R000226 BP1 Automation 9 v.0.1 03/21

5 INSTALLATION AND WIRING

This section describes the installation of a complete BP1 system, or an IMC3-J

automation that has been retrofitted with a BP1 control board. For instructions on

conversion of an IMC3-J automation to a BP1, see Appendix A.1.

5.1 Installation, BP1 Complete System p/n A000393

Connect the control cables as described in Sec. 5.2.

If the fire alarm panel provides a contact closure during an alarm, configure the Fire

Alarm input jumpers at JP2 to the “Contact” position. If the fire panel provides

voltage during an alarm, leave the two jumpers in the factory default “Volts” position.

Note: Both jumpers must be in the same position, either Contact or Volts (This

jumper setting has no effect when the BP1 board is used as a retrofit in an IMC3-J

automation – this function is controlled on the Fire Relay PCB).

If you wish the BP1 to only flash the fire alarm LED on the front panel rather than

hold it, change jumper JP1 to the “Pulse” setting. If you change it to Pulse, there

will not be a continuous indication of the alarm condition on the front panel LED.

Note: This jumper setting only affects the behavior of the LED on the front panel.

Install the unit in an available rack space.

Connect the power supply to an AC receptacle.

Configure the projector as described in Sec. 6.

5.2 Attaching Control Cables

Connect four cables as described below. See Figure 5-1 for images.

Connect an 8-conductor cable from the BP1 J1 to the Alchemy ICMP-X GPI1-4

(this cable delivers the Fire Alarm output signals back to the projector).

Connect an 8-conductor cable from the BP1 J2 to the Alchemy ICMP-X GPO5-8.

Note: This cable controls the Screen Lights only. If there are no screen lights at this

particular theater, this cable is optional.

Connect an 8-conductor cable from the BP1 J3 to the Alchemy ICMP-X GPO1-4

(this cable carries the dimmer control signals from the projector to the BP1).

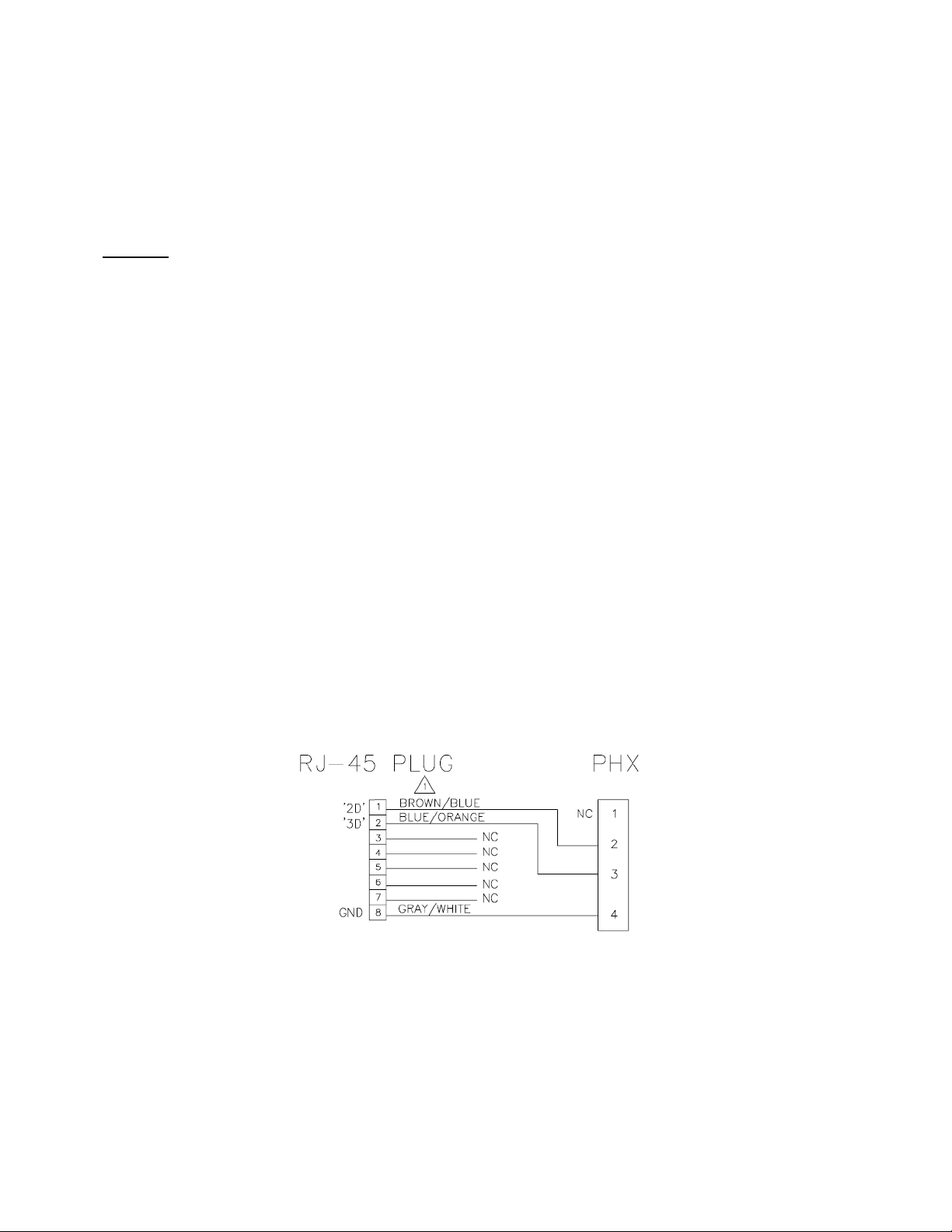

Connect an 8-conductor cable from the BP1 J4 to the Projector Cinema Controller

Board (CCB) GPO5-8 (this cable carries the Masking signals and XL-Mover signals

from the projector to the BP1).

Note: Depending on the projector model this last cable may have to be broken out at

the projector end for connection to the 37-pin “General Purpose I/O” connector as

shown in Figure 5-1. See Section 5.3 for more detailed information on making the

breakout connector. If a breakout cable isn’t required proceed to Section 6.