Mira Bijou Operation manual

Other Mira Plumbing Product manuals

Mira

Mira Advance ATL Operation manual

Mira

Mira Mode 1.1980.001 User manual

Mira

Mira Event XS User manual

Mira

Mira VISTA User manual

Mira

Mira Advance ATL J97A User manual

Mira

Mira FORM Operation manual

Mira

Mira everclear User manual

Mira

Mira escape Operation manual

Mira

Mira Sport Operation manual

Mira

Mira Azora Operation manual

Mira

Mira vigour User manual

Mira

Mira Sport 7.5 User manual

Mira

Mira COMBIFLOW User manual

Mira

Mira Sport 7.5 Operation manual

Mira

Mira Mode Maxim User manual

Mira

Mira Advance J97I User manual

Mira

Mira 1591.001 User manual

Mira

Mira JUMP User manual

Mira

Mira Advance Owner's manual

Mira

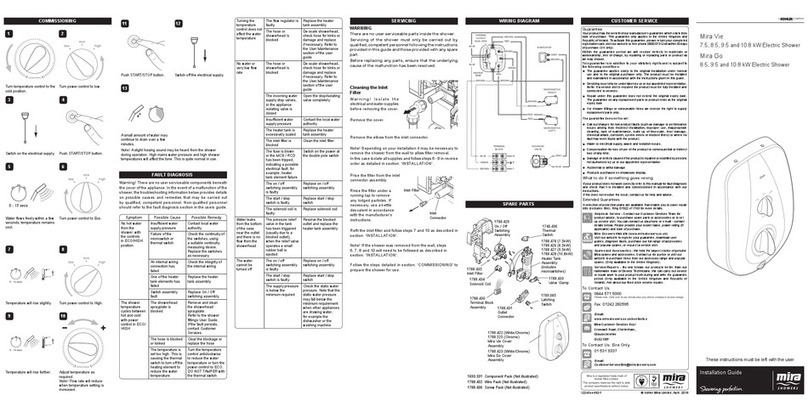

Mira Vie Operating and maintenance instructions

Popular Plumbing Product manuals by other brands

Moen

Moen SANI-STREAM 8797 manual

Grohe

Grohe Allure Brilliant 19 784 manual

Cistermiser

Cistermiser Easyflush EVO 1.5 manual

Kohler

Kohler Triton Rite-Temp K-T6910-2A installation guide

BEMIS

BEMIS FNOTAB100 Installation instruction

Hans Grohe

Hans Grohe ShowerTablet Select 700 13184000 Instructions for use/assembly instructions

Akw

Akw Stone Wash Basin Installation instructions manual

Enlighten Sauna

Enlighten Sauna Rustic-4 user manual

Moen

Moen ShowHouse S244 Series quick start guide

Sanela

Sanela SLWN 08 Mounting instructions

Franke

Franke 7612982239618 operating instructions

Heritage Bathrooms

Heritage Bathrooms Granley Deco PGDW02 Fitting Instructions & Contents List

Tres

Tres TOUCH-TRES 1.61.445 instructions

STIEBEL ELTRON

STIEBEL ELTRON WS-1 Operation and installation

Miomare

Miomare HG00383A manual

BELLOSTA

BELLOSTA revivre 6521/CR1 quick start guide

American Standard

American Standard Heritage Amarilis 7298.229 parts list

BorMann

BorMann Elite BTW5024 quick start guide