Contact

Miseno

at

(855)

480-2915

or

email

[email protected] with

any

questions.

Copyright

©2019,

Miseno.

All

rights

reserv

edPAGE 4

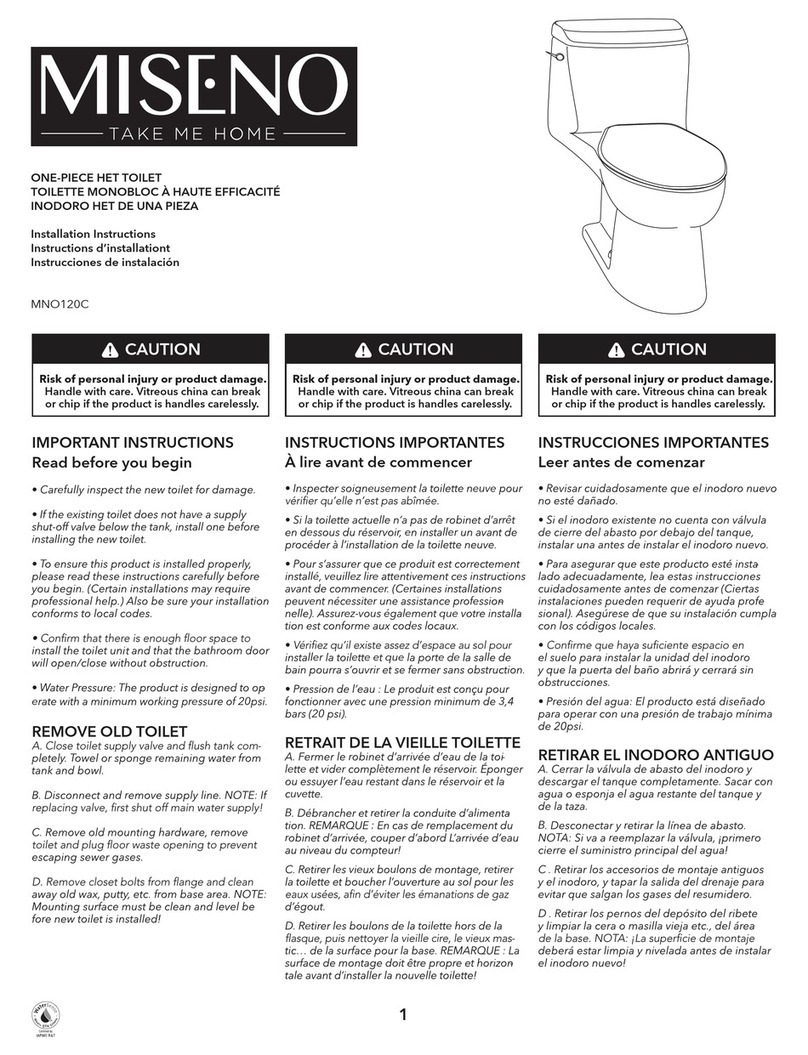

Skirted HET Single- and Dual-Flush Toilet

Installation Instructions

Step 6. Install tank lid and seat. U. Set the tank lid on the toilet tank.

V. To install the seat, push the quick-connect bolts

through seat hinges, then push them through the seat

bolt holes in toilet base. Adjust seat until it sits in

required position and snug down bolts.

WARNING!

.

A

C

H

D

R

N

O

B

L

E

A

C

H

D

R

O

P

-

I

N

S

N

O

B

L

E

O

P

-

I

N

S

A

C

H

D

R

DO NOT USE IN-TANK TOILET BOWL

CLEANERS CONTAINING

BLEACH OR CHLORINE

Use of such products will:

1. Result in damage to tank components and may

cause flooding and property damage.

2. Void the manufacturer’s warranty.

TANK REPLACEMENT PART INFORMATION: The inside back of the toilet tank is stamped with replacement part information. Please record

and maintain this record for future maintenance and reliable service of your new toilet.

TROUBLESHOOTING

Adjustable

Rod

Float Cup

Fill valve body

Triangle Gasket

Plastic Seal

Hexagon Seal Rubber Seal

Problem Reason Solution

Fill valve will not fill.

Fill valve will not stop.

Leaks!

Poor flush.

Water supply is closed?

Float valve is stuck?

Drain guards are stuck?

Water supply continues to run?

Float is stuck?

Flapper is stuck open?

Flush valve nut is loose?

Fill valve nut is loose?

Flapper is not seated properly?

Water level is not set to proper height?

Low water pressure?

Obstruction in bowl?

Short flush?

Turn on water supply at angle stop valve.

Loosen fill valve nut and turn fill valve away from back of tank.

Clean drain guard of debris.

Turn off water and clean inside of fill valve.

Loosen fill valve nut and turn fill valve away from back of tank.

Check chain length and flush valve seat.

Check that the flush valve is tightened into place.

Check hex nut on fill valve to assure that it is tight.

Clean flush valve seat, replace flapper if necessary.

Adjust the water level set screw to assure water is at the

maximum level line.

Make sure the minimum water pressure is above 35 PSI.

Plunger the bowl and clean the drain line as necessary.

Adjust the chain length of the flapper.

CARE AND MAINTENANCE

When cleaning your toilet, wash it with mild, soapy water then rinse thoroughly with clear water.

Dry with a soft cloth. Avoid detergents, disinfectants or cleaning products in aerosol cans.

NEVER use abrasive scouring powders or abrasive pads on your toilet set. Some bathroom chemicals and

cosmetics may damage the seat’s finish.

CAUTION: This product is fragile. To avoid breakage and possible injury handle with care.

DO NOT use abrasive powder or liquid cleaners which can damage the product surface. Overtightening of the

locknut or coupling nut could result in breakage and flooding.

DO NOT use the supplied cone washer with a plastic supply line.

DO NOT use pipe dope or other silicon-based materials to tighten supply coupling nut.