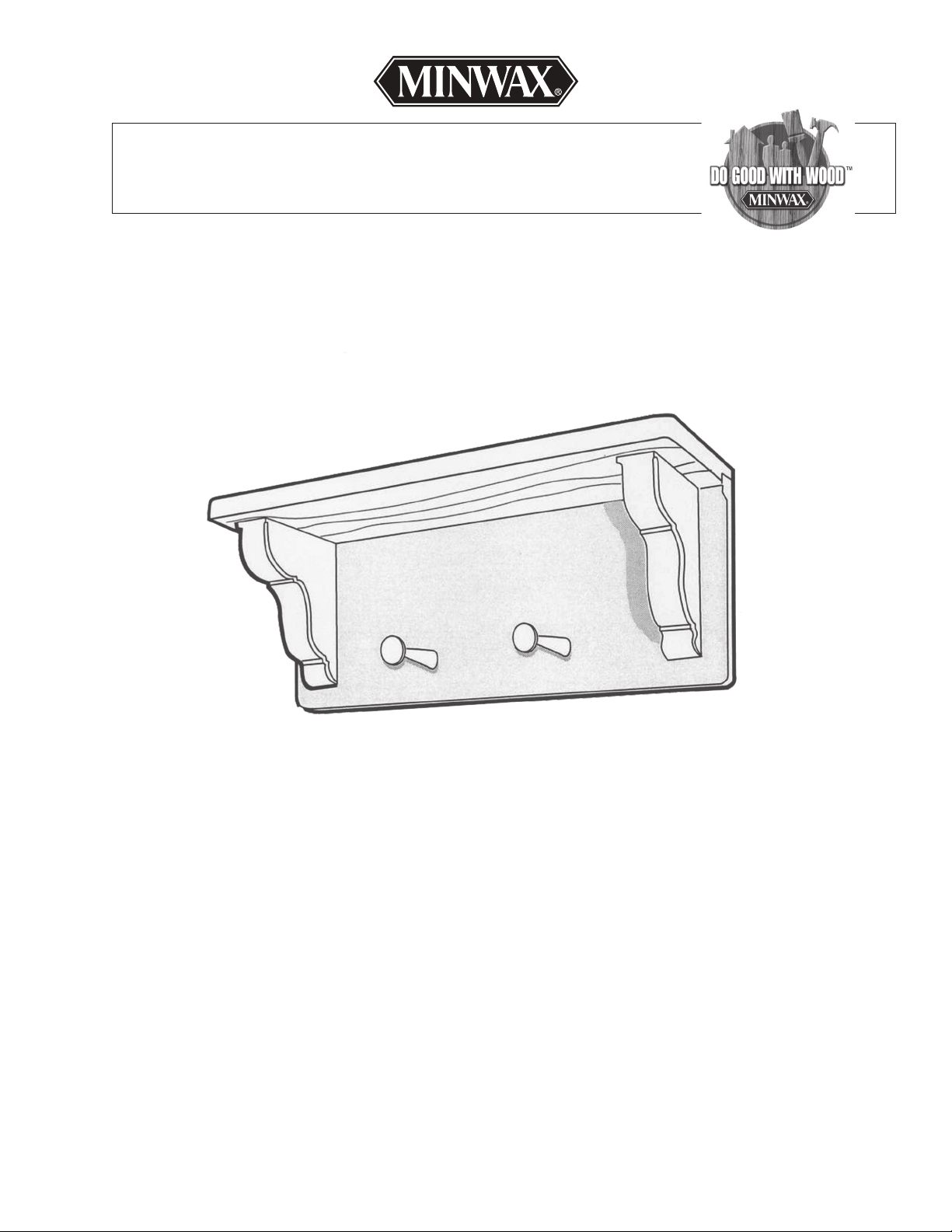

CONTINUED - WOODWORKS: BEGINNER PROJECT COLLECTIBLES SHELF

–2–

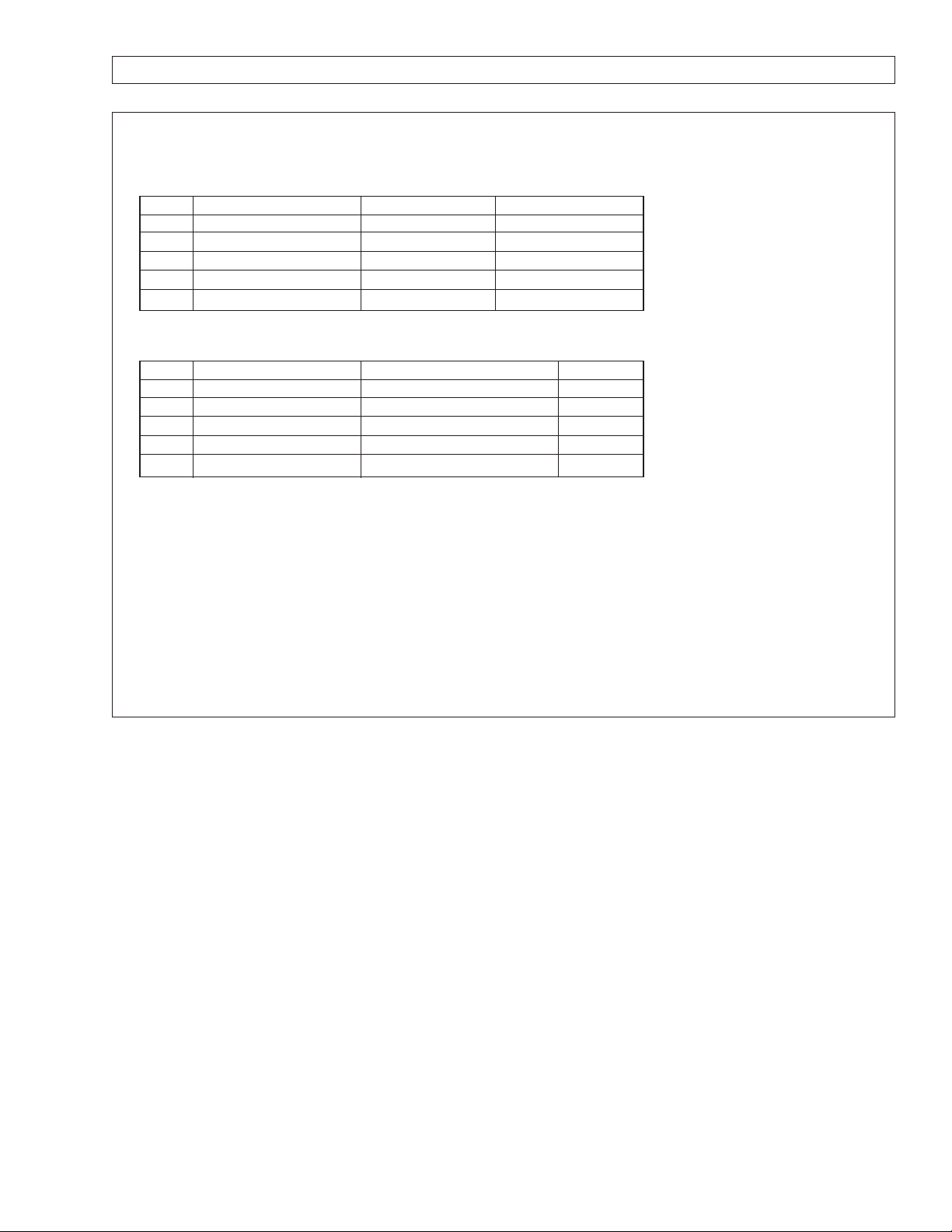

TOOLS REQUIRED:

MATERIALS REQUIRED:

See Shopping and Cutting Lists

WOOD FINISHING PRODUCTS:

– Pencil

– Ruler (zigzag or tape)

– Square (combination or try)

– Assorted files

– 1/2” or 3/4” Forstner bit

– Phillips screwdriver (medium)

– Hammer and 1/32" nail set

– Wooden mallet

Recommended Finish

Minwax®Pre-Stain Wood Conditioner

Minwax®Wood Finish™Cherry

Minwax®Fast-Drying Polyurethane

Miscellaneous

Minwax®Fine Finishing Brushes

Clean rags

Paint thinner, if required

Water-filled metal container with cover

Wood Glue

120. 150 and 220-grit sandpaper

– Safety glasses

– Rasp

– Scroll or saber saw

– Table saw and dado head

– Sanders (belt, random orbit, pad)

– Router (with assorted bits)

– Drill press (or portable electric drill)

BEFORE YOU BEGIN

Make no mistake, good craftsmanship begins and ends widi good

work habits. So, aspiring woodworkers should always remember

to review the plans for every project before picking up any tools or

purchasing materials. Also, discuss anything that seems unclear

with your instructor at the start, so you’ll avoid frustration and

wasted materials later.

PROCEDURE

I. Layout and Cutting

1. Layout and cut shelf and apron to size.

2. Create the template pattern for the brackets on heavy cardboard

or 1/4” plywood referring to the plans for design and dimensions.

(Note: If desired, use optional bracket drawings for Shelf with Throw

Rack.) When satisfied with template’s form, carefully cut it out and

transfer the design to the two pieces of 5/4” stock.

3. Cut brackets to size using a scroll saw or saber saw.

Builder’s Tip: Because of the stock’s thickness and the tight cuts

required, you should not attempt to tack boards together to cut

both brackets at the same time.

4. Install the dado head on the table saw and plough the 1/4” x 3/4”

edge-rabbet in the shelf to receive the apron.

5. Slightly round front corners of shelf and bottom corners of apron

using a rasp and pad sander, or stationary belt sander.

6. Using 120-grit sandpaper, sand all surfaces smooth. Remember,

always sand with the wood grain to avoid cross-grain scratches.

7. Using a router and beading bit, dress front bracket edges as

shown. Also, rout the front plane of the apron along the two end and

bottom edges. Do not rout the shelf edges. This piece is rounded-over

using Dies and sandpaper.

8. Lay out parts on workbench and temporarily assemble piece

(without using glue or nails) to check parts for fit and dimensions.

Trim parts to exact size if necessary.

9. With parts temporarily assembled, use a pencil to lightly mark the

inside planes of the brackets on the apron.

10a. For Shelf with Shaker Pegs:

i. Determine hole location for Shaker pegs. Start by carefully

measuring the distance between the pencd lines just drawn and divide

by three. Lightly draw a second set of pencil tines approx. 4-5/8” in

from the original lines. Set a combination square to 1-3/4” and,

measuring up from the apron’s bottom edge along these new fines,

mark peg location.

ii. Bore die two mortises to receive peg tenons.

Builder’s Tip: Peg dimensions can vary, so carefully measure

both the diameter and length of the tenons on the pegs you are

using. The pegs for the prototype project required mortises that

were 1/2” diameter by 5/8” deep. They were made with a 1/2”

diameter hole cutter with a brad point. If the mortise exits back

side of the apron, don’t worry. This provides an escape hole for

excess glue if any is present.

10b. For Shelf with Throw Rack:

i. Locate and mark position for blind mortises on brackets to hold

dowel (see plans).

ii. Use a 3/4” dia. Forstner bit to bore bodi mortises 1/4” deep.