Safety Regulations

For the eletronic installation activity, please pay attention to the local directives.

We would like to draw your attention to some dangers, which may occur. You should therefore read the following instructions carefully

and proceed accordingly.

It is not allowed to use the device in a dusty, humid or explosive environment => Danger of shortcircuit!

The VGX-21 must not be used with a opened chassis!

To bypass or paste-over the handgrip-switch as well, can be very dangerous!

During processing the valve seats, there must be worn safety goggles! There must be worn a hairnet for long hair as well!

Risk of injury by the formtool of the rotating spindle!

Avoid to suck in any dirt or dust while the vacuum pump is running!

The filter and the suction cable should be controlled in constant intervalls!

Clean the suction cable if it is polluted and exchange the filter!

Before working on electronic elements and repairs, the device must be fully isolated from the current electric circuits!

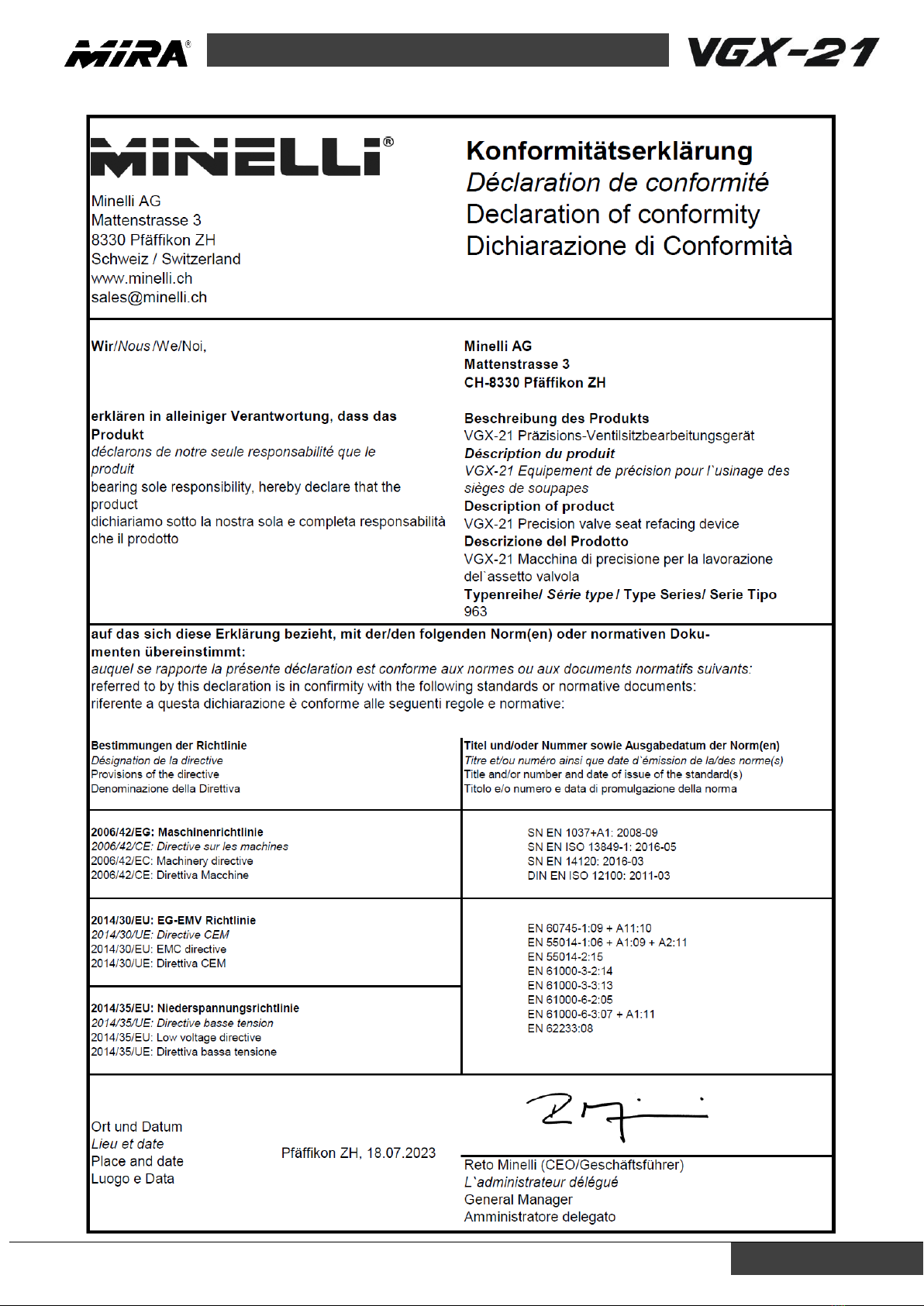

Repairs are only allowed by the local MIRA-dealer or the manufacturer (MINELLI Corporation) in every case!

Only use genuine MIRA spare parts, which are registered in the respective instruction manual!

Do not touch the electric circuits of the device = Contact with these circuits are dangerous to life!

Modifying of the electronical elements could cause severe aftermath!

Repairs of the VGX-21 must be basically accomplished ONLY by authorised personnel or the MINELLI Corporation.

Safety advices for the VGX-21 valve seat refacing unit

The following safety advices must be observed in every phase of the launching, during processing valve seats and the maintenance or

repairs. Disregarding of these assignments is a incorrect use of the device.

Earthing of the device

To reach an optimum touch protection, the device must be earthed. Therefore the earth-clamp must be connected with the earthing

of the main circuit.

Do not use in explosive environment!

The use of the device in explosive environment (flammable gases, vapours or dust) may induce the lightning of these materials and are

strictly forbidden.

ATTENTION!

1. To avoid the risk of partial overheating, the device must not be used in dusty or steamy atmossphere.

2. The device must not be used in wet environment, respectively the device must not be exposured to rain or dew. This may induce an

electric connection between electonic elements in the devices.

3. The User of this device must accomplish access, launching, setting and service by authorised personnel. Operations by the

electronic elements of the device are dangerous because of the electric tension, that can be a high risk of an electric shock. The

electric tension can even exist for a short time if the device is already switched off. Before starting service-operations on the

device, make sure that the capacitors of the device do not carry electric tension.

4. The device builds no physical separation. It is prohibited to work on the connectors of the device if the electric tension is running.

Running of the device without mechanical switch or fuse in the power supply is forbidden.

5. Service and adjusting operations must always be done by a minimum of 2 people. In an emergency, there must be a person that

can cut off the electric circuit to execute first aid.

6. This device must not be used for emergency- and safety tests. A failure or damage of the connected VGX-21 by the running electric

tension can be induced.

7. Every contact with the electric circuits must be avoid. During the operation, every contact with these circuits are dangerous to life.

Therefore added, the device can be damaged by careless contact of sensitive elements.

8. To avoid further risks, you must gain the agreement of the manufacturer MINELLI Corporation, if you want to add, change, replace

and/or manipulate some parts of the device by yourself.

9. If there are some repairs or replacing works to do, the VGX-21 must always becompletely disconnectec from the electric circuits.

By Repairs and replacing works read carefully the certain chapters in the Instruction manual. (See “Maintenance of the VGX-

21“on Page 27)