2. Safety warnings and instructions

2.1 Safety signs

=GXTOTM

Improper use of the inverter will cause electric shock and burn. During installation

and maintenance. Please strictly follow the instructions on this manual. Please read

the user manual carefully before using the inverter. And please keep the instructions

properly for afterwards use.

Safety signs are used to emphasize potential safety risk and important safety

information. The manual includes below sings:

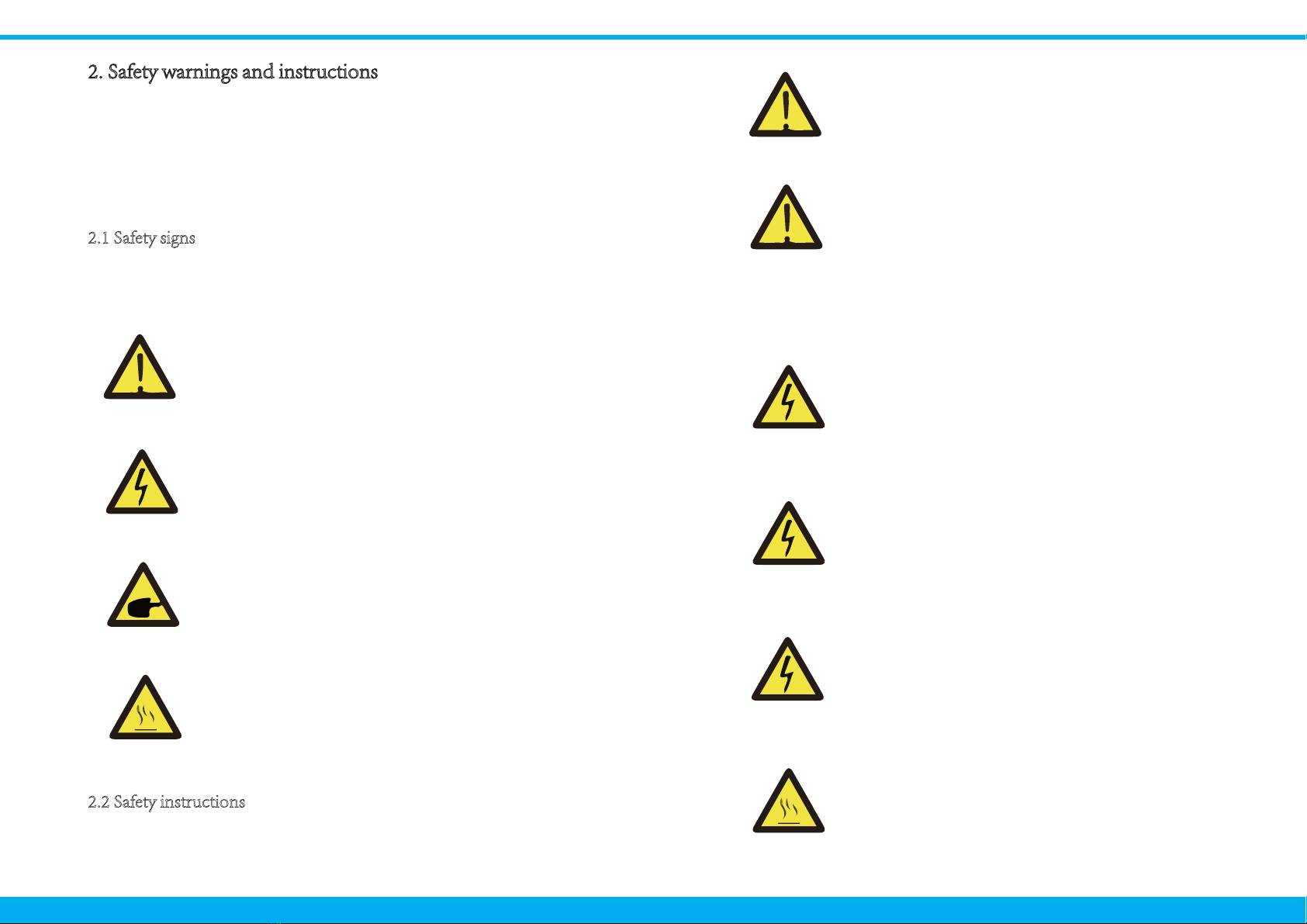

2.2 Safety instructions

Safety warning——Indifference of the signs in the manual

may cause injure or even death.

9NUIQ.G`GXJ

Shock warning sign——Incorrect follow of this sign may get

shocked.

9GLKZ_.OTZ

Prudent operation——Incorrect follow of the safety

operation hints in this manual may cause inverter defective.

.OMN:KSVKXGZ[XK.G`GXJ

Inverter’s local temperature may exceed 80℃ while

under operating. Please do not touch the inverter’s surface.

=GXTOTM

Electrical installation of the inverter must conform to the

safety operation rules of the country or local area.

=GXTOTM

Inverter is non-isolated topology structure, hence must

insure DC input and AC output are electrical isolated before

operating the inverter. Strictly prohibit ground the positive

and negative poles of the PV string. Otherwise it will

damage the inverter.

9NUIQ.G`GXJ

Prohibit disassembling inverter case. There existing shock

hazard, may cause serious injury or death, please ask

qualified person to maintenance.

9NUIQ.G`GXJ

When PV module is exposed to sunlight, The output will

generate DC voltage.Prohibit touching to avoid shock

hazard.

9NUIQ.G`GXJ

After disconnecting the input and output of the inverter,

it takes at least 5 minutes for the inverter to completely

release the residual energy and wait for at least 5 minutes

before it can be overhauled.

.OMN:KSVKXGZ[XK.G`GXJ

Inverter’s local temperature may exceed 80℃ while under

operating. Please do not touch the inverter’s surface.

- 3 - - 4 -