Filter Machine Model No. __________________________ Serial No. ____________________

Oil Pump Model No. ______________________________ Serial No. ____________________

Filter Bag Model No.______________________________ Serial No. ____________________

Owner ___________________________________________

Contact Person ___________________________________

Purchased From __________________________________

Date purchased ___________________________________ Date placed in service ___________

Division of Oil Process Systems Inc.

602-20 North Tacoma Street Allentown, Pennsylvania 18103

Cut and fax / send lower portion Cut and fax / send lower portion Cut and fax / send lower portion

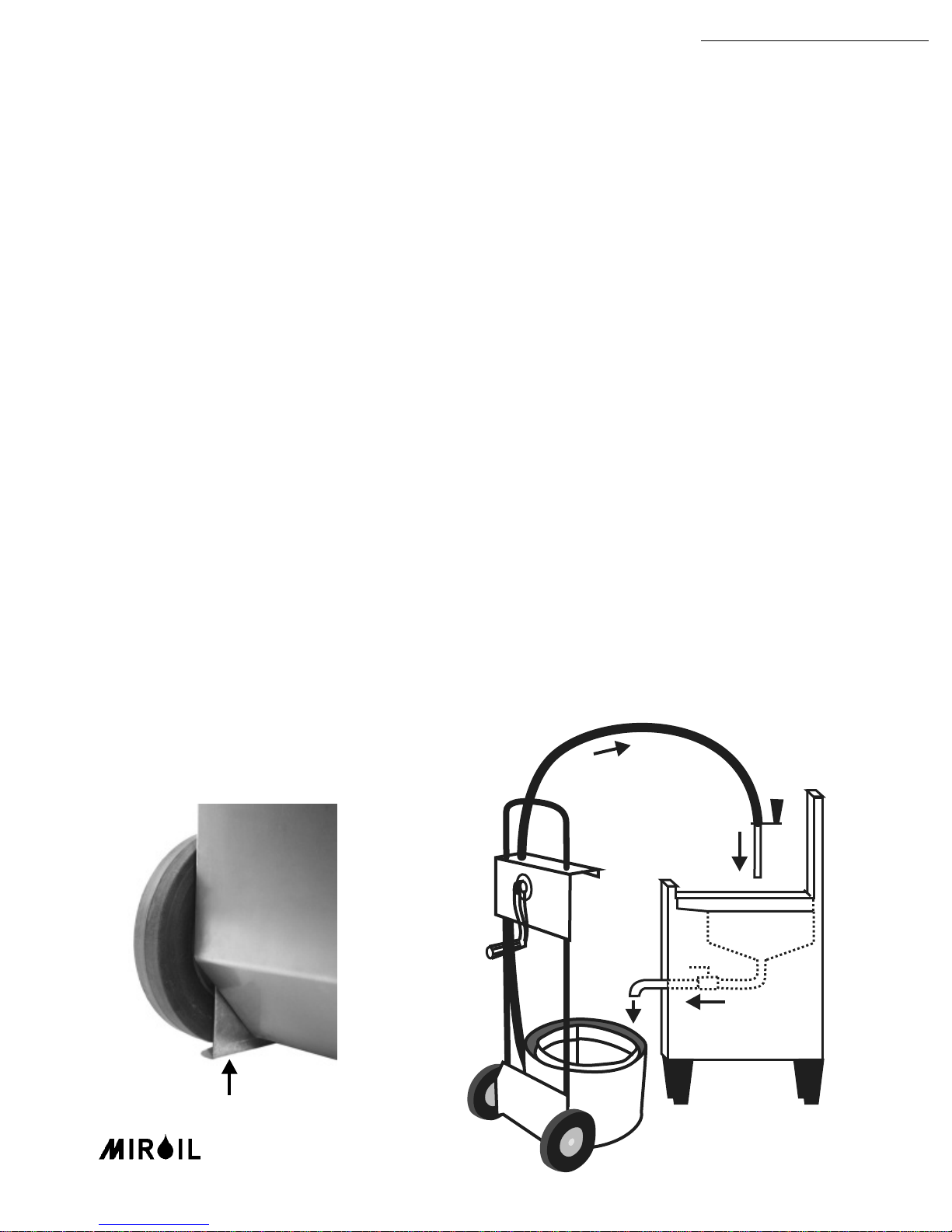

Loss or Damage During Shipment

Inspect all cartons for damage before unpacking. Your MirOil pump was thoroughly inspected before

leaving our factory. The carrier is responsible for safe delivery. All claims for any loss or damage in transit

mustbemadetothecarrier.MirOilwillassistwithclaimsIFdamagehasbeenpromptlyreportedtothecarrier.

This product is warranted only against defects in workmanship or materials for 1 year from date of the

filter machine is placed in service or not longer than 15 months from date of purchase. Liability under

the basic 1 year limited warranty is limited to replacing or repairing parts FOB Allentown PA. Parts

must be returned to our factory with shipping costs prepaid. The 1 year warranty does not cover the

costsofservicelabororshippingtoreplaceparts.

The use of the filter pump for pumping any liquid other than fryer oil will contaminate the pump and

piping.Thiswillcontaminatetheoilandmayvoidthiswarranty

The filter bag has a pro rata warranty for 6 months. This is similar to a warranty for a battery or tire. The

filter bag must be returned to MirOil for repair, FOB Allentown, PA 18103. If the filter bag is not able to

berepaired, It willbe replacedwitha newfilter bag atthe prevailingcost.Credit towardthe purchase of

thenewfilterbagwillbeprovidedfortheunusedservicelifeoftheoldfilterbag.Thiswarrantydoesnot

coverthecostsshippingtoreplaceparts.

No warranty described above covers the replacement of parts that become inoperative because of

wear(exceptfilter bags) orabuseor forpartssubjectedto abuse/misuse,negligence,accident or ifthe

producthasbeenimproperlyrepairedoralteredbyuseror a 3rd party.Nootherwarranty,expressedor

implied,isauthorizedtobemadebyanypartiesonbehalfofMirOil.

The manufacturer and the manufacturer's sales agents and/or agencies accept no liability for the use

or misuse of this machine. Expressly excluded from warranty are implied warranties of

merchantability and fitness for purpose. Manufacturer, agents and sales agencies disclaim all liability

foraccidentsresultingfromuseorthemisuseofthisequipment.

Toll Free Call for warranty information 1.800.523.9844

1 Year Limited Warranty on your Filter Machine

6 month Limited Warranty on your Filter Bag

Important Limits for Coverage Under All Warranties

AvoidlosingprotectionundertheWarranty

FAXthisWarrantyRegistrationpromptlyto(610)4373377

or...addpostageandmailto:

602-20N.TacomaSt.,Allentown,PA18103

Return to main menu