–4–

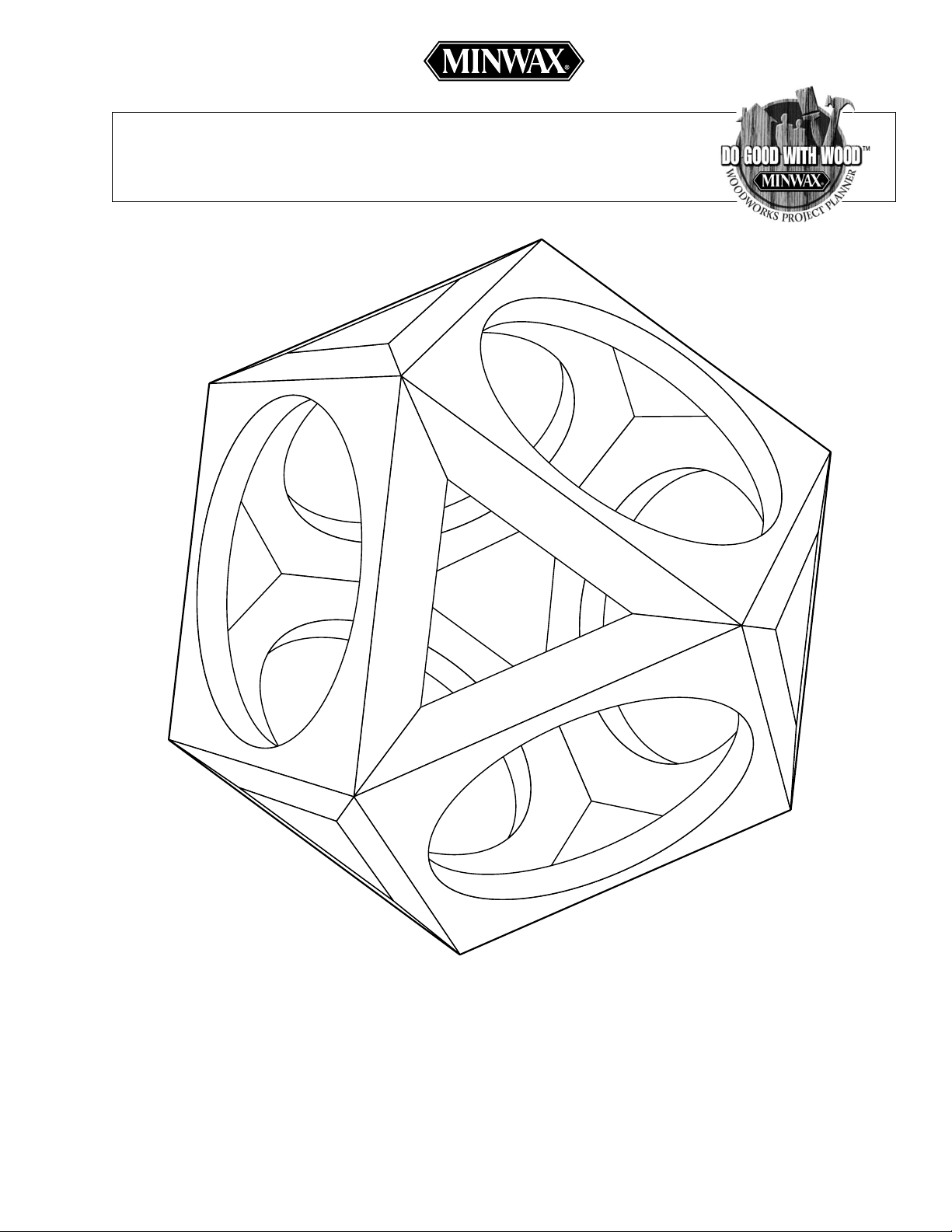

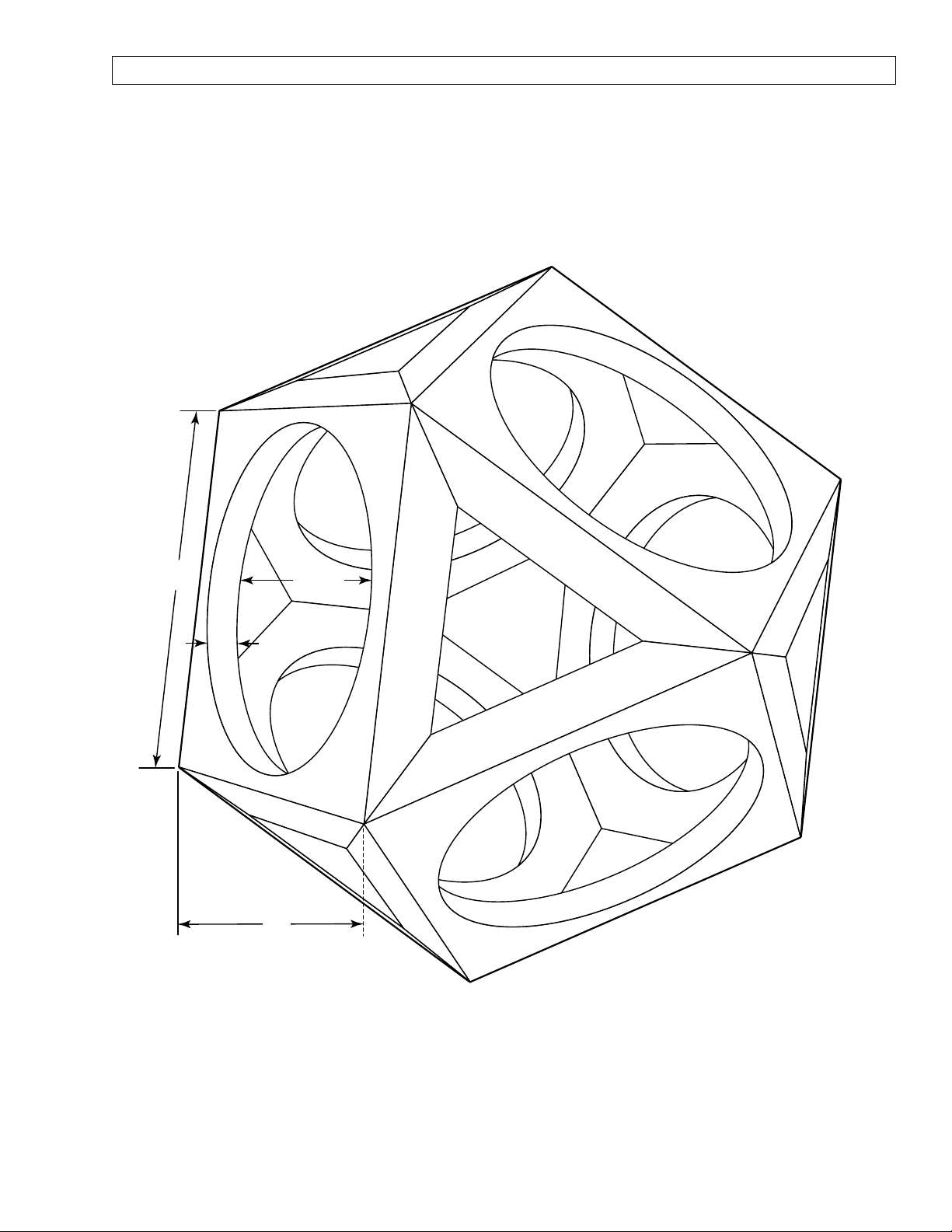

CONTINUED - WOODWORKS: INTERMEDIATE PROJECT 2009-2010 WIFFLE BALL

19. Do the staining in two steps, starting on the interior surfaces and

then do to the exterior surfaces. Apply Minwax®Gel Stain using a

clean, lint-free cloth or natural-bristle brush. Follow the directions on

the can. Allow the Gel Stain to set for about 3 minutes, then wipe off

any excess with a clean, lint-free cloth. To achieve a deeper color, you

may apply a second coat after 8 to 10 hours, repeating the application

directions for the first coat. Allow the stain to dry for 24 hours before

applying the finish.

Woodworker’s Tip: When wiping off stain, make certain that

your last wipe with the cloth goes with the grain of the wood. This

way, any stain you might miss during wipe-off will be visually

minimized by the wood grain.

20. Apply Minwax®Fast-Drying Polyurethane following the directions

on the can. Use a good quality, natural-bristle brush. Allow the first

coat to dry overnight.

21. The next day, sand all surfaces lightly with 220-grit or finer sand-

paper using with-the-grain strokes. Dust off and wipe all surfaces with

a cloth lightly dampened with mineral spirits. Apply a second coat of

polyurethane and set the piece aside to cure overnight.

22. The following day, sand all surfaces lightly with 220-grit paper.

Dust off and wipe the piece with a cloth lightly dampened with mineral

spirits and apply the third and final coat of polyurethane.

Alternate Finish

23. Before applying Minwax®Water-Based Wood Stain to a hardwood

or softwood, apply Minwax®Pre-Stain Water-Based Wood Conditioner

following the directions on the can. Applying the conditioner will

help to ensure even absorption of stain and prevent blotchiness that

can occur with some woods. After 1 to 5 minutes, wipe off all excess

conditioner using a clean, soft cloth. Wait 15 to 30 minutes, then use

220-grit or finer sandpaper to sand off any “whiskers” raised by the

conditioner. Proceed to the staining within 2 hours.

24. Do the staining in two steps, starting on the interior surfaces and

then do to the exterior surfaces. Apply the Minwax®Water-Based

Wood Stain you’ve chosen to the wood using either a nylon/polyester

brush or a cloth. Allow stain to penetrate no longer than 3 minutes.

While stain is still wet, wipe off all excess with a clean cloth that’s been

lightly dampened with stain. Allow the piece to dry for 2 hours before

applying a second coat, if desired. Allow the piece to dry overnight

before applying the protective clear finish.

Woodworker’s Tip: Minwax®Water-Based Wood Stain is available

in 6 wood-tones, a White Wash Pickling Stain, 60 custom-mixed

colors, and 8 bold Accents™colors. This means that you are not

limited to just traditional wood colors (pine, oak, walnut, etc.).

Instead, you can pick and apply a color to complement the décor

of the room in which the bench will be placed. For this reason,

make sure you look over all of the Minwax®color charts or go

to minwax.com before making your final selection.

25. After allowing the piece to dry overnight, apply Minwax®

Polycrylic®Protective Finish following the directions on the can.

Stir the can contents thoroughly before starting and periodically

repeat the stirring during your work session.

26. Working a small area at a time to maintain a wet edge, apply the

first coat. Work quickly and make the final strokes in each newly

finished section using with-the-grain brushstrokes.

27. Allow the finish to dry a minimum of 2 hours. Then sand lightly

with 220-grit or finer sandpaper wrapped around a soft backup block.

Thoroughly dust off and wipe all surfaces with a cloth lightly damp-

ened with water.

28. Repeat steps 25 and 26 to apply the second and final coat.

PRODUCT SAFETY

For your safety and the safety of those you work with, always read the

safety warnings, which manufacturers print on their labels, and follow

them to the letter. Typical safety advice and instructions will contain

information such as the following:

WARNING! Removal of old paint by sanding, scraping or other means

may generate dust or fumes that contain lead. Exposure to lead dust

or fumes may cause brain damage or other adverse health effects,

especially in children or pregnant women. Controlling exposure to

lead or other hazardous substances requires the use of proper protec-

tive equipment, such as properly fitted respirator (NIOSH approved)

and proper containment and cleanup. For more information, call the

National Lead Information Center at 1-800-424-LEAD (in U.S.) or

contact your local health authority.

When using oil-based wood finishing products:

CAUTIONS: CONTAINS ALIPHATIC HYDROCARBONS.

Contents are COMBUSTIBLE. Keep away from heat and open

flame. VAPOR HARMFUL. Use Only With Adequate Ventilation. To

avoid overexposure, open windows and doors or use other means to

ensure fresh air entry during application and drying. If you experi-

ence eye watering, headaches, or dizziness, increase fresh air, or wear

respiratory protection (NIOSH approved), or leave the area. Avoid

contact with eyes and skin. Wash hands after using. Keep container

closed when not in use. Do not transfer contents to other containers

for storage.

FIRST AID: In case of eye contact, flush thoroughly with large

amounts of water for 15 minutes and get medical attention. For

skin contact, wash thoroughly with soap and water. In case of

respiratory difficulty, provide fresh air and call physician. If

swallowed, call Poison Control Center, hospital emergency room,

or physician immediately.