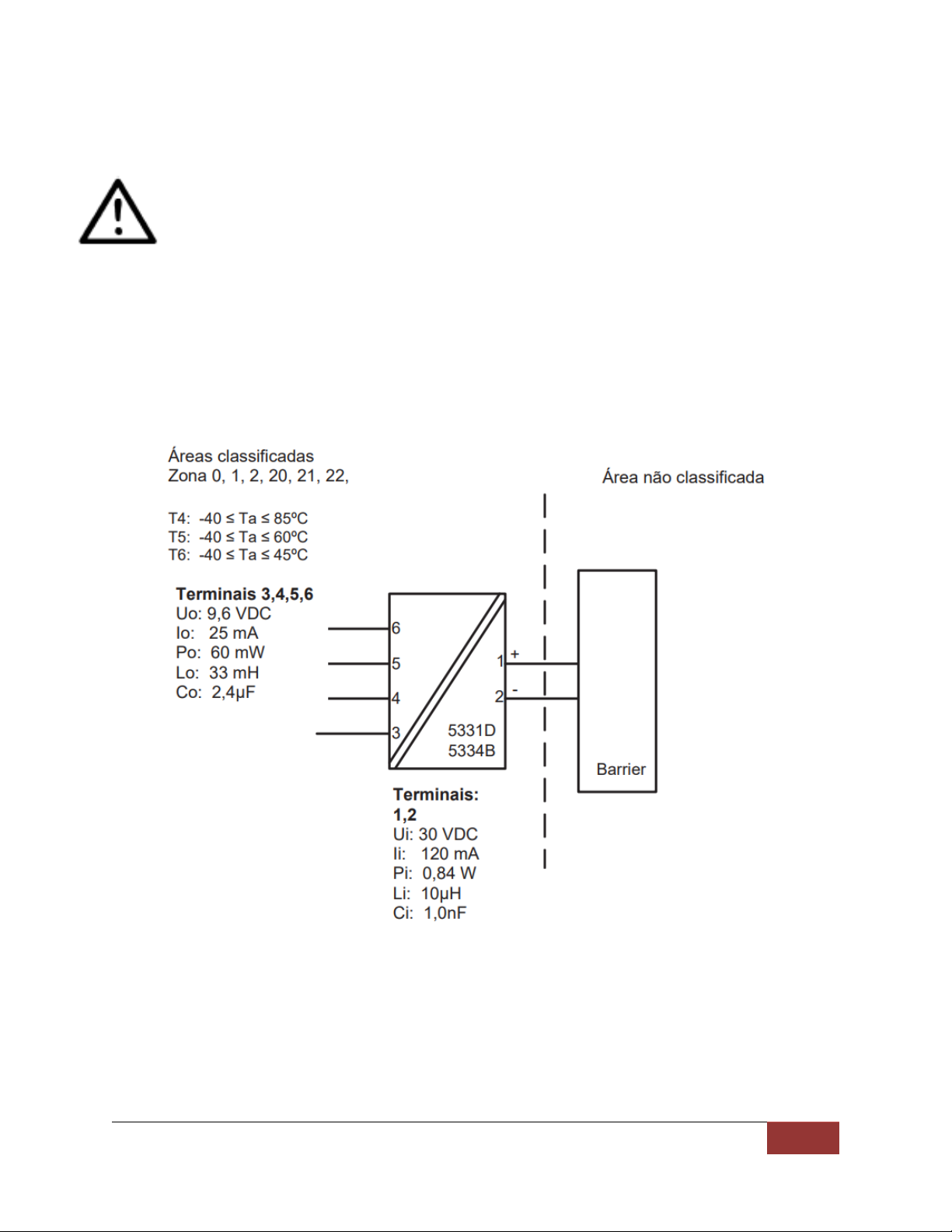

Desenho de Instalação InNMETRO

Para instalação segura do TT519 o seguinte deve ser observado. O modo deve apenas ser

instalado por pessoas qualificadas que são familiarizadas com as leis nacionais e internacionais,

diretrizes e padrões que se aplicam a esta área.

Ano de fabricação pode ser pego dos dois primeiros dígitos do número de série.

Certificado DEKRA 16.0013 X

Marcas Ex ia IIC T6…T4 Ga

Ex ia IIIC Da

Normas ABNT NBR IEC 60079-0 : 2013; ABNT NBR IEC 60079-11 : 2013

16

Minco Products, Inc. | Tel: 763.571.3121 • www.minco.com •2612427 (B).......

Notas para instalação

O circuito do sensor não é isolado galvanicamente infalível do circuito de entrada. Contudo, a

isolação galvânica entre os circuitos é capaz de resistir a um teste de tensão de 500Vac

durante 1 minuto.

Em uma atmosfera de gás potencialmente explosiva, o transmissor deve ser montado em um

enclousure a fim de garantir um grau de proteção de no mínimo IP20 de acordo com

EN60529. Se contudo o ambiente requer um nível de proteção maior, isso deve ser levado em

conta

Se o transmissor é instalado em uma atmosfera explosiva exigindo o uso de equipamento de

categoria Ga e se o enclosure é feito de alumínio, ele deve ser instalado de modo que, mesmo

em caso de avaria rara, fontes de ignição devido a impacto e fricção, faíscas são eliminadas; se

o enclosure é feito de materiais não metálicos, cargas eletroestáticas devem ser evitadas.

Para instalação em atmosfera de poeira potencialmente explosiva, as instruções a seguir:

O transmissor deve ser montado em enclosure de metal forma B de acordo com DIN43729

que está fornecendo um grau de proteção de pelo menos IP6X de acordo com EN60529. Isso é

adequado para aplicação e corretamente instalado.

As entradas dos cabos e os elementos de obturação que podem ser utilizados são adequados

para a aplicação e corretamente instalados.

Para temperatura ambiente >= 60ºC, fios de resistência ao calor devem ser usados com uma

faixa de pelo menos 20K acima da temperatura ambiente.

A temperatura da superfície do enclosure é igual à temperatura ambiente mais de 20 K, por

uma camada de pó, com uma espessura até 5 mm.

Table of contents

Other Minco Transmitter manuals

Popular Transmitter manuals by other brands

R.V.R. Elettronica

R.V.R. Elettronica TEX702TFT Operator's manual

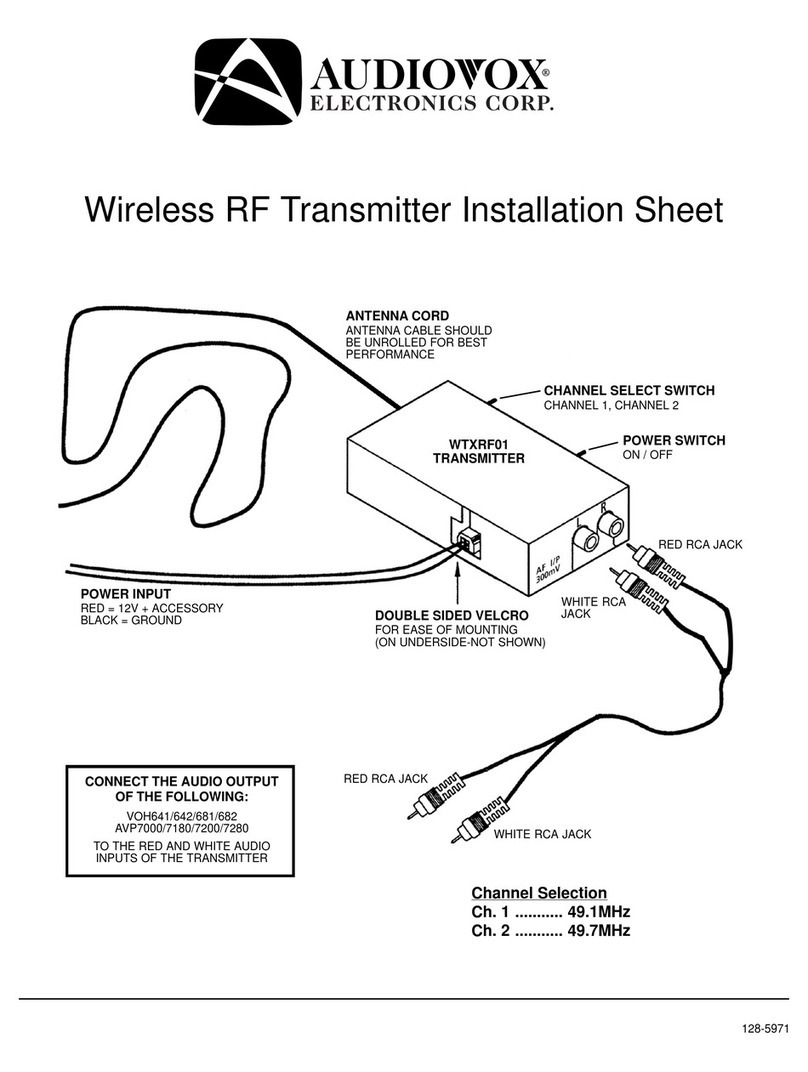

Audiovox

Audiovox 128-5971 Installation sheet

E+E Elektronik

E+E Elektronik EE870 manual

Absolute Process Instruments

Absolute Process Instruments APD 6380 quick start guide

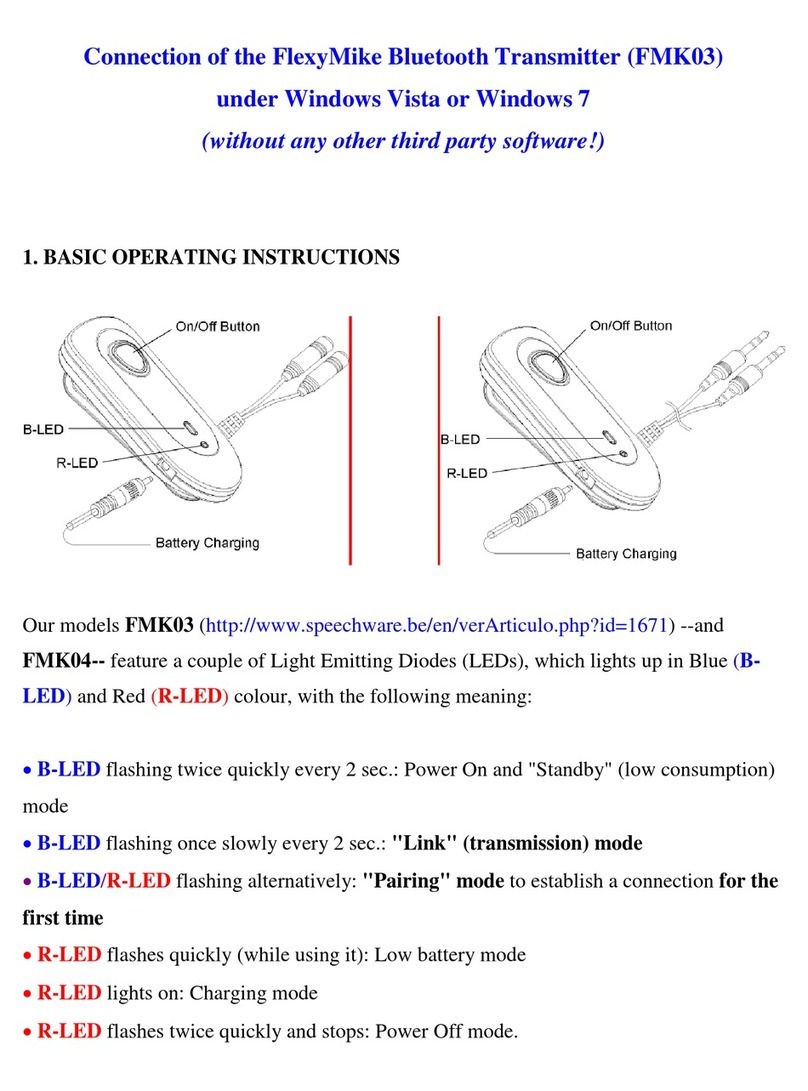

SpeechWare

SpeechWare FlexyMike FMK03 quick start guide

Emerson

Emerson Rosemount 2051HT quick start guide