2

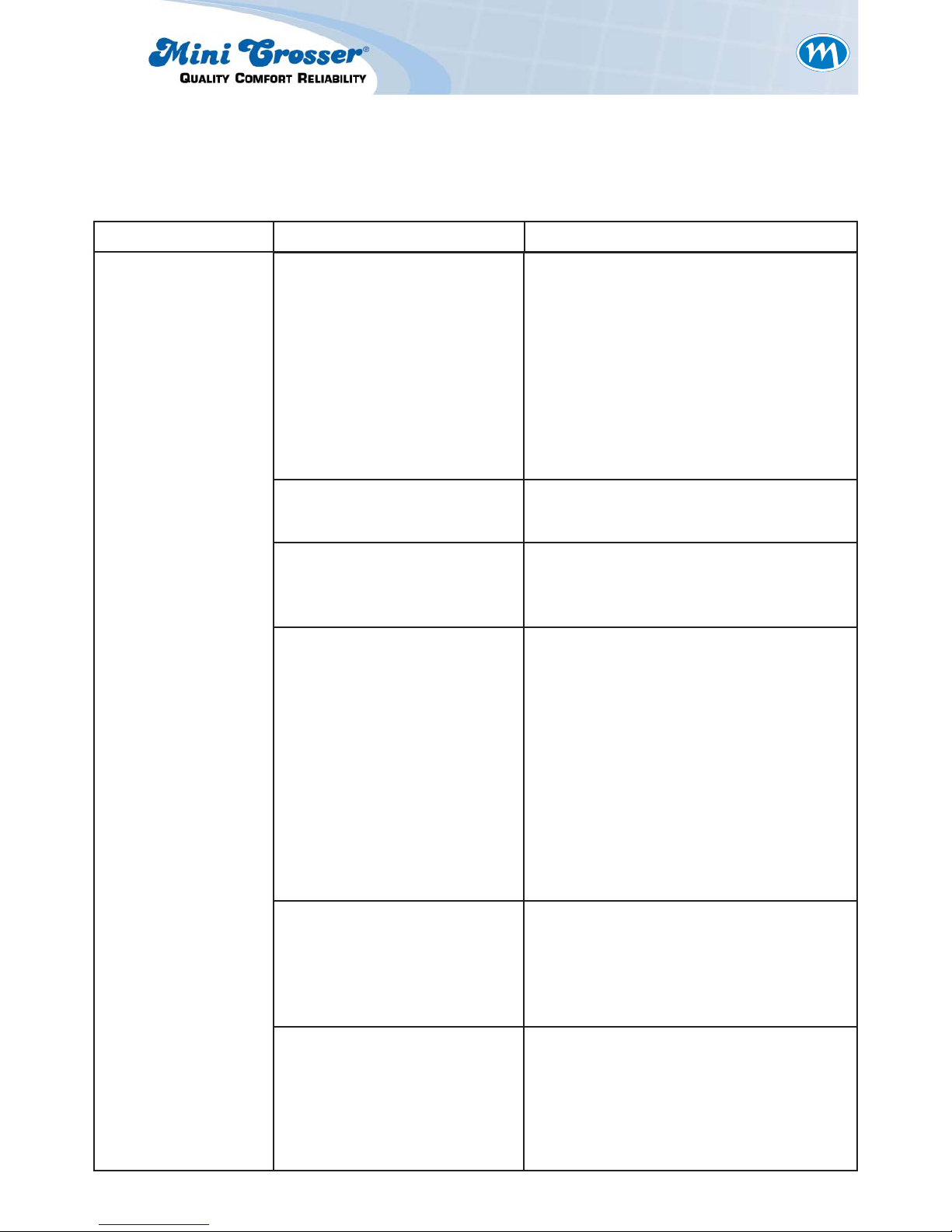

Table of contents

1.0..................Introduction ............................................................................................................. 3

2.0..................Safety service .......................................................................................................... 4

3.0..................List of tools .............................................................................................................. 5

4.0.................. Maintenance ............................................................................................................ 6

4.1..................Once a day............................................................................................................... 6

4.2..................Once a quarter ........................................................................................................ 6

4.3..................Safety inspection..................................................................................................... 6

5.0..................Service list, MC standard model............................................................................ 7

5.1..................Heating................................................................................................................... 13

6.0..................Fuses and bulbs .................................................................................................... 17

6.1..................Diagram of battery connections.......................................................................... 17

6.2..................Plugs and fuses in the operating panel............................................................... 18

7.0..................Batteries / charging .............................................................................................. 19

8.0..................Storage................................................................................................................... 20

9.0..................Cleaning ................................................................................................................. 20

10.0................ Trouble-shooting ................................................................................................... 21

10.1................Programming unit ................................................................................................. 23

11.0................International addresses........................................................................................ 23

12.0................Air transport certificate ........................................................................................ 24

13.0................Special adaptations .............................................................................................. 26

14.0................Declaration of conformity .................................................................................... 26

15.0................Installing accessories........................................................................................... 27

15.1................Throttle regulation................................................................................................. 27

15.2................Speedometer ......................................................................................................... 29

15.3................Lowering curve...................................................................................................... 31

15.4................Parent potentiometer............................................................................................ 32

15.5................Hour counter ......................................................................................................... 33

15.6................Parent key .............................................................................................................. 35

15.7................Foot pedal throttle 3W and 4W ............................................................................ 36

15.8................Electric seat adjustment ...................................................................................... 39

15.9................Twist grip throttle regulator – right and left ........................................................ 41

15.10..............Installing accessories in the C rail ...................................................................... 44

15.11..............Replacing bulb in headlight.................................................................................. 45

15.12..............Installing a side-view mirror................................................................................. 46

16...................Technical data ....................................................................................................... 47

17...................Belts for securing an MC in a car ........................................................................ 51

18...................Programming......................................................................................................... 53

18.1................125T 3 & 4W ........................................................................................................... 53

18.2................130T 3 & 4W ........................................................................................................... 54

18.3................140T 3 & 4W ........................................................................................................... 55

19...................Front wheel alignment 4W.................................................................................... 56

20...................Wiring diagram ...................................................................................................... 58

21...................PG Drivers Technology ......................................................................................... 60

Appendix A ... Check list ............................................................................................................. 108