Maintenance and Security

A radio controlled model helicopter and a speed helicopter especially is not a toy. A mistake

can result in serious accidents and injuries. So keep the following rules always in your mind:

1- Start always with an Idle Up 1 of about 1600 rpm and switch up to Idle Up 2 first when the

model is at least 10 metres high and 20 metres away.

2- Fly high speed passes always with a minimum distance of 50 metres / 150 ft to you. No per-

son should be between you and the model (f.e. modelers with cameras).

3- Keep a minimum flight height of 30 metres. Nore that reaching extreme speeds you reach

at the blades tips the transsonic area which can result in particulary stalls on the airfoil. To res-

cue the model you need a minimum height to react and start actions to save the model.

4- Fly with discipline. Do not fly more passes that you have calculated before. Do never fly

deep and closed to enlarge the impressions of spectators.

5- Do not fly with crosswind that press the model in your direction. All aerodynamic bodies,

also the Diabolo S are sensitive against crosswinds and can move cross to you more than you

have expected.

6- Do not go over your personal limit. High speed flight needs a lot of training and experience

that you must learn first. With increasing speed you must calibrate your FBL system perhaps

different, modify parametres like headspeed and pitch.

7- Do not fly faster and only so far away how your eyes allow this. The model can climb after a

pass very fast heights and distances that are difficult to observe. So be careful.

8- The most important rule: Do never start if you are not absolutely sure that everything is ok!

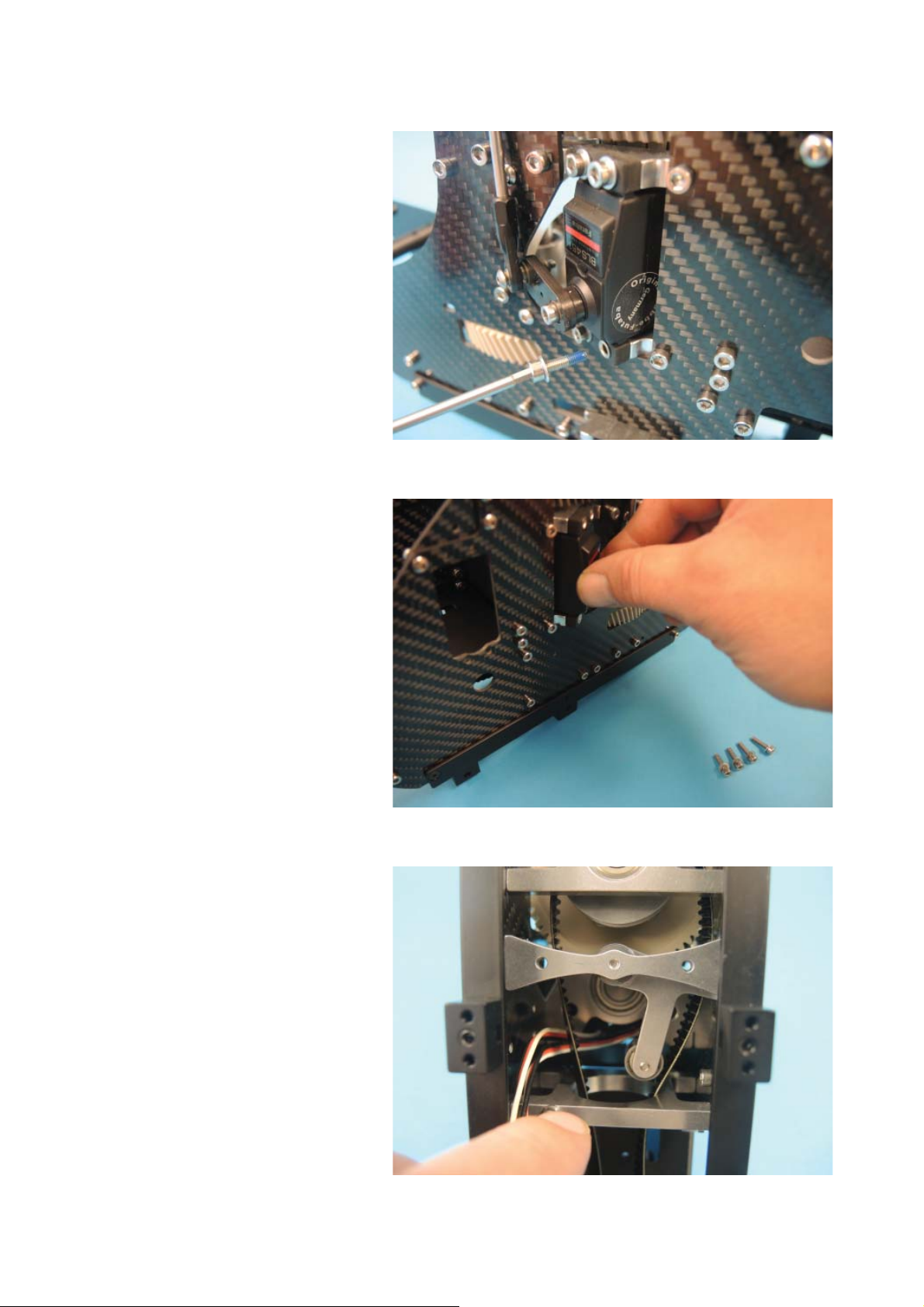

Maintenance: The Diabolo S was designed for a high standard reliability and durability. But

that does not mean that you must not do any maintenance. After each flight you should do a

check of ALL mechanical parts. Look for loose screws, cables. Check the bearings, gears, all

electric connections, ball joints, antennas.

The second stage gear must be lubricated. Calculate that after each flight you must add two or

three drops from the oil bottle that is in the kit. In each casee it may never run dry. Avoid to fly

in a dusty environment and if you do that then climb up fats from the ground to minimize dust

in the body.

Pitch adjustments: -6°/+5°/+16°

Idle up 1: 1600 rpm Idle up 2: 2200 rpm Idle up 3: Max rpm

Because we cannot control what a modeler is doing with the model we cannot give any war-

ranty.

Vellmar, in February 2014