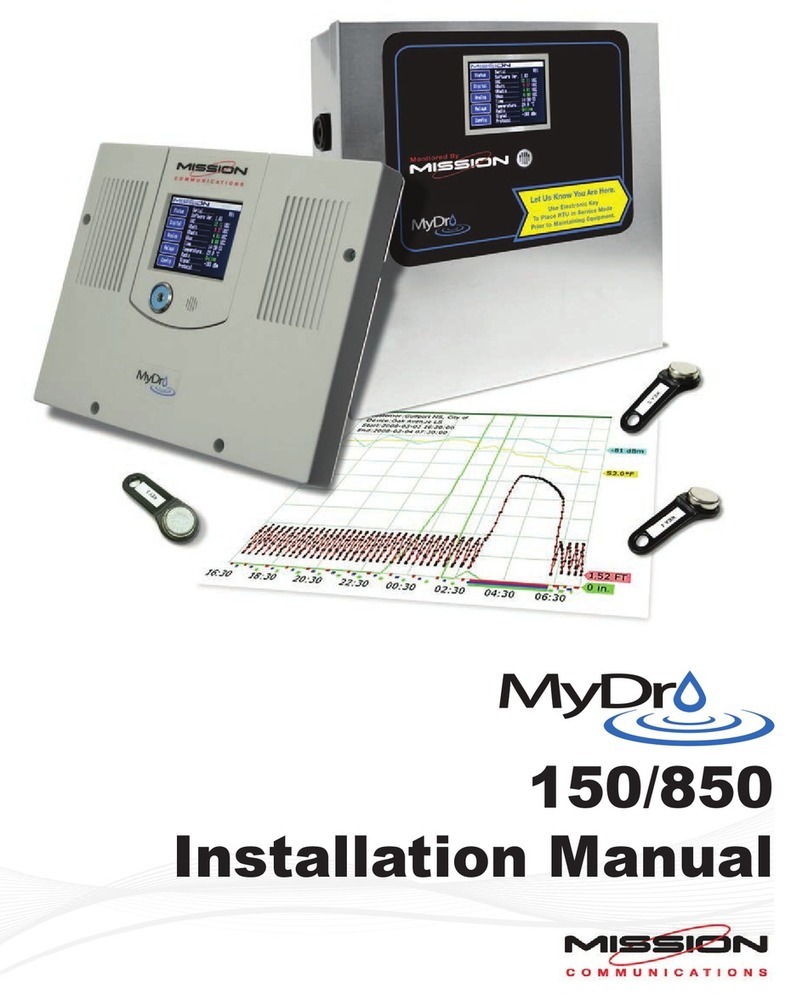

Mission MyDro M150 User manual

150/850

Installation Manual

PMS 660

2

Welcome,

This manual is intended to guide end-users through the proper installation for MyDro

(M150 and M850) remote terminal units (RTUs). The beginning chapters focus on pre-

installation and are intended to optimize installation. Mission recommends users read

this document completely and conrm that all necessary materials have been gathered

before beginning the installation process.

Prior to installation, users should complete and submit the RTU Setup Forms associated

with the units to be installed to [email protected]. New customers will have

additionally received the Account Setup Form and Notication Setup Form, which should

also be submitted before installing RTUs.

See the back cover of this document for information about available support resources,

including weekly webinars, training tutorials, quarterly newsletters, troubleshooting

documentation, and Twitter updates.

Mission Technical Support is available 24-7-365 on a responsive callback basis for after-

hour emergencies at (877) 993-1911 option 2 or [email protected]. Please have

the customer name and appropriate unit serial number ready.

Thank you,

The Mission Communications Team

Warning: This symbol indicates there is caution or warning to avoid damage to your property or product.

Note: This symbol indicates that there is something that requires your special attention.

This device complies with part 15 of the FFC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This device is SGS Safety Certied

710198

3

Contents

Chapter 1: Overview

Chapter 2: Site Survey and Connectivity Test

Chapter 3: Antenna Installation

Chapter 4: RTU Installation and Wiring

Chapter 5: RTU Startup

Chapter 6: Test the Installation

Chapter 7: Site Commissioning

Appendix A: Terminology

Appendix B: Solid State Relay Wiring Diagram

4

6

8

10

15

17

19

20

22

4

Chapter 1: Overview

M150/M850 at a Glance

Each RTU is packaged with everything

necessary for a standard installation

Enclosures

NEMA 1—indoor mounting

NEMA 4X—outdoor mounting

FlatPak—control panel inner door mounting

FlatPak Retrot—(convert M110 or M800

to MyDro)

Hardware Included with RTUs

RTU with NEMA 1, NEMA 4X, or FlatPak enclosure

RTU Installation Packet: RTU Form, User Guide, and emergency notice label

Battery—12 volt, 5 amp-hour

Flying Lead Transformer—120 VAC to 12 VAC, 1.2 amp

Universal Antenna Mount Kit: 11’ RG58 cable with SMA-M connector, pole, or wall

mount bracket, dual-band antenna whip, mini whip antenna, (2) pole clamps, and

(2) MOVs rated for 120-volt control circuits

Accessory Bag: (4)1000 ohm long, yellow EOL resistors, (8) 1000 ohm EOL

resistors, (2) current sensing switches, tie wraps, (4) wire nuts, (8) screws, (2)

ferrite cores, and an interchangeable Phillips/athead screwdriver

New customers will also be given a New Customer Packet which includes Account and

Notication Setup Forms, (5) electronic keys with instructions, and the Managed SCADA

document.

5

Recommended Tools and Materials (Not Included)

Mechanical Tools Electrical Tools Materials

Drill motor Voltmeter/multimeter 18 or 22 gauge wire—2,

4, or 8 conductor stranded

and shielded

Step drill or 3/4” hole saw Wire cutters 12–14 gauge green wire

for grounding the RTU

(follow NEC standards)

Hack/reciprocating saw Wire strippers 3/4” Flex conduit with

straight and elbow ttings

Metal cutting blades Unistrut rail and hardware

for mounting

Pliers Interposing relays and

bases (if no dry contacts

are available)

5/16” nut driver Interposing relay (if output

relays will be used)

Phillips-head screwdriver Sealant

Ladder (for antenna

mounting)

Available Input/Output Expansion

Mission offers a variety of expansion modules to extend the utility of the RTU. Available

options are summarized below:

• Safe Module Plus: intrinsically safe oat circuit, local relay, 4 pulse channels

• Digital Input: adds 8 channels

• Analog Input: adds 4 channels

• Analog Output: provides 2 channels

• Pulse Input: provides 2 channels

For more information, see the Safe Module Plus and

MyDro Expansion Module specication sheets, as well

as the Expansion Module Installation manual.

6

Chapter 2: Site Survey and Connectivity Test

Prior to installation, please complete and submit the RTU Installation Form via fax

at (770) 685-7913 or email to [email protected] so Mission can set up the

new unit(s) on your web portal. New customers must also complete and submit both

forms within the New Customer Packet. The web portal can be accessed with the

login credentials you provided within the Account Setup Form. Once completed and

entered by Technical Support, alarms can be enabled for your RTU(s) immediately after

installation so you can perform end-to-end testing.

By powering the RTU and testing connectivity before mounting the hardware, you can

optimize the signal strength for years of trouble-free communication. The test only takes

a few minutes because the included battery provides temporary power. Refer to Chapter

3 for best practices when positioning the antenna.

1. Remove the RTU from the box and place it on or near the control panel it will be

monitoring. Remove the antenna cable and antenna whip from the package and

hand-tighten the SMA-M connector to the radio SMA-F connection on the RTU

(see Figure 1).

2. Screw the antenna whip onto the molded antenna base and place it outside as high

as possible. Mount the antenna to the aluminum bracket.

Warning: Hand-tighten the nut on the underside plus 1/4 turn with a wrench. Do

not overtighten.

3. Power the RTU with the 12 VDC battery (see Figure 1). Connect the negative (black)

lead to the battery and then connect the positive (red) lead. Once the sequence is

completed, you will hear three beeps from the buzzer. This indicates the unit has

connected to Mission servers. If the RTU does not connect after two attempts, call

Technical Support.

4. Notice the signal strength reading on the LCD as shown in Figure 1. The goal is

to mount the antenna where the signal is the strongest. A -75 dB signal is better

than that of -100 dB. Temporarily position the antenna for about a minute in a few

locations and take note of the signal strength.

7

Figure 1:

Main Printed Circuit Board Wired for Site Survey

8

Overview

The antenna should be mounted outdoors

and above other objects. By optimizing the

placement of the antenna, you increase the

chances that the radio can communicate with

more than one cell tower. The coaxial cable

should reach the Mission RTU radio connection

with no severe routing of the coaxial cable.

Consider where the RTU will be mounted in

relation to the location of the antenna.

1. Install the antenna cable and antenna whip.

Connect the SMA-M cable connector to the

SMA-F connector on the mainboard (see

Figure 1). Unscrew the nut from the molded

antenna base. Feed the molded antenna

base through the square cut out on the

bracket. Place the molded antenna base in

the circle cutout.

Warning: Secure the molded antenna

base to the bracket with the nut. Hand-

tighten the nut, plus ¼ turn with a

wrench. Do not overtighten.

2. Install the mounting bracket. Mount the

Universal Antenna Mount directly on the

face of a at surface or a metal pipe using

the included pipe clamps (placing above

any obstruction).

Note: The mini whip antenna may provide

superior connectivity for applications

using LTE service. Mission recommends

trying this antenna during installation

and appreciates any feedback from eld

experience.

Chapter 3: Antenna Installation

Tie wraps Hose clamp nut

9

Antenna Best Practices

Do Don’t

Mount the antenna outside as high as possible,

preferably above the roof or other objects.

Mount the antenna underground, in a dry well, or

inside a canned lift station.

Mount the antenna above all metal surfaces close

to the installation.

Mount the antenna horizontally or bend the antenna

whip.

Coil excess coaxial in circles of 5–7 inches in

diameter. Pinching or tight bends in the coaxial can

restrict the high frequency/low power radio signal

path in much the same way water ow is restricted

through a tight bend in a hose.

Mount the antenna inside a metal control cabinet.

Even berglass cabinets degrade the signal.

Ensure that the weight of the cable does not

damage the antenna base. There should be enough

slack in the cable so it does not rest or touch the top

surface of the mounting bracket.

Mount the antenna on the side of a metal cabinet

or adjacent to a tank. Metal surfaces will reect

the radio signal, preventing it from traveling in all

directions.

Incorporate a drip loop when installing the cable to

prevent water from penetrating into the building or

enclosure.

Cut, lengthen, or shorten the coaxial cable.

Mission can supply antenna extension cables and

connectors up to 50 feet. For lengths above this

limit, another RTU mounting location should be

considered.

Wiring Best Practices

• Signal cables should not run parallel with high voltage AC wires (load conductors).

• Where signal wires and load conductors must cross, do so at right angles.

• High voltage should not enter the Mission RTU. Mount the supplied transformer outside the Mission

enclosure.

• Lay wires in wire trays with the excess near terminations. Replace wire race covers

• Cables used for digital and analog inputs should be 18 to 22 gauge, shielded, twisted pair wire with the

shield connected to ground at the RTU and not on the other end of the cable (to prevent ground loop

current).

• MOVs can be installed across AC contactor coil terminals to shunt voltage spikes away from the RTU

inputs and other electronics in the panel. Voltage spikes can be caused by coils de-energizing. The

included MOVs are rated for 120 V circuits and will suppress excess voltage above 150 V. These parts

are application dependent. They have a nite lifespan and will need to be replaced over time.

Warning: Follow requirements for eld wiring installation and grounding as

described in NEC and the local/state electrical codes.

10

Locate the RTU as close as possible to the

control cabinet while considering the antenna

cable length.

Warning: Turn off station power to

avoid damage to mainboard.

Note: MyDro units should be connected

to a LPS-certied power supply (12 VAC

60 Hz ~ or 12 VDC ).

1. Mount the enclosure.

2. Cut the conduit and wiring holes. Drill and

attach the conduit in the control cabinet

and Mission RTU. Use sealant where

appropriate.

3. Pull the wires and cables.

4. Ground the RTU. Use 12 to 14 gauge

green wire to connect the grounding lug

on the backplate in the RTU to the stations

Earth ground (refer to Figure 1).

Note: If using the Safe Module Plus

for sensing the high-level oat in an

intrinsically safe manner, install it now.

Refer to the MyDro Expansion Module

Installation Manual for more information.

5. Terminate digital inputs. Refer to the

wiring diagram on the M150/M850 cover/

door and the RTU Installation Form in the

packing box. Record input names on the

setup form and the diagram.

Chapter 4: RTU Installation and Wiring

Enclosure Options

NEMA 4X

Mount outdoors on

unistrut or a wall. Allow

clearance for hinge (left)

and key reader (right).

Consider the NEMA 4 for

indoor application where

wash-downs occur.

Conduit connections

can enter from bottom,

but leave space for the

included battery.

NEMA 1

FlatPak

Use indoors where no wash-downs occur.

Allow for space on bottom of the enclosure for

the battery.

Mount inside the control cabinet.

Two large holes are provided for through-wires.

Place battery inside the control cabinet.

This manual suits for next models

1

Table of contents

Other Mission Touch Terminal manuals